Patents

Literature

38results about How to "Large flow adjustment range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

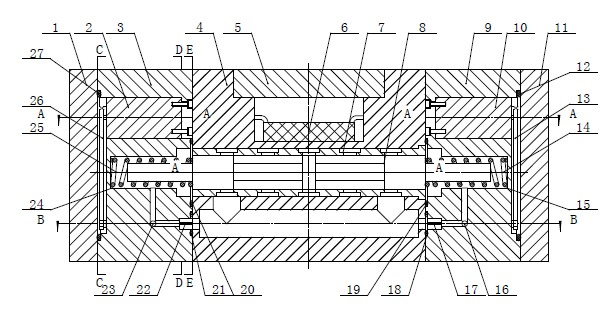

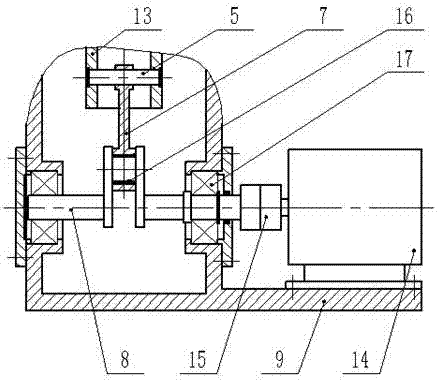

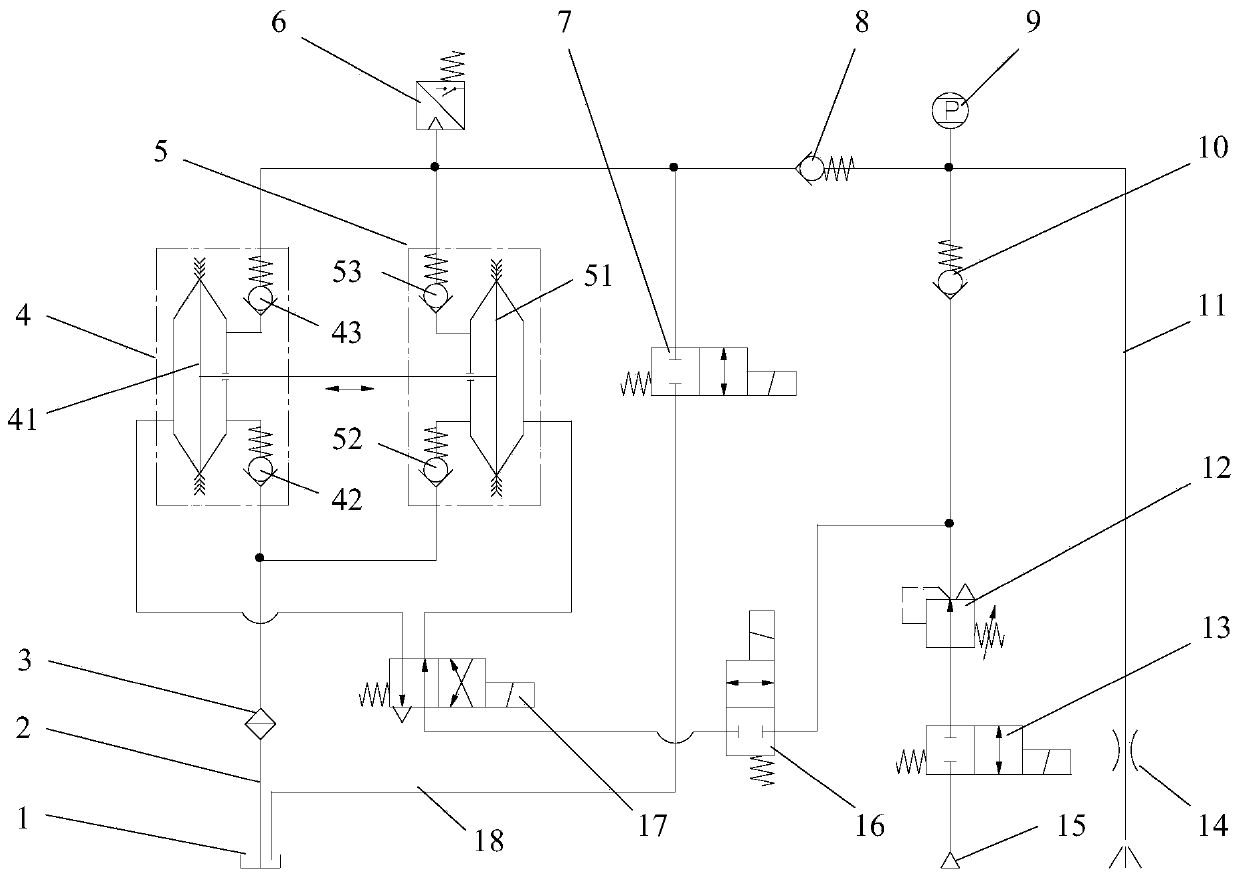

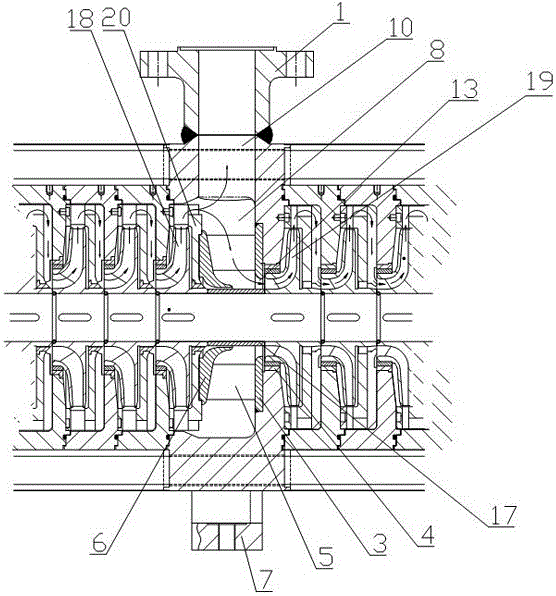

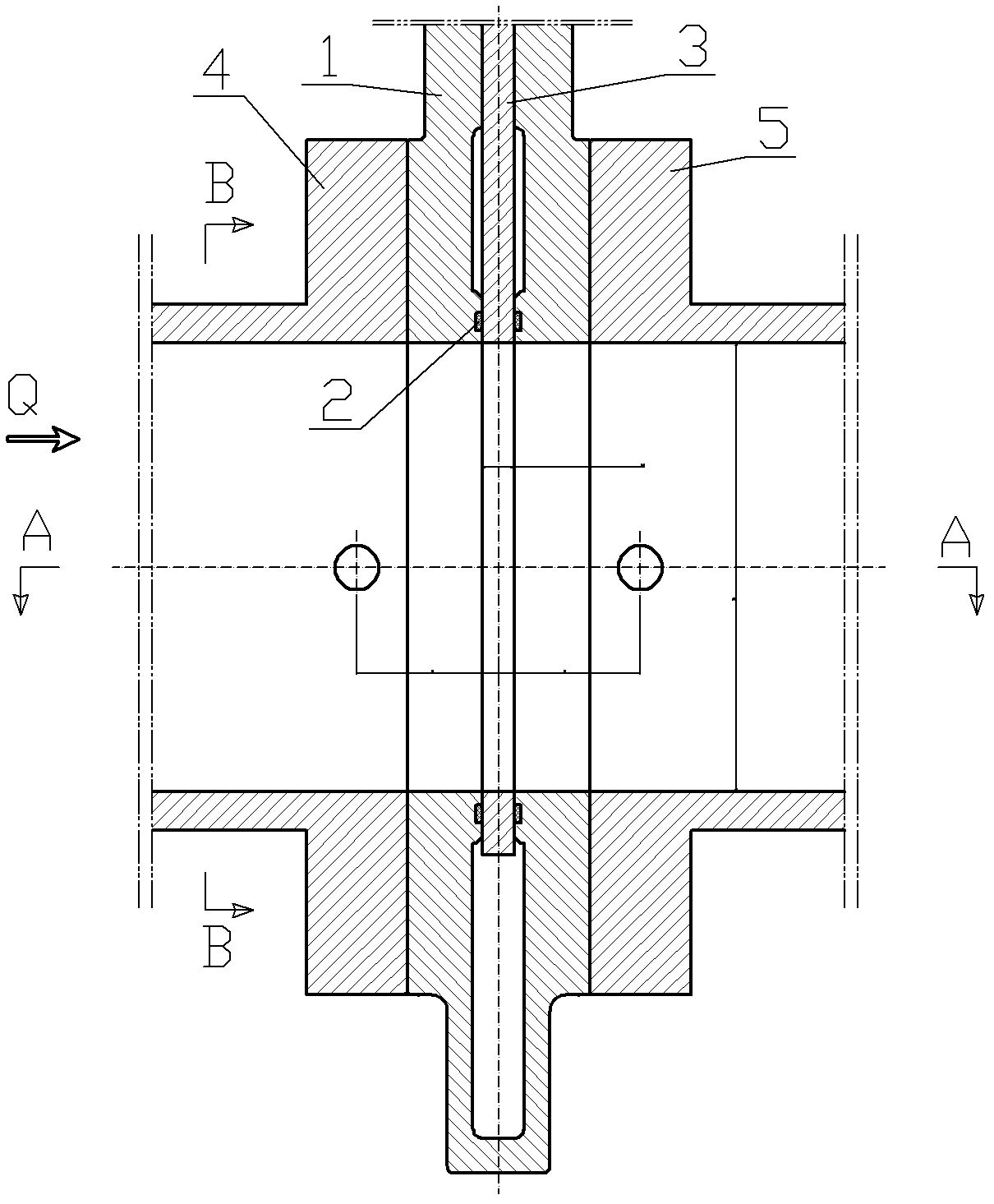

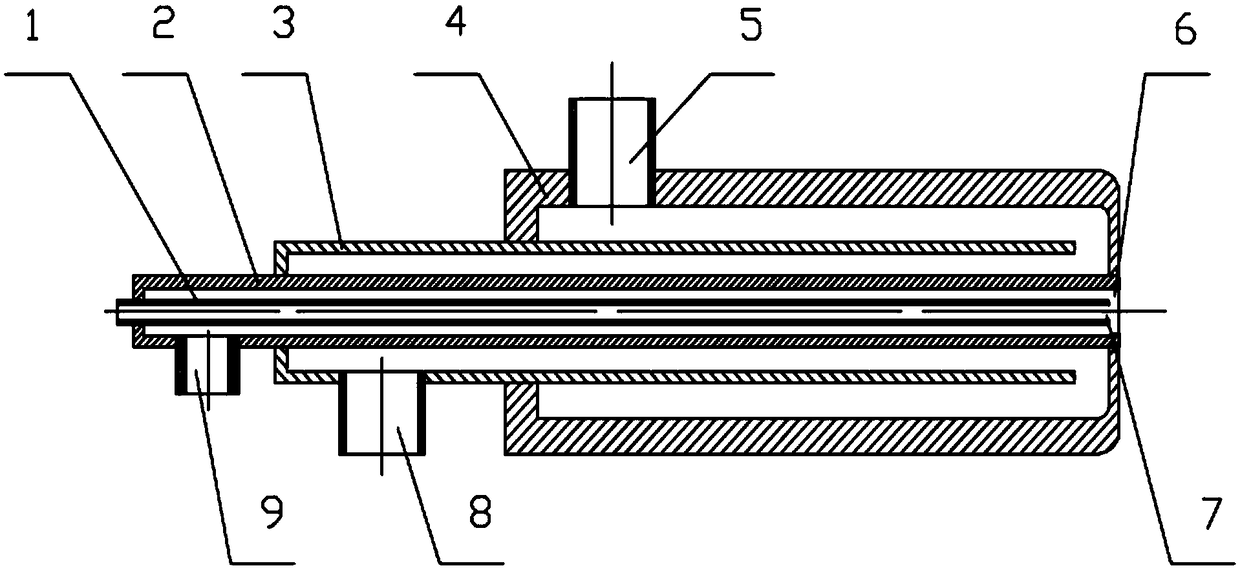

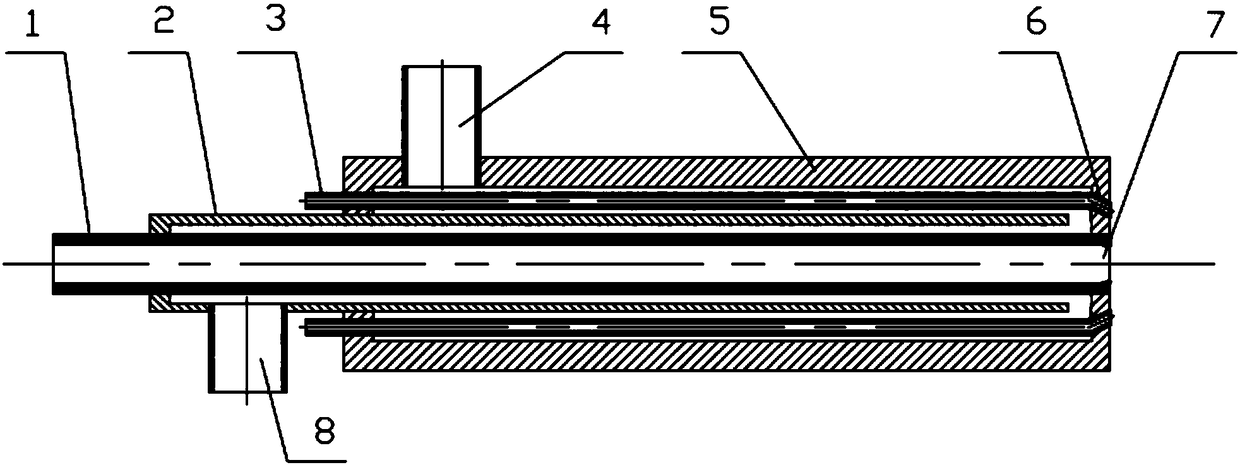

Pilot-operated type water hydraulic pressure digital proportional direction valve

InactiveCN102121487ANo pollution in the processSimple structureServomotor componentsCompliant mechanismEngineering

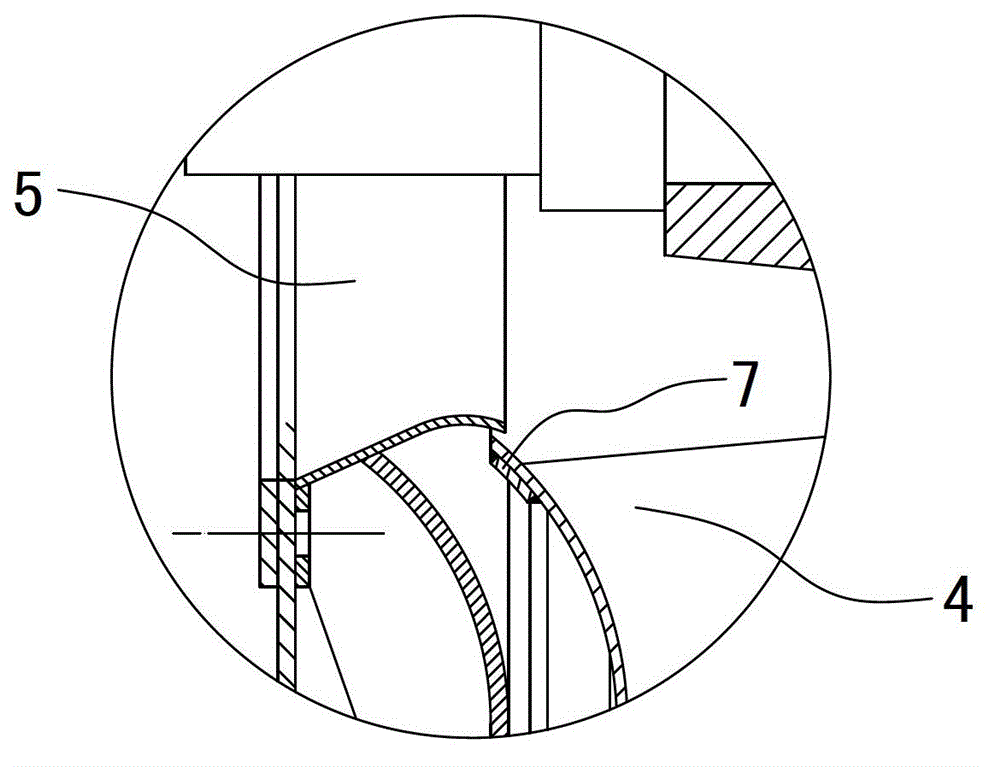

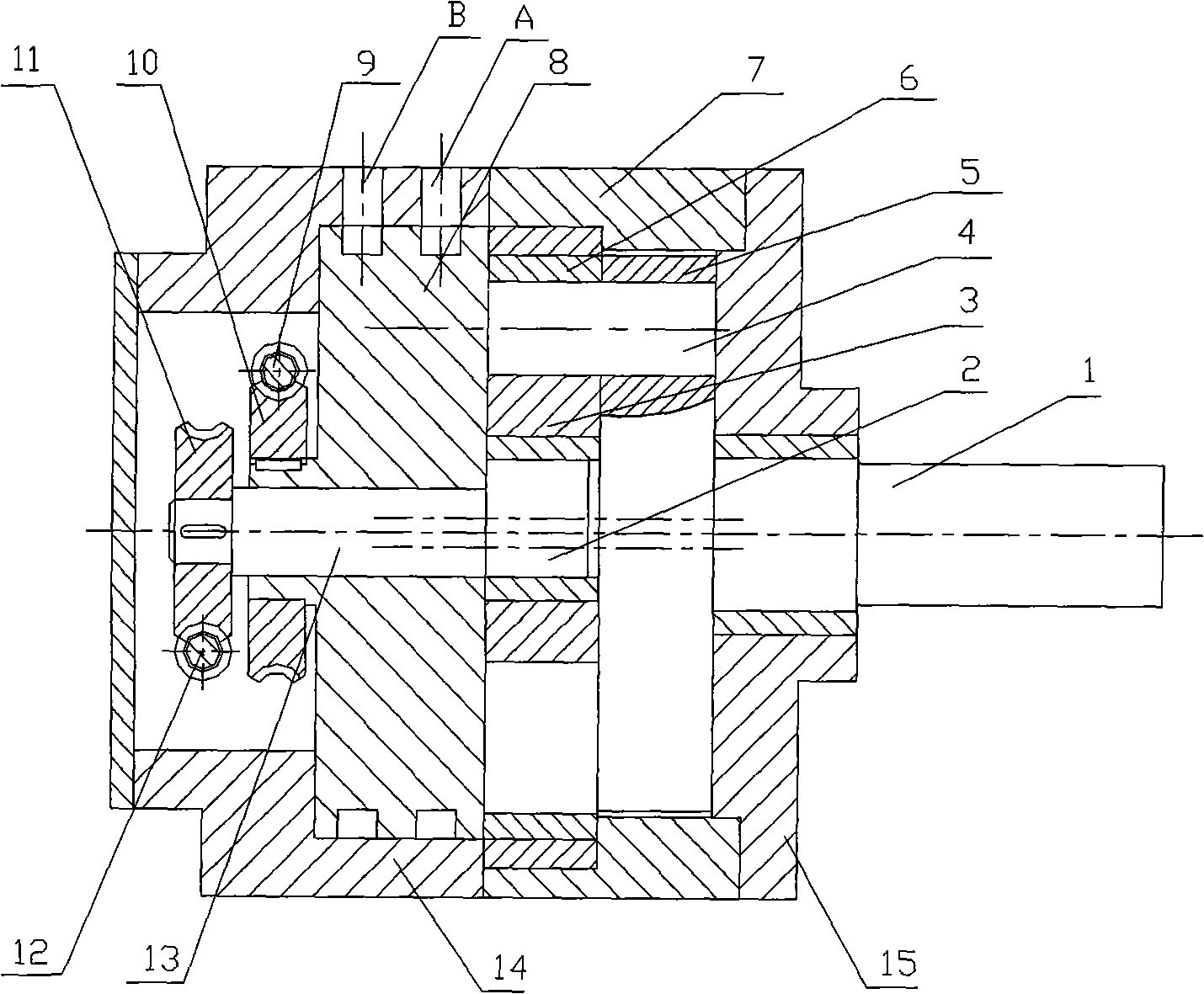

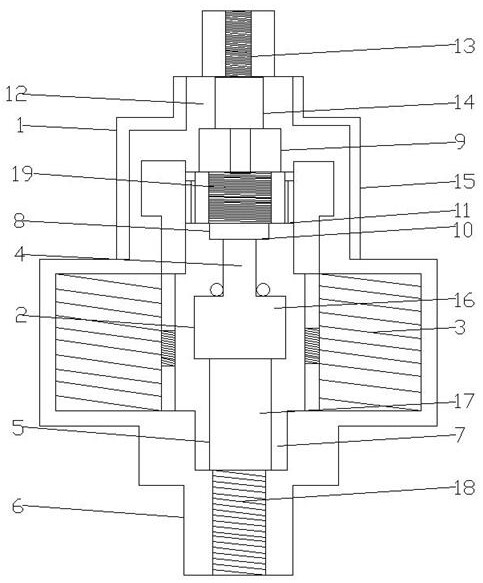

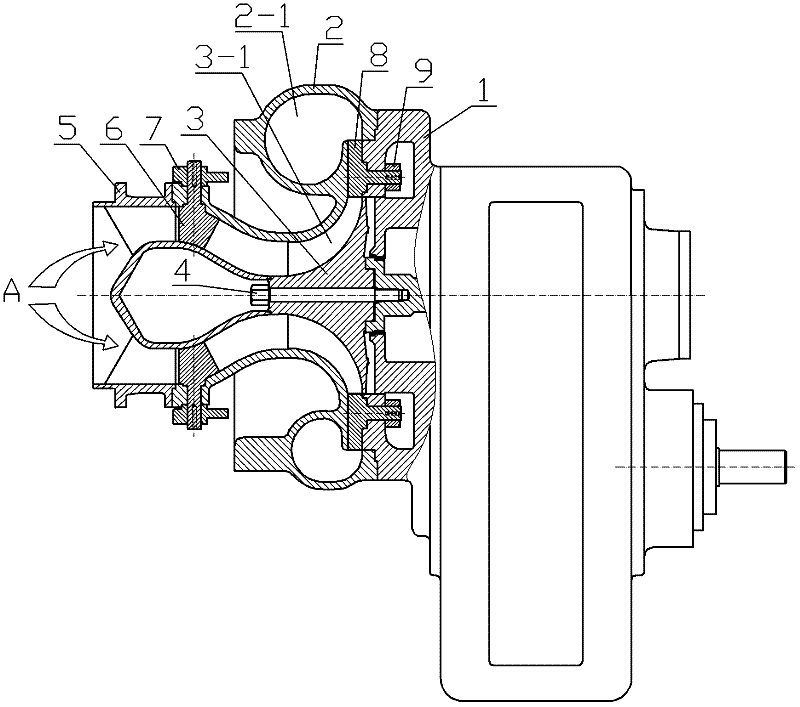

The invention discloses a pilot-operated type water hydraulic pressure digital proportional direction valve, which comprises a main valve and two pilot valves, wherein the pilot valves are positioned on the left side and the right side of the main valve respectively and are arranged on the main valve through an end face in a matching way; each pilot valve comprises a variable liquid resistor and a fixed liquid resistor which is connected in series with the variable liquid resistor; a control port communicated with the end face of a valve core of the main valve is positioned between the variable liquid resistor and the fixed liquid resistor; and the pressure of the control port can be changed by changing the resistance value of the variable liquid resistor so as to control the valve core of the main valve and control the direction and the flow rate of a liquid flow. In the invention, pulse code modulation (PCM) pilot control is adopted, so that the proportional direction valve can be simply and reliably controlled, and has high precision, high frequency and long service life; and the main valve has high flow rate. The pilot valves consist of a switching valve and a damping hole, have low leakage, high pollution resistance and high interference resistance and can be used in a marine environment containing a large number of solid impurities. The valve cores of the pilot valves are driven through piezoelectric ceramics, perform amplification displacement through a compliant mechanism and have simple driving mechanism structures, quick response and long service life.

