A multi-channel double-layer flat membrane module

A flat-panel membrane stack and multi-channel technology, applied in the physical field, can solve the problems of insufficient aeration, waste of vacuum pump drive energy, and reduced membrane water flux, so as to reduce aeration demand and improve injection pressure tolerance ability, reduce the effect of suction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

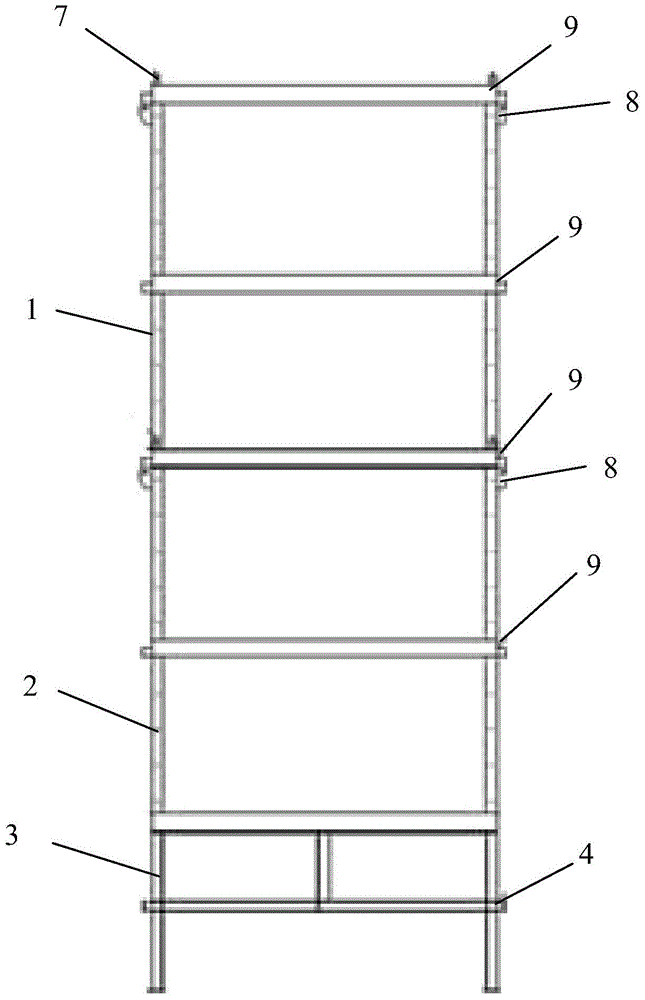

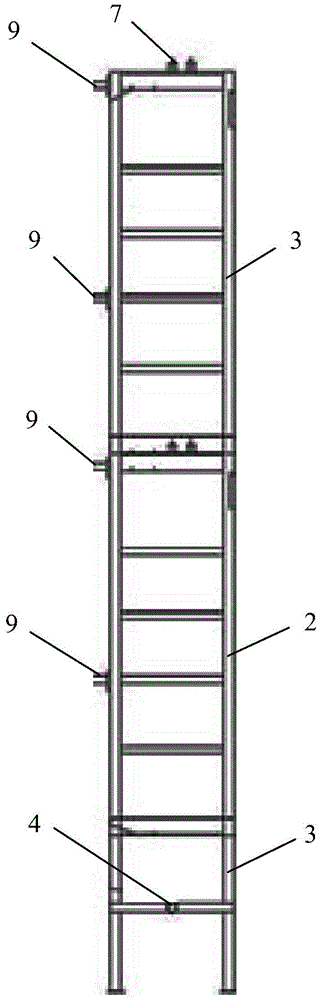

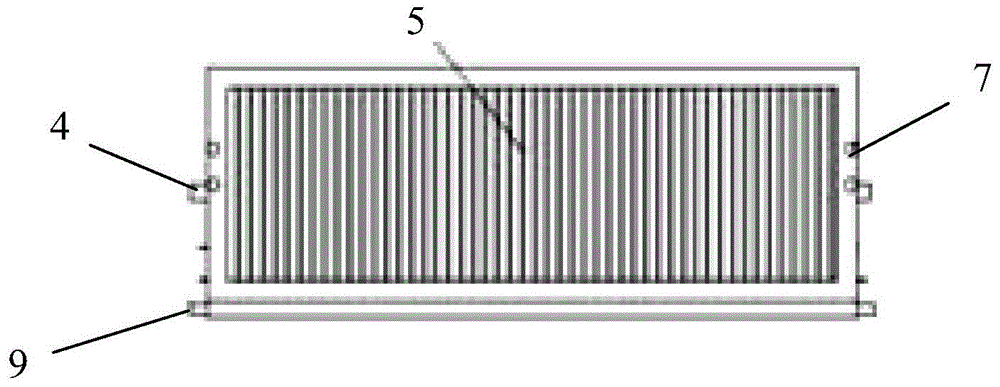

[0025] like figure 1 , figure 2 and image 3 As shown in the figure, a multi-channel double-layer type flat membrane packer of the present invention includes a first membrane box 1 and a second membrane box 2, wherein the first membrane box 1 is arranged on the upper side of the second membrane box 2 , the lower side of the second membrane box 2 is provided with an aeration box 3, the aeration box 3 includes an aeration box body, a bracket and an aeration pipeline 4, and the aeration pipeline 4 is arranged in the aeration box body, the bracket and the aeration box The boxes are connected, the first membrane box 1 and the second membrane box 2 are each filled with at least two double-water outlet membrane elements 5, and any double-water outlet membrane element 5 includes two water outlets 6, and the water outlet 6 are each connected to a water collecting pipe 9, and one end of the water collecting pipe 9 extends to the outside of the first membrane box 1 and the second memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com