Plate-type aerator diaphragm perforation device

Disclosed is a technology of aerator and disc type, which is applied in the field of disc type aerator diaphragm opening devices, and can solve the problems of shortened service life of disc type aerator diaphragm, tearing or failure of micropores, troublesome and time-consuming processing, etc. Achieve the effect of obvious bubble diffusion, improve service life and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

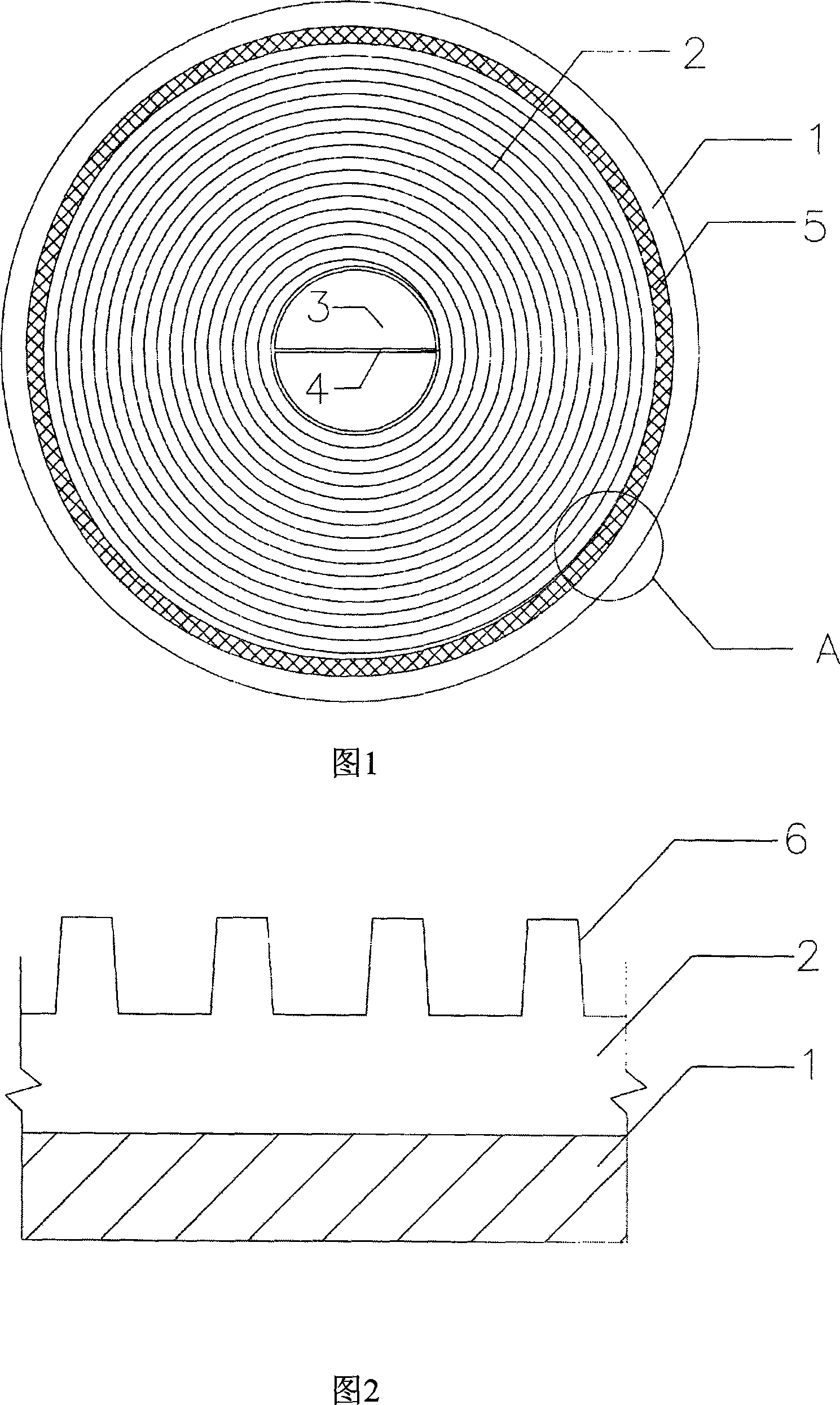

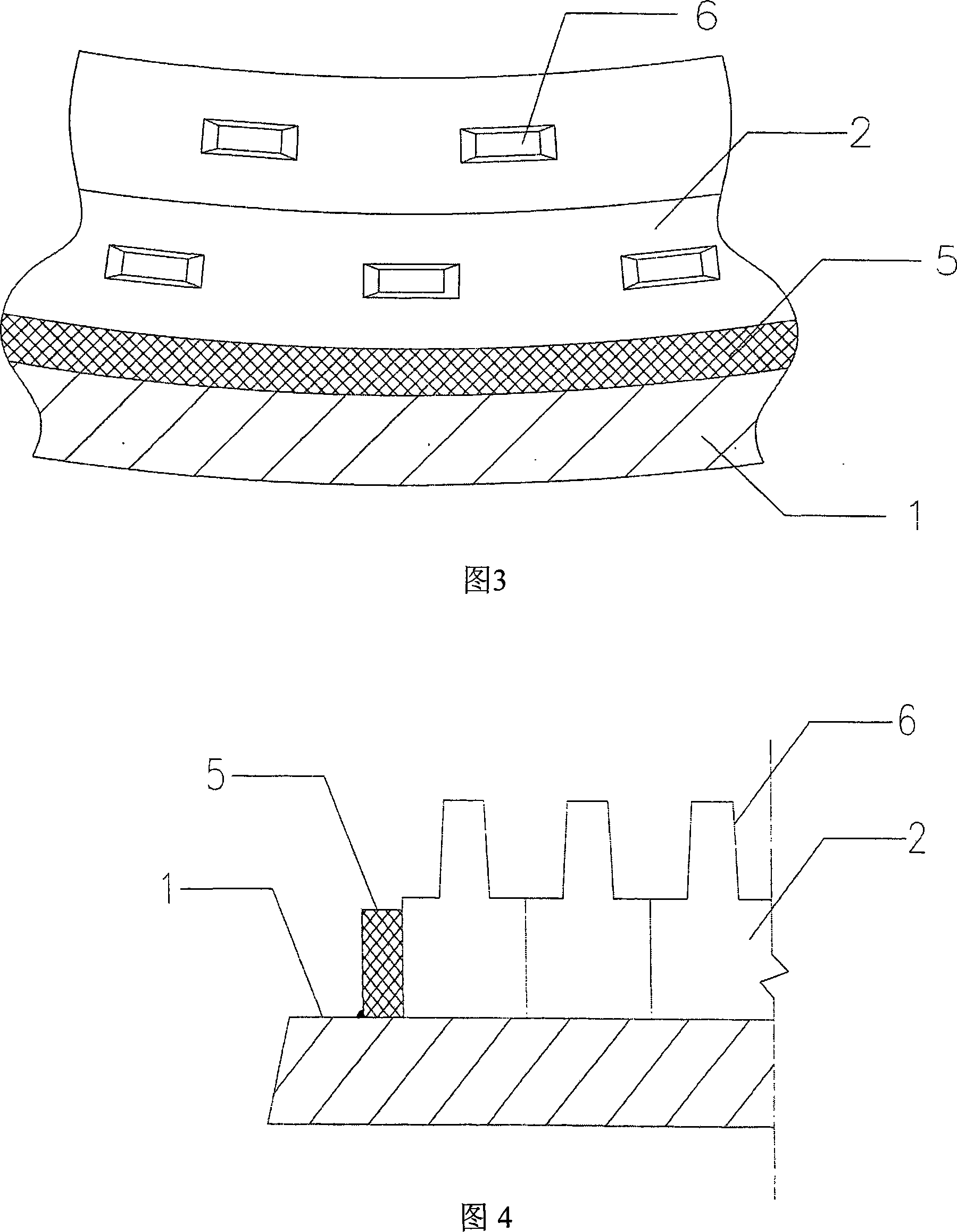

[0019] Example 1. See Fig. 1, the perforating device of this example has a steel disc base 1, and the center of the base has a fixed shaft 3, and the shaft is provided with a middle slot 4 passing through the fixed shaft. The cutter belt 2 is made of alloy steel, and its specifications are: length×width×thickness=14500mm×25mm×1.5mm. There are continuous ladder-shaped cutter heads on the cutter belt (see Fig. 2 and Fig. 3), and the thickness of the cutter head is 0.5 mm. mm, the tooth height of the cutter head is 5mm (equal to the thickness of the processed aeration diaphragm), evenly distributed, and the blade is in the shape of a line. With the cutter head 6 facing upwards, the head end of the cutter belt 2 is embedded in the middle slot 4 of the fixed shaft, and then tightly coiled on the fixed shaft. After reaching the designed diameter, the end of the cutter belt 2 is welded on the outer ring 5 . An outer ring 5 with an internal diameter of 270mm is welded to the disc bas...

Embodiment 2

[0021] Example 2. The distance between the cutter heads gradually increases from the outside to the inside, so that the inner and outer layers of the micropores of the aerator membrane are relatively uniform. The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com