Owner:HUAZHONG UNIV OF SCI & TECH

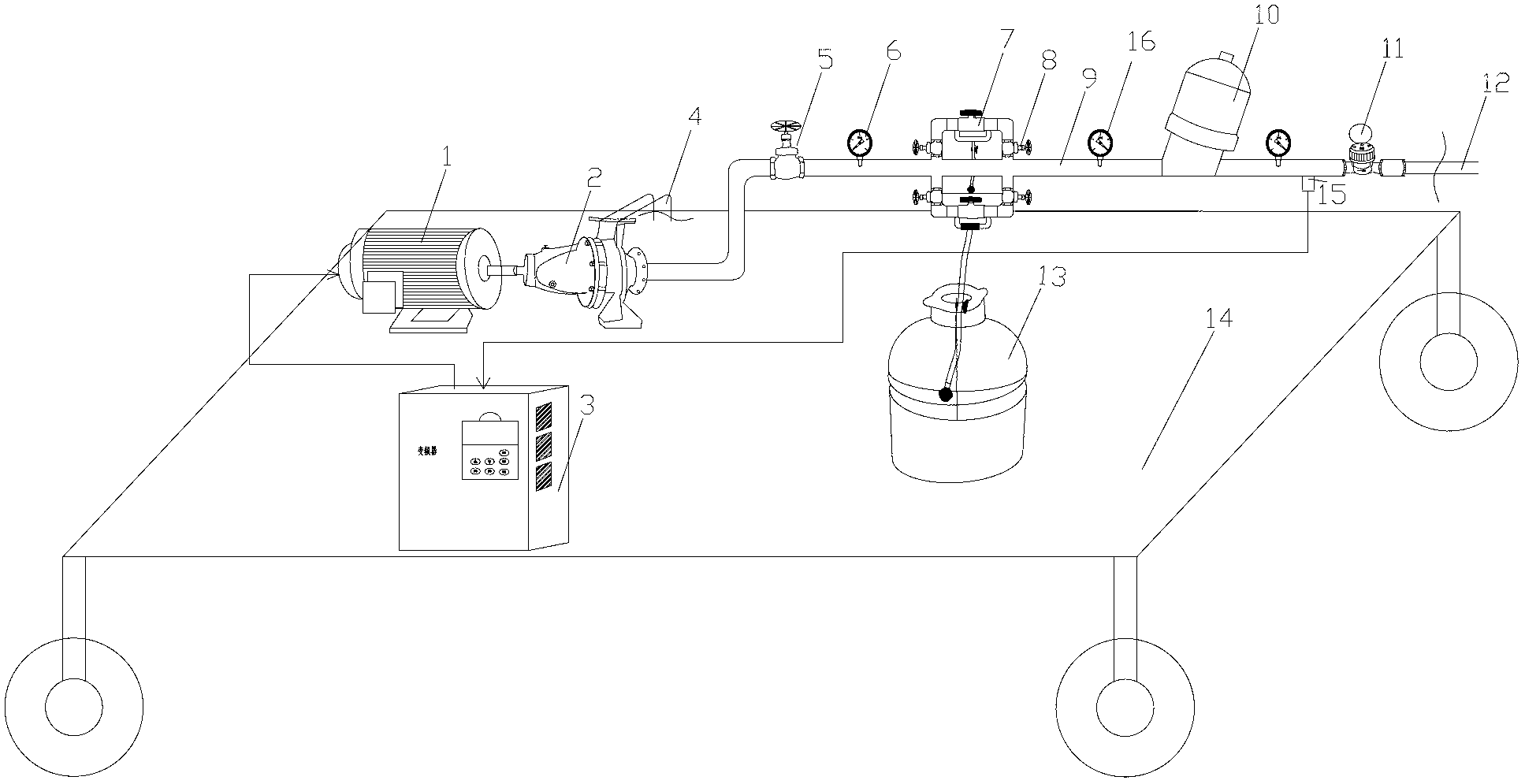

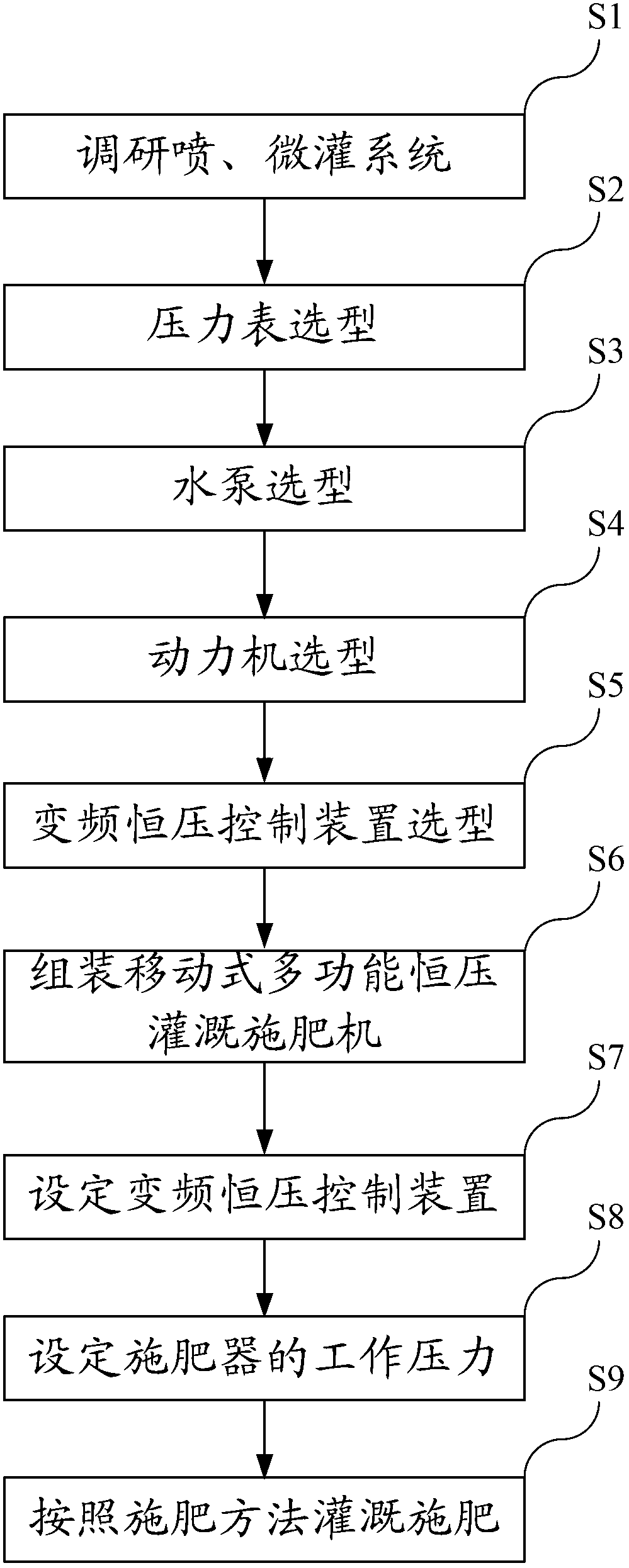

Mobile multifunctional constant-pressure irrigation fertilizer distributor and irrigation and fertilizer distribution method thereof

InactiveCN103053385ARealize the purpose of energy savingIncrease pressureWatering devicesPressurised distribution of liquid fertiliserDistribution methodNutrient solution

The invention belongs to the field of field irrigation and fertilizer distribution and discloses a mobile multifunctional constant-pressure irrigation fertilizer distributor and an irrigation and fertilizer distribution method thereof. The irrigation fertilizer distributor comprises a main pipeline, a water pump and a fertilizer applicator. The main pipeline is used for conveying water-fertilizer fixed liquid. The water pump is used for extracting irrigation water of the main pipeline and adjusting water inflow of the irrigation water. The water pump is controlled by a variable frequency constant-pressure control device to pressurize the irrigation water. The fertilizer applicator is used for conveying fertilizer and nutrient solution to the main pipeline. The variable frequency constant-pressure control device is connected with the main pipeline through a pressure sensor and used for receiving pressure signals acquired by the pressure sensor and controlling rotation speed of the water pump. By the irrigation fertilizer distributor and the irrigation and fertilizer distribution method thereof , irrigation pressure and flow can be controlled simultaneously, stable system fertilizer distribution concentration can be guaranteed while blocking and corrosion of the irrigation system can be prevented, the requirements for even and high-quality irrigation and fertilizer distribution can be satisfied, and energy conservation can be achieved.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

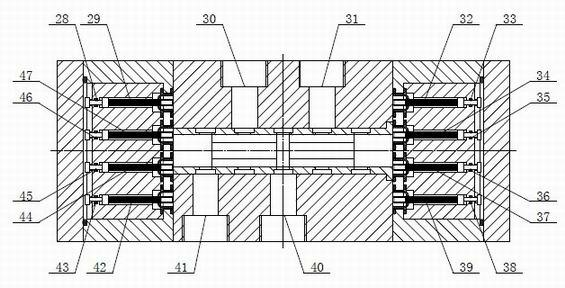

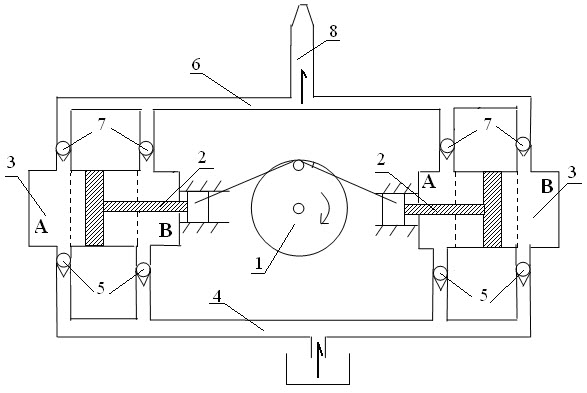

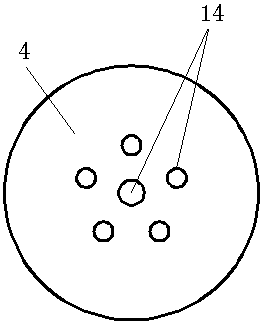

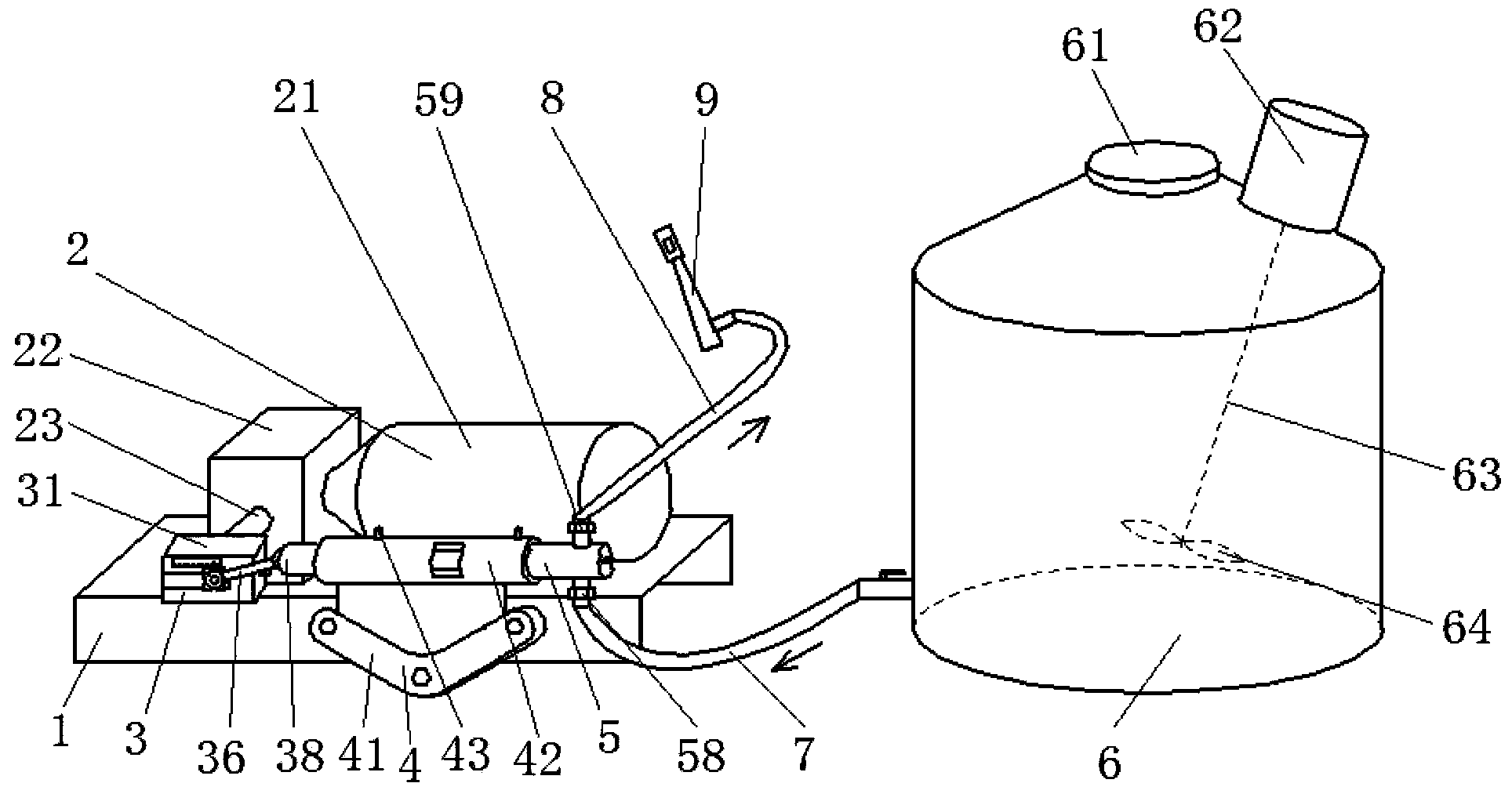

Double-action plunger-type deicing liquid pump

InactiveCN101975150AViscosity effectMaintain propertiesPiston pumpsPositive-displacement liquid enginesMarine engineeringCrank

The invention discloses a double-action plunger-type deicing liquid pump for airplane deicing liquid operation. Two plunger pump cylinders in the same structure are connected into an integral body by a crank connecting link through a piston, the plunger pump cylinders are divided into two regions, and each region is provided with a non-return valve; one power source is used for driving the two plunger pumps to work simultaneously; a liquid feed channel is connected with a liquid feed non-return valve on each plunger pump cylinder; a liquid discharge channel is connected with a liquid discharge non-return valve on each plunger pump cylinder, and the outlet of the liquid discharge channel is provided with an injection gun; and the plunger pump cylinders, liquid feed channels and liquid discharge channels are made of stainless steel. Compared with single-action pumps with the same flow rate, the double integrated pumps can raise the pressure of the injected fluid and increase the injection distance. Compared with centrifugal pumps, the frictional heat of the invention generated in the working process is very low so as not to influence the viscosity of the deicing liquid, and the invention can well maintain the characteristics of the deicing liquid. The invention is mainly used as a special pump for airplane deicing liquid for deicing and anti-icing operations.

