Conveying device for paste materials

A conveying device and material technology, which is applied in the field of mobile conveying equipment for paste materials, can solve the problems of shaftless screw conveying that cannot change direction, increase cost, and difficulty in equipment installation, so as to realize change, facilitate transfer, and prevent adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

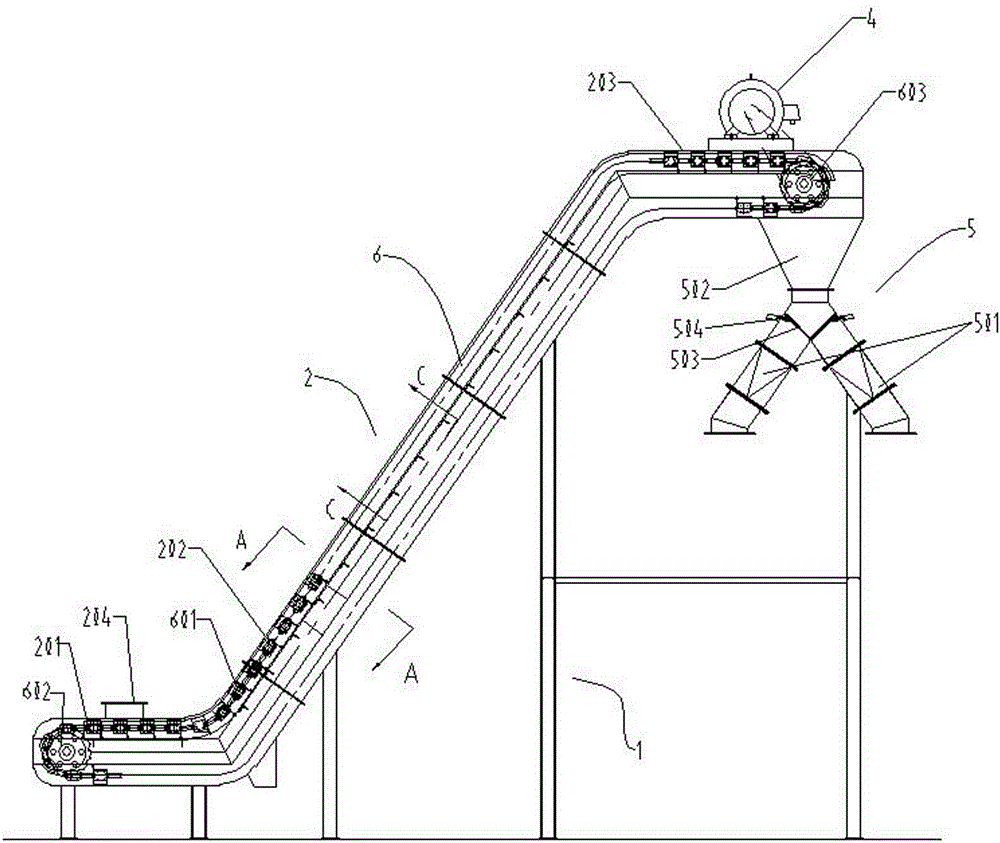

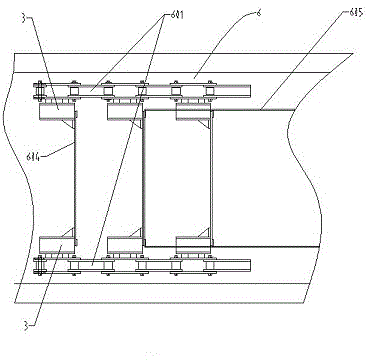

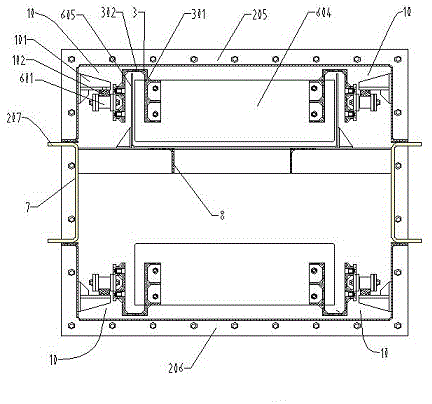

[0036] Examples such as figure 1 , figure 2 , image 3 As shown, the paste material conveying device includes a housing 2, and the housing 2 includes an inclined lifting section 202, the upper end of the lifting section 202 is connected with a horizontally arranged discharge section 203, and the lower end of the lifting section 202 is connected with a horizontally arranged In the feeding section 201, the housing 2 is fixed on the horizontal surface through the frame 1. The internal transmission of the housing 2 is connected with a conveying mechanism 6 for conveying materials. The conveying mechanism 6 runs through the lifting section 202, the discharging section 203 and the feeding section 201. The position on the casing 2 at the discharge section 203 is set as the power mechanism 4 powered by the conveying mechanism 6 .

[0037] The housing 2 is provided with a feed pipe 204 at the position of the feed section 201 , and the housing 2 is provided with a discharge pipe 5 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com