Load moment limiting device self-adaption accuracy calibrating method based on artificial neural network algorithm

An artificial neural network, lifting torque technology, applied in the direction of load hanging components, safety devices, transportation and packaging, can solve the problems of low efficiency, easy to produce errors, long accuracy calibration time, etc., to ensure the safety of operation, eliminate Errors, the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention needs to be implemented through core algorithm and software implementation, hardware design and prescribed man-machine operation flow.

[0007] 4.1 Core algorithm and software implementation

[0008] The present invention adopts neural network self-adaptive technology as the foundation of core algorithm, comprises the following parts:

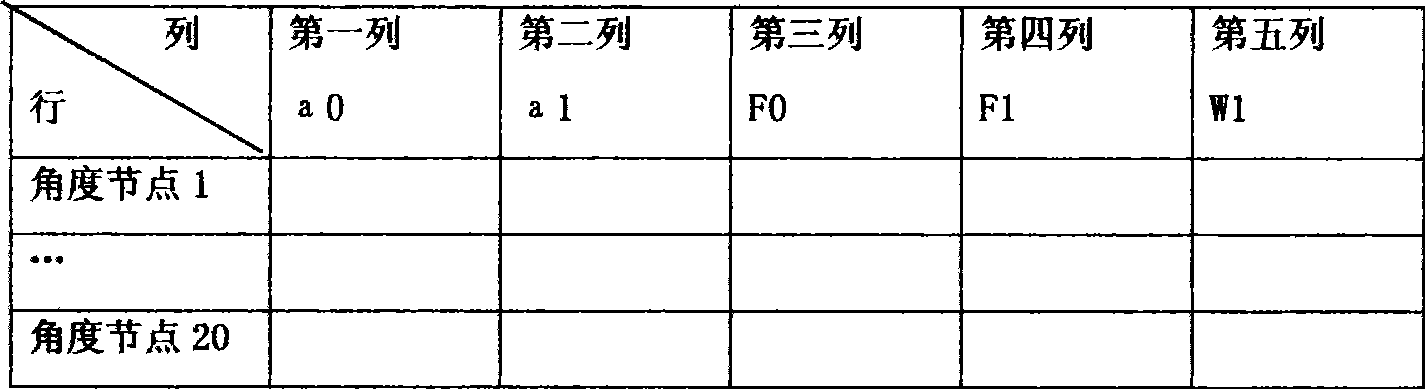

[0009] 4.1.1 Construction of artificial neural network coordinate system

[0010] According to the working characteristics of the cranes, the present invention divides the cranes into two types, freely expandable and non-freely expandable, and uses the length of the boom and the angle between the boom and the horizontal as coordinate axes to construct a coordinate system. For cranes that can be freely retracted (such as truck cranes), the length section indicated in the table of lifting characteristics is used as the basis for division of the arm length coordinate nodes; Different arm lengths are used as the basis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com