Owner:CIVIL AVIATION UNIV OF CHINA

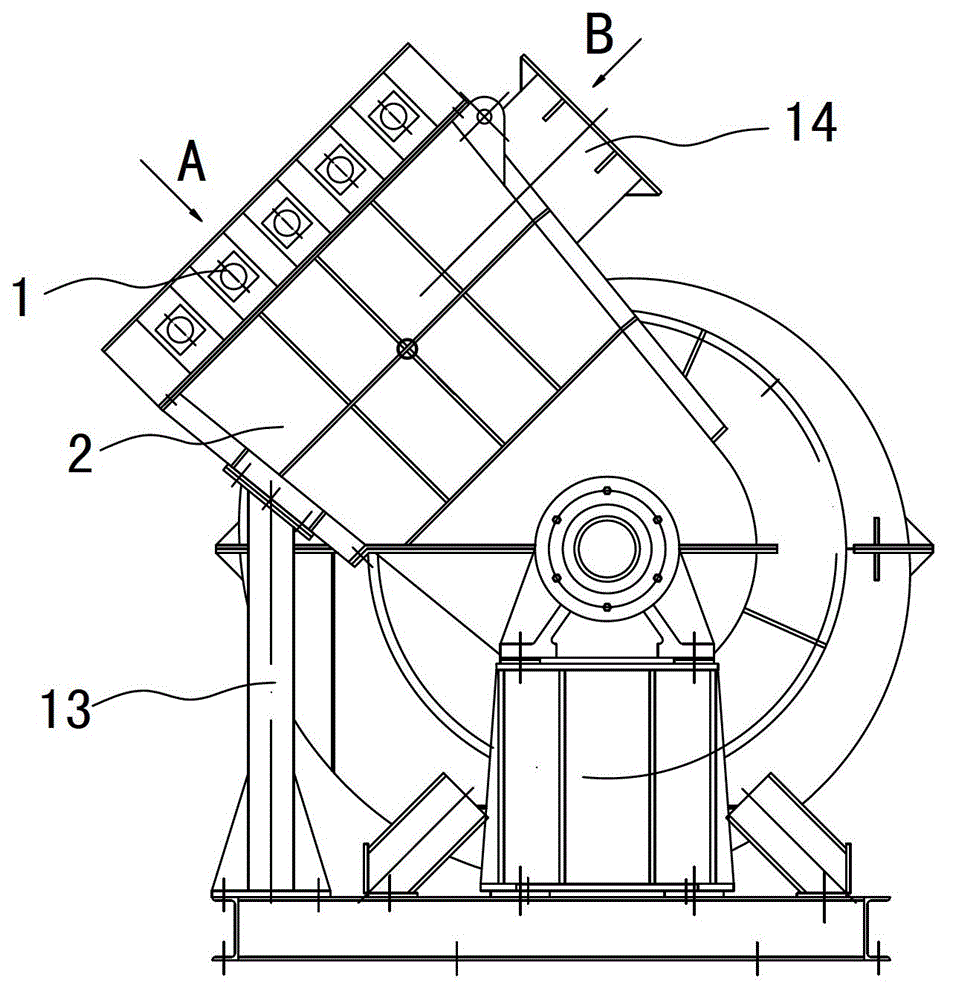

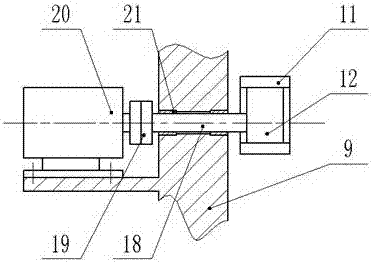

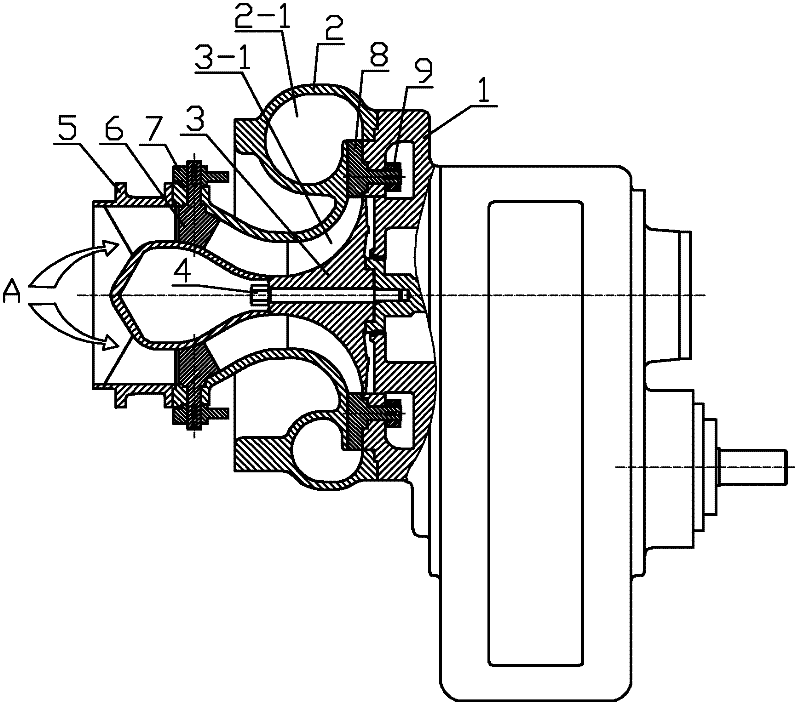

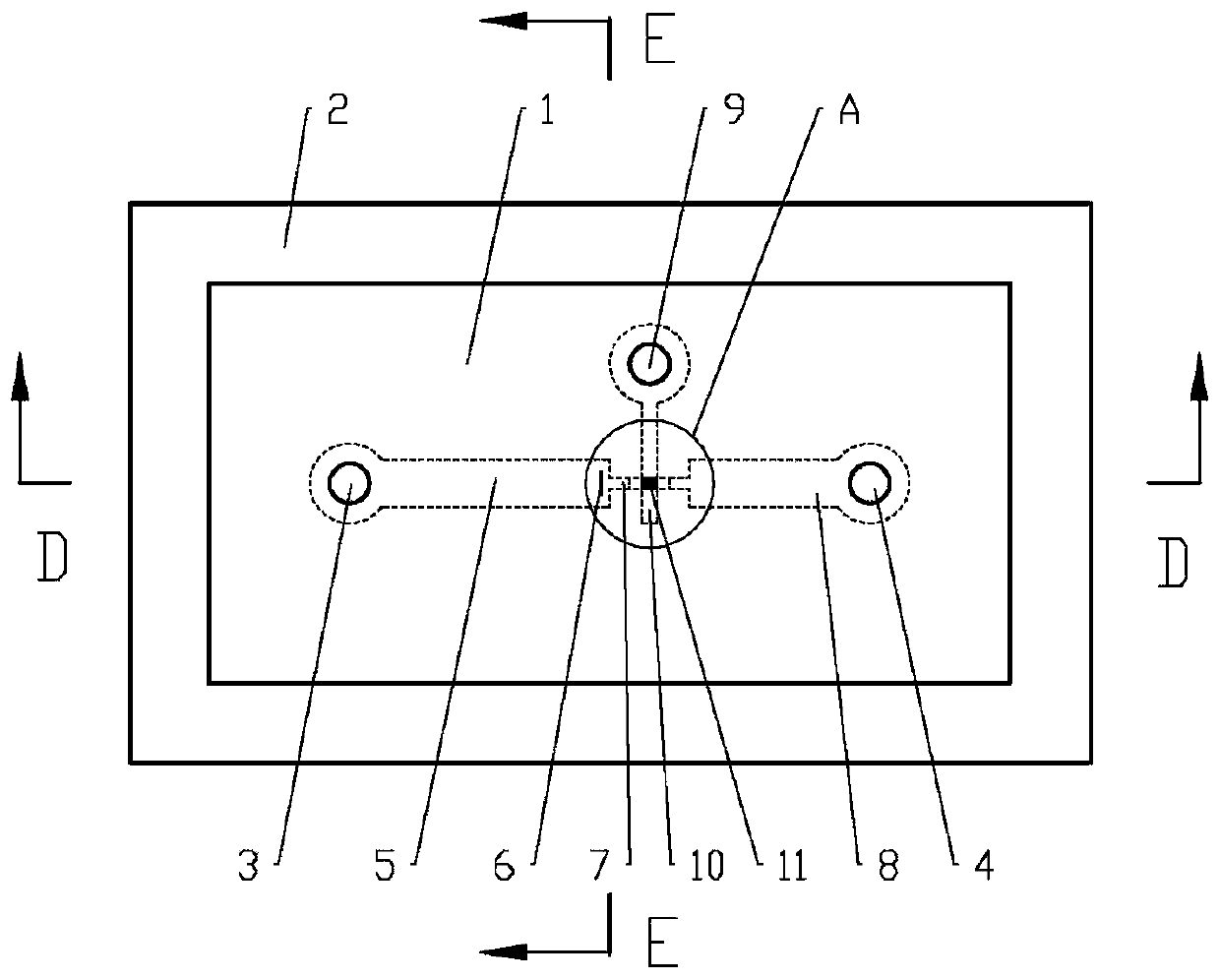

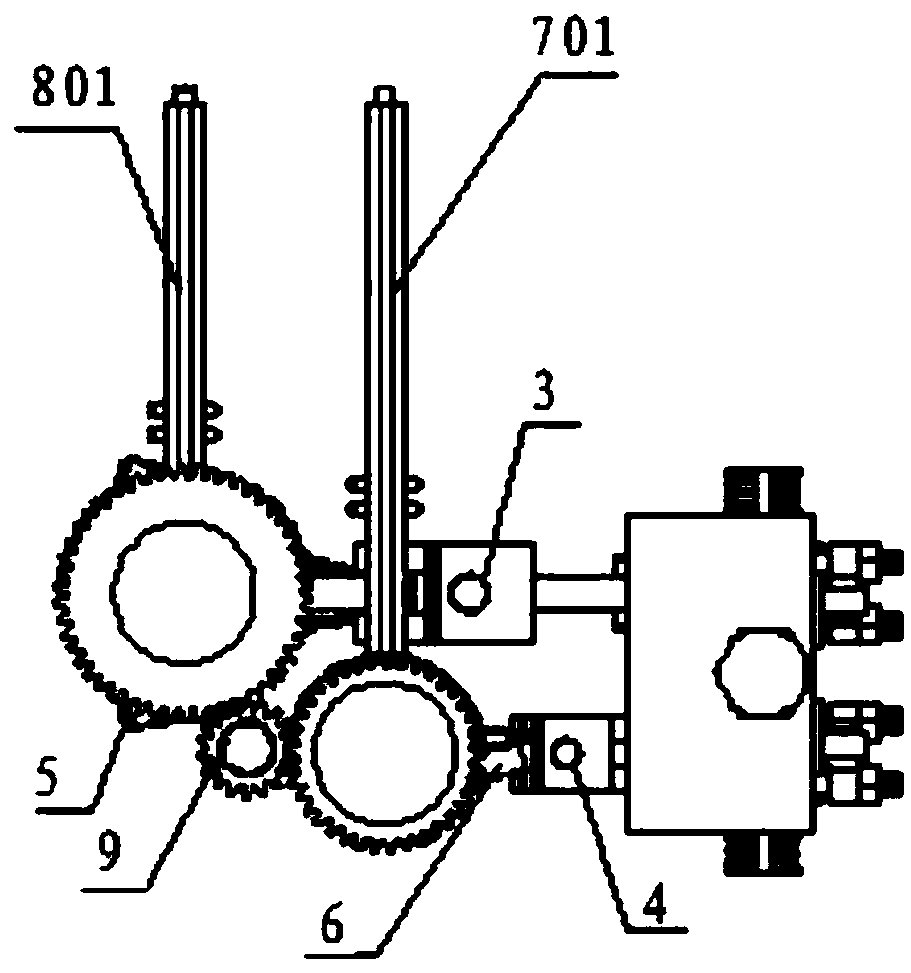

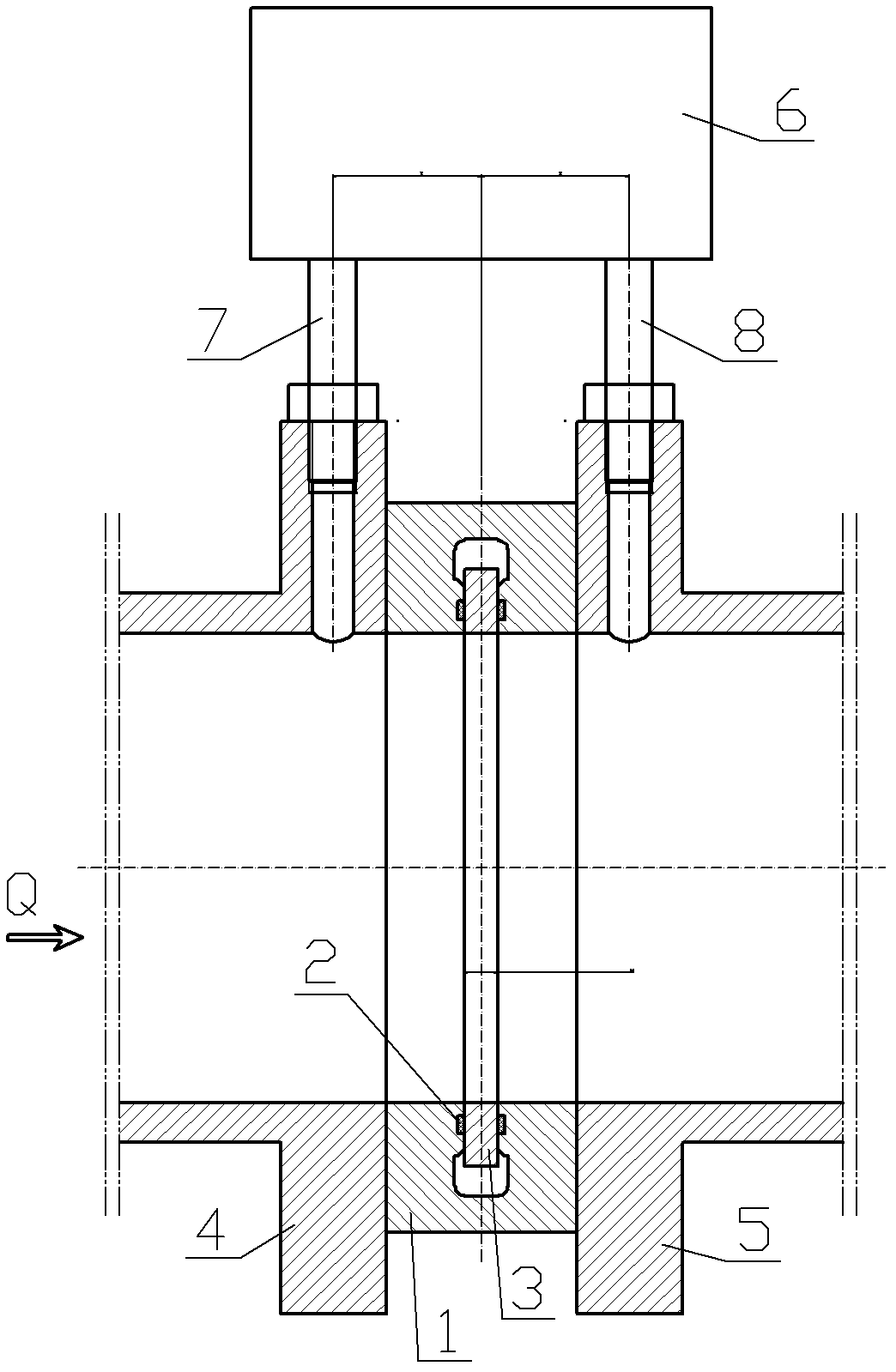

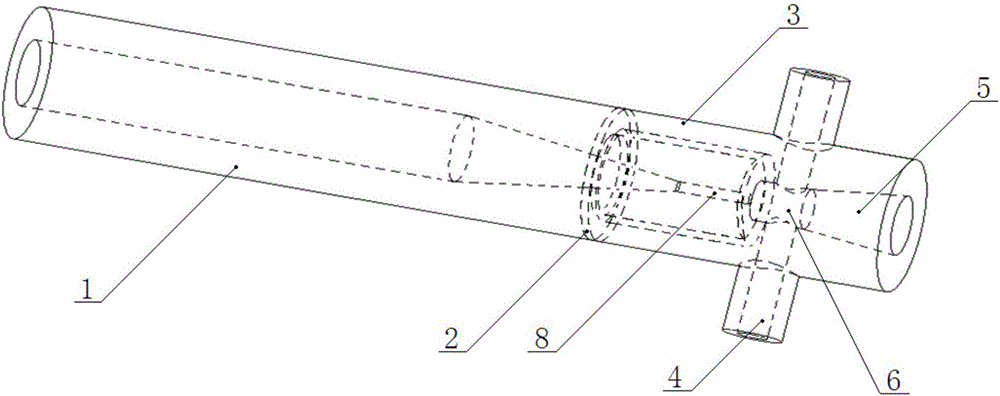

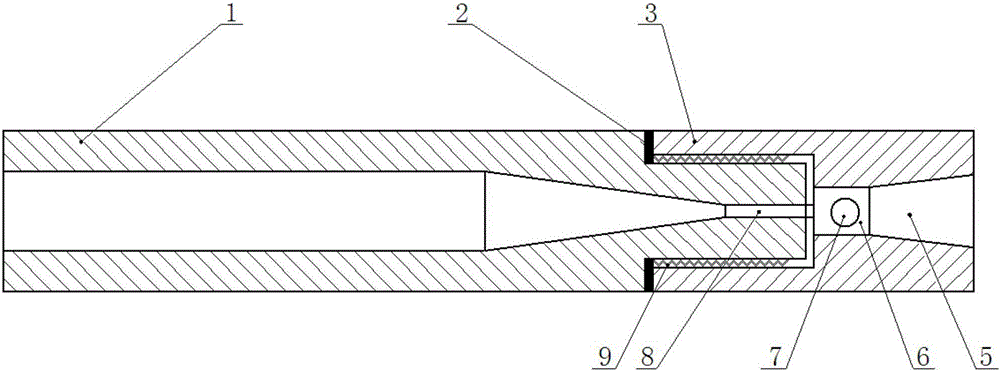

Solid rocket ramjet engine gas flow adjusting device

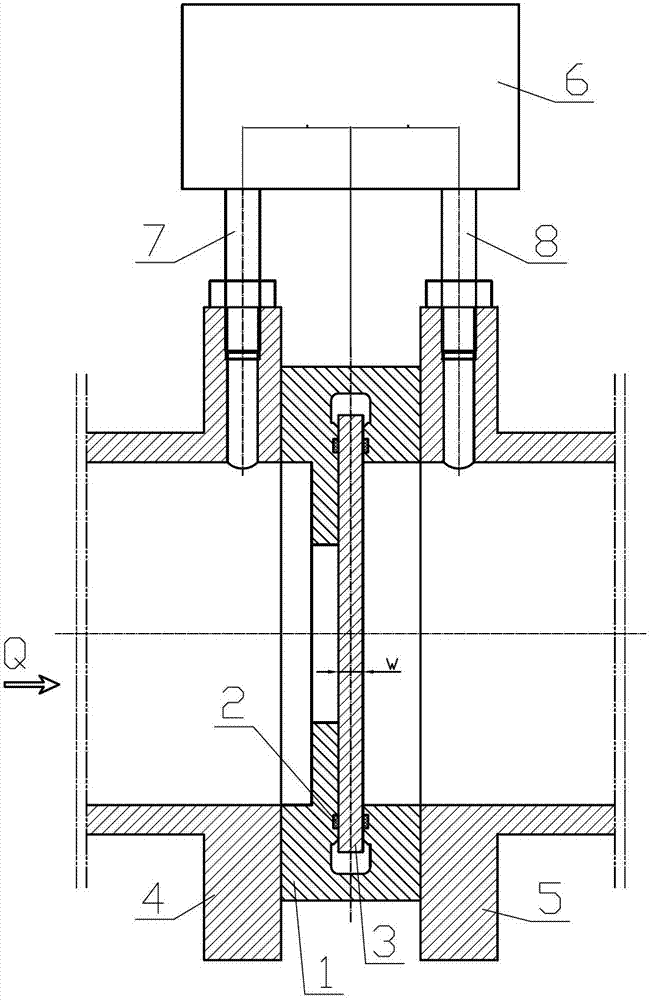

PendingCN107795409ALarge flow adjustment rangeChange trafficRocket engine plantsRam jet enginesRamjetElastomer

The invention discloses a solid rocket ramjet engine gas flow adjusting device. The solid rocket ramjet engine gas flow adjusting device comprises a master controller, a projectile body, a gas generator and a spraying pipe; the spraying pipe comprises a sealing plate and a hollow pipe, an unthreaded hole is formed in the wall of the pipe in the direction vertical to the pipe axis direction, a plunger sliding valve is installed in the unthreaded hole in a sealed manner, and a driving device is arranged on the plunger sliding valve; N through air inlet holes are formed in the sealing plate, theair inlet holes are distributed within the pipe diameter scope, plugging covers capable of sealing and plugging the air inlet holes are arranged in N-1 air inlet holes, and detonation devices capableof detonating the plugging covers are arranged on the plugging covers; and a pressure sensor is installed in a cavity between the pipe outer wall and the projectile body and is electrically connectedwith the master controller, and the master controller is electrically connected with the driving device; and the pressure sensor is electrically connected with the detonation devices. By means of thesolid rocket ramjet engine gas flow adjusting device, a larger flow adjusting scope can be achieved under the non-jamming state and the jamming state of a solid rocket ramjet engine, and the beneficial effects of being low in price, accurate and reliable in work and the like are achieved.

Owner:湖南宏大日晟航天动力技术有限公司

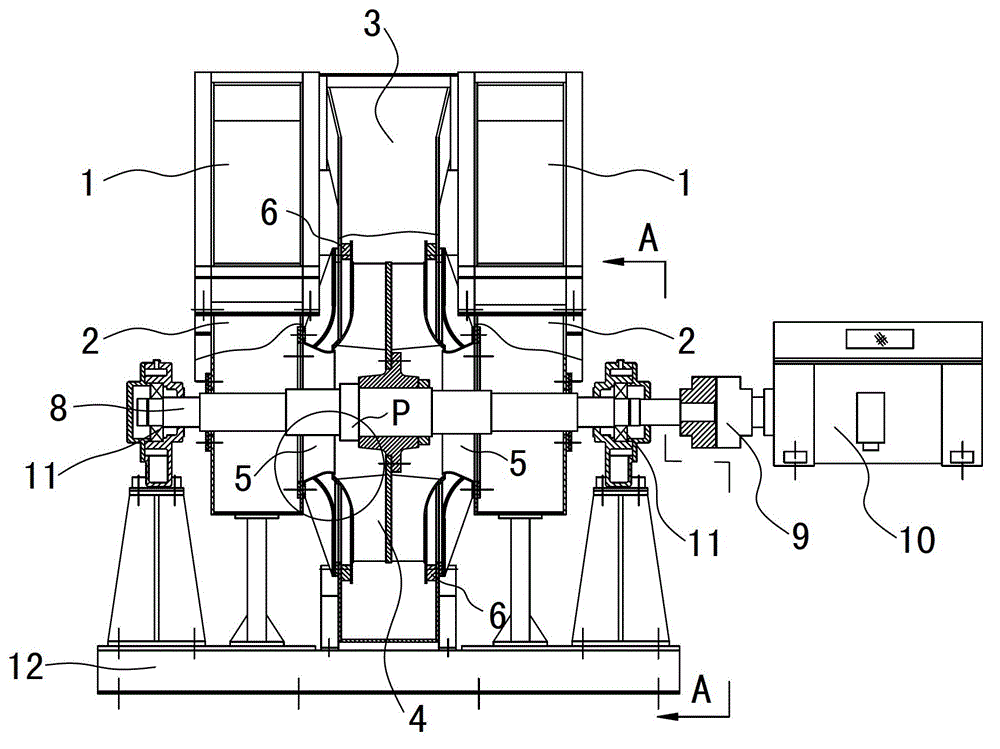

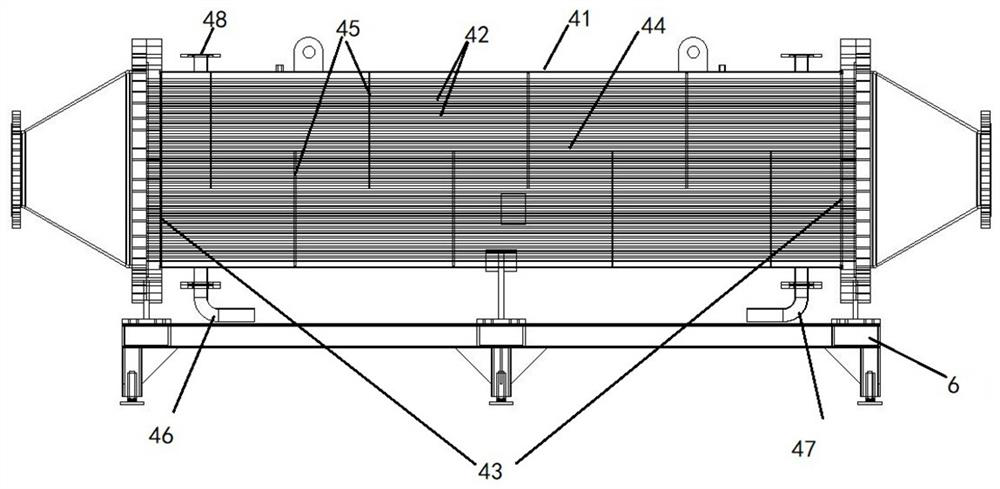

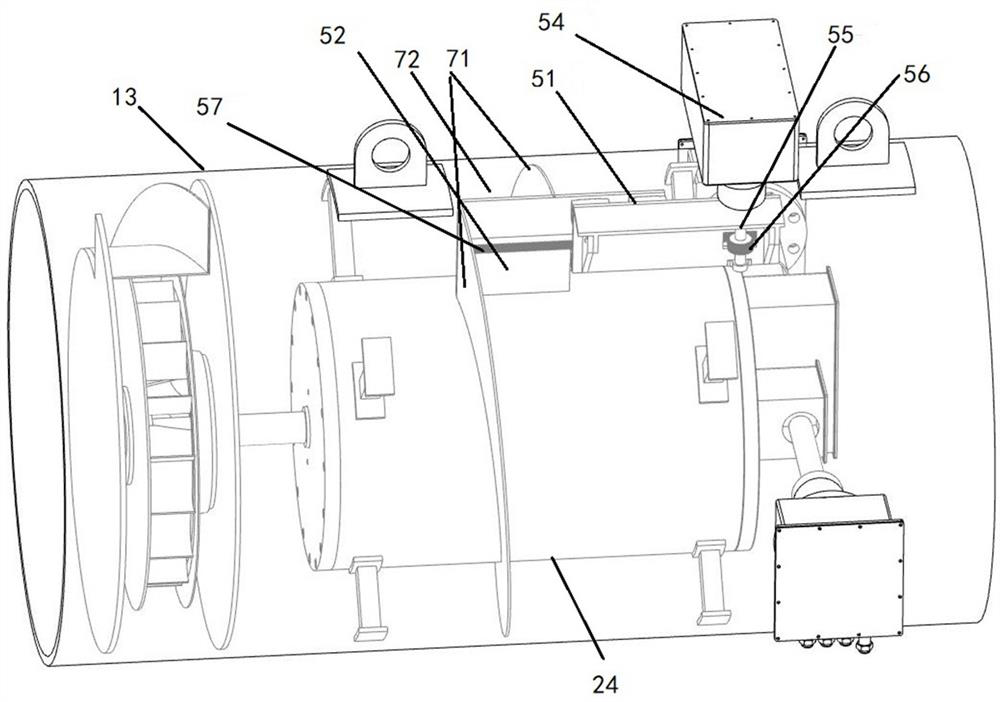

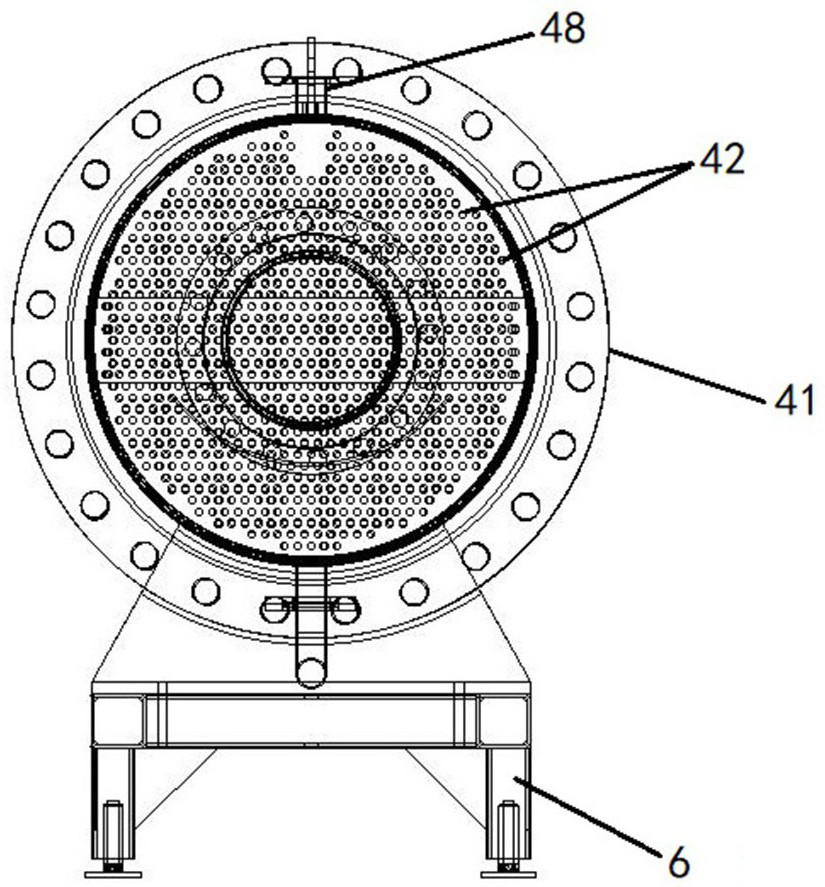

Double intake high-pressure large flow rate cement kiln centrifugal fan

InactiveCN103148019AReduce thicknessReduce overall outer diameterPump componentsPumpsImpellerAgricultural engineering

The invention discloses a centrifugal fan, particularly discloses a double intake high-pressure large flow rate cement kiln centrifugal fan, which comprises a centrifugal fan casing and a blade group in the centrifugal fan casing, the blade group is positioned in the centrifugal fan casing via a main shaft in a rotating manner; two air intake groups are connected to the centrifugal fan casing in a back-to-back manner; the two air intake groups take the same central axis with the main shaft, and are communicated with the interior of the centrifugal fan casing; the blade group is formed by a blade disc fixedly arranged on the main shaft and two groups of blades respectively fixed on the two side surfaces of the blade disc, the centers of the two groups of blades correspond to the two air inlet groups, reinforcing rings are arranged at the two front disc inlets of the blade groups, pressure expansion guide rings are respectively arranged on the two inner walls of the centrifugal fan in positions close to the blade air outlet end part, and the pressure expansion guide rings do not collide with the impeller. The centrifugal fan is flat in performance curve, large in flow capacity regulation range and high in efficiency.

