Snake-shaped wellhead viscosity reduction device based on coupling effect

A serpentine and viscosity-reducing technology, applied in the direction of engine seals, engine components, pipeline systems, etc., can solve the problem of inability to disperse and propel the crude oil, and achieve the effect of preventing crude oil clogging, preventing adhesion and accumulation, and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

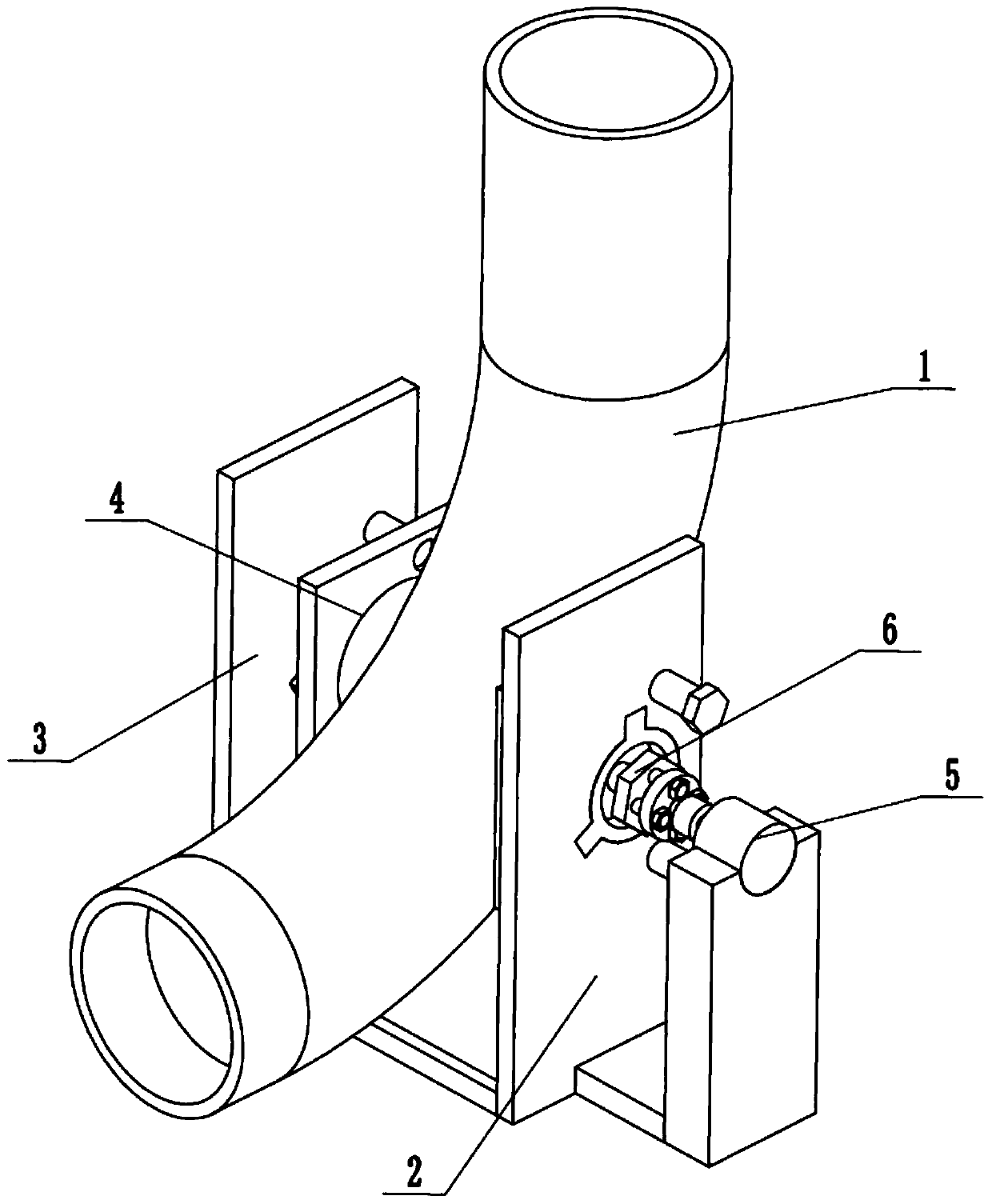

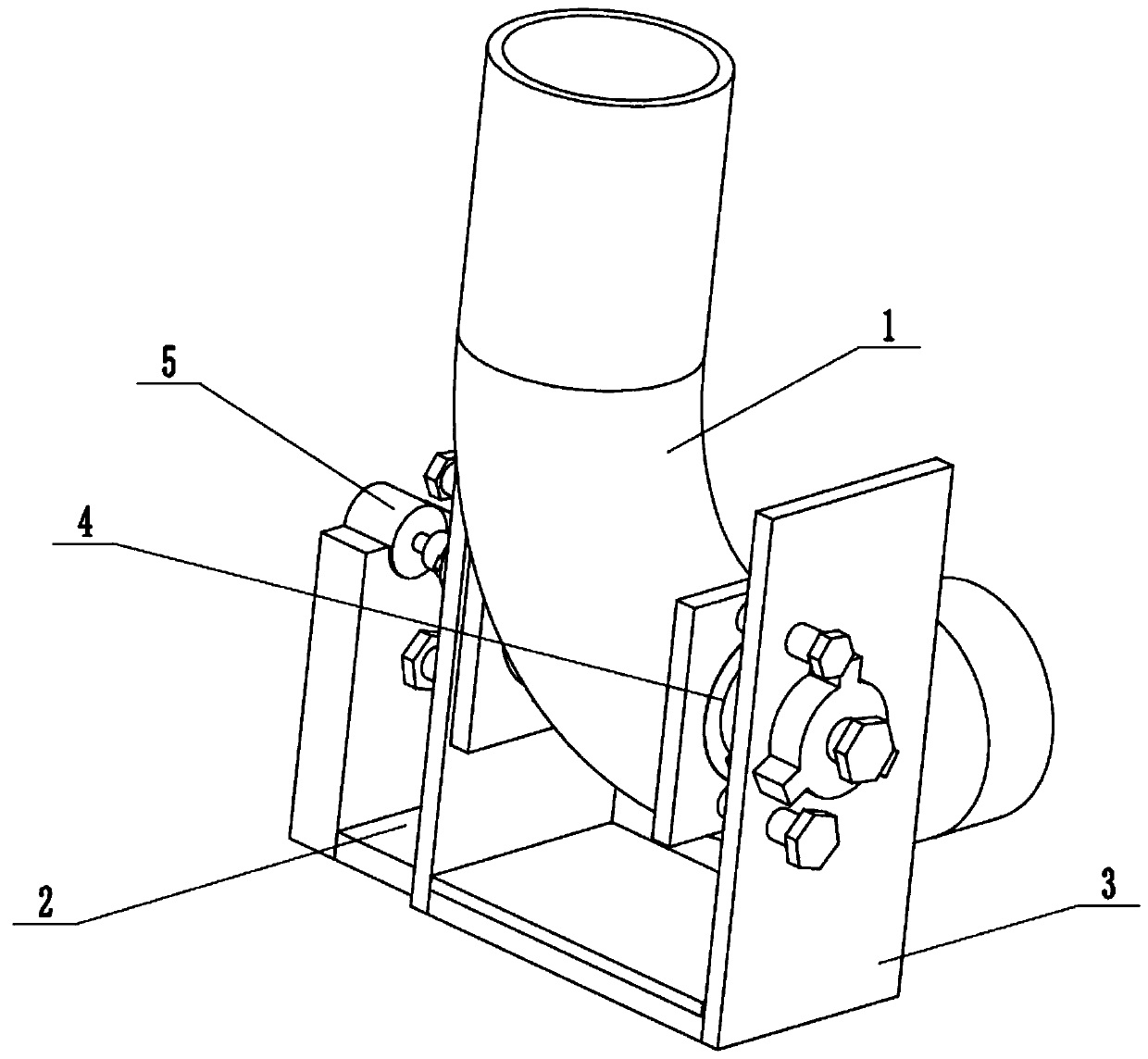

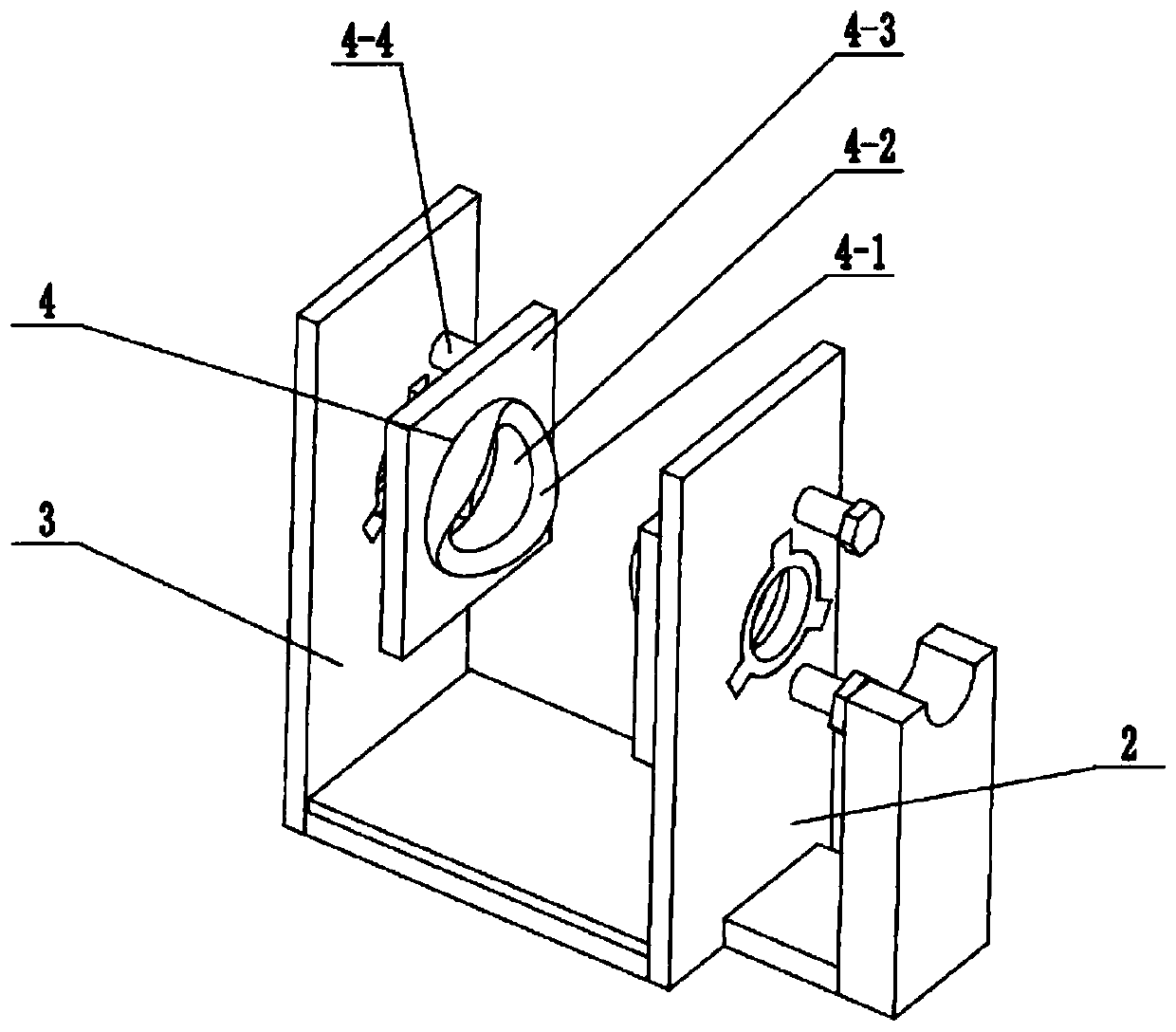

[0033] Such as Figure 1 to Figure 13As shown, a serpentine wellhead viscosity reduction device based on coupling, including a serpentine bend pipe 1, a right propulsion fixing seat 2, a left propulsion fixing seat 3, two sealing seats 4, a propulsion driver 5 and a drive regulator 6 , the left push fixed seat 3 is