Preparation device of copper alloy bar for wear-resistant gear

A preparation device and copper alloy technology, applied in the direction of cleaning methods using tools, cleaning methods using liquids, dry gas arrangement, etc., can solve the problems of reducing the preparation efficiency and effect of alloy rods, poor cleaning effect of alloy rods, and processing of alloy rods Errors and other problems, to improve the cleaning effect and cleaning efficiency, prevent dust adhesion, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

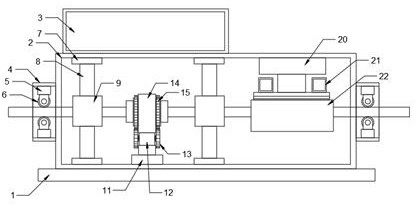

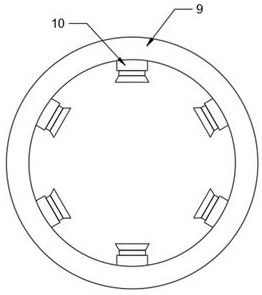

[0022] see Figure 1~5 , in an embodiment of the present invention, a copper alloy rod preparation device for wear-resistant gears, including a base plate 1, a cleaning box 2 and a brush 19, the upper end of the base plate 1 is equipped with a cleaning box 2, and the upper end of the cleaning box 2 is installed with a Water tank 3, fixed frame 4 is installed in the middle part of the left end of cleaning box 2, fixed cylinder 5 is installed on the inside of fixed frame 4, limit frame 27 is installed on the inside of fixed tube 5, limit wheel 6 is installed in the middle of limit frame 27; A water pump 7 is installed on the upper side, a water delivery pipe 8 is installed at the bottom of the water pump 7, a cleaning frame 9 is installed at the bottom of the water delivery pipe 8, and a nozzle 10 is installed on the inside of the cleaning frame 9; the shape of the fixed frame 4 is circular, and the fixed cylinder 5 and The limit frame 27 is concave-convex connected, and the ins...

Embodiment 2

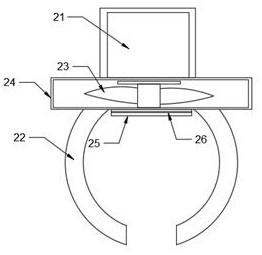

[0026] In the embodiment of the present invention, a copper alloy rod preparation device for wear-resistant gears includes a bottom plate 1, a cleaning box 2 and a brush 19, a cleaning box 2 is installed on the upper end of the bottom plate 1, and a water tank is installed on the upper end of the cleaning box 2 3. A fixed frame 4 is installed in the middle of the left end of the cleaning box 2, a fixed cylinder 5 is installed on the inside of the fixed frame 4, a limit frame 27 is installed on the inside of the fixed cylinder 5, and a limit wheel 6 is installed in the middle of the limit frame 27; A water pump 7 is installed on the side, and a water delivery pipe 8 is installed at the bottom of the water pump 7, and a cleaning frame 9 is installed at the bottom of the water delivery pipe 8, and a nozzle 10 is installed on the inside of the cleaning frame 9; The upper end of the seat 11 is equipped with a biaxial motor 12, the front end of the biaxial motor 12 rotating shaft is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com