Owner:贵阳远大风机制造有限公司

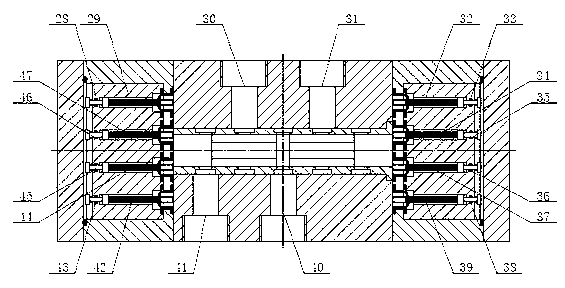

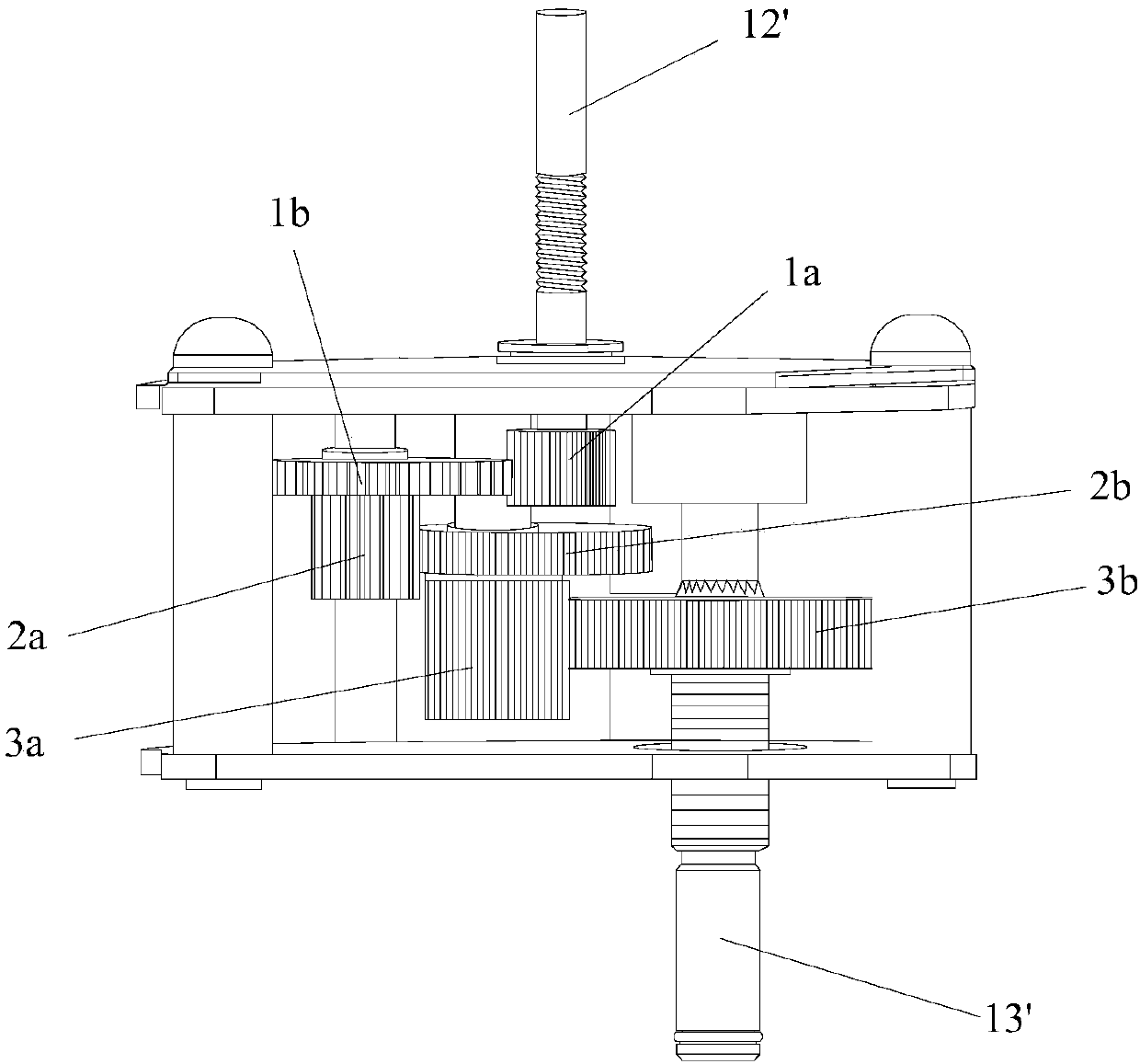

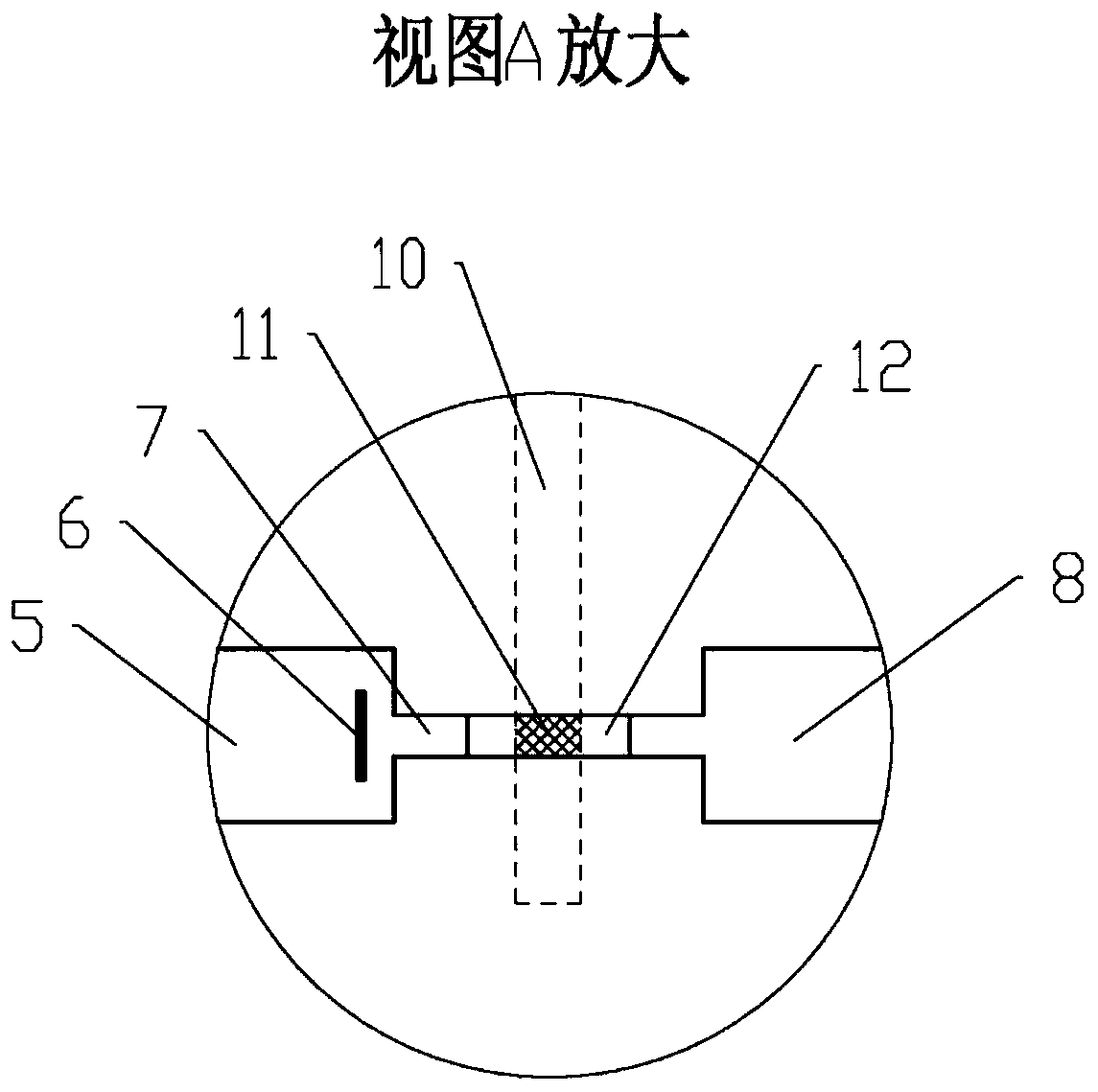

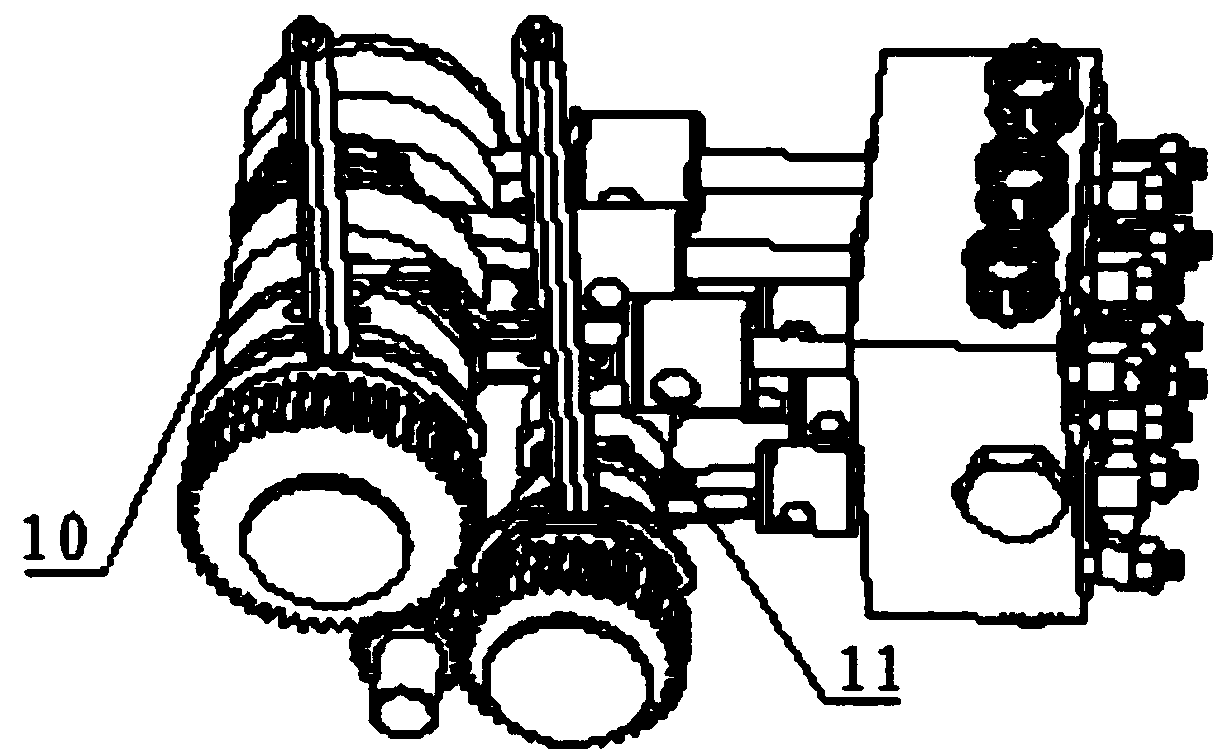

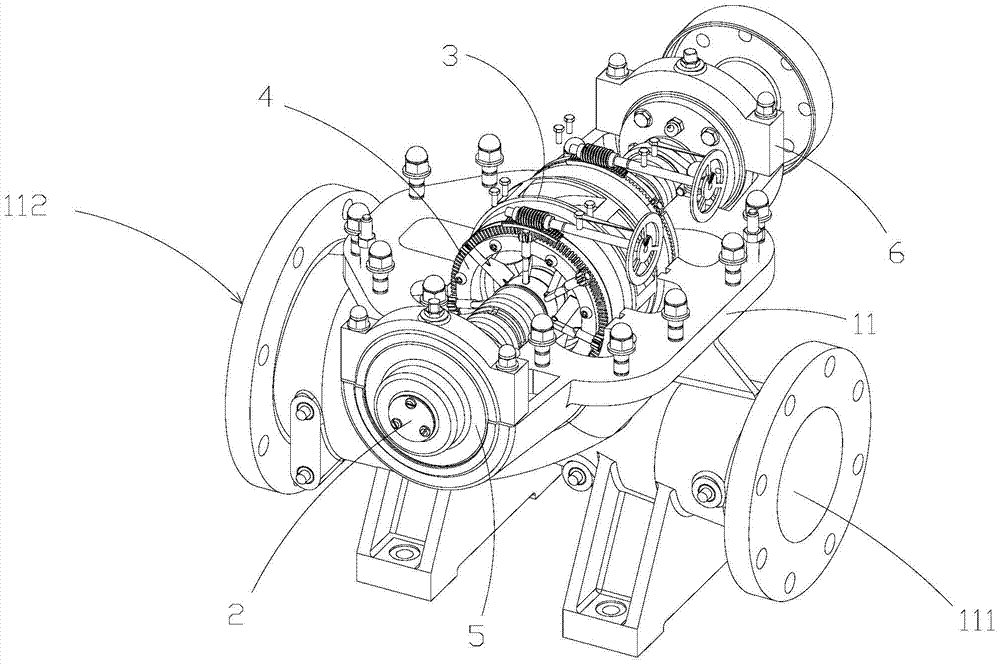

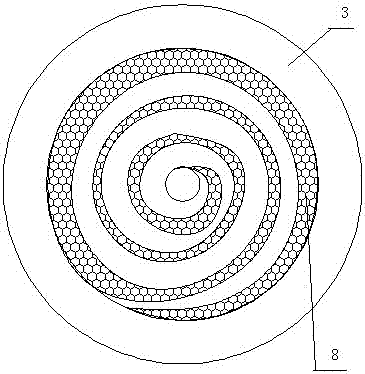

Double-cycloid rotor variable pump

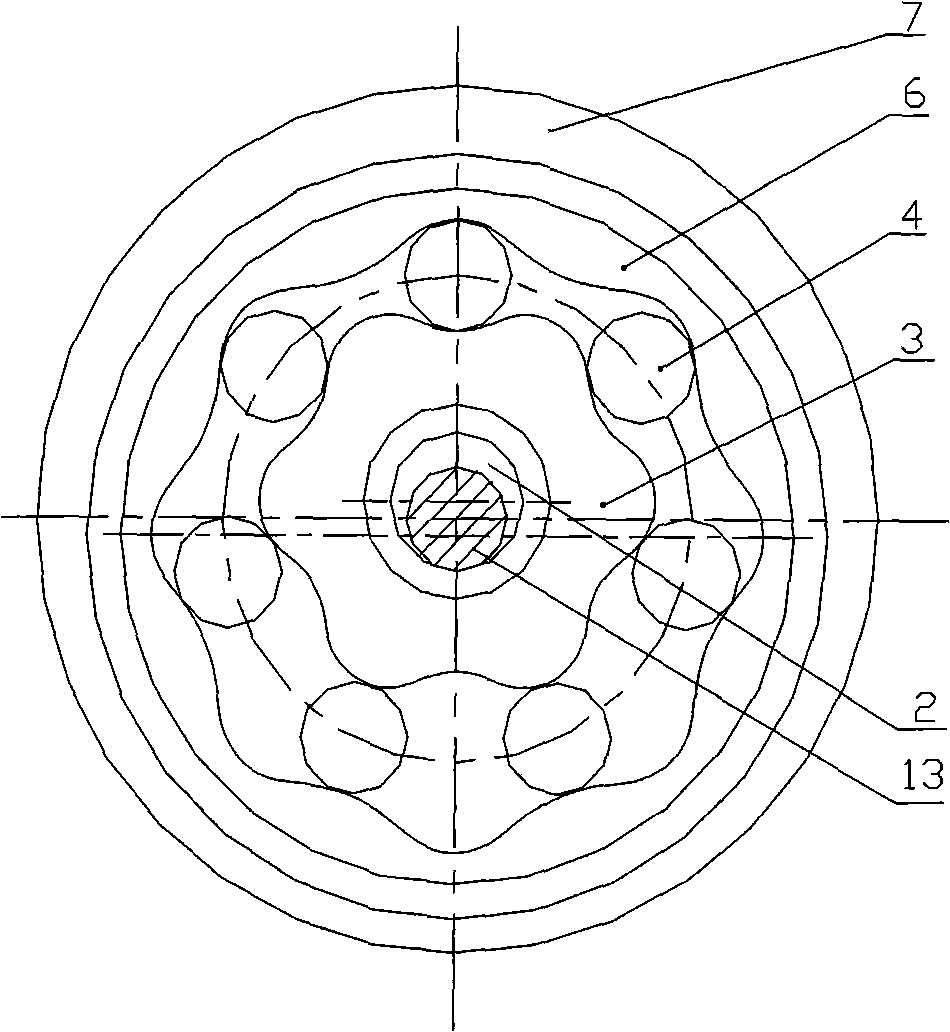

InactiveCN101560973AEasy to adjustSimple structureRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention relates to a rotor pump structure which can change flow rate, in particular to a double-cycloid rotor variable pump; a rear end cover (14) is internally provided with a valve plate (8) which is provided with an oil inlet (A) and an oil outlet (B); a variable shaft (13) is inserted into the center of the valve plate (8); a variable mechanism is configured on the variable shaft (13); the right end of the variable shaft (13) is fixedly connected with an eccentric shaft (2) with the mutual axis position being deviated; a transmission shaft (1) is inserted into the center of a front end cover (15) and is fixedly connected with a rotating disc (5); a ring of cylindrical pin teeth (4) are arranged on the rotating disc (5) by a cantilever; the pin teeth exposed outside of the cantilever are inserted in a ring groove formed by matching of an outer rotor (6) and an inner rotor (3); and the axis of the front end cover (15) and the center of the circular inner wall of a shell (7) have eccentricity. The flow rate can be changed by rotating the eccentric shaft (2); the adjustment of the flow rate is simple, convenient and easy; and the continuity of absorbing and discharging oil is strong and the requirement to hydraulic oil is not high.

