A milk powder box and a milk making device

A milk powder box and milk powder technology, applied in transportation and packaging, beverage preparation equipment, packaging, etc., can solve problems such as easy residual milk powder, insufficient simplification of milk powder brewing steps, poor sealing of milk powder box and milk bottle, etc., to achieve simplified steps and convenience The effect of carrying and heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

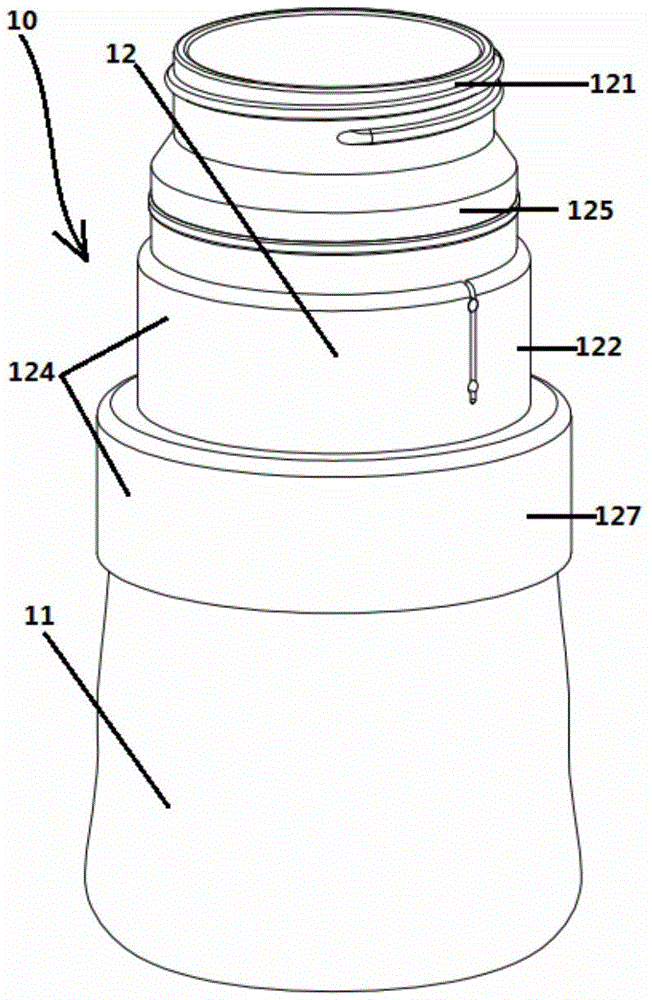

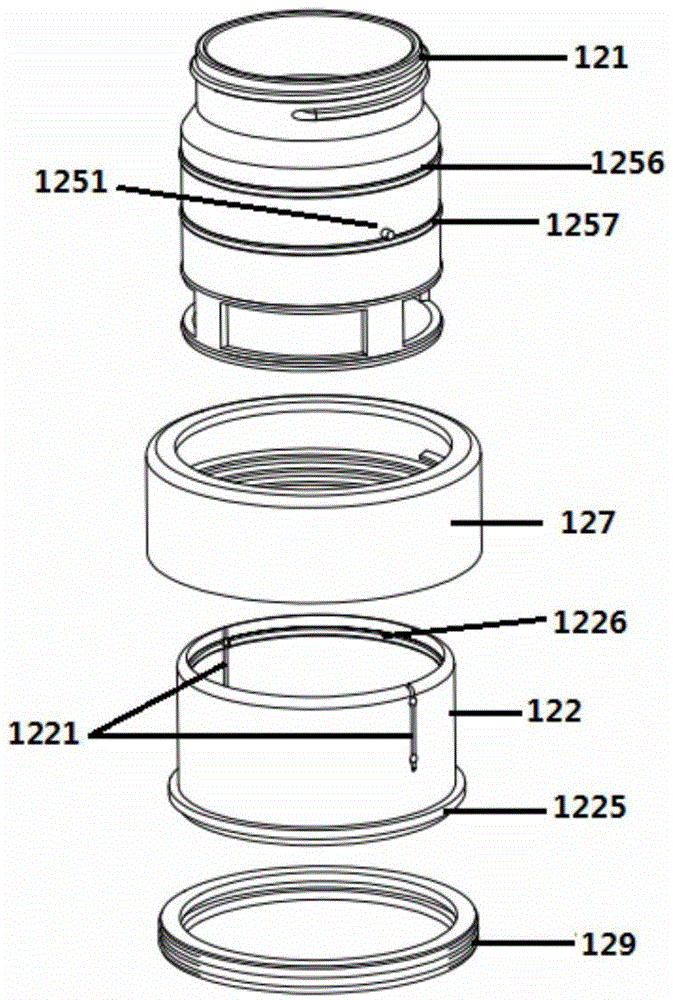

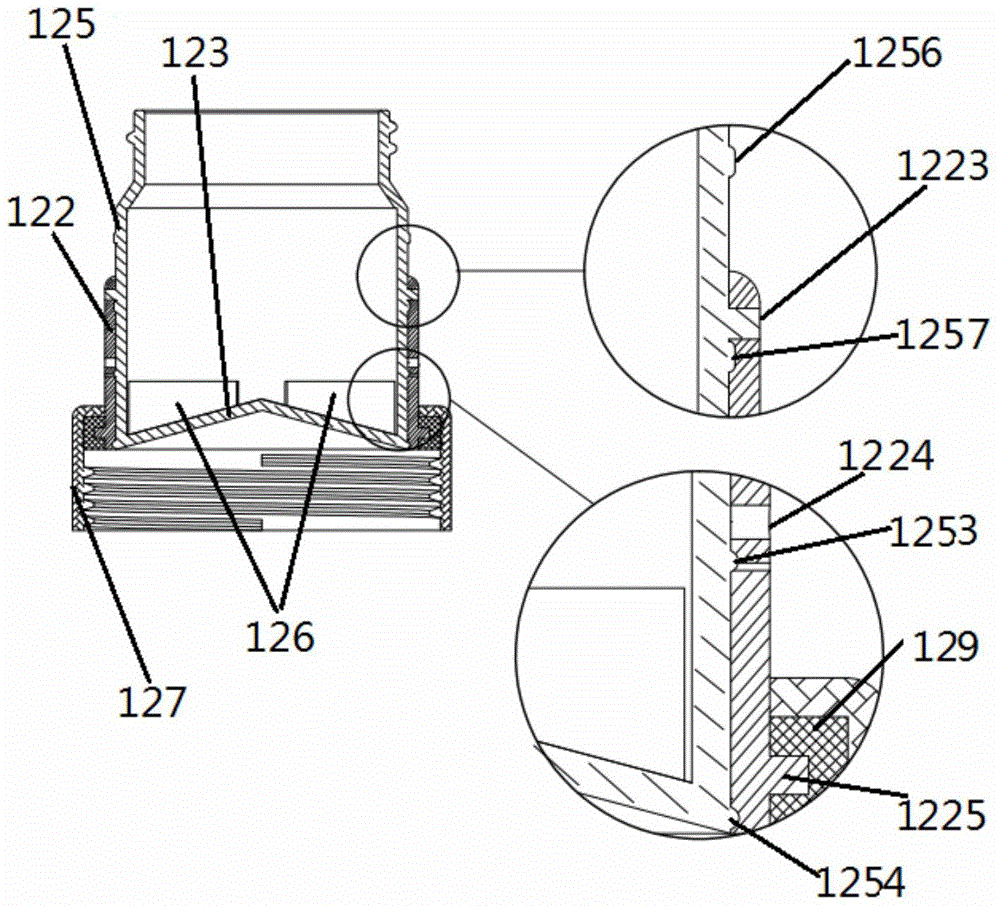

[0046] This embodiment provides a figure 1 The shown milk preparation device 10 includes a feeding bottle 11 and a milk powder box 12. The milk powder box 12 includes a box bottom 123, a box body 125, a first connecting mechanism 121 and a second connecting mechanism 124, wherein the first connecting mechanism 121 is located in the box The upper part of the body 125, and can be connected with a pacifier (not shown). The feeding bottle 11 is connected with the milk powder box 12 by a second connection mechanism 124, such as image 3 As shown, the milk powder box also includes a milk powder outlet 126, which can combine the milk powder in the milk powder box with the book in the feeding bottle to brew the milk powder. Such as Figure 1 to Figure 2 As shown, the box body 125 is movably connected with the second connecting mechanism 124, and can carry out longitudinal relative movement, and the milk powder box 12 has a first working position and a second working position through...

Embodiment 2

