System and method for controlling hydrological winch

A control system and winch technology, applied in hoisting devices, clockwork mechanism, etc., can solve problems such as large installation space requirements, unreliable systems, and increased equipment manufacturing costs, so as to achieve simple and clear lines, ensure operation safety, and optimize The effect of speed regulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

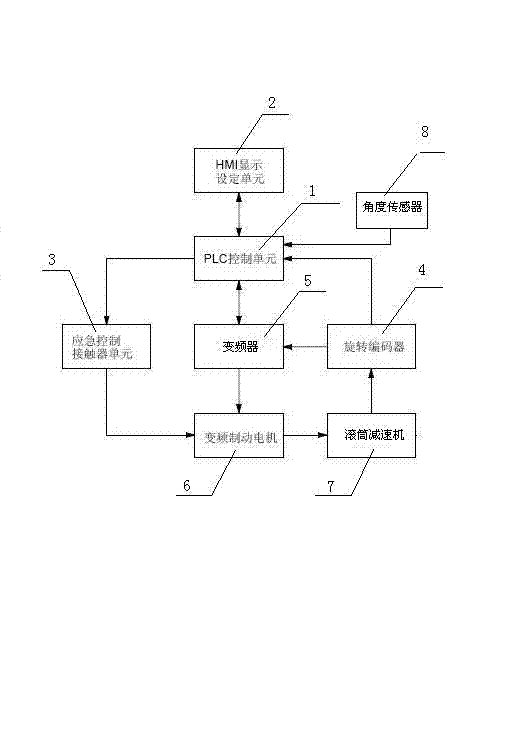

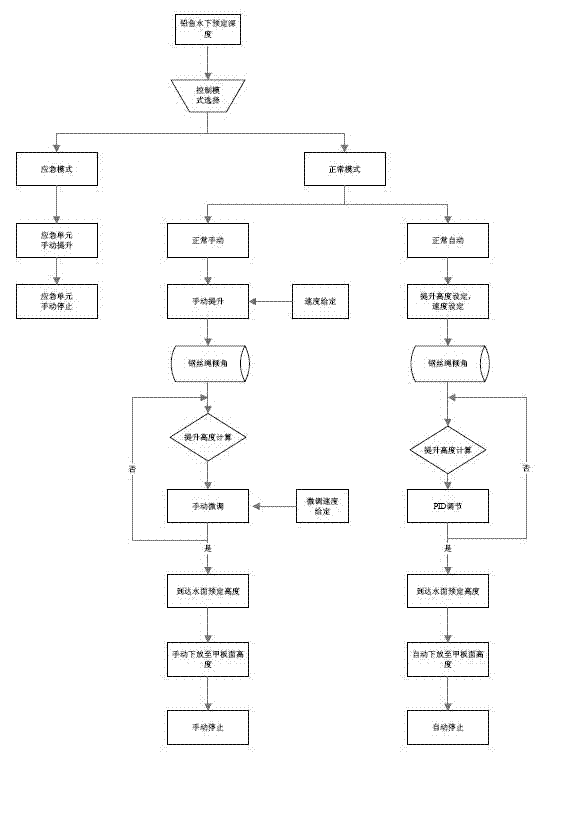

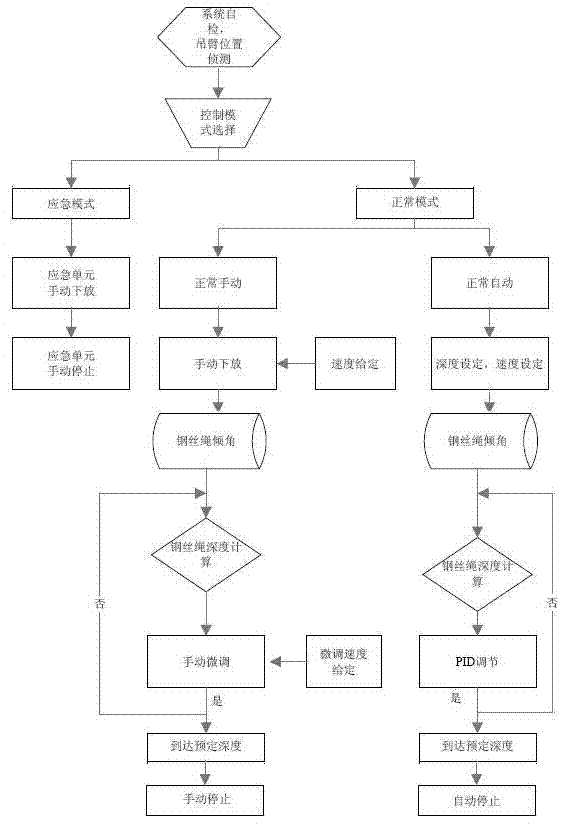

[0021] This example is a hydrological winch device of a hydrographic survey ship. Measuring parameters: the measuring water depth is 70M, the maximum speed of retracting and releasing the steel wire rope is required to be ≥20M / min, and the weight of conventional hydrological measuring equipment is about 70kg. The mechanical transmission part of the winch mainly includes a frequency conversion braking motor, a reducer, a wire rope drum, a guide wheel, a dancer pulley tensioning device, and a folding boom. Such as figure 1 As shown, the hydrological winch control system includes PLC control unit 1, HMI display setting unit 2, emergency control contactor unit 3, rotary encoder 4, frequency converter 5, frequency conversion braking motor 6, drum reducer 7, angle sensor 8 , the HMI display setting unit 2 is connected to the PLC control unit 1 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com