Owner:SHANGHAI NORMAL UNIVERSITY

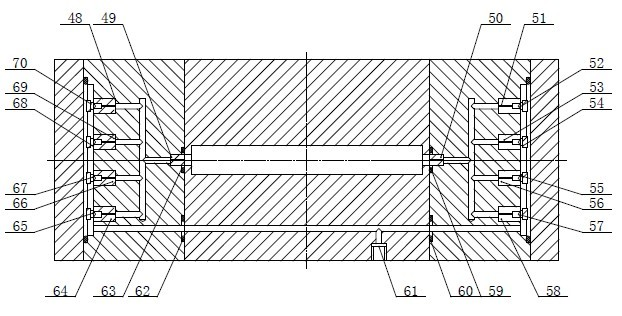

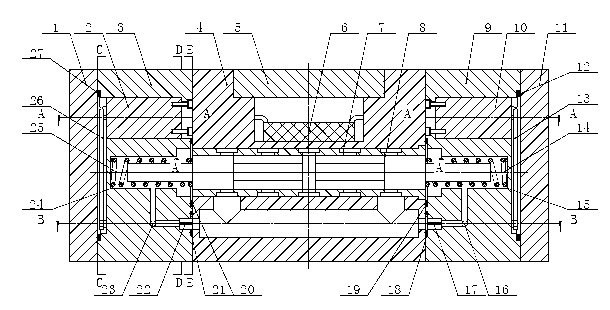

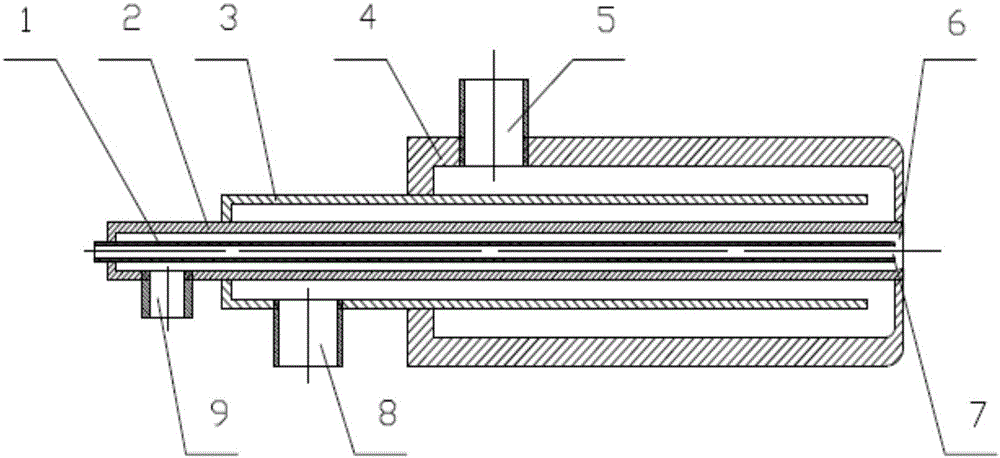

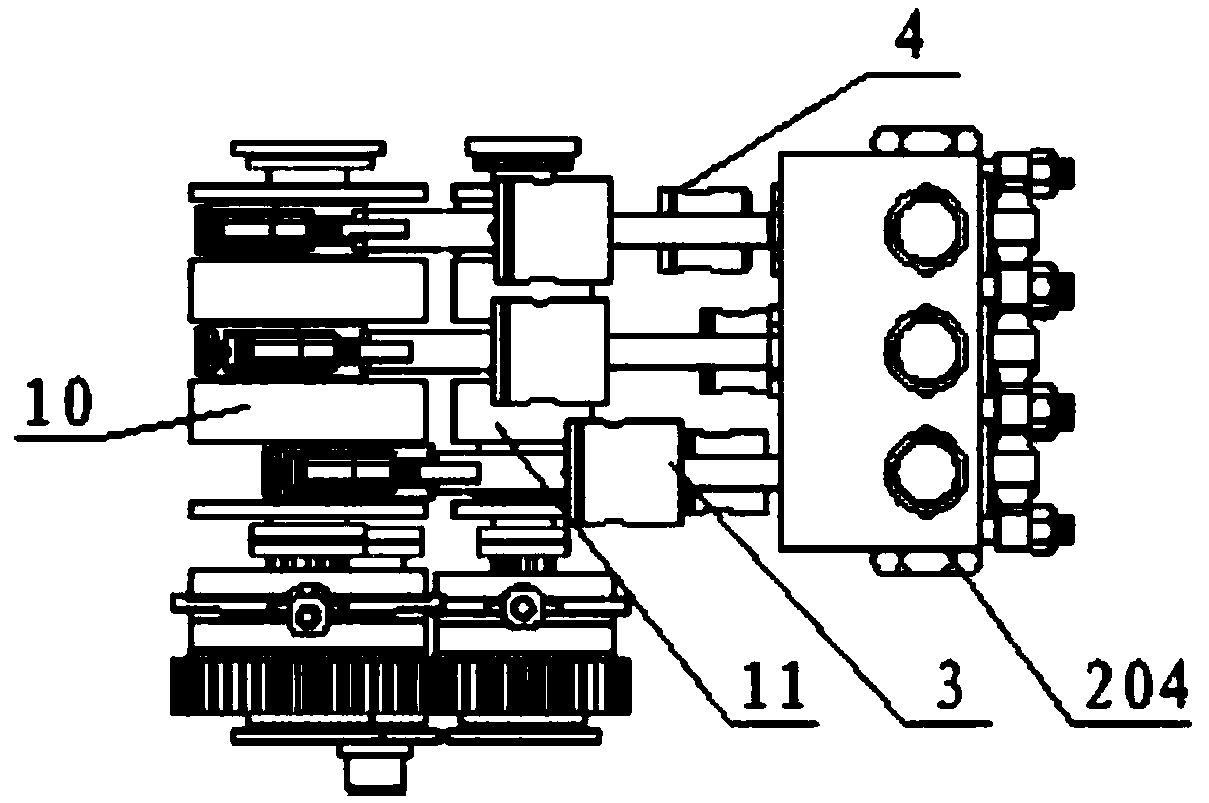

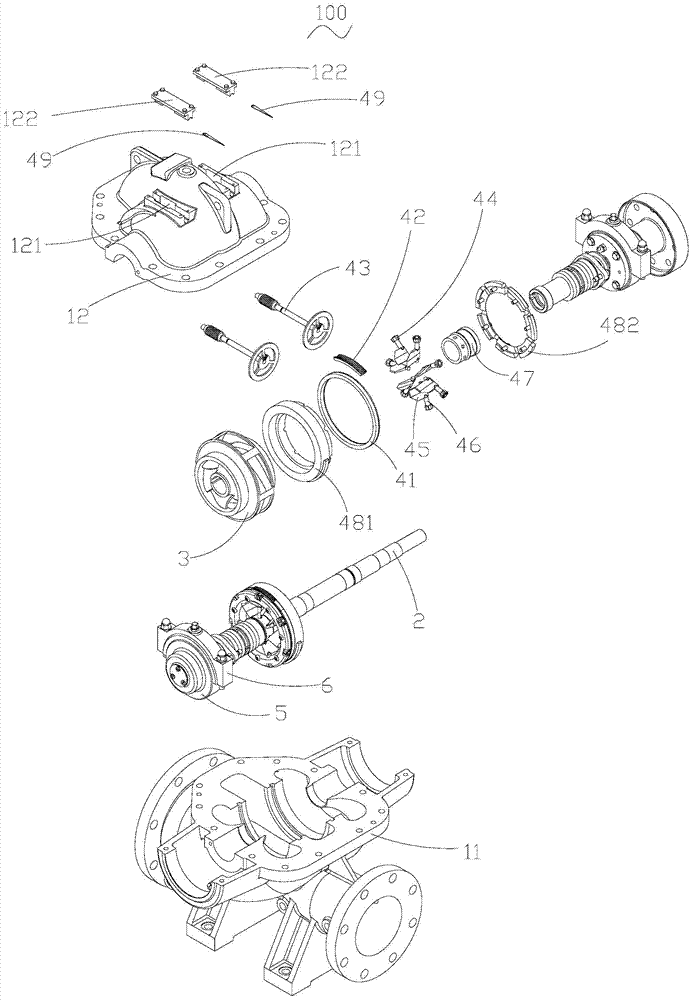

Axial plunger variable pump

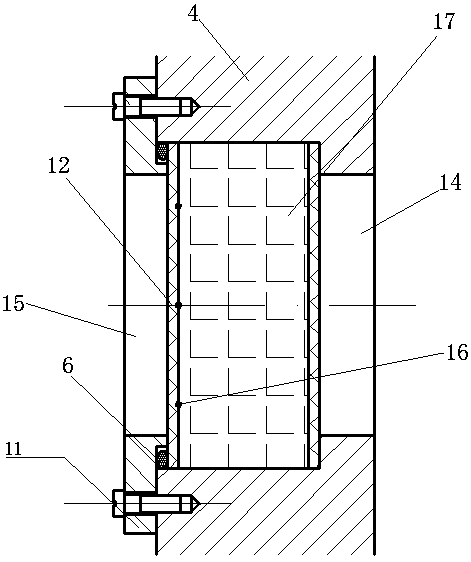

InactiveCN107035639AAvoid "swashplate-shoe" structureLarge flow adjustment rangePiston pumpsPositive-displacement liquid enginesRolling-element bearingCoupling

The invention discloses an axial plunger variable pump. The axial plunger variable pump is characterized in that a sliding sleeve is mounted in a cylinder sleeve; a plunger is mounted in the sliding sleeve; holes are formed in the side surfaces of the sliding sleeve and the cylinder sleeve; the holes in the side surface of the sliding sleeve are accommodated in the holes in the side surface of the cylinder sleeve; a flange at the lower part of the sliding sleeve and an eccentric wheel frame are welded; an eccentric wheel is mounted in the eccentric wheel frame; a stepping motor is mounted on a pump body and is connected with an eccentric wheel shaft through a stepping motor coupling; a motor is mounted on the pump body and is connected with a crank shaft through a motor coupling; the crank shaft is supported on the pump body through a rolling bearing; the lower end of a connecting rod is assembled in a rod journal of the crank shaft through a connecting rod bearing shell; and the upper end of the connecting rod is in interference connection with a plunger pin. The axial plunger variable pump avoids the swash plate-sliding shoe structure and has a relatively large flow regulation range.

Owner:LUZHOU VOCATIONAL & TECHN COLLEGE

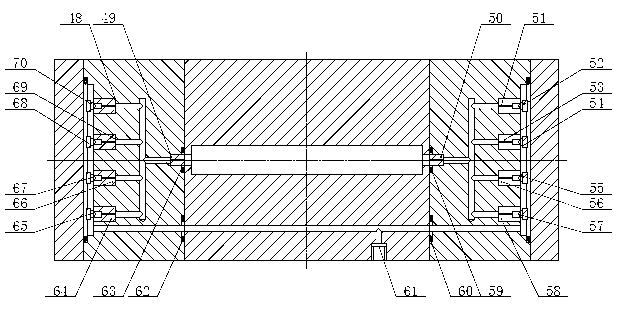

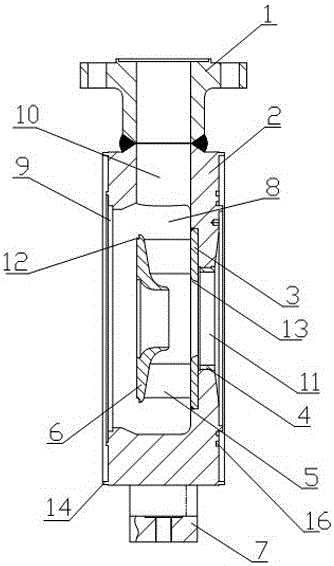

Pilot-operated type water hydraulic pressure digital proportional direction valve

InactiveCN102121487BNo pollution in the processSimple structureServomotor componentsCompliant mechanismEngineering

The invention discloses a pilot-operated type water hydraulic pressure digital proportional direction valve, which comprises a main valve and two pilot valves, wherein the pilot valves are positioned on the left side and the right side of the main valve respectively and are arranged on the main valve through an end face in a matching way; each pilot valve comprises a variable liquid resistor and a fixed liquid resistor which is connected in series with the variable liquid resistor; a control port communicated with the end face of a valve core of the main valve is positioned between the variable liquid resistor and the fixed liquid resistor; and the pressure of the control port can be changed by changing the resistance value of the variable liquid resistor so as to control the valve core of the main valve and control the direction and the flow rate of a liquid flow. In the invention, pulse code modulation (PCM) pilot control is adopted, so that the proportional direction valve can be simply and reliably controlled, and has high precision, high frequency and long service life; and the main valve has high flow rate. The pilot valves consist of a switching valve and a damping hole, have low leakage, high pollution resistance and high interference resistance and can be used in a marine environment containing a large number of solid impurities. The valve cores of the pilot valves are driven through piezoelectric ceramics, perform amplification displacement through a compliant mechanism and have simple driving mechanism structures, quick response and long service life.

Owner:HUAZHONG UNIV OF SCI & TECH

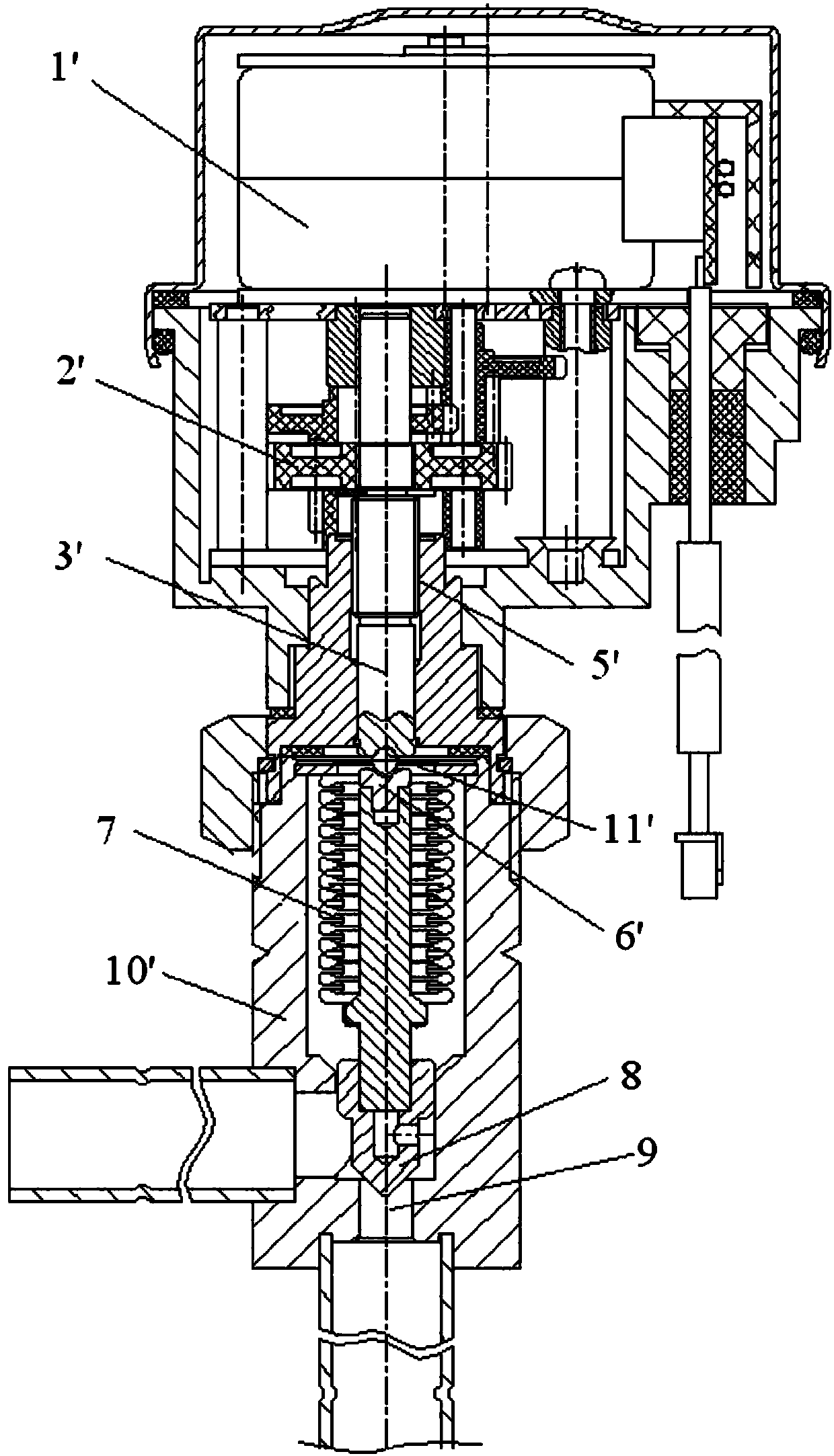

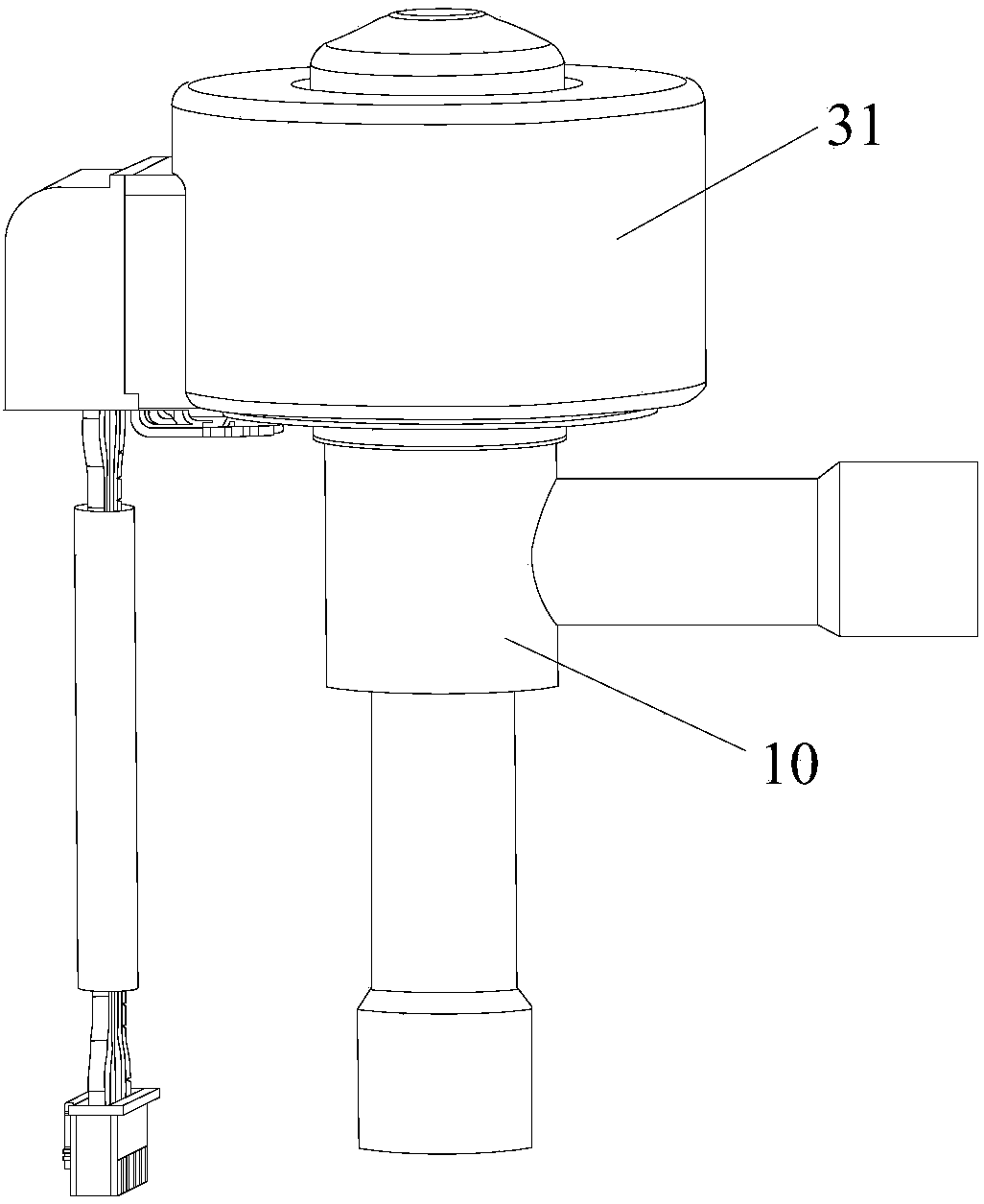

Electronic expansion valve and refrigeration system provided with same

ActiveCN109723832AHigh stroke control accuracyLarge flow adjustment rangeOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringElectronic expansion valve

The invention provides an electronic expansion valve and a refrigeration system provided with the same. The electronic expansion valve comprises a valve seat, a valve needle and a planetary gear reducing mechanism, wherein the valve needle is movably arranged in a cavity and is provided with an opening position and a closing position; the planetary gear reducing mechanism comprises a planet carrier driven by a driving mechanism to rotate, a planet wheel and a gearbox; a first mounting shaft is arranged on the planet carrier; the planet wheel is arranged on the first mounting shaft in a sleeving manner; the gearbox comprises a box body fixedly arranged on the valve seat, a fixed inner gear ring arranged on the box body, and a rotating inner gear ring rotatably arranged on the box body; an output shaft is arranged on the rotating inner gear ring; the planet wheel is meshed with the fixed inner gear ring and the rotating inner gear ring; and a transmission mechanism enables the valve needle to move between the opening position and the closing position. With adoption of the technical scheme, the problem in the prior art that high precision and miniaturization cannot be realized when the flow regulation range of the electronic expansion valve is increased is effectively solved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Electromagnetic pump capable of adjusting flow range

InactiveCN111946579ALarge flow adjustment rangeIngenious designPositive displacement pump componentsBearing componentsEngineeringElectromagnetic pump

The invention discloses an electromagnetic pump capable of adjusting a flow range. The electromagnetic pump comprises a pump shell. A pipe body is arranged in the pump shell. An electromagnetic assembly is arranged on the inner wall of the pipe body. A bearing is arranged in the pipe body. A return spring is arranged at the bottom of the bearing. A pipe body through groove is formed in the bottomend of the pipe body. The bearing and the groove wall of the pipe body through groove define a first flow channel. The interior of the pump shell and the groove wall of the pipe body through groove define a second flow channel. A sealing cavity is formed in the pump shell. A piston cavity and an axial valve port are formed in two ends of the sealing cavity. An output end is arranged at one end ofthe pump shell. An output hole is formed in the output end. A first one-way valve device is arranged in the sealing cavity, and a second one-way valve device is arranged in the output hole. A lower limit value of a flow adjusting range of the electromagnetic pump is reduced, working efficiency is improved, mounting and dismounting are facilitated, and later maintenance is facilitated.

Owner:蚌埠正峰电子科技有限公司

V-shaped valve for measuring and controlling flow

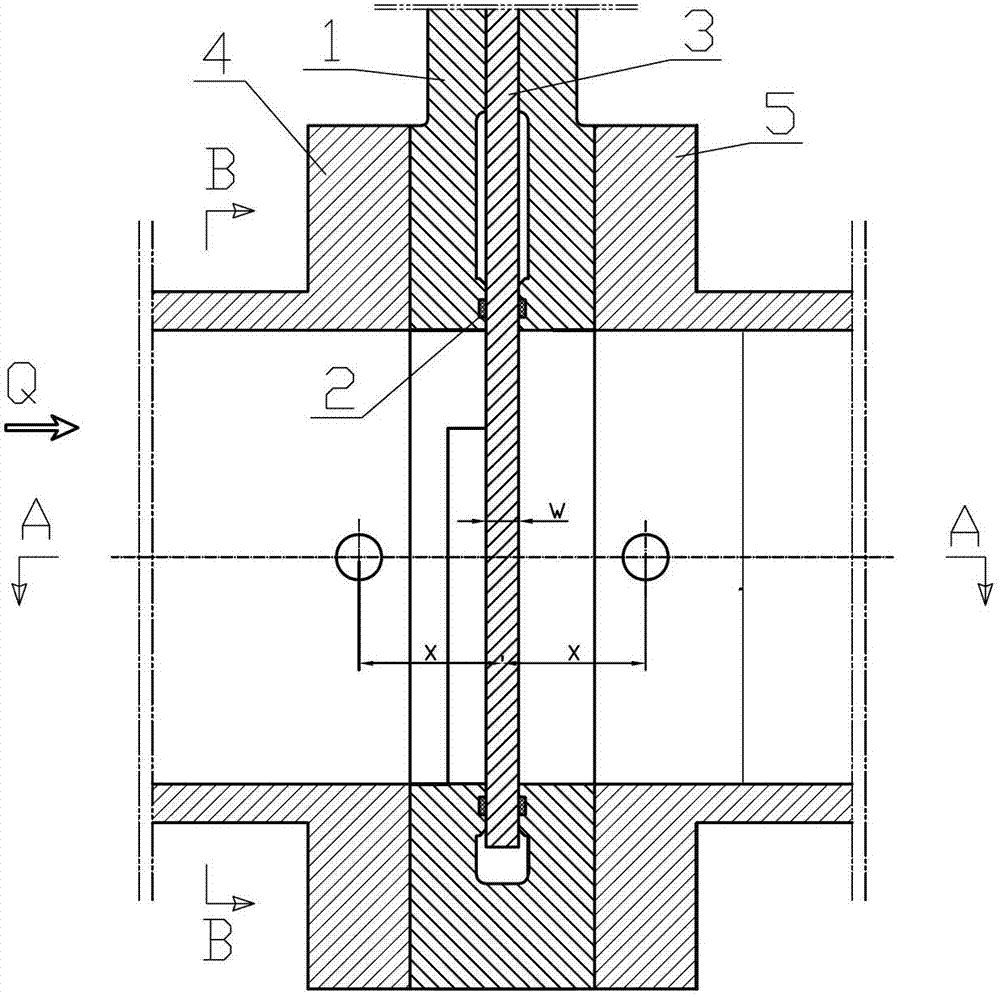

InactiveCN102734520AMeet the requirements of instant adjustmentSimple structureWater aerationEqualizing valvesAeration systemPositive pressure

The invention relates to a V-shaped valve for measuring and controlling flow, and particularly relates to a special device for accurately measuring and controlling the flow of air on a wastewater treatment and accurate aeration system. The V-shaped valve comprises a valve body, a valve plate, a valve front pipeline, a valve back pipeline and an air difference pressure transmitter, wherein the valve plate is installed in the valve body and the valve body is provided with a sealing ring. The V-shaped valve is characterized in that a positive pressure joint of the air difference pressure transmitter is connected with an inner cavity of the valve front pipeline through a positive pressure joint pipe, a negative pressure joint of the air difference pressure transmitter is connected with an inner cavity of the valve back pipeline through a negative pressure joint pipe, the valve front pipeline is arranged at the front end of the valve body, and the valve back pipeline is arranged at the back end of the valve body. The V-shaped valve is good in stability, large in flow regulation range and high in metering accuracy, and can completely satisfy the requirements of the wastewater treatment and accurate aeration system on immediate regulation of the air flow; and according to the V-shaped valve disclosed by the invention, flow variation and the opening of the valve plate show a better linear relationship, so that the V-shaped valve has good air regulation linearity.

