Double-action plunger-type deicing liquid pump

A deicing fluid and plunger pump technology, applied in the field of special pumps, can solve the problems of deicing fluid viscosity reduction and achieve the effects of eliminating flight safety hazards, improving service quality, and increasing the adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

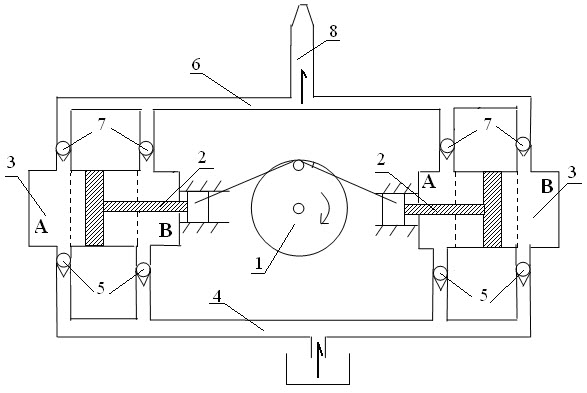

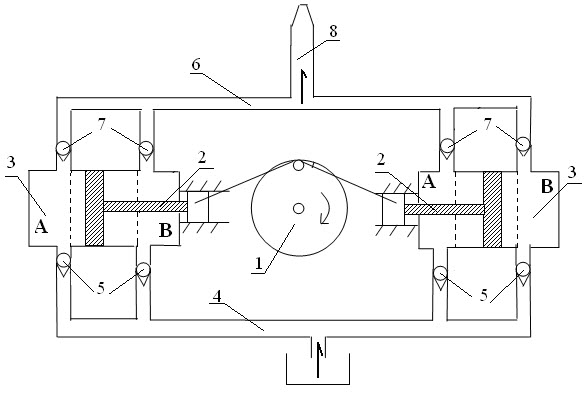

[0009] The structure and working process of the present invention will be described in detail below with reference to the drawings and specific examples. As shown in the figure, the crank connecting rod 1 connects the two plunger pump cylinders 3 with the same structure through the piston 2, and the liquid inlet channel 4 is connected with the liquid inlet check valve 5 on each plunger pump cylinder. The liquid channel 6 is connected with a liquid discharge check valve 7 on each plunger pump cylinder. The outlet of the drainage channel is provided with a spray gun 8. The plunger pump cylinder is divided into two zones, A and B, each zone is equipped with a one-way valve. Considering the corrosion caused by the deicing liquid, the plunger pump cylinder 3, the liquid inlet channel 4, and the liquid discharge channel 6 are made of stainless steel.

[0010] The working process of the dual-pump-in-one plunger deicing fluid pump is: the power source is activated, the crank connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com