Double-fluid internal mixing type nozzle based on high-pressure water

A high-pressure water, two-fluid technology, applied in the production of hydrogen, the manufacture of combustible gas, the petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

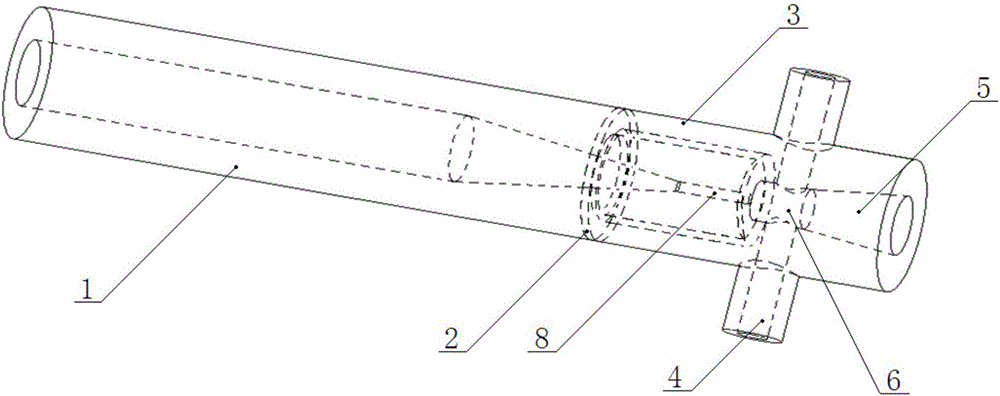

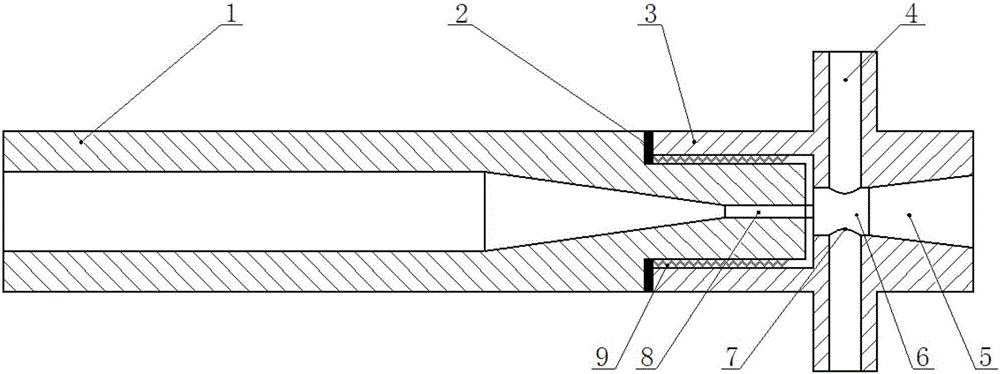

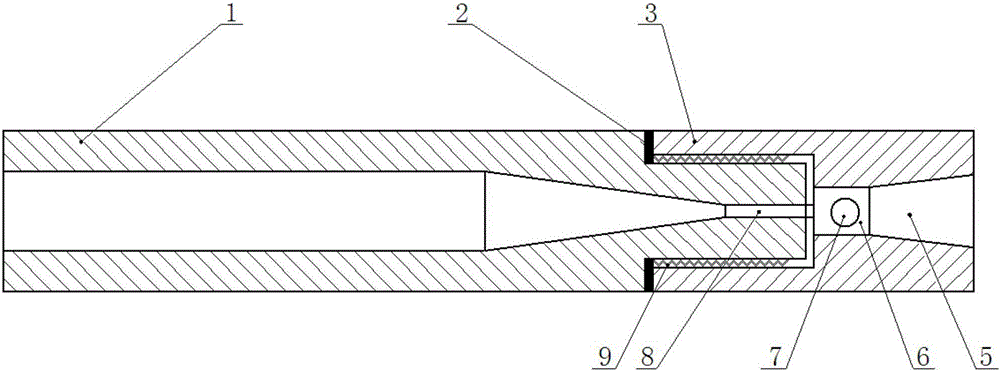

[0022] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] refer to Figure 1 to Figure 4 , The dual-fluid internal mixing nozzle based on high-pressure water provided by the present invention includes a high-pressure water pipe 1 and a connecting piece 3, both of which are made of high-temperature-resistant and corrosion-resistant alloy materials. The front end of the high-pressure water pipe 1 is connected with the high-pressure water pump, and the end of the high-pressure water pipe 1 is provided with a high-pressure water nozzle 8; a water flow control device for realizing intermittent injection of high-pressure water is arranged between the front end of the high-pressure water pipe 1 and the high-pressure water pump; Inner diameter structure, the front section of the inner cavity of the high-pressure water pipe 1 is a relatively thick cylinder, and the end section is a high-press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com