A monitoring method for artificial intelligence video recognition of belt deviation

A video recognition and artificial intelligence technology, applied in conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

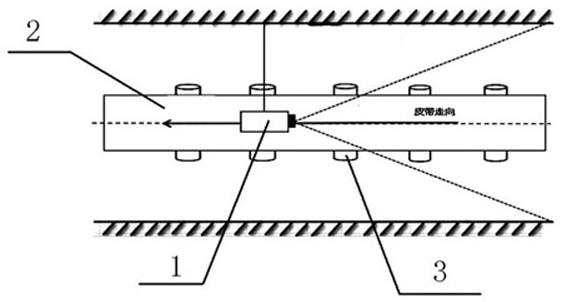

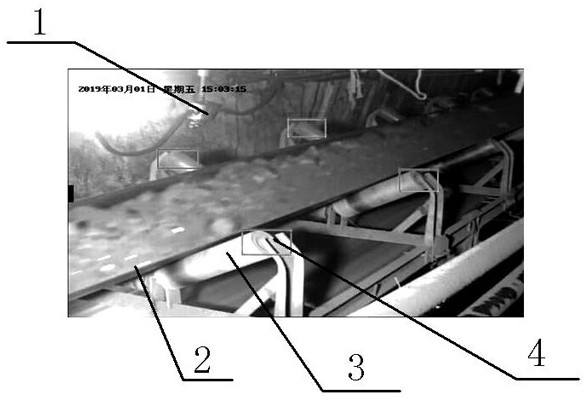

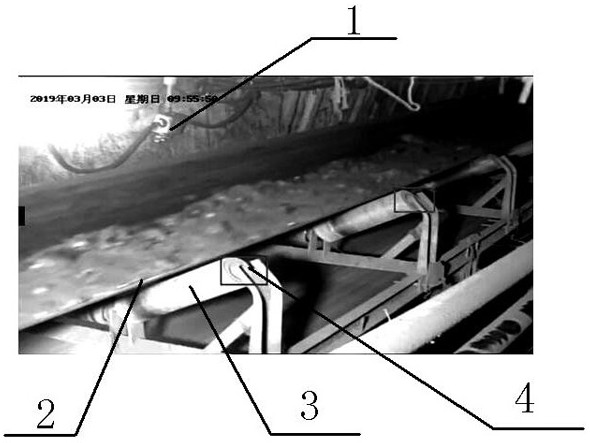

[0022] like Figures 1 to 4 As shown, the artificial intelligence video recognition method for monitoring the belt deviation of this embodiment firstly selects no less than two idlers 3 on both sides of the belt 2 as more than two tracking targets 4, and then passes the mine high-definition explosion-proof camera. 1 Real-time acquisition of the tracking target video, mine high-definition explosion-proof camera 1 transmits the tracking target video to the server in real time through the network, and the server analyzes the tracking target video through the artificial intelligence video recognition model. When the tracking target 4 is blocked, it is detected whether it is blocked by the belt 2. In order to track target 4, the detection result is that the occlusion caused by the belt 2 determines the deviation of the belt 2, and the detection result is not the occlusion caused by the belt 2, and it is not determined that the belt 2 deviates.

[0023] Preferably, the tracking targ...

Embodiment 2

[0031] like Figures 1 to 4 As shown, the artificial intelligence video recognition monitoring method of belt deviation in this embodiment firstly selects no less than two outer ends of idlers 3 on both sides of the belt 2 as more than two tracking targets 4, and then passes the mining high-definition Explosion-proof camera 1 collects and tracks the target video in real time, mine HD explosion-proof camera 1 transmits the tracking target video to the server in real time through the network, and the server analyzes the tracking target video through the artificial intelligence video recognition model. When the tracking target 4 is blocked, it detects whether it is a belt 2. The tracking target 4 is blocked. The detection result is that the blocking caused by the belt 2 determines the deviation of the belt 2. The detection result is not the blocking caused by the belt 2, and it is not determined that the belt 2 is running.

[0032] Preferably, the tracking target 4 is no less tha...

Embodiment 3

[0040] like Figures 1 to 4 As shown, the artificial intelligence video recognition monitoring method of belt deviation in this embodiment firstly selects no less than two outer ends of idlers 3 on both sides of the belt 2 as more than two tracking targets 4, and then passes the mining high-definition Explosion-proof camera 1 collects and tracks the target video in real time, mine HD explosion-proof camera 1 transmits the tracking target video to the server in real time through the network, and the server analyzes the tracking target video through the artificial intelligence video recognition model. When the tracking target 4 is blocked, it detects whether it is a belt 2. The tracking target 4 is blocked. The detection result is that the blocking caused by the belt 2 determines the deviation of the belt 2. The detection result is not the blocking caused by the belt 2, and it is not determined that the belt 2 is running.

[0041] Preferably, the tracking target 4 is no less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com