Owner:WUXI GL TUBRO COMPRESSOR

High-efficiency energy-saving single-stage high-speed centrifugal blower

The invention relates to a high-efficiency energy-saving single-stage high-speed centrifugal blower which comprises a high-speed gear case, a spiral case, an impeller, an air inlet body, an inlet guide vane and an inlet guide vane adjusting mechanism and is characterized by also comprising a plurality of outlet guide vanes and an outlet guide vane adjusting mechanism, wherein the plurality of outlet guide vanes are installed in the corresponding axle holes on the high-speed shaft end flange of the high-speed gear case and are evenly distributed in the radial direction, and the outlet guide vane adjusting mechanism is arranged on the shafts of the outlet guide vanes. The centrifugal blower provided by the invention has the advantage of compact and reasonable structure; the impeller is of an entire ternary structure with primary blades and secondary blades and is made of a small quantity of aluminum alloy, thus the efficiency is further improved; and simultaneously the inlet guide vane and the outlet guide vanes have wider flow adjustable ranges and maintain higher continuous adjustment efficiency within a range of 40%-100% of the rated flow, thereby being adaptable to the flow requirements under different working conditions and achieving the purpose of omnidirectional energy conservation.

Owner:WUXI GL TUBRO COMPRESSOR

Dual fluid nozzle based on high-pressure water

The invention provides a dual fluid nozzle based on high-pressure water. The dual fluid nozzle comprises a high-pressure water pipeline and a slurry pipeline. The high-pressure water pipeline is coaxially sleeved with the slurry pipeline, flowing space of the high-pressure water is arranged in the high-pressure water pipeline, and flowing space of slurry is arranged between the slurry pipeline and the high-pressure water pipeline. The slurry pipeline communicates with a slurry inlet. A slurry nozzle is formed in the tail end of the slurry pipeline. The front end of the high-pressure water pipeline is located outside the slurry pipeline and connected with a high-pressure water source. A high-pressure water nozzle is formed in the tail end of the high-pressure water pipeline and located in the slurry nozzle. When the dual fluid nozzle is used, high-pressure water flow in the high-pressure water nozzle collides with the slurry in the slurry nozzle, and the slurry is atomized into fine slurry drops to be sprayed out of the slurry nozzle. The dual fluid nozzle is simple in design structure, large in flow adjustment range, excellent in anti-blocking performance, especially suitable for high-pressure and ultrahigh-pressure environments and capable of solving the problems that in a traditional supercritical water gasification technology, a feeding device is too high in local temperature, and a feeding port is blocked.

Owner:陕西中核交大超洁能源技术有限公司

Centrifugal fan with flow and temperature adjusting function

InactiveCN114320976AContinuous and stable operationReduce heating ratePump componentsPump controlElectric machineryCentrifugal fan

The invention provides a centrifugal fan with flow and temperature regulation, which is characterized in that a temperature regulation device for regulating the temperature of fluid in the centrifugal fan in a coolant heat exchange manner is arranged at an air outlet of the fan, and the temperature regulation device is arranged in the fan or at an air inlet of the fan or at the air outlet of the fan; the flow adjusting device capable of adjusting the actual flowing-through flow by adjusting the actual flowing-through area of the fluid is arranged in a mode of sealing the flowing-through area of the fluid, and the flow adjusting device is combined with the variable frequency motor for use, so that the flow adjusting range of the centrifugal fan, especially the low-frequency adjusting range, can be effectively widened; the flow of the fan can be further reduced by reducing the actual flowing area of fluid, and ideal air pressure is obtained; the temperature adjusting device for adjusting the temperature of fluid in the centrifugal fan in a coolant heat exchange mode is arranged at the air outlet of the fan, air discharged from the fan can be directly cooled, the fluid does not need to be cooled independently, and convenience and high efficiency are achieved.

Owner:南京深度系统工程有限公司

Double-adjusting-distance curtain coating head

InactiveCN109663709ASimple structureLarge flow adjustment rangeLiquid surface applicatorsCoatingsCooking & bakingEdge surface

The invention provides a double-adjusting-distance curtain coating head. The double-adjusting-distance curtain coating head is simple in structure, wide in curtain coating flow rate adjusting range and facilitates varnish baking work of various structures. The double-adjusting-distance curtain coating head comprises vertical mounting racks which are positioned at two sides, wherein a first die iserected on top plates of the two vertical mounting racks; the bottom parts of two ends, in the length direction, of the first die are fixedly mounted to the top plates of the corresponding vertical mounting racks; a second die is arranged close to one side of the first die; the opposite end surfaces of the second die and the first die are combined to form a rear center area oil chamber, and the center area oil chamber covers length areas in the inner sides of end plates, in the length direction, of the first die and the second die; all areas, excepting the bottom parts, in the length direction, in surface areas of the end plates of the first die and the second die are close to each other and sealed to each other; a 90-degree curtain coating cutter is arranged at the bottom part in the length direction of an oil chamber of the first die; a single curtain coating cutter is arranged at the bottom part, in the length direction, of an oil chamber of the second die; an edge surface of the single curtain coating cutter faces a vertical surface of the 90-degree curtain coating cutter in a clearance manner.

Owner:昆山丰巧机械有限公司

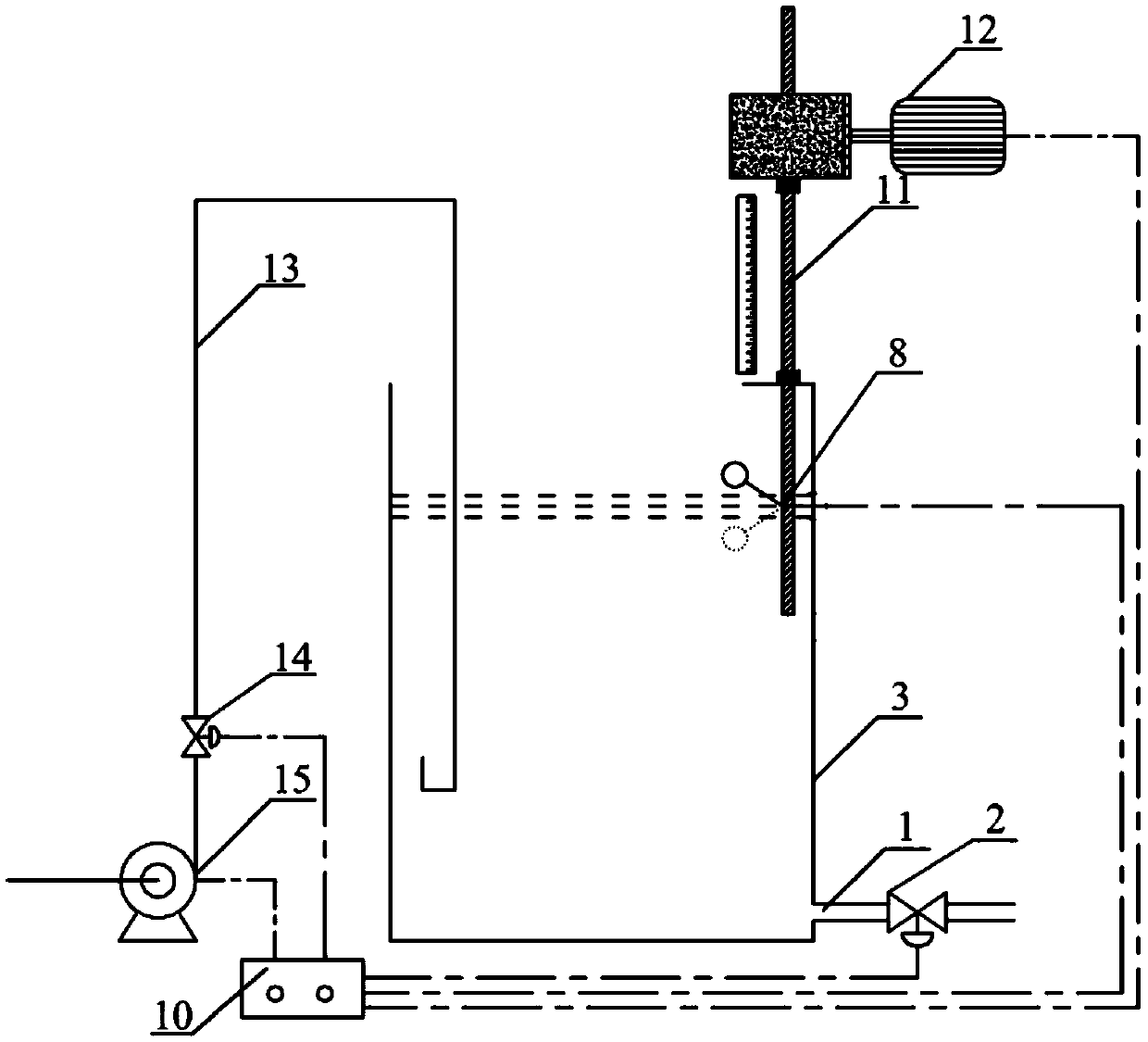

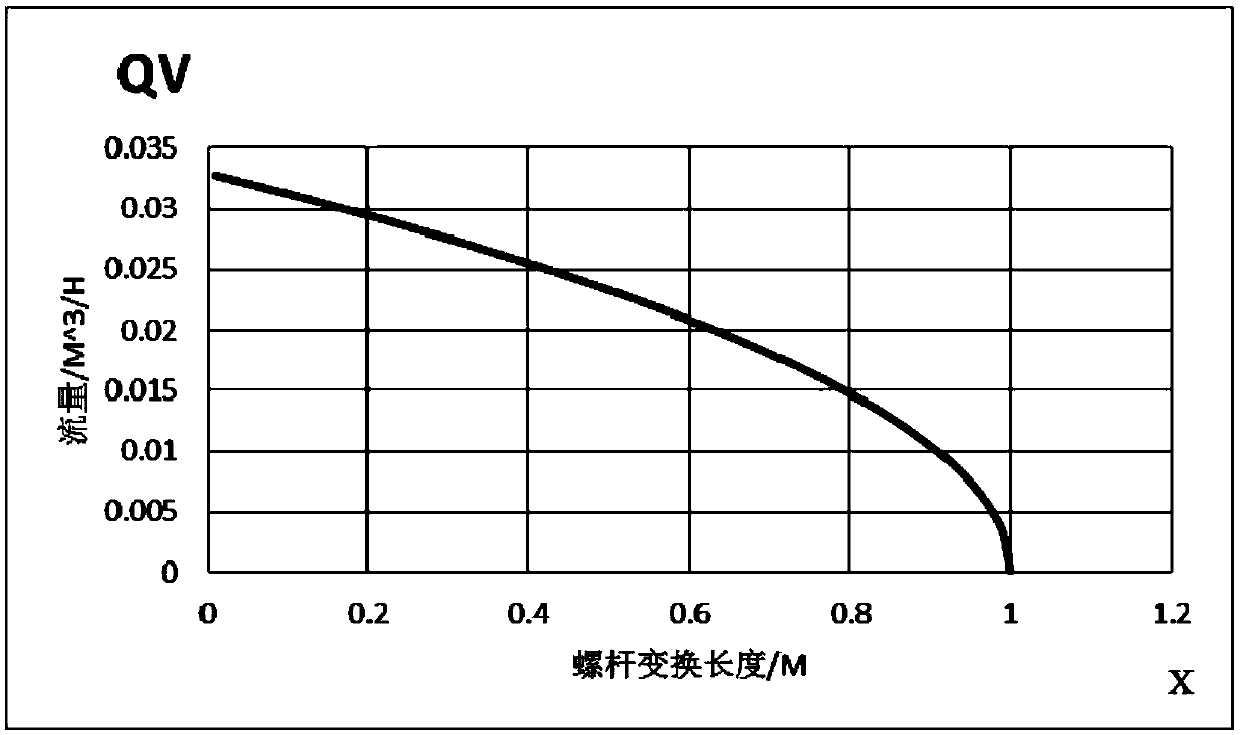

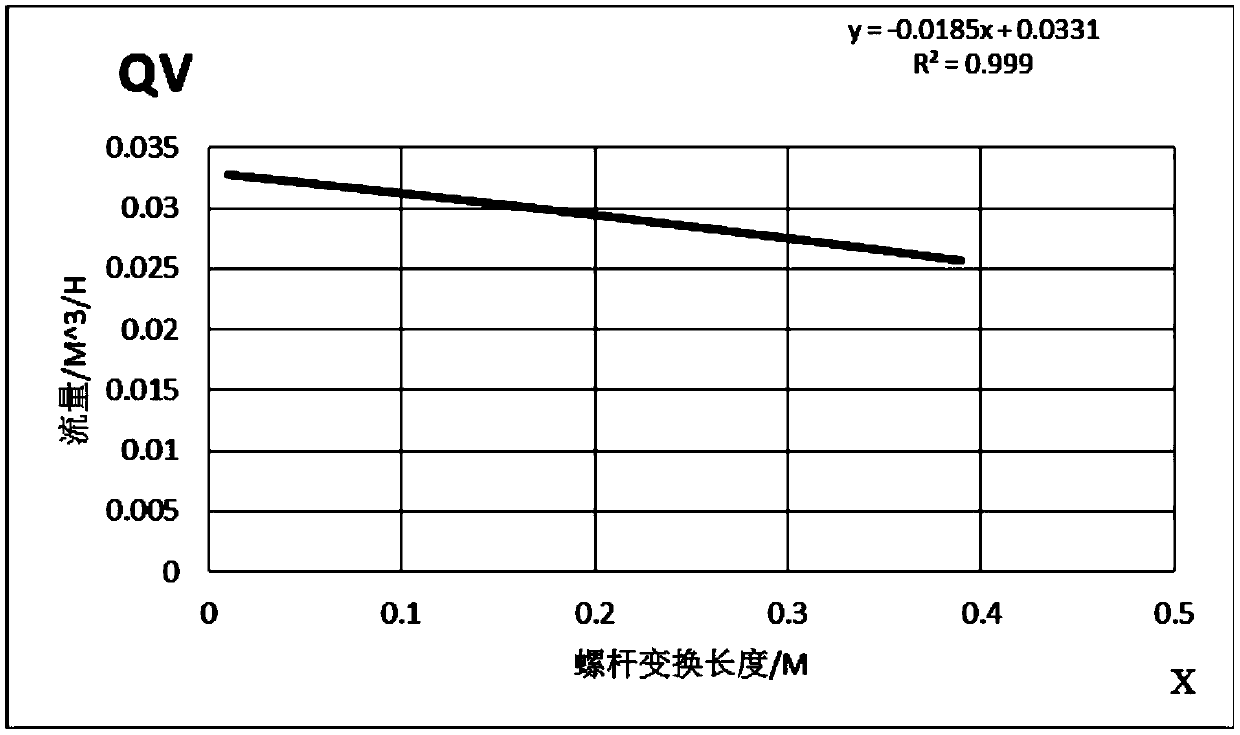

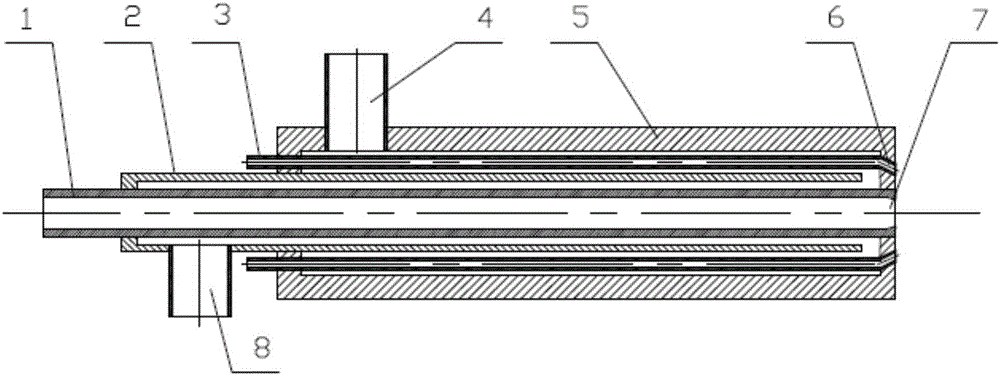

Stable flow accurate control device based on liquid level pressure difference

InactiveCN109650473AAvoid damageExtended service lifeWater treatment parameter controlFlow control using electric meansWater storage tankLiquid storage tank

The invention relates to the technical field of flow control devices, and particularly relates to a stable flow accurate control device based on liquid level pressure difference, which comprises a liquid storage tank, wherein a water outlet is formed in the bottom of the liquid storage tank; a water supply system of the water storage tank, and a liquid level adjusting device of the water storage tank; the liquid level adjusting device of the water storage tank is used for adjusting the target height of the water stored in the liquid storage tank, and the water supply system is used for supplying water to the target height in the liquid storage tank; the water outlet is connected with a water outlet pipe, and the water outlet pipe is provided with a bent pipe section; the water supply system comprises a water pump, a control device and a floating ball switch, wherein the control device is in signal connection with the water pump and the floating ball switch; the control device is used for controlling the opening and closing of the water pump according to the signal of the floating ball switch, and the water level adjusting device of the water storage tank adjusts the target height of the water supply of the water supply system by adjusting the height of the floating ball switch. The stable flow accurate control device based on the liquid level pressure difference can solve the problems of easy blockage, high cost and large damage to the water pump in the prior art.

Owner:CHONGQING TECH & BUSINESS UNIV +1

Double-fluid external mixing type nozzle based on high-pressure water

The invention provides a double-fluid external mixing type nozzle based on high-pressure water. The double-fluid external mixing type nozzle comprises a slurry pipe and multiple high-pressure water pipes. The high-pressure water pipes are arranged outside the slurry pipe in parallel and are evenly distributed in the circumferential direction of the slurry pipe. A slurry nozzle body is formed at the tail end of the slurry pipe. The tail ends of the high-pressure water pipes incline in the axis direction of the slurry pipe and are provided with high-pressure water nozzle bodies. The extending lines of the high-pressure water nozzle bodies intersect with the extending line of the slurry nozzle body. After high-pressure water flow in the high-pressure water pipes is sprayed out obliquely from the high-pressure water nozzle bodies, the high-pressure water flow collides with slurry sprayed out from the slurry nozzle body outside the nozzle, and the slurry is broken and atomized into small slurry drops under the colliding and shearing effects of the high-pressure water flow. The double-fluid external mixing type nozzle based on high-pressure water is particularly suitable for the supercritical water gasifier technology and has the beneficial effects of being good in anti-blockage performance, resistant to corrosion and high temperature and the like.

Owner:陕西中核交大超洁能源技术有限公司

Urea solution supply system adopting double pneumatic diaphragm pumps

ActiveCN110792489AReduce complexityExtended service lifeExhaust apparatusSilencing apparatusDiaphragm pumpWork cycle

The invention belongs to the field of diesel engine tail gas after-treatment, and particularly discloses a urea solution supply system adopting double pneumatic diaphragm pumps. The system comprises the first pneumatic diaphragm pump, the second pneumatic diaphragm pump, a urea box, an air source and a urea nozzle. The liquid inflow ends of the first pneumatic diaphragm pump and the second pneumatic diaphragm pump communicate and then are connected with the urea box through a liquid inflow pipeline, the liquid outflow ends of the first pneumatic diaphragm pump and the second pneumatic diaphragm pump communicate and then are divided into two paths, one path is connected with the urea box through a return pipeline, the other path is connected with the urea nozzle through a spraying pipeline,the air source is divided into two paths, one path is connected with the air inflow ends of the first pneumatic diaphragm pump and the second pneumatic diaphragm pump through a two-position four-wayelectromagnetic valve, the other path is connected with the urea nozzle, and a urea solution is purged. Suction of one path of pneumatic diaphragm pump and pressing-out of the other path of pneumaticdiaphragm pump always exist in one working cycle, the flow pulsation rate of the system is effectively reduced, and the flow stability and the metering precision of the urea solution supply system areimproved.

Owner:HUAZHONG UNIV OF SCI & TECH

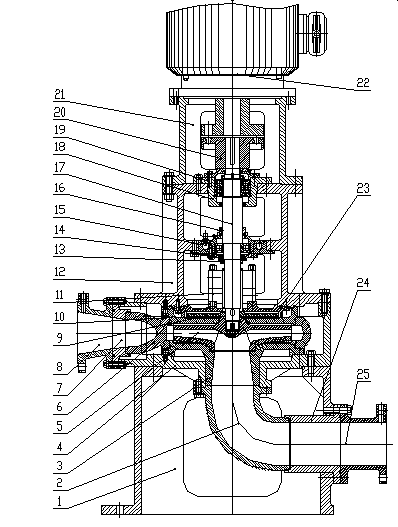

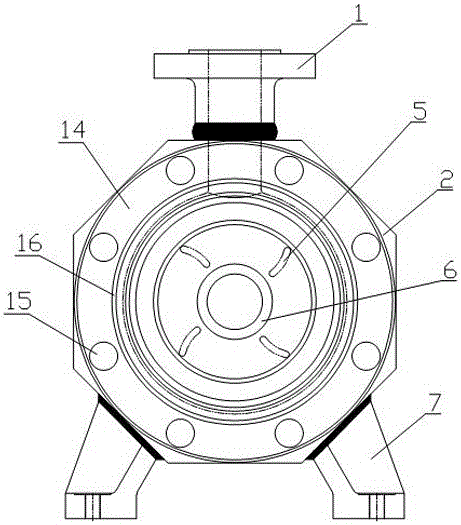

Low-pressure centrifugal coal slurry pump

InactiveCN103511322AMeet deliveryMeet the use requirementsPump componentsPumpsImpellerChemical industry

A low-pressure centrifugal coal slurry pump comprises a pump base, a water inlet elbow and a pump body. The pump body is arranged on the pump base, a pump cover is built in the pump body, a water outlet volute and a water outlet pipe are sequentially arranged at the left end of the pump cover, and the water inlet elbow, a water inlet short pipe and a water inlet pipe are sequentially arranged at the lower end of the pump cover. A pump shaft penetrates through a pump bracket and the pump body, one end of the pump shaft is connected with an impeller of the pump cover in a linkage mode, and the other end of the pump shaft is supported by two sets of bearings. Mechanical seals are arranged on the pump bracket, on the pump shaft in the pump body and between quench guide vanes and the bearings. The low-pressure centrifugal coal slurry pump meets the ISO28258 international standard and the API610 standard and is used for conveying media of which the solid content can be up to 65%, and the medium temperature is lower than or equal to 150 DEG C. New material, new technologies and high-quality accessories are adopted for a whole set of system to ensure stability and reliability of working of the system. The low-pressure centrifugal coal slurry pump has the advantages of being low in price, reasonable in structure, wide in range of flow regulation, easy to operate, convenient to assemble and disassemble and the like and can meet requirements for conveying coal slurry in the coal chemical industry and be used in the working condition of high solid content in the chemical industry.

