Centrifugal fan with flow and temperature adjusting function

A centrifugal fan and temperature adjustment technology, which is applied to the components, electromechanical devices, mechanical equipment, etc. of the pumping device for elastic fluid, which can solve the problems of huge cost, occupying site space, and limited frequency conversion range of variable frequency motors, and achieve high efficiency. High, low pressure loss, widening the effect of flow adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

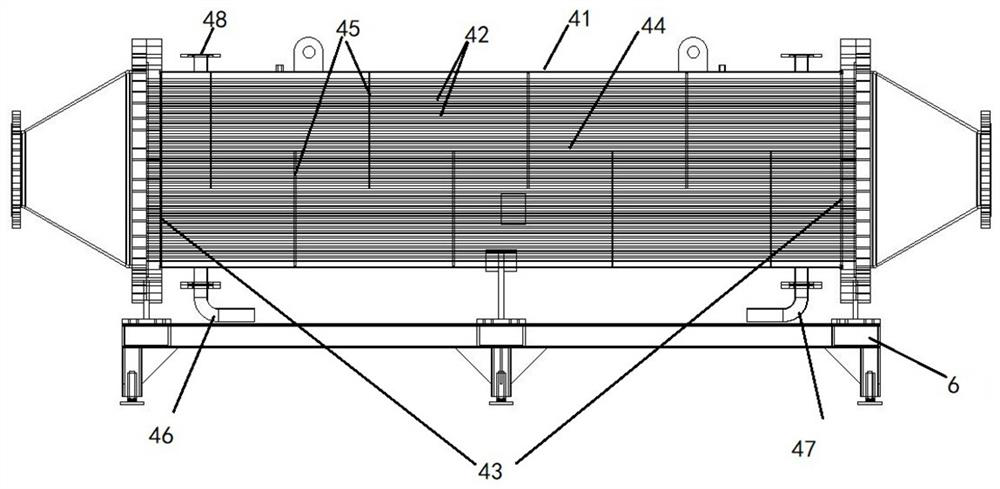

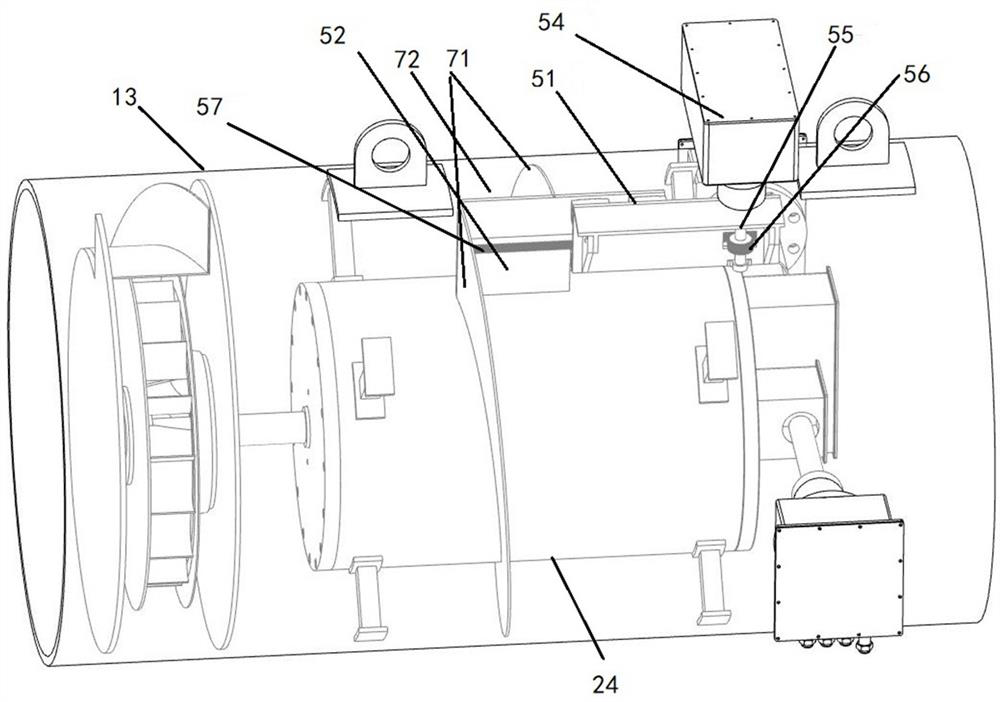

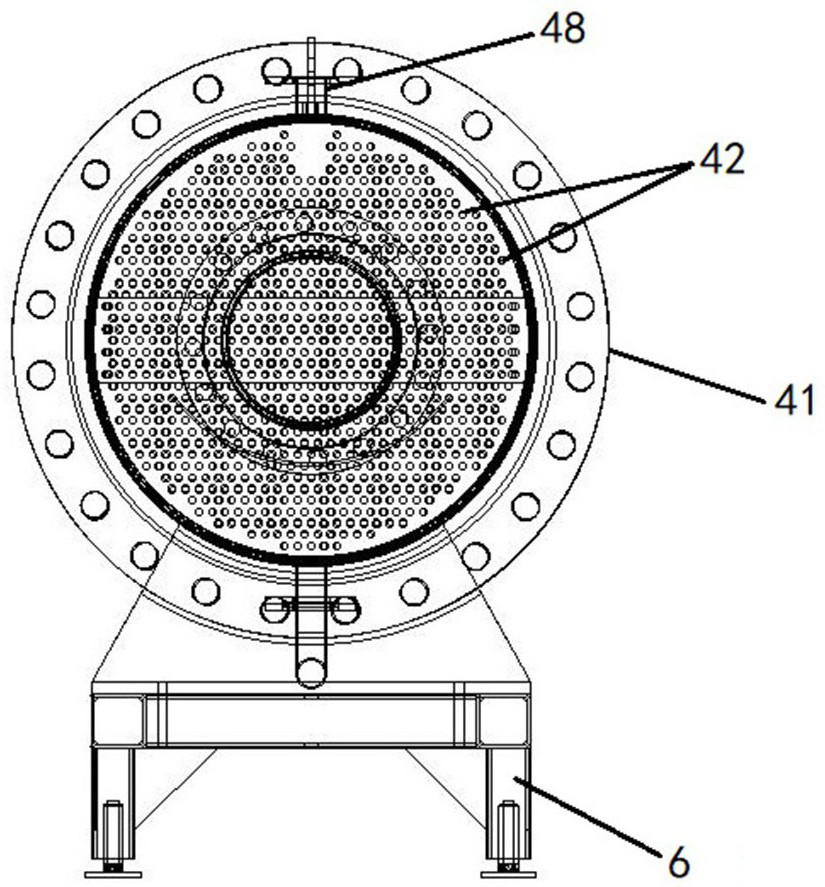

[0026] Example 1, such as Figure 1-5 As shown, a centrifugal fan with flow rate and temperature adjustment includes a centrifugal fan with a fan air inlet 11 and a fan outlet 12, including a volute 21 embedded in the fan housing 13, a centrifugal impeller 22, and a variable frequency motor 23, The centrifugal impeller 22 is placed inside the volute 21, the variable frequency motor 23 is placed in the motor housing 24, and the rotating shaft of the variable frequency motor 23 is coaxial with the centrifugal impeller 22 and connected to each other; the volute 21 includes a volute air inlet 211, a volute air outlet 212, the air inlet of the volute is connected with the air inlet 11 of the fan, the air outlet 212 of the volute is connected with the air outlet 12 of the fan, the air inlet end of the fan housing 13 is provided with an inlet end cover plate 31, and the air outlet end is provided with an outlet end cover plate 32, The temperature adjustment device 4 that adjusts the ...

Embodiment 2

[0041] Example 2, such as Figure 7 , the flow regulating device 5 is arranged on the same vertical plane as the variable frequency motor 23, the flow regulating device 5 includes an annular baffle 71 that seals the motor housing 24 and the fan housing 13, and the annular baffles 71 are arranged in a staggered position and set in the staggered position The flow opening 72 is provided with an adjustment base 51 on the side of the inner flow opening 72, and also includes an adjustment baffle 52 clamped on the adjustment base 51 and connected to the adjustment base 51 through a slide rail, and driving the adjustment baffle 52 sliding adjustment electronic control unit; the adjustment electronic control unit includes a motor 54 placed outside the fan housing 13, the motor 54 is used to drive the transmission shaft 55 that passes through the fan housing 13 and penetrates into the inside of the fan, and the transmission shaft The end of 55 is provided with gear 56, and the bar-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com