Production method of bainite steel with excellent low-temperature impact toughness

A low-temperature impact toughness, bainite steel technology, applied in the direction of improving process efficiency, manufacturing converters, etc., can solve problems such as rail cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0033] A method for producing a bainitic steel rail with excellent low-temperature impact toughness, characterized in that:

[0034] (1) Pretreatment of molten iron by KR method;

[0035] (2) Converter smelting with combined top-bottom blowing, deoxidizer is added during tapping of molten steel in converter smelting, and the amount of deoxidizer added is 1.5-2.0kg / t molten steel;

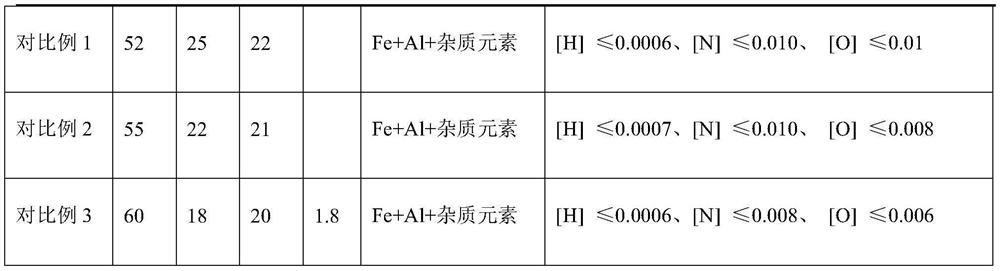

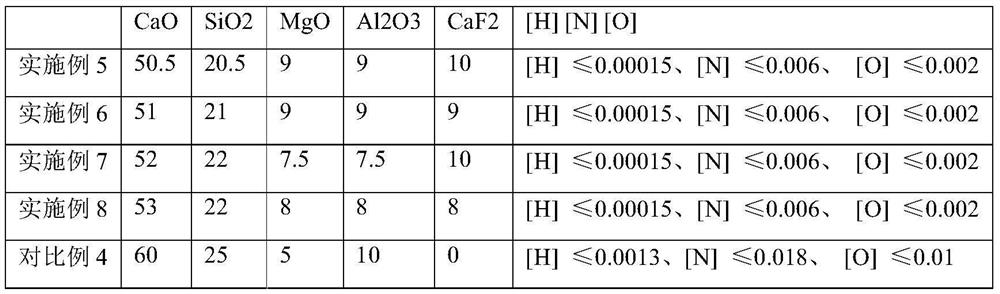

[0036] (3) LF furnace refining, LF furnace adopts specific refining slag, which is CaO 50-53%, SiO2 20-23%, MgO 5-10%, Al2O3 6-10%, CaF2 6-10%, FeO in mass percentage ≤1.5%;

[0037] (4) VD treatment;

[0038] (5) Billet continuous casting, continuous casting adopts full protection pouring;

[0039] (6) Rolling and heat treatment, the soaking temperature of the continuous casting slab is 1260-1310°C, and the holding time is 1-1.5 hours; the rough rolling start temperature is 1100-1150°C, and the rough rolling end temperature is 960-1000°C, The starting temperature of finish rolling is 940-980°C,...

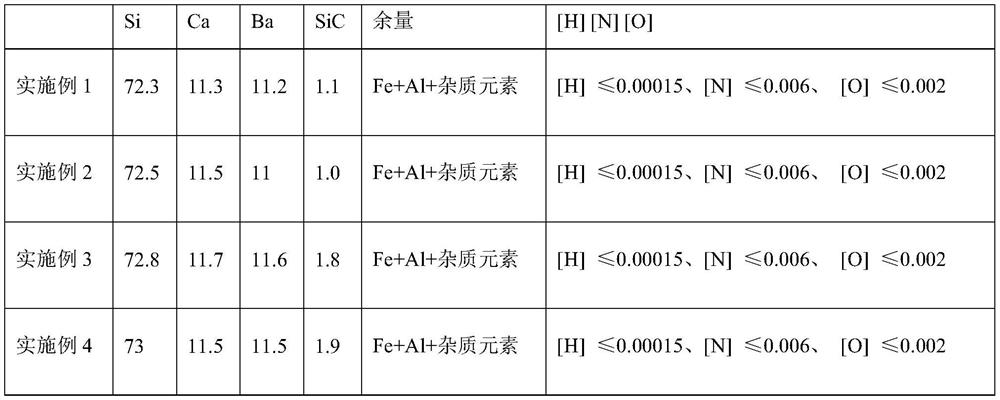

Embodiment 5-8

[0047] A method for producing a bainitic steel rail with excellent low-temperature impact toughness, characterized in that:

[0048] (1) Pretreatment of molten iron by KR method;

[0049] (2) Converter smelting with top-bottom combined blowing, deoxidizer is added during tapping of molten steel in converter smelting, and deoxidizer contains Si 72-73%, Ca 11-12%, Ba 11-12%, SiC 1- 2%, the balance is Fe+Al+impurity elements, and the amount of deoxidizer added is 1.5-2.0kg / t molten steel;

[0050] (3) LF furnace refining;

[0051] (4) VD treatment;

[0052] (5) Billet continuous casting, continuous casting adopts full protection pouring;

[0053] (6) Rolling and heat treatment, the soaking temperature of the continuous casting slab is 1260-1310°C, and the holding time is 1-1.5 hours; the rough rolling start temperature is 1100-1150°C, and the rough rolling end temperature is 960-1000°C, The starting temperature of finish rolling is 940-980°C, the end temperature of final roll...

Embodiment 9

[0061] A method for producing a bainitic steel rail with excellent low-temperature impact toughness, characterized in that:

[0062] (1) Pretreatment of molten iron by KR method;

[0063] (2) Converter smelting with top-bottom combined blowing, deoxidizer is added during tapping of molten steel in converter smelting, and deoxidizer contains Si 72-73%, Ca 11-12%, Ba 11-12%, SiC 1- 2%, the balance is Fe+Al+impurity elements, and the amount of deoxidizer added is 1.5-2.0kg / t molten steel;

[0064] (3) LF furnace refining, LF furnace adopts specific refining slag, which is CaO 50-53%, SiO2 20-23%, MgO 5-10%, Al2O3 6-10%, CaF2 6-10%, FeO in mass percentage ≤1.5%;

[0065] (4) VD treatment;

[0066] (5) Billet continuous casting, continuous casting adopts full protection pouring;

[0067] (6) Rolling and heat treatment, the soaking temperature of the continuous casting slab is 1260-1310°C, and the holding time is 1-1.5 hours; the rough rolling start temperature is 1100-1150°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com