Board washing machine for PCB processing and use method thereof

A technology for PCB boards and board washing machines, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of insufficient cleaning of PCB boards and unfavorable PCB board manufacturing, and improve the cleaning quality and cleaning efficiency, reduce labor costs, and improve feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] In the first aspect, the embodiment of the present application discloses a washing machine for processing PCB boards.

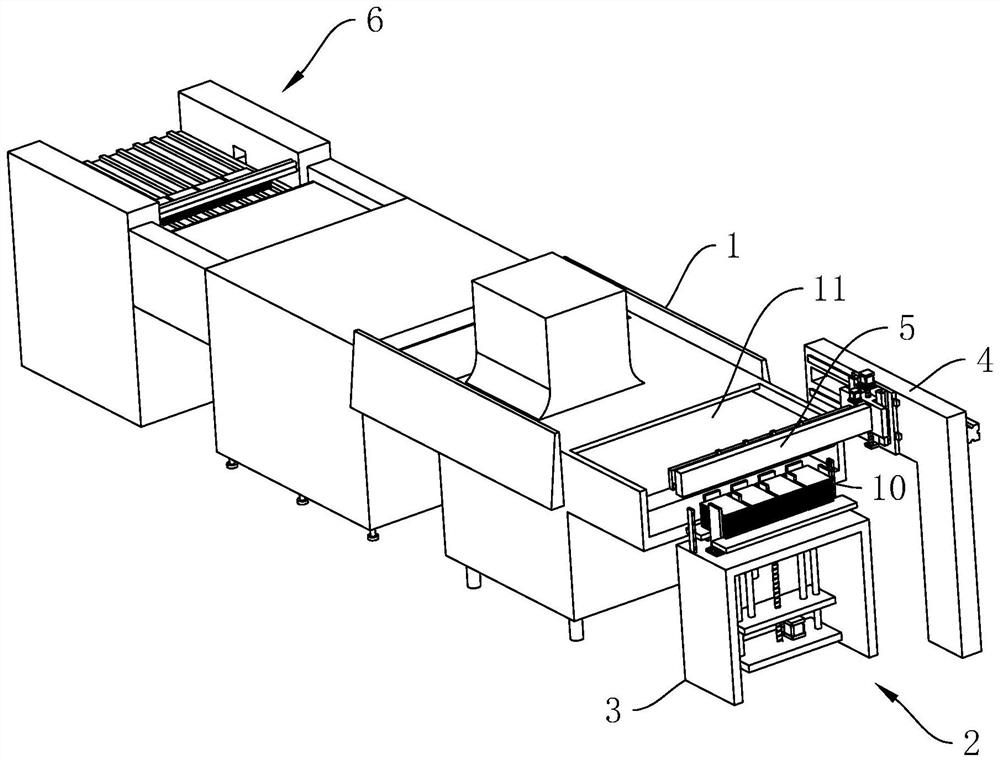

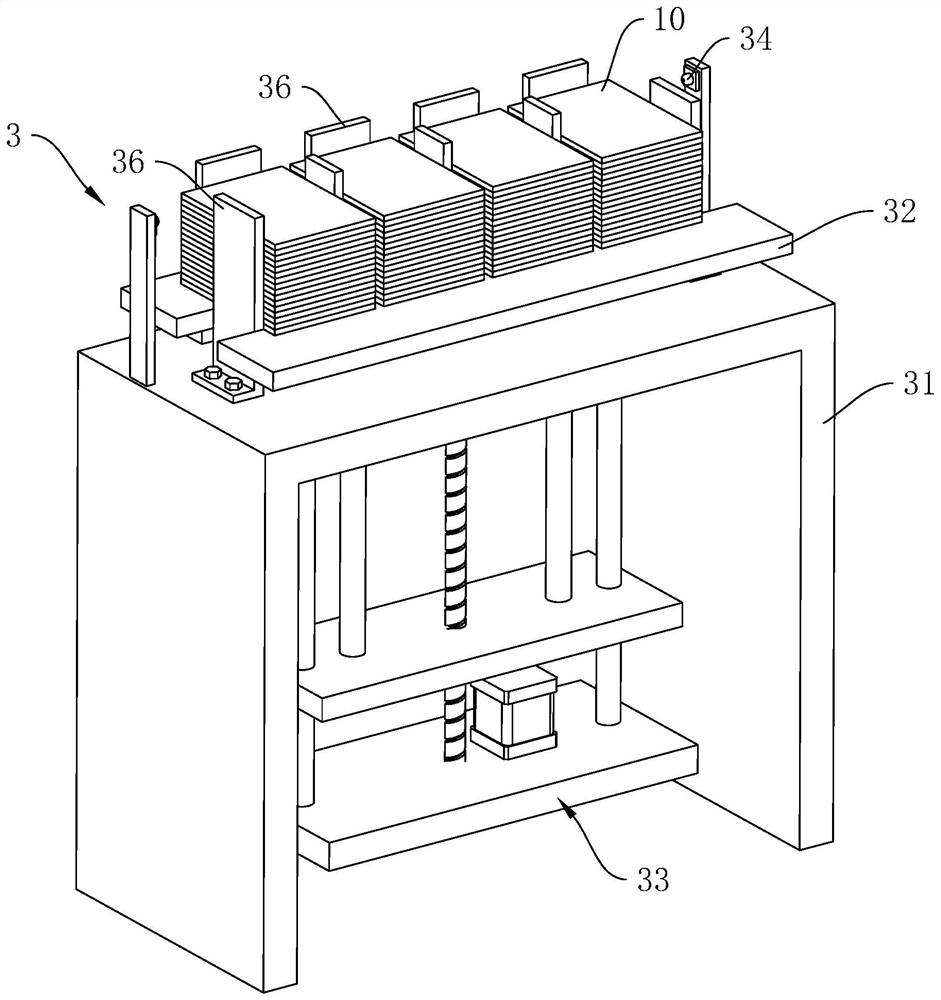

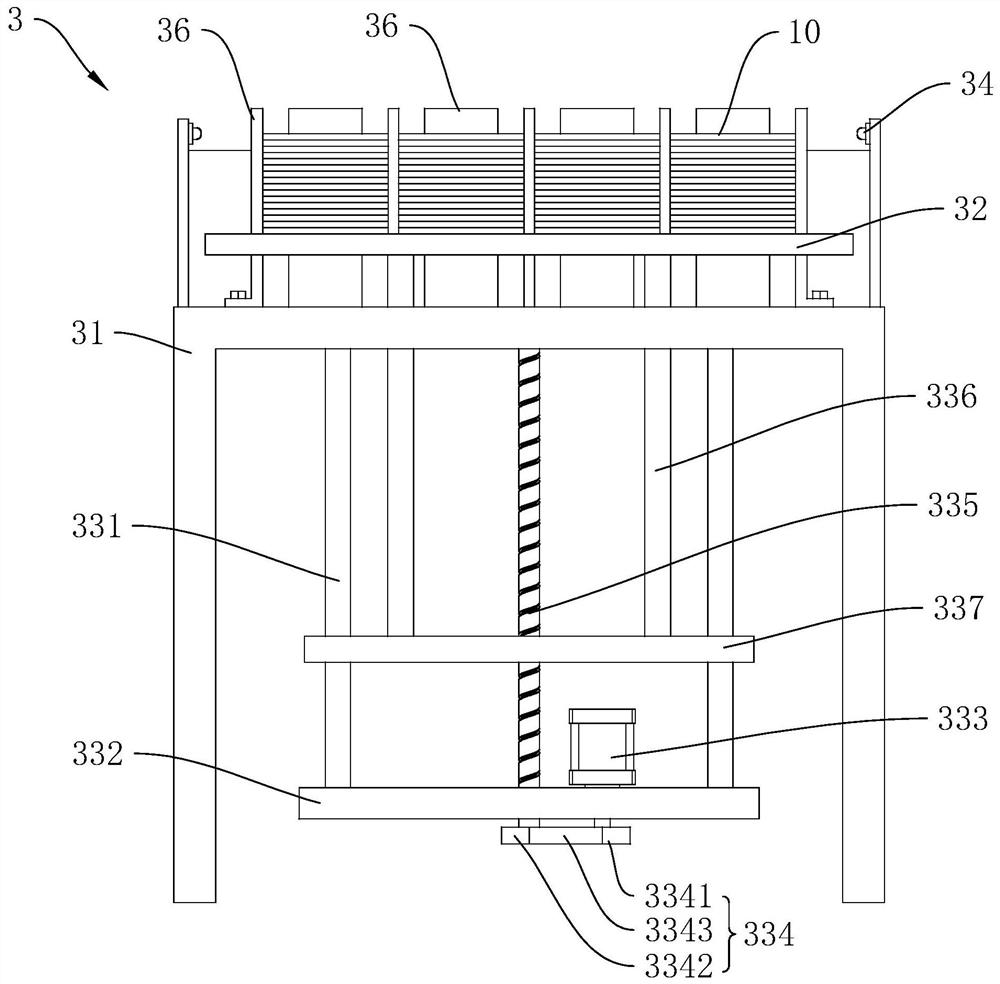

[0041] refer to figure 1 , the plate washer includes a plate washer body 1, a conveying line 11 is arranged in the plate washer body 1, and a feeding mechanism 2 is arranged at the feeding end of the conveying line 11, and the feeding mechanism 2 includes a jacking separation device 3, a two-axis The driving device 4 and the grabbing device 5, the jacking and separating device 3 are set on the feeding end of the conveying line 11 for placing the stacked PCB boards 10, and the two-axis driving device 4 is set on the side of the conveying line 11 for driving the grasping The grabbing device 5 moves horizontally and vertically. The grabbing device 5 is arranged at the output end of the two-axis driving device 4. The grabbing device 5 is used to separate and gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com