Middle discharge section of multi-outlet horizontal single-suction segmental multi-stage centrifugal pump

A multi-outlet and segmental technology, applied in the field of centrifugal pumps, can solve the problems of energy consumption and non-energy saving, and achieve the effect of good flow state, large diameter and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

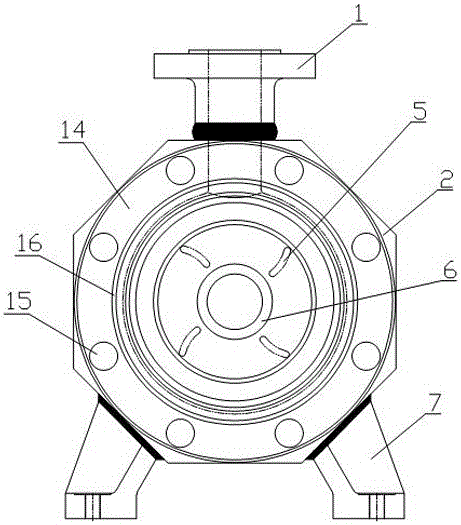

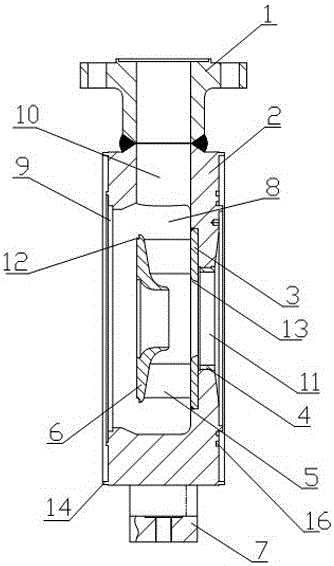

[0026] exist figure 1 , figure 2 In the shown embodiment, the middle discharge section of the multi-outlet horizontal single-suction segmental multistage centrifugal pump is arranged between the middle section of the multistage pump and respectively connected with the upper stage impeller and the next stage of the multistage pump. Stage impeller connection, including discharge flange 1, discharge section 2, support bottom plate 3, sealing ring 4, deswirling flow guide vane 5, support plate 6 and discharge section leg 7, discharge section 2 is fixed on the discharge section leg 7 , the shape of the discharge section 2 is set in a regular hexagonal structure, the two ends of the discharge section 2 are respectively provided with connecting flanges 14, and the connecting flange 14 is provided with a sealing structure 15 and a connecting structure 16. A pressurized water chamber 8 with an annular structure is arranged inside the discharge section 2, and an inlet 9, an outlet 10,...

Embodiment 2

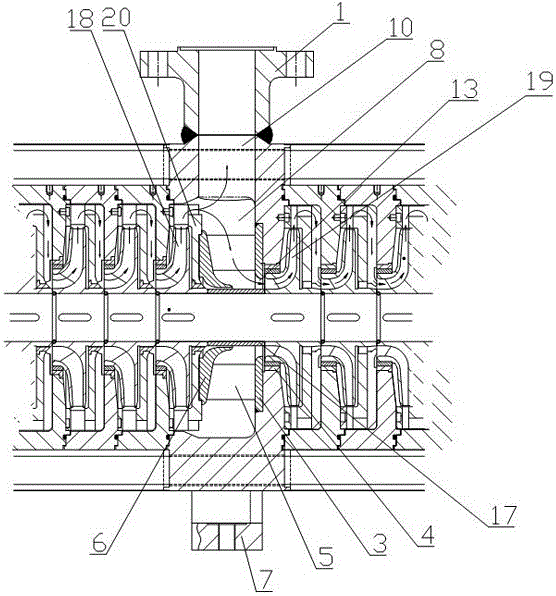

[0032] The middle discharge section of the multi-outlet horizontal single-suction segmental multistage centrifugal pump shown in Embodiment 2 is basically the same as that in Embodiment 1, except that the shape of the discharge section 2 is set in a cylindrical structure, and the discharge A pressure water chamber 8 with a spiral structure is arranged inside the section 2, and the deswirling flow guide vane 5 has a straight plate structure, and 7 deswirling flow guide vanes 5 are provided.

[0033] For the middle discharge section of the multi-outlet horizontal single-suction segmental multi-stage centrifugal pump shown in the above embodiment, the middle outlet section can be easily installed into any stage in the middle of the horizontal single-suction segmental multi-stage pump. It can output the pressure and part of the flow of the impeller in front of it with the minimum loss, and can smoothly input the remaining flow to the impeller of the next stage to continue to pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com