Aluminum rod continuous casting and rolling production line

A continuous casting, continuous rolling, production line technology, applied in metal rolling, metal rolling, keeping the roll equipment in an effective state, etc., can solve the problems of reducing output, blocking rods, low production efficiency, etc., to avoid heat dissipation of aluminum alloy rods The effect of soot pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

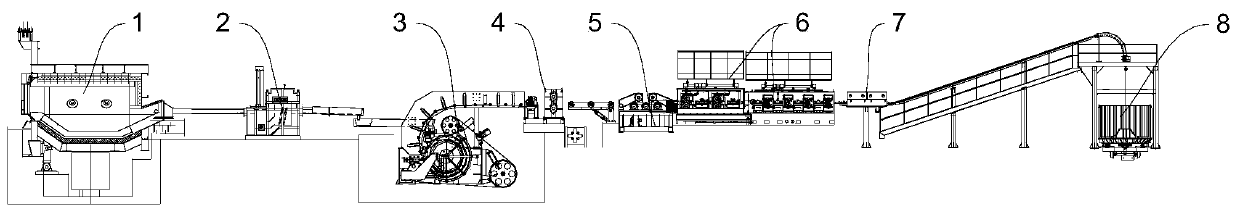

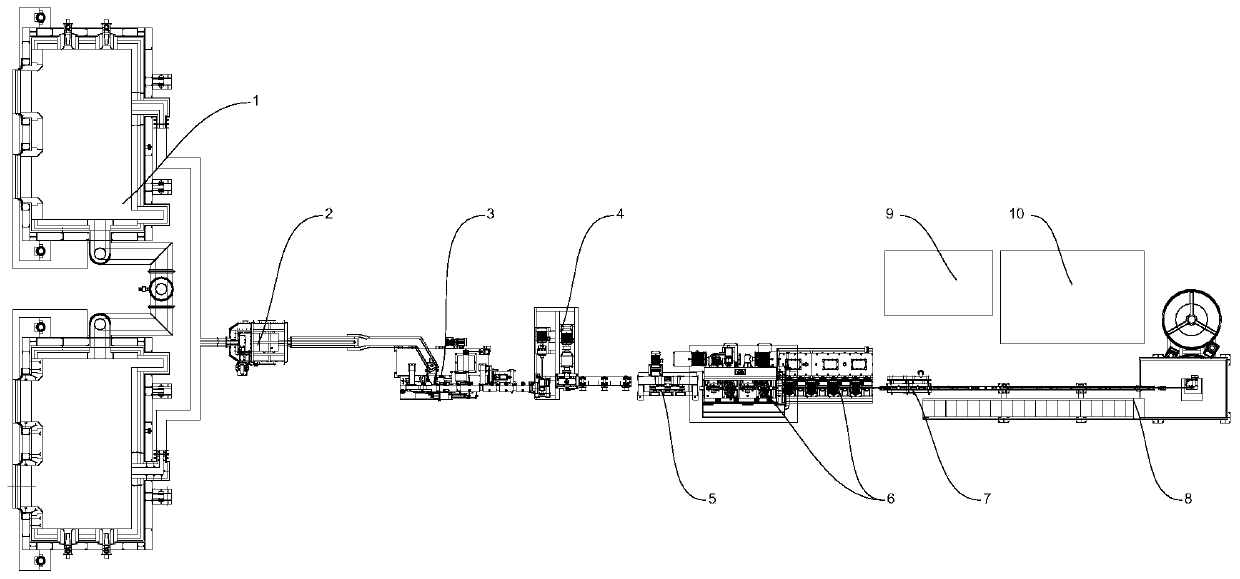

[0067] see Figure 1~2 , an aluminum rod continuous casting and rolling production line, including an aluminum furnace 1 for melting raw materials, a casting machine 3 for cooling and solidifying metal liquid, a rolling shear traction device 4 for pulling the casting machine 3 to form aluminum rods, for The continuous rolling mill 6 for aluminum rod rolling and forming, the wire take-up device 8 for taking up the wire, the wire take-up device 8 includes a wire winding device 87 for winding the rod wire, and the wire take-up device 8 also includes a take-up device for sliding the aluminum rod into The wire pipe 82 and the emulsion pipe 83 for transporting the emulsified cooling liquid are distributed with a plurality of guide milk blowing assemblies 84 on the wire take-up pipe 82, and the guide milk blow assembly 84 includes a guide wheel mounting seat 8401 arranged on the wire take-up pipe 82, The guide wheel mounting base 8401 is covered with a guide base seal cover 8402 for ...

Embodiment 2

[0080] The differences between this embodiment and Embodiment 1 mainly lie in: 1. The continuous rolling mill 6 in the production line is further improved.

[0081] see Figure 1~2 , an aluminum rod continuous casting and rolling production line, including an aluminum furnace 1 for melting raw materials, a casting machine 3 for cooling and solidifying metal liquid, a rolling shear traction device 4 for pulling the casting machine 3 to form aluminum rods, for The continuous rolling mill 6 for aluminum rod rolling and forming, the wire take-up device 8 for taking up the wire, the wire take-up device 8 includes a wire winding device 87 for winding the rod wire, and the wire take-up device 8 also includes a take-up device for sliding the aluminum rod into The line pipe 82 and the emulsion pipe 83 for conveying the emulsified cooling liquid are distributed with a plurality of guide milk blowing assemblies 84 on the line take-up pipe 82, and the guide milk blow assembly 84 includes ...

