Trolley hydraulic control system of dredge boat positioning pile

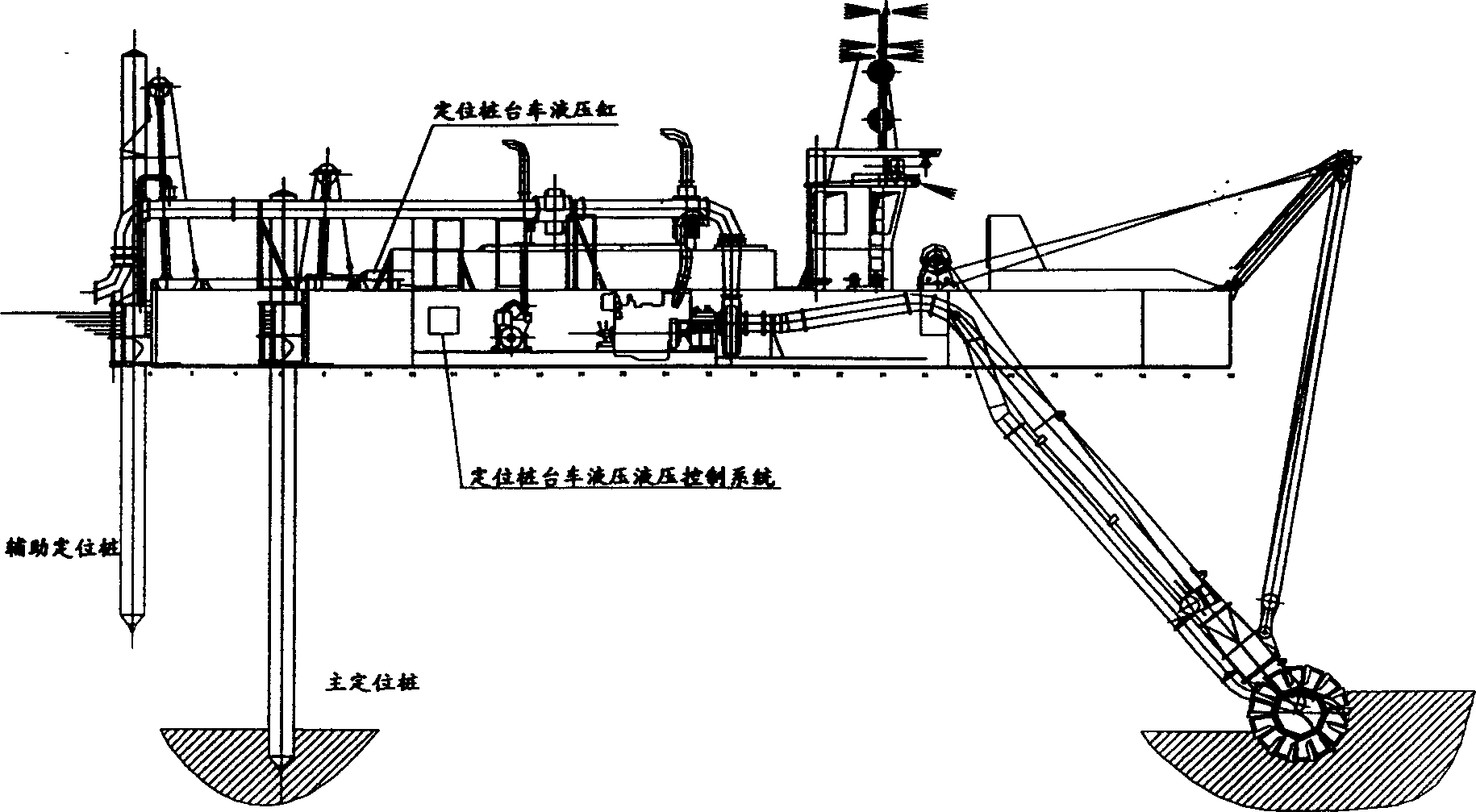

A technology of hydraulic control system and pile trolley, which is applied in the direction of ship auxiliary drive, fluid pressure actuator, ship, etc. It can solve the problem of poor positioning accuracy, inability to adapt to severe weather and special working conditions such as strong winds and waves, and inconvenient adjustment of moving speed and other issues, to achieve the effect of long service life, compact structure and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The details of the present invention are given below by describing the embodiments in conjunction with the accompanying drawings.