Owner:JIANGSU FEIYUE PUMP GRP

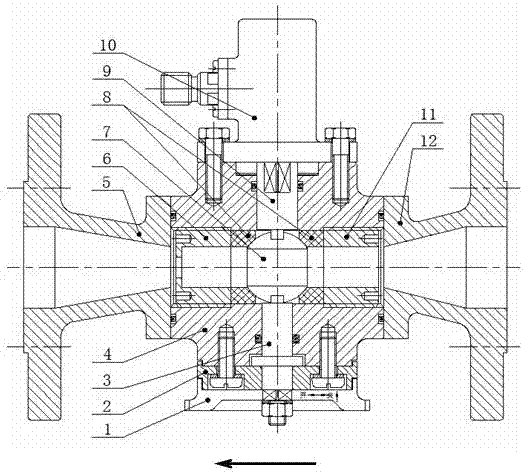

Control ball valve for metering self-balancing type foam fire extinguishing system

InactiveCN107166077ASmall pressure drop lossSimple structurePlug valvesOperating means/releasing devices for valvesEngineeringDrive motor

The invention discloses a control ball valve for a metering self-balancing type foam extinguishing system. The control ball valve comprises a valve body; a ball body is arranged in the valve body; the upper end of the ball body is connected to a driving motor through an upper valve rod; the lower end of the ball body is connected to a manual knob through a lower valve rod; an outlet threaded connector is arranged on the left side of the ball body; one end of the outlet threaded connector is connected to an outlet flange; an inlet threaded connector is arranged on the right side of the ball body; and one end of the inlet threaded connector is connected to an inlet flange. The control ball valve has the advantages that the structure is simple, control is easy, the performance is reliable, the response speed is high, the adjusting precision is high, the mixing precision of a foam mixture and the fire extinguishing efficiency of a system can be improved, and automatic and manual adjustment can be realized.

Owner:九江中船消防设备有限公司

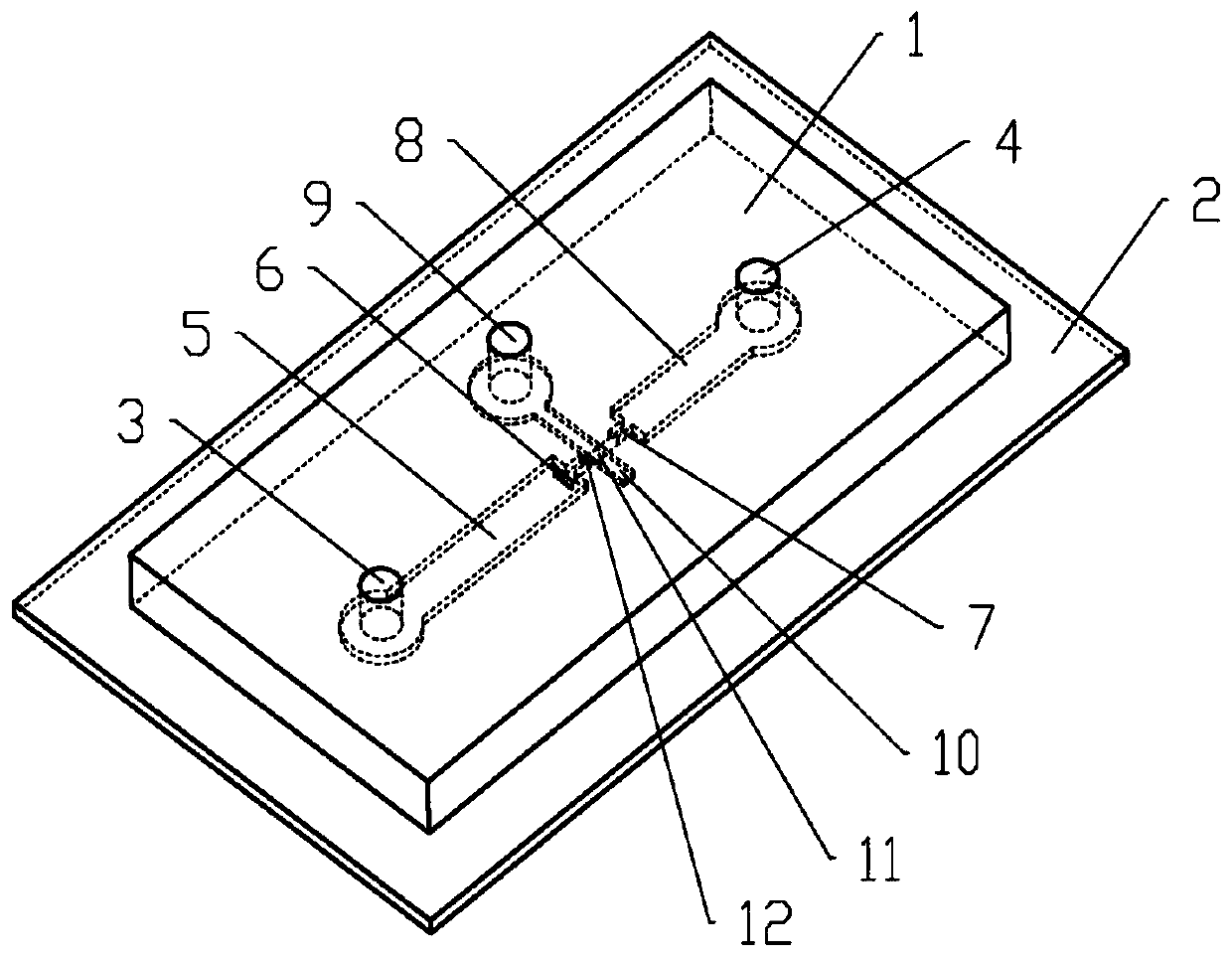

A microfluidic valve and a microfluidic control method thereof

Owner:HOHAI UNIV CHANGZHOU

Middle discharge section of multi-outlet horizontal single-suction segmental multi-stage centrifugal pump

ActiveCN104314827BLarge caliberSolve the problem of different pressure water supplyPump componentsRadial flow pumpsPump chamberSpiral flow

The invention discloses a middle discharging section of a multi-outlet horizontal single-suction sectional multistage centrifugal pump. The middle discharging section comprises a discharging flange, a discharging section, a bracket bottom plate, a sealing ring, a spiral flow eliminating guide vane, a bracket plate and a discharging section supporting leg, wherein the discharging section is fixed on the discharging section supporting leg; a pumping chamber is arranged in the discharging section; an importing opening, a discharging opening and an exporting opening are formed in the discharging section; the importing opening and the exporting opening are respectively corresponding to an upper-stage impeller and a lower-stage impeller; the discharging opening is formed in the upper end of the discharging section and communicated with the discharging flange; the bracket bottom plate is arranged on the discharging section on the inner side of the exporting opening; the bracket plate is arranged in the pumping chamber and close to one side of the importing opening; the spiral flow eliminating guide vane is arranged on the bracket plate and extends toward the end of the bracket bottom plate; the sealing ring is matched with the inner wall of the exporting port. The middle discharging section has a function of supplying water with different pressures and flows, and is wide in flow regulation range, good in flow regime and high in efficiency.

Owner:南方中金环境股份有限公司

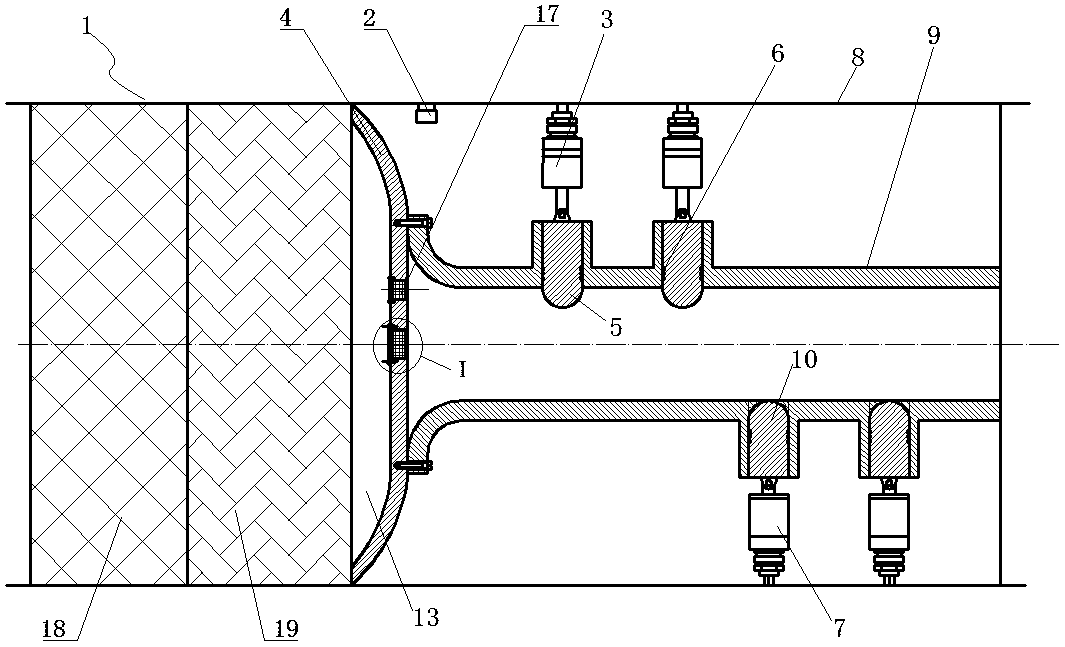

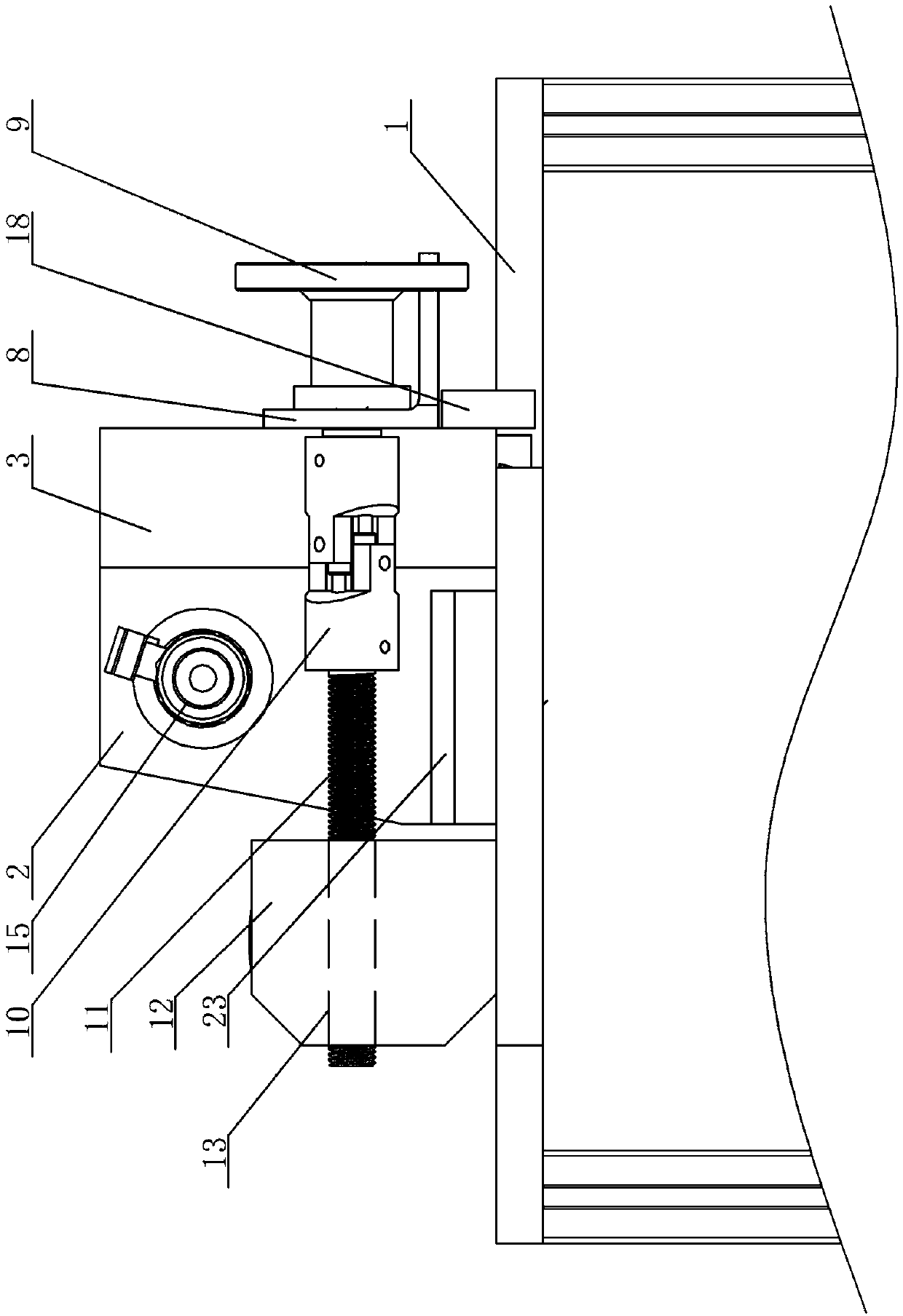

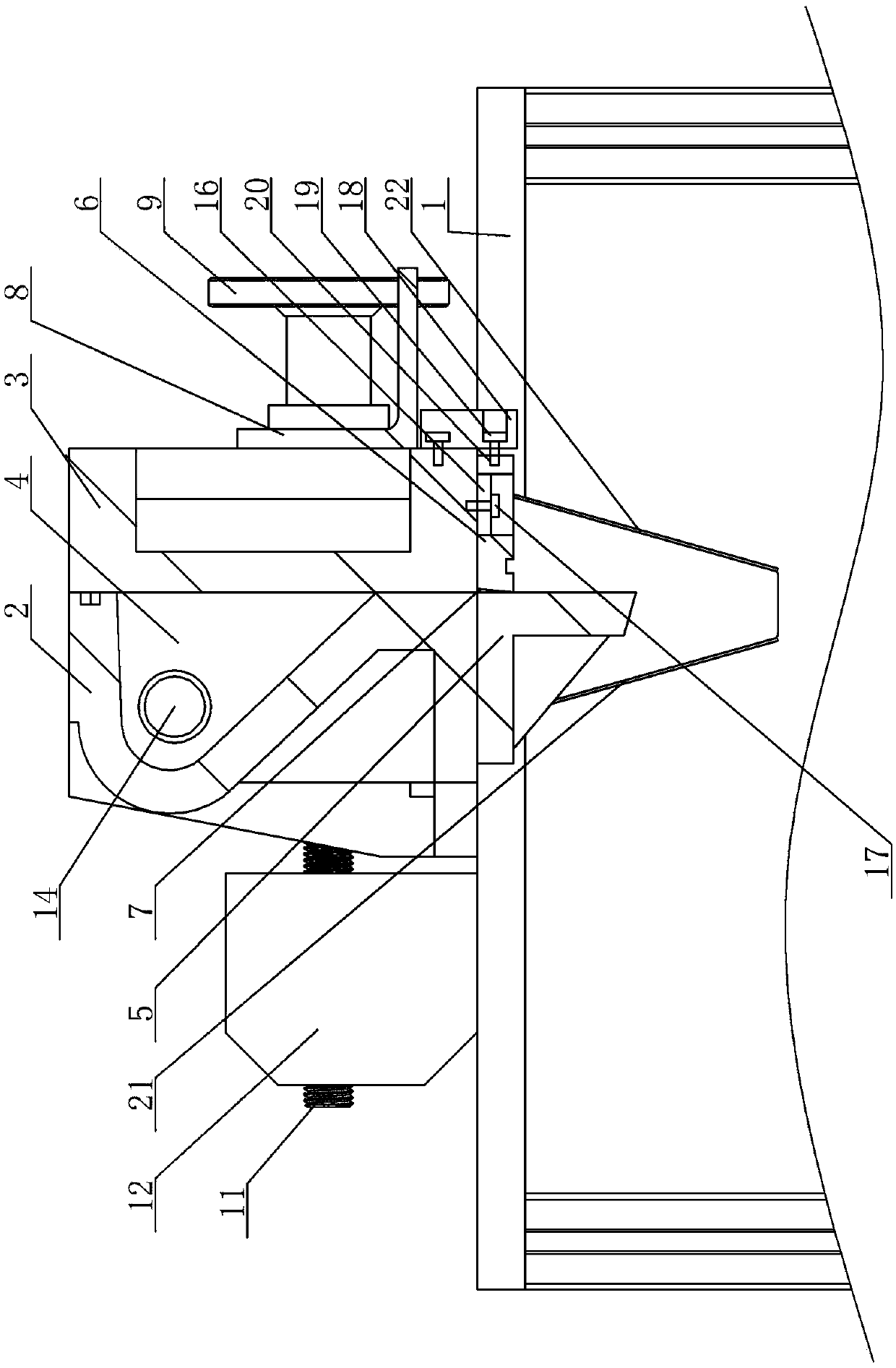

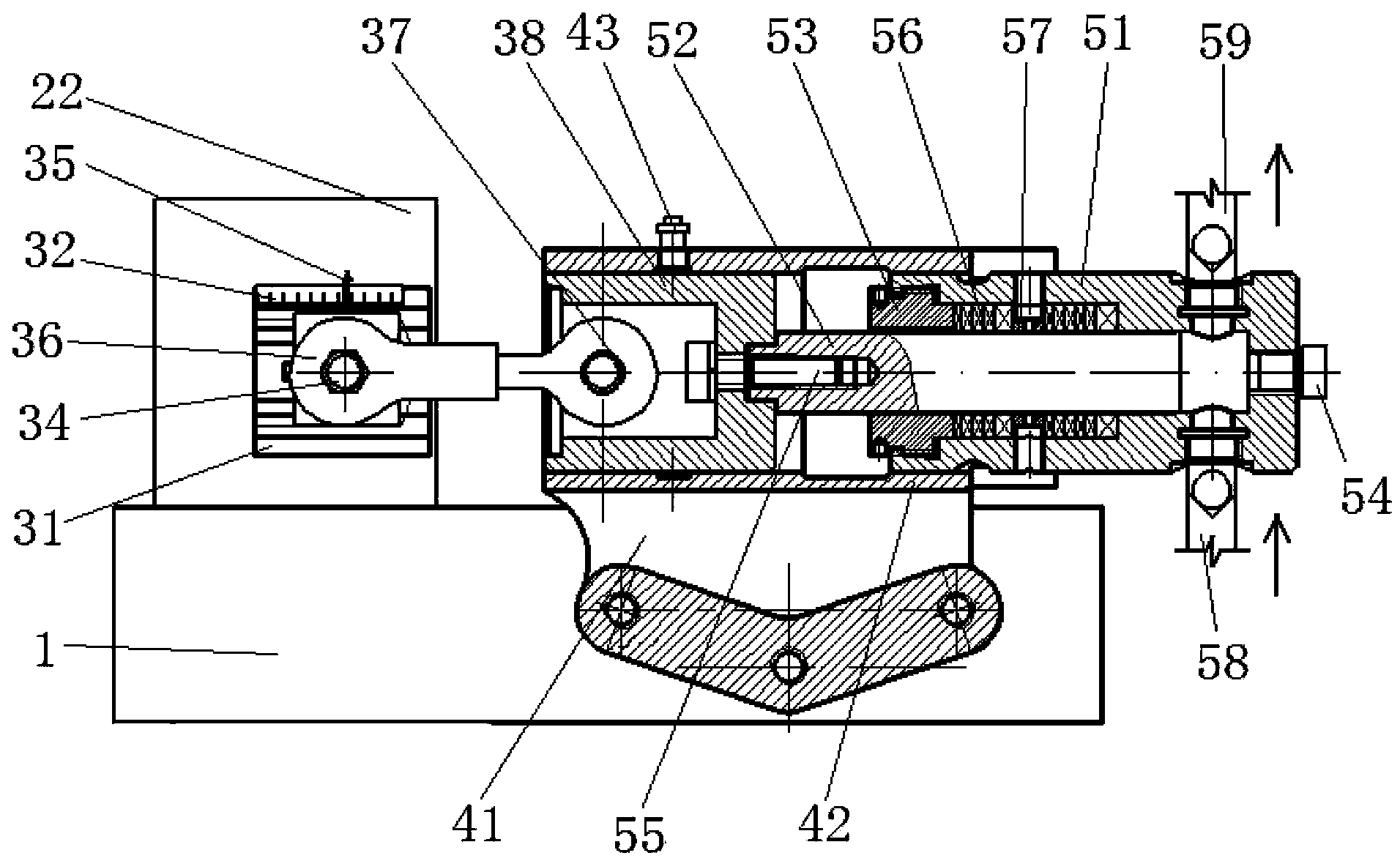

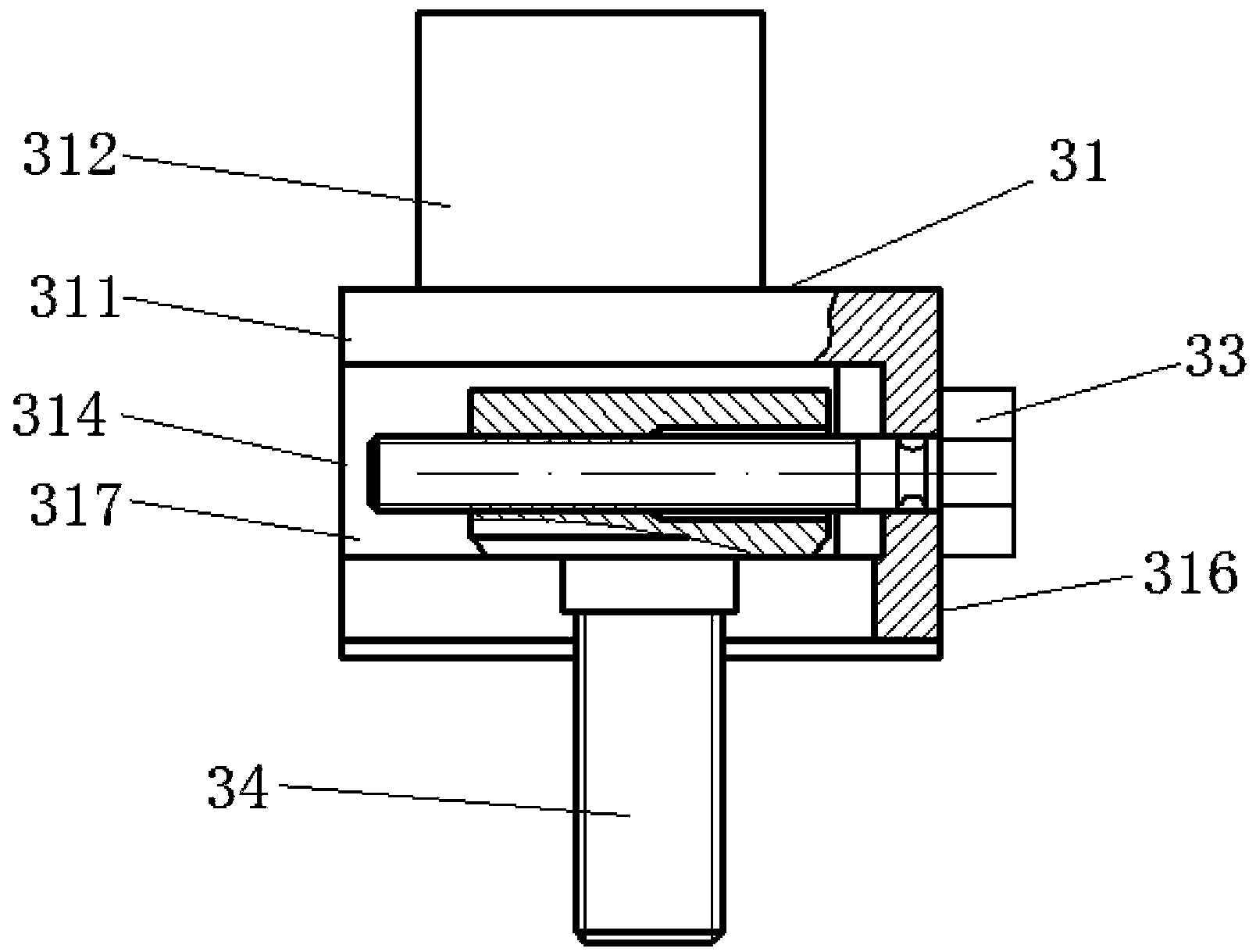

Pump-injection-type fertilizer application device

ActiveCN102893745BChange the fertilizer injection flowSimple structurePressurised distribution of liquid fertiliserAgriculture gas emission reductionAgricultural irrigationAgricultural engineering

The invention relates to a pump-injection-type fertilizer application device, which is characterized in that the pump-injection-type fertilizer application device comprises a base, a power device, a fertilizer quantity adjusting device, a cylinder body bracket, a piston cylinder and a fertilizer bucket; the power device, the fertilizer quantity adjusting device, the cylinder body bracket and the piston cylinder are arranged on the base; the fertilizer quantity adjusting device comprises a scale crank, a travel adjusting screw, a connecting rod bolt, a connecting rod and a connecting rod device, the scale crank is connected with the output end of the power device, the travel adjusting screw is engaged with the connecting rod bolt through threads, and the travel adjusting screw and the connecting rod bolt are arranged on the scale crank; the connecting rod is connected with the connecting rod bolt and the connecting rod device, the connecting rod device is arranged in the cylindrical body of the cylinder body bracket and the cylinder body of the piston cylinder is also arranged in the cylindrical body; one end of a plunger is connected with the connecting rod device, and the other end of the plunger is arranged in the cylinder body, is matched with the cylinder body, moves back and forth and is used for sucking and draining fertilizer solution; and a fertilizer solution inlet and a fertilizer solution outlet are arranged on the cylinder body, the fertilizer solution inlet is connected with the fertilizer bucket through a pipeline and the fertilizer solution outlet is connected with a fertilizer injection nozzle through a pipeline. The pump-injection-type fertilizer application device is convenient to operate and can be used as a special fertilizer application / injection device in agricultural irrigation systems or agricultural irrigation equipment such as center pivot sprinkling machines.

