Low-pressure centrifugal coal slurry pump

A centrifugal and coal slurry pump technology, which is applied in the direction of non-variable pumps, pumps, pump components, etc., can solve the problems of harsh use environment, silt blocking and sealing reliability, etc., achieve low price, ensure stability, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

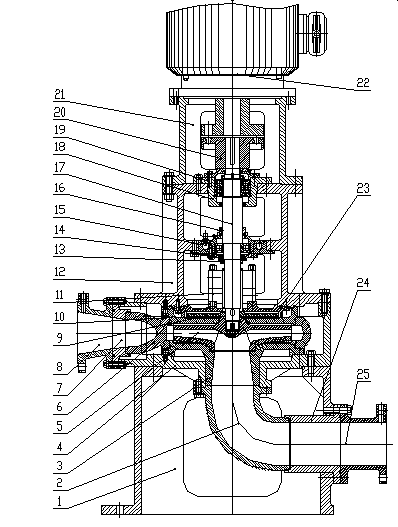

[0011] Below in conjunction with accompanying drawing, the present invention will be further described;

[0012] Low-pressure centrifugal coal slurry pump, the impeller adopts a closed structure, the front and rear cover plates are equipped with blocking impellers, and the impeller sealing ring is canceled to reduce wear, and the blocking impeller of the front cover can effectively reduce the local deposition of coal slurry , The blocking impeller on the back cover can prevent the coal slurry from flowing to the shaft machine seal as much as possible and reduce the pressure on the shaft machine seal, and at the same time can balance part of the axial force. A blocking impeller is installed behind the impeller to more effectively isolate the impeller from the shaft mechanical seal.

[0013] The axial seal of the pump adopts back-to-back double-end mechanical seals, and a blocking guide vane is set in front of the inner mechanical seal to cooperate with the blocking impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com