Hub jet polishing machine

A polishing machine, jet technology, applied in abrasive jet machine tools, used abrasive treatment devices, abrasives, etc., can solve the problems of unstable processing quality, affecting workers' health, and high labor intensity, avoiding dust explosion accidents, Beneficial to health and avoid dust explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

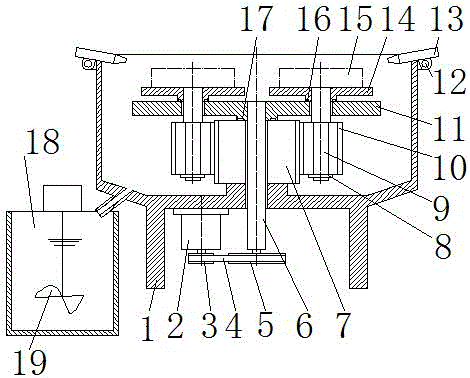

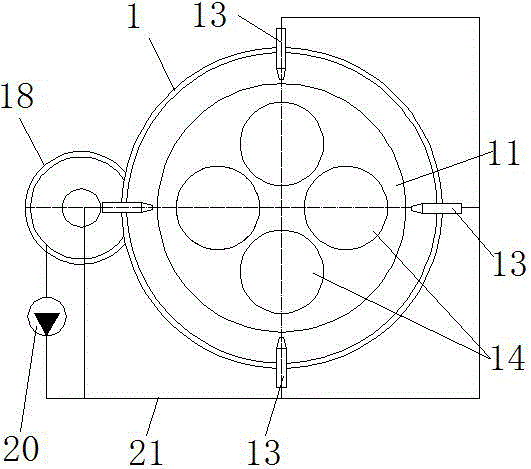

[0013] Such as figure 1 , figure 2 Shown: a wheel hub jet polishing machine, which is composed of two parts: a wheel hub polishing transmission device and a jet polishing liquid circulation device. The transmission device consists of a base (1), a drive motor (2), a pulley I (3), a transmission belt (4), a pulley II (5), a central shaft (6), a sun gear (7), and a retaining ring ( 8), planetary shaft (9), planetary gear (10), turntable (11), clamping disc (14). The jet polishing liquid circulation device is composed of a polishing liquid tank (18), an agitator (19), a booster pump (20), a polishing liquid pipeline (21), a nozzle (13), and a pin shaft (12).

[0014] The driving motor (2) of the hub polishing transmission device is fixed on the base (1), the pulley I (3) is fixedly connected to the lower end of the output shaft of the driving motor (2), and the sun gear (7) is an outer cylindrical gear. Its center is a cylindrical through hole, the lower end surface of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com