Composite type immersed membrane component

A immersed membrane, composite technology, applied in membrane technology, semi-permeable membrane separation, sustainable biological treatment and other directions, can solve the problem of high energy consumption of aeration, improve degradation, save energy, and improve the utilization of aeration rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description, in order for readers to better understand the present application, the details of the present invention will be further described in detail in conjunction with the accompanying drawings.

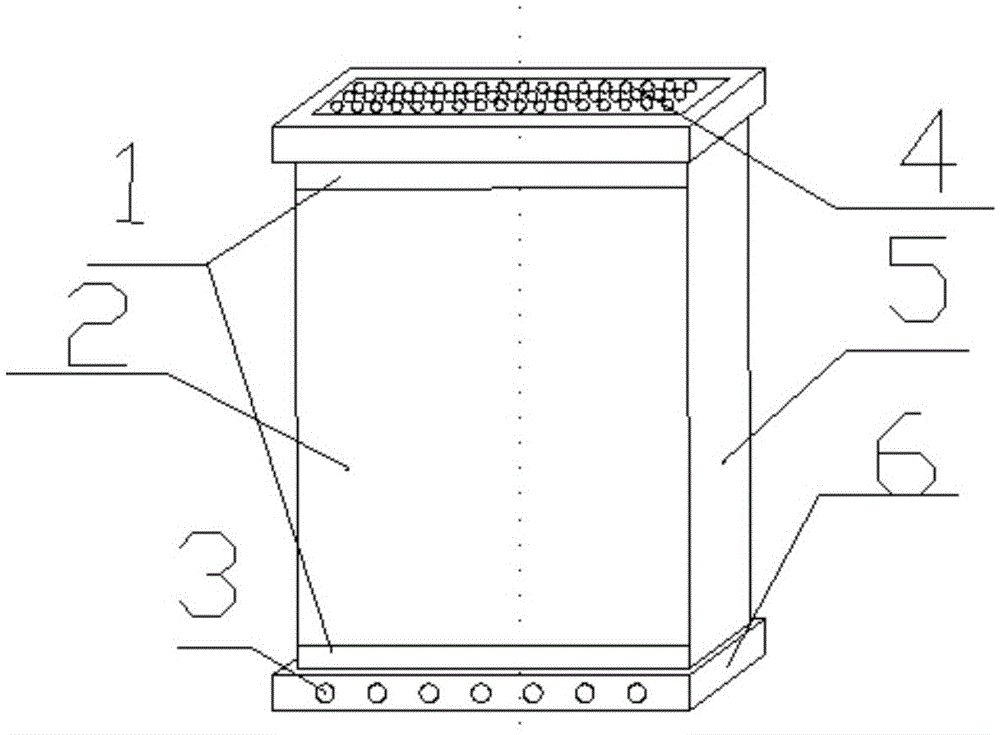

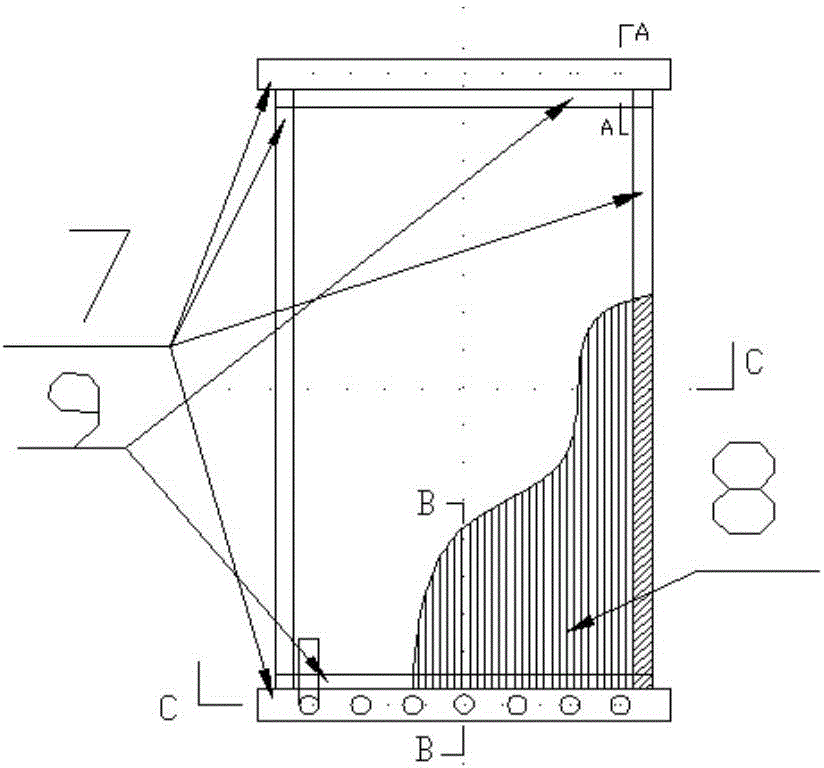

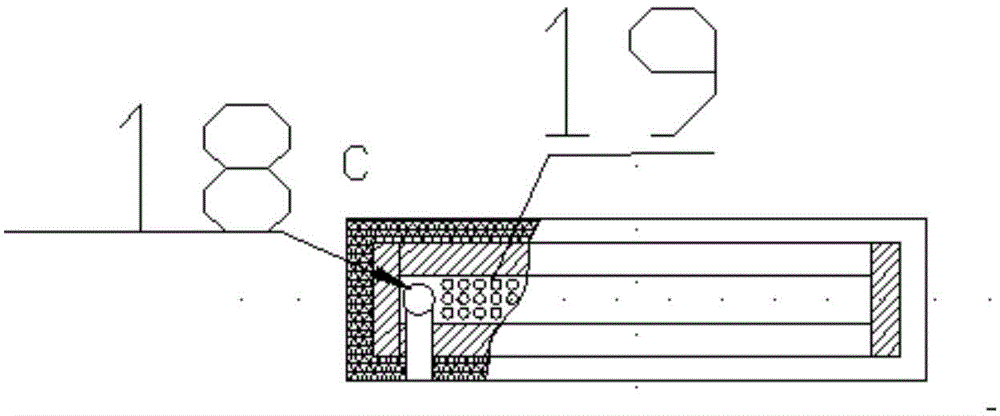

[0032] The embodiment of the present invention relates to a composite submerged membrane module, which is applied to MBR membrane bioreactor sewage treatment and fluid filtration and separation. The structure of the composite submerged membrane module is as follows: figure 1 shown, including:

[0033] Flat membrane and non-woven fabric (2), the flat membrane is a polyvinylidene fluoride microfiltration membrane, which has a complete overall asymmetric network cross-sectional structure, and the pore size is 0.1 to 1.0 microns. As a preference, the pore size ranges from 0.2 to Between 0.5 microns, the pure water flux is 800-1200L / m 2. bar.hr, the support layer is non-woven.

[0034] The flat film is fixed on the front and rear sides of the bracket (5) (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com