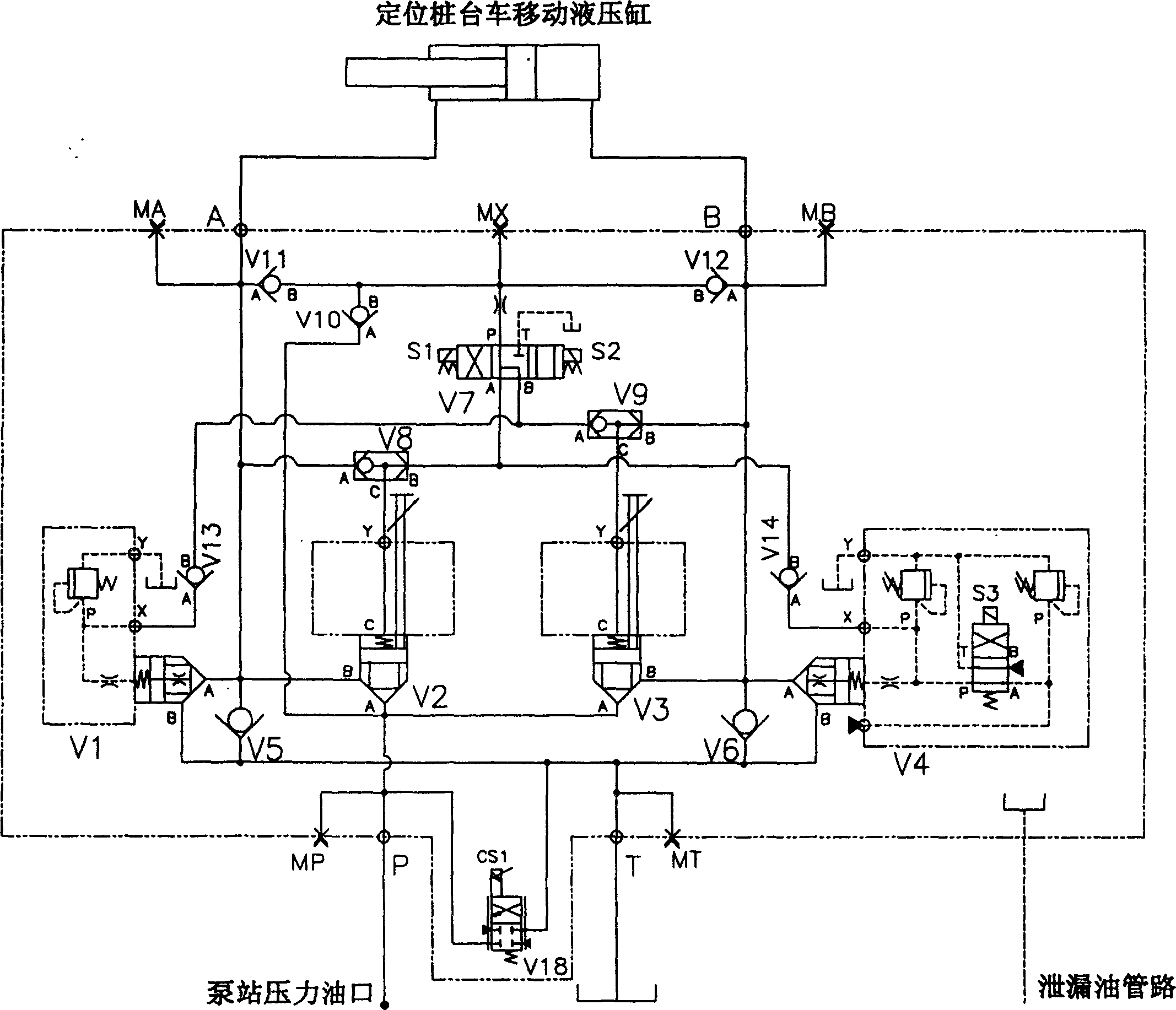

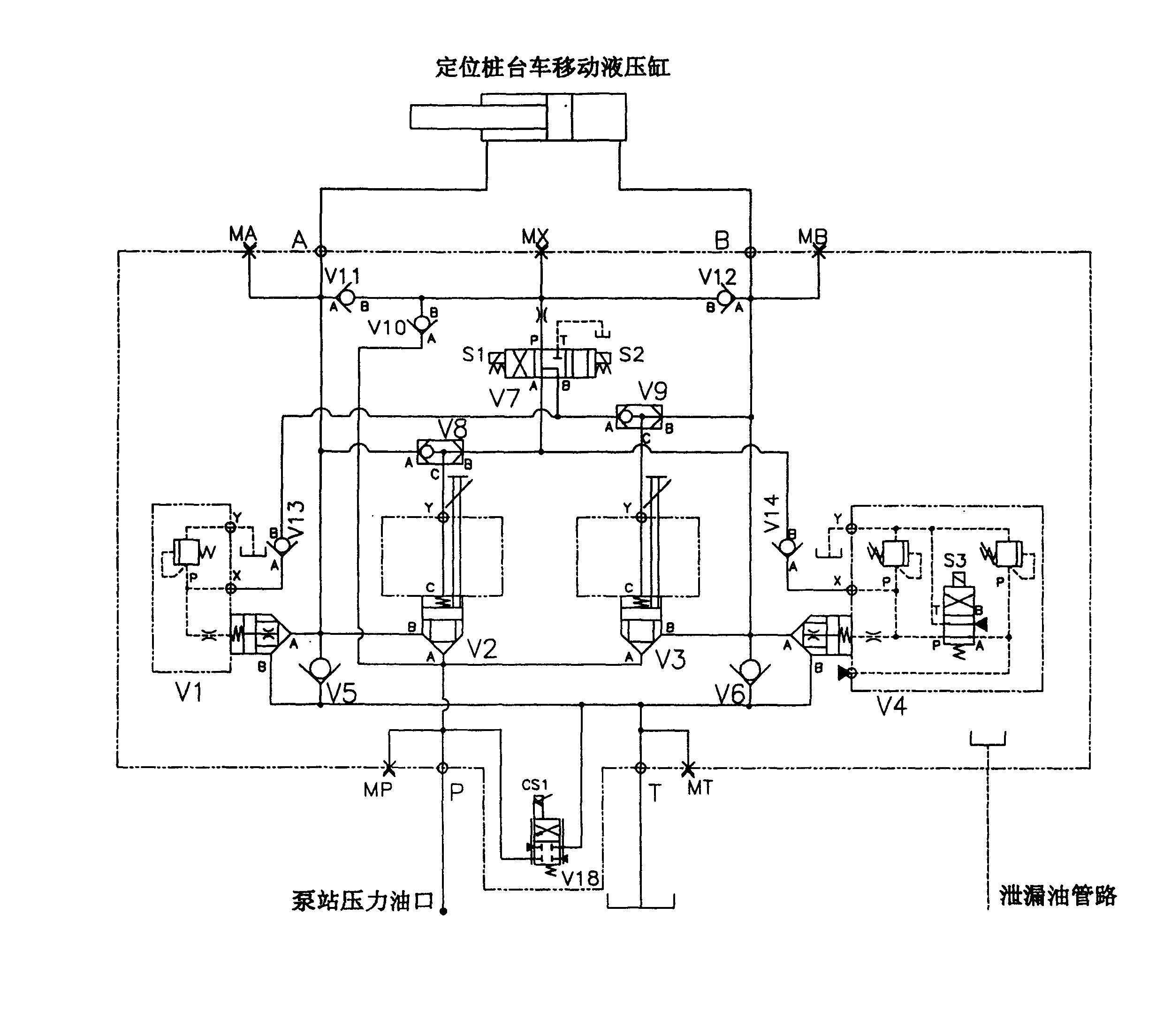

[0020] Such as figure 1 As shown, it includes: two cartridge check valves V2, V3, two shuttle valves V8, V9, two cartridge relief valves V1, V4, one electromagnetic reversing valve V7, two locking Function check valves V5, V6, a proportional throttle valve V18 and five check valves V10, V11, V12, V13, V14 with logic control functions; the connection relationship is as follows:

[0021] 1) The pressure oil port of the pumping station is connected to the A port of the first and second check valves V2 and V3, and the B ports of the first and second cartridge check valves V2 and V3 are respectively connected to the positioning pile trolley The rod chamber of the hydraulic cylinder is connected to the oil port of the rodless chamber; the pilot control oil Y port of the first and second cartridge check valves V2 and V3 is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com