Owner:CHINA AGRI UNIV

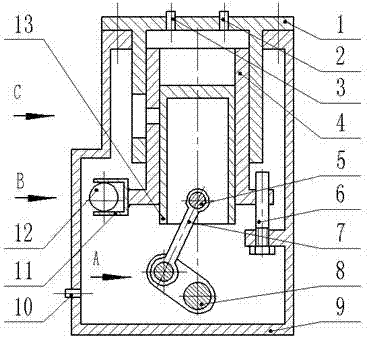

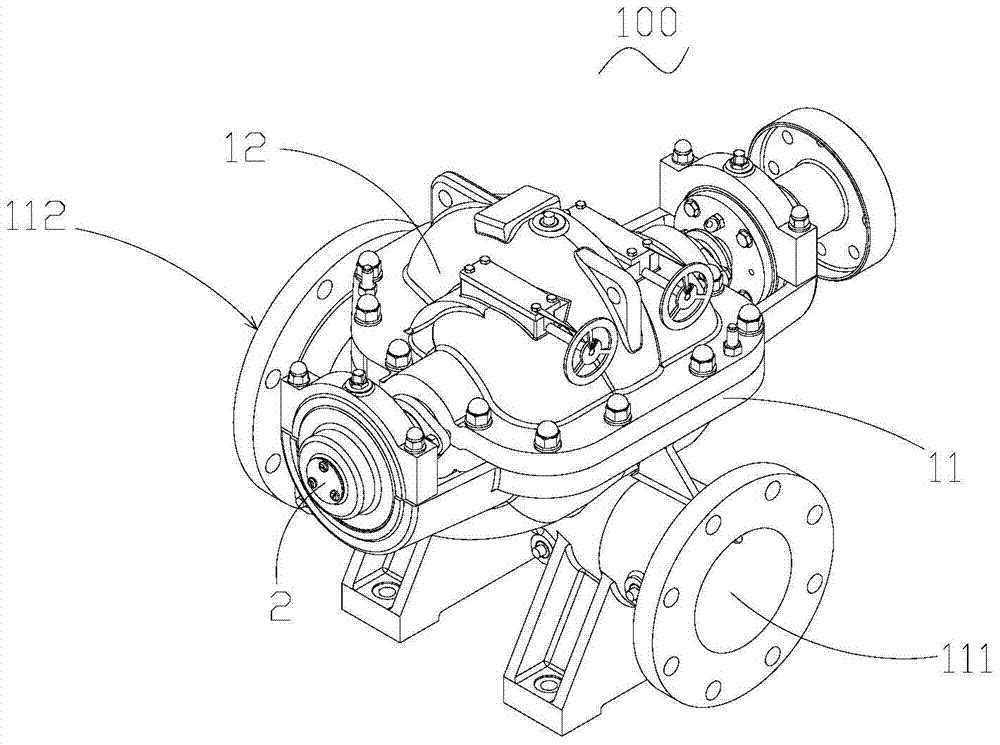

A large and small double crankshaft multi-displacement reciprocating pump

ActiveCN108105046BAddressing changing needsReduce the sliding speed variation rangePositive displacement pump componentsPiston pumpsEngineeringPump head

The invention discloses a multi-discharge-capacity reciprocating pump provided with large and small crankshafts. The multi-discharge-capacity reciprocating pump comprises a housing, a pump head component, a first piston component, a second piston component, a first crankshaft, a second crankshaft, a first connecting rod component, a second connecting rod component, a first clutching device, a second clutching device and an input shaft. The multi-discharge-capacity reciprocating pump disclosed by the invention is provided with the first crankshaft and the second crankshaft which are different in size so that the flow rate of the second piston component in work is smaller than that of the first piston component; by arranging the first clutching device and the second clutching device, the first crankshaft and the second crankshaft can work independently or simultaneously; by virtue of the first connecting rod component and the second connecting rod component. The first piston component and the second piston component can work independently or simultaneously, so the rotating speed of the pump is constant, while the flow rate can be divided into three modes including a small flow rate mode, an intermediate flow rate mode and a large flow rate mode, and thus the requirements on flow rate changes of the reciprocating pump are met, the rotating speed is constant so that the change range of a sliding speed of a sealing ring and a cylinder wall is reduced, and the service life of the reciprocating pump is prolonged.

Owner:ANHUI UNIV OF SCI & TECH

An adjustable pump with an adjusting device for changing the water inlet direction of the impeller

ActiveCN104806572BLarge flow adjustment rangeLarge adjustment rangePump componentsPumpsImpellerInlet channel

The invention provides an adjustable pump with an adjusting device for changing an impeller inflow direction. The adjustable pump with the adjusting device for changing the impeller inflow direction comprises a driving shaft and an impeller sleeves at the driving shaft; the impeller comprises a fluid inlet channel, and both sides of the impeller are respectively provided with fluid adjusting devices; each of the fluid adjusting device comprises a main gear rotated by taking the driving shaft as an axis, a rotating rod for pushing the main gear to rotate, a secondary gear meshed with the main gear and a water baffle held in the fluid inlet channel of the impeller; the water baffle and the secondary gear are rotated synchronously.

Owner:湖南山水节能科技股份有限公司

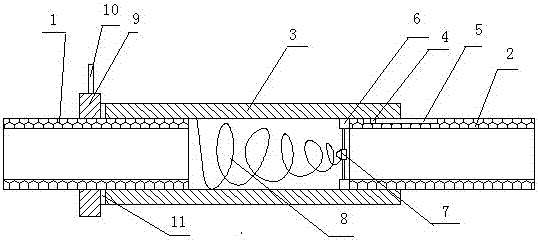

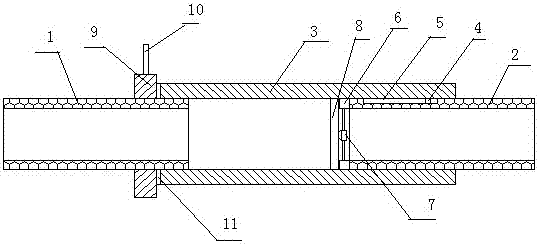

Continuously adjustable throttle valve

PendingCN107883011AGuaranteed fluencyGuaranteed flow effectDiaphragm valvesOperating means/releasing devices for valvesEngineeringStreamflow

The invention relates to the technical field of throttle valve mechanical manufacturing and in particular to a continuously adjustable throttle valve which comprises a water inlet tube and a water outlet tube. The continuously adjustable throttle valve is characterized in that a flow adjusting tube is arranged between the water inlet tube and the water outlet tube; two ends of the flow adjusting tube are connected with the outer sides of the water inlet tube and the water outlet tube in a sleeved manner with a micro gap; a sliding platform is arranged on an inner tube wall connected with the water outlet tube, of the flow adjusting tube; a chute is formed in the water outlet tube; the flow adjusting tube slides on the water inlet tube and the water outlet tube through the sliding platformand the chute; a baffle piece is arranged at the end part of the water outlet tube; the baffle piece consists of an annular piece and a central piece; the annular piece is connected with the central piece through a support rod; a conical spring piece is arranged inside the flow adjusting tube; the opening end of the conical spring piece is arranged at the water inlet end of the flow adjusting tube; and the sharp end of the conical spring piece is connected with the central piece of the baffle piece. The continuously adjustable throttle valve has the advantages of being simple in structure, large in flow adjustment range, smooth in flow pressure difference variation, simple and convenient to operate, and the like.

Owner:荣成市固废综合处理与应用产业园有限公司

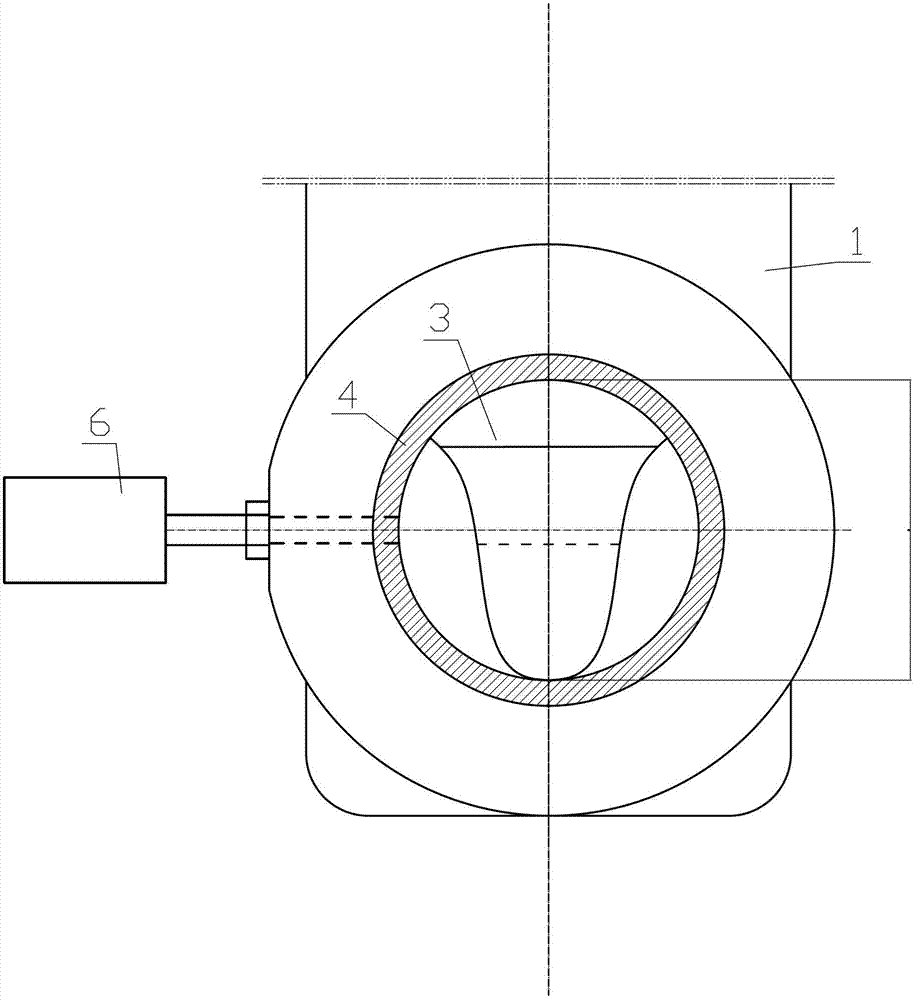

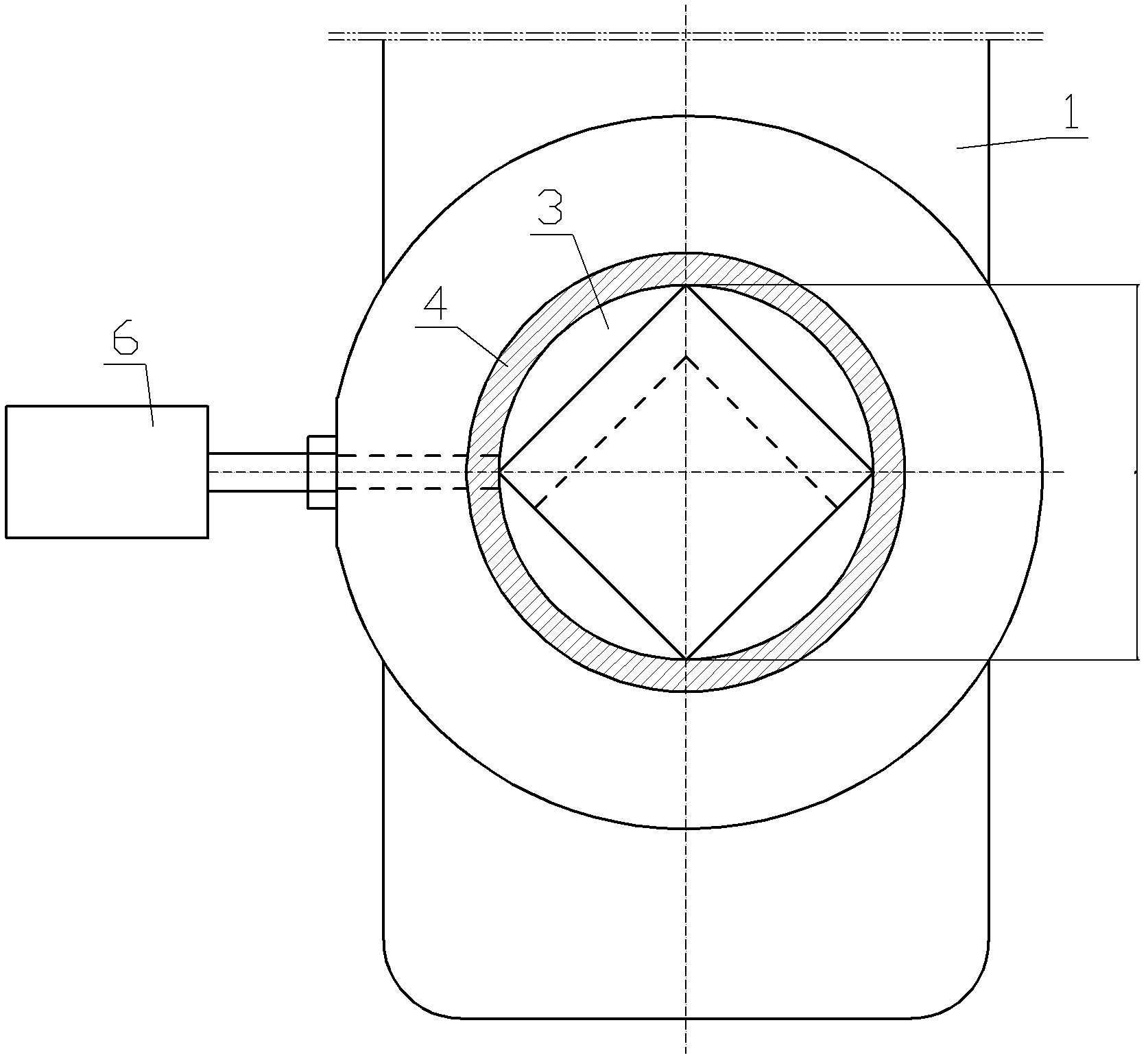

Flow Measurement and Control Device of Rhombus Valve

InactiveCN102287560AMeet the requirements of instant adjustmentSimple structureEqualizing valvesSafety valvesAeration systemDifferential pressure

The invention discloses a flow measurement and control device for a rhombic valve, which includes a valve body and a butterfly plate, and is characterized in that it also includes an air differential pressure transmitter, a pipeline in front of the valve and a pipeline behind the valve, the air differential pressure transmitter The positive pressure interface of the air differential pressure transmitter is connected to the inner cavity of the pipeline in front of the valve through a positive pressure connecting pipe, and the negative pressure interface of the air differential pressure transmitter is connected to the inner cavity of the pipeline behind the valve through a negative pressure connecting pipe. The pipeline in front of the valve is set At the front end of the valve body, the pipeline behind the valve is arranged at the rear end of the valve body. The flow path formed by the valve plate and the valve body is a square, and the two vertices of the square are located at the highest point and the lowest point in the opening and closing direction of the valve plate, and the maximum diagonal length is equal to that of the pipe before the valve or after the valve. pipe inner diameter. The invention has simple, compact and reasonable structure, good stability, large flow adjustment range and high metering accuracy, can fully meet the requirement of the sewage treatment precise aeration system for real-time adjustment of air flow, and has obvious energy-saving effect.

Owner:WUXI GL TUBRO COMPRESSOR

A dual-fluid nozzle based on high-pressure water

The invention provides a dual fluid nozzle based on high-pressure water. The dual fluid nozzle comprises a high-pressure water pipeline and a slurry pipeline. The high-pressure water pipeline is coaxially sleeved with the slurry pipeline, flowing space of the high-pressure water is arranged in the high-pressure water pipeline, and flowing space of slurry is arranged between the slurry pipeline and the high-pressure water pipeline. The slurry pipeline communicates with a slurry inlet. A slurry nozzle is formed in the tail end of the slurry pipeline. The front end of the high-pressure water pipeline is located outside the slurry pipeline and connected with a high-pressure water source. A high-pressure water nozzle is formed in the tail end of the high-pressure water pipeline and located in the slurry nozzle. When the dual fluid nozzle is used, high-pressure water flow in the high-pressure water nozzle collides with the slurry in the slurry nozzle, and the slurry is atomized into fine slurry drops to be sprayed out of the slurry nozzle. The dual fluid nozzle is simple in design structure, large in flow adjustment range, excellent in anti-blocking performance, especially suitable for high-pressure and ultrahigh-pressure environments and capable of solving the problems that in a traditional supercritical water gasification technology, a feeding device is too high in local temperature, and a feeding port is blocked.

Owner:陕西中核交大超洁能源技术有限公司

A two-fluid external mixing nozzle based on high-pressure water

ActiveCN106111377BImprove applicabilityGood anti-blockingLiquid spraying apparatusSpray nozzleWater flow

The invention provides a double-fluid external mixing type nozzle based on high-pressure water. The double-fluid external mixing type nozzle comprises a slurry pipe and multiple high-pressure water pipes. The high-pressure water pipes are arranged outside the slurry pipe in parallel and are evenly distributed in the circumferential direction of the slurry pipe. A slurry nozzle body is formed at the tail end of the slurry pipe. The tail ends of the high-pressure water pipes incline in the axis direction of the slurry pipe and are provided with high-pressure water nozzle bodies. The extending lines of the high-pressure water nozzle bodies intersect with the extending line of the slurry nozzle body. After high-pressure water flow in the high-pressure water pipes is sprayed out obliquely from the high-pressure water nozzle bodies, the high-pressure water flow collides with slurry sprayed out from the slurry nozzle body outside the nozzle, and the slurry is broken and atomized into small slurry drops under the colliding and shearing effects of the high-pressure water flow. The double-fluid external mixing type nozzle based on high-pressure water is particularly suitable for the supercritical water gasifier technology and has the beneficial effects of being good in anti-blockage performance, resistant to corrosion and high temperature and the like.

Owner:陕西中核交大超洁能源技术有限公司

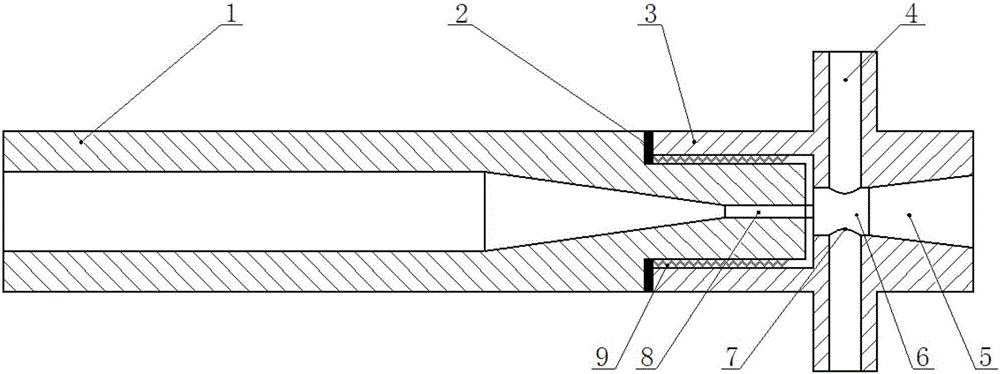

Double-fluid internal mixing type nozzle based on high-pressure water

ActiveCN106082122AImprove applicabilityImprove atomization qualityHydrogen productionCombustible gas productionWater pipeHigh pressure

The invention provides a double-fluid internal mixing type nozzle based on high-pressure water. The double-fluid internal mixing type nozzle comprises a high-pressure water pipe and a connection part; a high-pressure water nozzle is opened in the tail end of the high-pressure water pipe; the front end of the connection part is connected with the tail end of the high-pressure water pipe; a jetting nozzle is opened in the tail end of the connection part; the connection part is internally provided with an internal mixing cavity and a plurality of slurry channels; the axes of the slurry channels are vertically crossed with that of the high-pressure water nozzle; the inner ends of the slurry channels are slurry nozzles; the slurry nozzles and the high-pressure water nozzle are communicated with the internal mixing cavity; the internal mixing cavity is communicated with the jetting nozzle. After high-pressure water flow in the high-pressure water pipe is sprayed out from the high-pressure water nozzle, the high-pressure water flow collides with slurry sprayed out from the slurry nozzle and the slurry is crushed and atomized to form slurry drop under the action of impacting and shearing effects of the high-pressure water flow; and then, the slurry drops are sprayed out from the jetting nozzle. The double-fluid internal mixing type nozzle is simple in design structure and large in flow adjusting range and is especially suitable for high-pressure and ultrahigh-pressure environments.

Owner:陕西中核交大超洁能源技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com