Monitoring method for identifying belt coal piling through artificial intelligent video

A technology of video recognition and artificial intelligence, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve time-consuming and labor-intensive security and stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

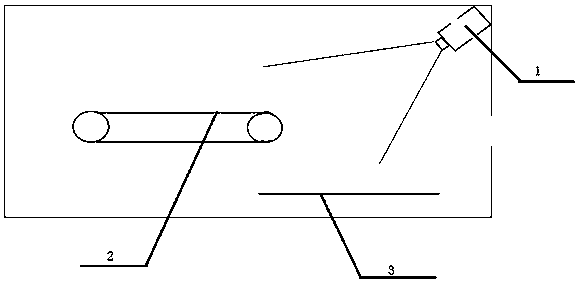

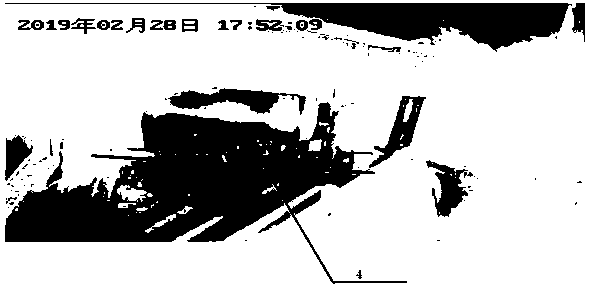

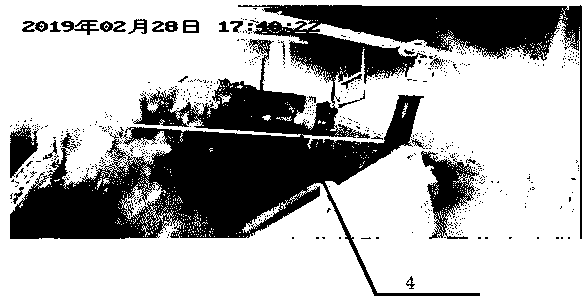

[0031] Such as Figures 1 to 4 As shown, the monitoring method of the artificial intelligence video recognition belt pile of coal of the present embodiment comprises the following steps: first set up a cordon 4 between the belt coal chute and the transfer point and the belt 2, and then pass the mining high-definition explosion-proof camera 1 in real time The video of the warning line is collected, and the high-definition explosion-proof camera 1 for mine transmits the video of the warning line to the server in real time through the network. The server analyzes the video of the warning line through the artificial intelligence video recognition model. If the target is covered by the amount of coal accumulation, the detection result is that the coal accumulation is caused by the occlusion, and the belt 2 is determined to be piled with coal.

[0032] Preferably, the warning line 4 is set at 1 / 3 between the belt coal chute and the transfer point and the belt 2 .

[0033] Further, ...

Embodiment 2

[0040] The monitoring method of the artificial intelligence video recognition belt pile of coal of the present embodiment comprises the following steps: first set up a warning line 4 between the belt coal chute and the transfer point and the belt 2, and then collect the warning line in real time through the mine-used high-definition explosion-proof camera 1 Video, mining high-definition explosion-proof camera 1 transmits the video of the warning line to the server in real time through the network, and the server analyzes the video of the warning line through the artificial intelligence video recognition model. If the target is met, if the detection result is the occlusion caused by the coal accumulation, it is determined that the belt 2 is piled with coal. If the detection result is not the occlusion caused by the coal accumulation, it is not judged as the belt 2 pile of coal.

[0041] Preferably, the warning line 4 is set at 1 / 3 between the belt coal chute and the transfer poi...

Embodiment 3

[0049] The monitoring method of the artificial intelligence video recognition belt pile of coal of the present embodiment comprises the following steps: first set up a warning line 4 at 1 / 3 between the belt chute and the transfer point and the belt 2, and then pass through the mine high-definition explosion-proof camera 1 The video of the warning line is collected in real time, and the high-definition explosion-proof camera 1 for mine transmits the video of the warning line to the server in real time through the network. The server analyzes the video of the warning line through the artificial intelligence video recognition model. When the warning line 4 is blocked, it detects whether it is a coal pile 3 If the coal accumulation blocks the target, the detection result is that the coal accumulation is caused by the coal accumulation, and the belt 2 pile of coal is determined. If the detection result is not caused by the coal accumulation, the coal accumulation is not judged as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com