Embodiment 3

[0093] The difference between this embodiment and embodiment 2 is: 1) replace the continuous rolling mill, and replace the continuous rolling mill 6 independently driven by each rolling unit in embodiment 2 with a linked rolling mill 6; 2) add a roughing mill 11 before the continuous rolling mill .

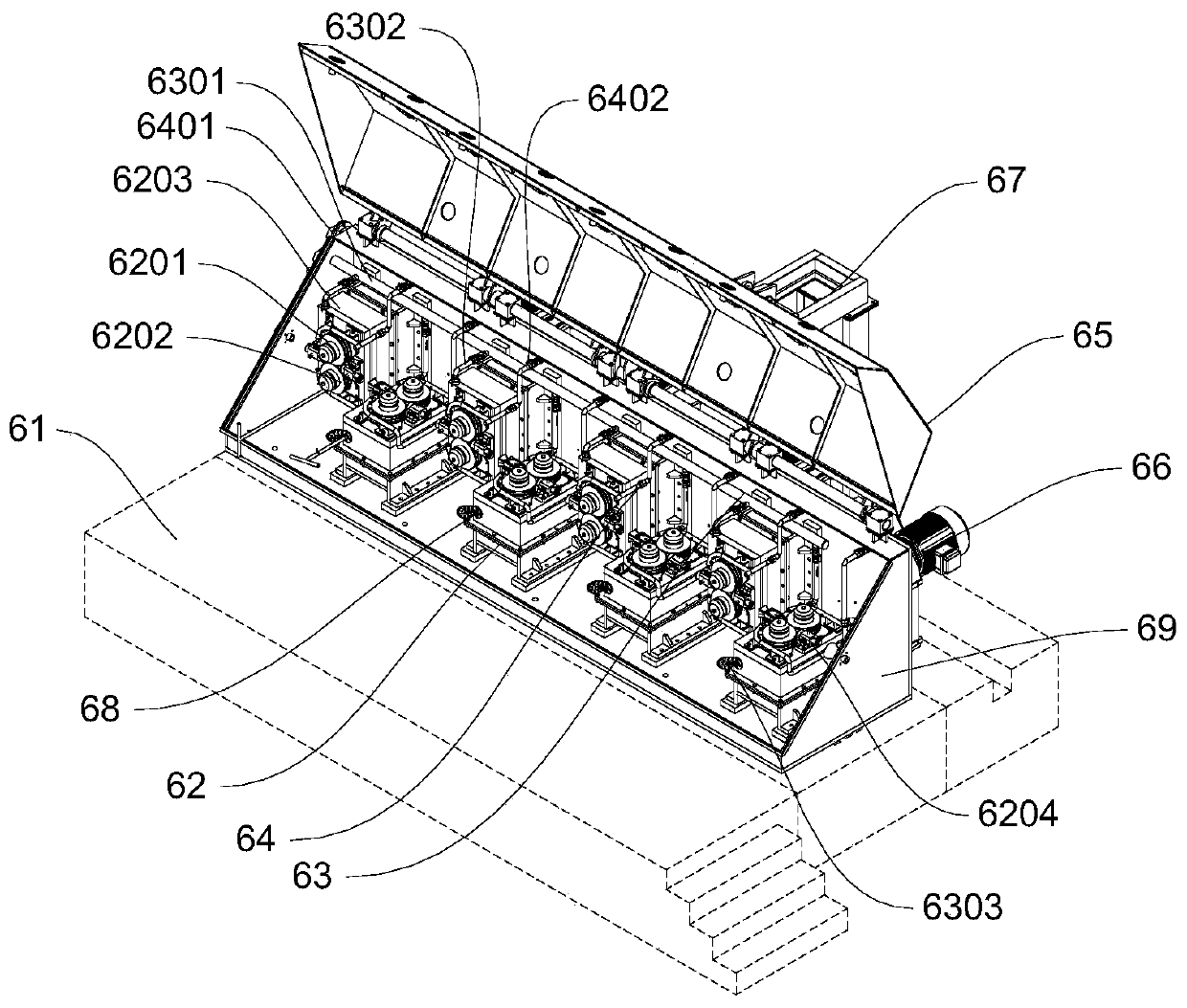

[0094] see Figures 16-19 , the linked rolling mill 6 and the continuous rolling mill of embodiment 2 all contain the rolling unit 602 and the system for cooling and lubricating. Drive concentrated continuous rolling unit 602, refer to Figure 20-21 , the horizontally arranged centralized continuous rolling unit 602 and the transmission linkage box 603 are driven through bevel gears for transmission and reversing, the vertically arranged centralized continuous rolling unit 602 and the transmission linkage box 603 are driven through direct connection for transmission, and the transmission parts of the above-mentioned centralized drive are arranged There are many ways, such as gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com