[0061] This embodiment provides a Figure 5 The shown milk preparation device 20 includes a feeding bottle 21 and a milk powder box 22, and the milk powder box 22 includes a box bottom 223, a box body 225, a first connecting mechanism 221 and a second connecting mechanism 224, wherein the first connecting mechanism 221 is located in the box The upper part of the body 225, and can be connected with a pacifier (not shown), the feeding bottle 21 and the milk powder box 22 are connected by the second connection mechanism 224, and the lower port of the box body 225 is the milk powder outlet 226, which can be used in the milk powder box. The powdered milk is combined with the water in the bottle to make the powdered milk. Such as Figure 5 and Figure 6 As shown, the second connection mechanism 224 includes a box body support 222 and a bottle mouth connection 227, and in this embodiment, these two components are provided separately. The box body 225 is movably connected to the se...

Embodiment 3

[0074] This embodiment provides a Figure 10 and Figure 11 The shown milk preparation device 30 includes a feeding bottle 31 and a milk powder box 32. The milk powder box 32 has a box body 325, a box bottom 323 and a first connecting mechanism 321 positioned at the top of the box body 325, and is also provided with a water-combining mechanism for milk powder. The milk powder outlet 326, the structural design of the milk preparation device 30 is generally similar to the milk preparation device 20 provided in Embodiment 2, please refer to Embodiment 2 for specific descriptions, and only the differences between the two or equivalent replacement parts are described as follows:

[0075] Such as Figures 11 to 13 As shown, the box body support 322 and the bottle mouth connector 327 of the second connection mechanism 324 are integrally formed; the first sealing ring 329 is equivalent to the first sealing ring 229 in the milk preparation device 20, but the first sealing ring 229 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com