slidably connected to the right push fixed seat 2, and the two sealing seats 4 are connected to the left push fixed seat 3 and the right push fixed seat 2 respectively by threaded fit, and the inside of the two seal seats 4 Both ends are fitted on the serpentine curved pipe 1, the right end of the propulsion driver 5 is fixedly connected to the right propulsion fixing seat 2, and the propulsion driver 5 is clearance-fitted on the right propulsion fixing seat 2 and the left propulsion fixing seat 3, and the propulsion driver 5 Connected in the two sealing seats 4 through the sealing thread, the propulsion driver 5 rotates in the serpentine curved pipe 1, the right en...

specific Embodiment approach 2

[0035] Such as Figure 1 to Figure 13 As shown, this embodiment further describes the first embodiment, and the left and right ends of the bend of the serpentine pipe 1 are provided with communicating circular openings. It is convenient for the insertion of the device for breaking and stirring.

specific Embodiment approach 3

[0037] Such as Figure 1 to Figure 13 As shown, this embodiment will further explain the second embodiment. The right pusher fixing seat 2 includes a lower bottom plate 2-1, a combined sliding T-shaped slot 2-2, a right limit fixing plate 2-3, a right limit The hole 2-4 and the motor holder 2-5, the right end of the lower base plate 2-1 are fixedly connected to the lower end of the right limit fixed plate 2-3, the combined sliding T-shaped groove 2-2 is arranged on the lower base plate 2-1, the right The limit hole 2-4 is arranged on the right limit fixed plate 2-3, and the right end of the right limit fixed plate 2-3 is fixedly connected to the motor holder 2-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com