Anti-corrosion method of steel and anti-corrosion steel

An anti-corrosion and steel technology, applied in the direction of metal material coating process, etc., can solve the problems of harsh working environment, time-consuming and laborious, and hindering the operation of staff, and achieve uniform surface oxide film, avoid mutual accumulation, and simplify operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

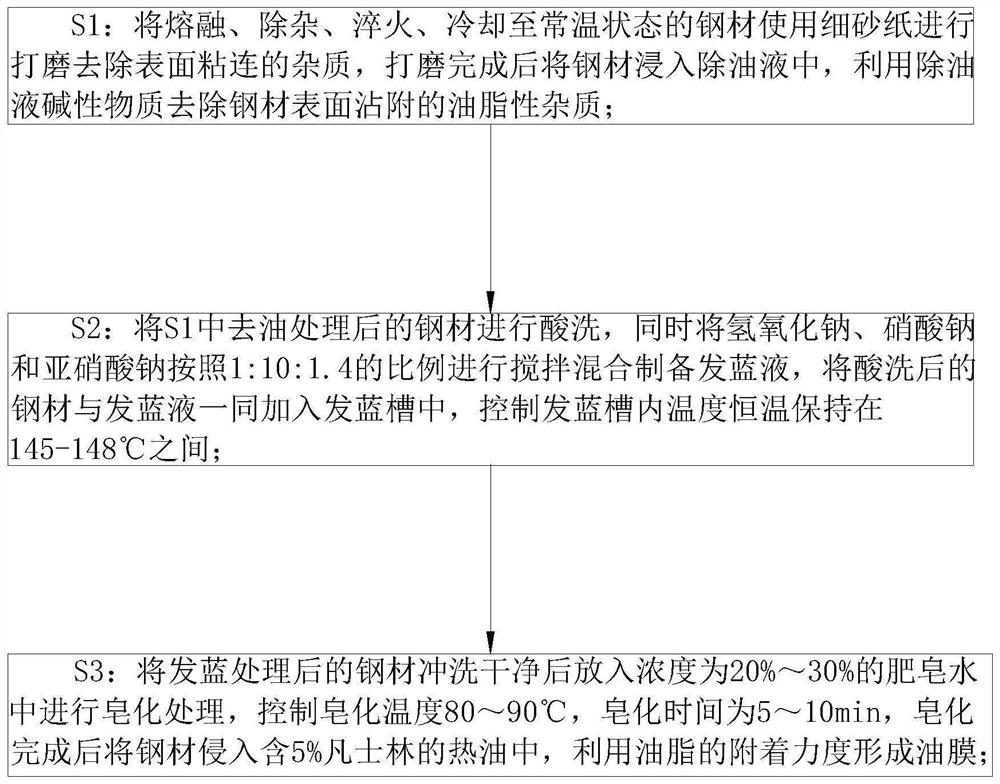

Method used

Image

Examples

Embodiment approach

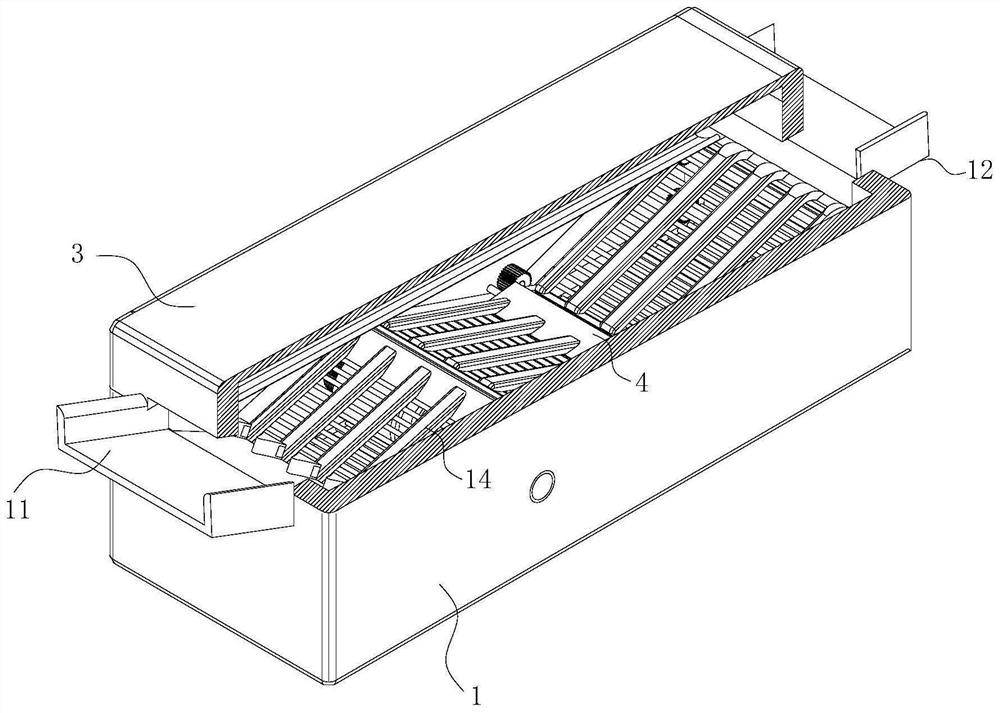

[0038] As an embodiment of the present invention, the cavity of the tank body 1 is located below the material inlet and is hinged with a rotating plate 5 through a guide rod; the rotating plate 5 is elastically connected to the inner wall of the tank body 1 through a spring; the rotating The side of the plate 5 away from the spring is fixed with evenly distributed guide plates 51; the guide plates 51 are used to discharge the materials sent into the rotating plate 5 through the feed port to the conveyor belt 2 at equal intervals; during work, the components pass through The feeding trough 11 leads into the tank body 1 and slides down along the rotating plate 5. During the process of sliding down on the rotating plate 5, multiple components are gradually guided by the guide plate 14, so that the components are in different positions. Between the guide plates 14, and in the process of sliding down, they are evenly arranged on the conveyor belt 2, thereby effectively avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com