A microfluidic valve and a microfluidic control method thereof

A microfluidic and microfluidic technology, applied in valve devices, mechanical equipment, engine components, etc., can solve the problem of inability to have both microfluidic low-cost, accurate flow and on-off operation control functions, inability to use fluids, and inability to use fluids. Real-time motion and cut-off control, etc., to achieve the effects of easy miniaturization integration, low threshold pressure, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

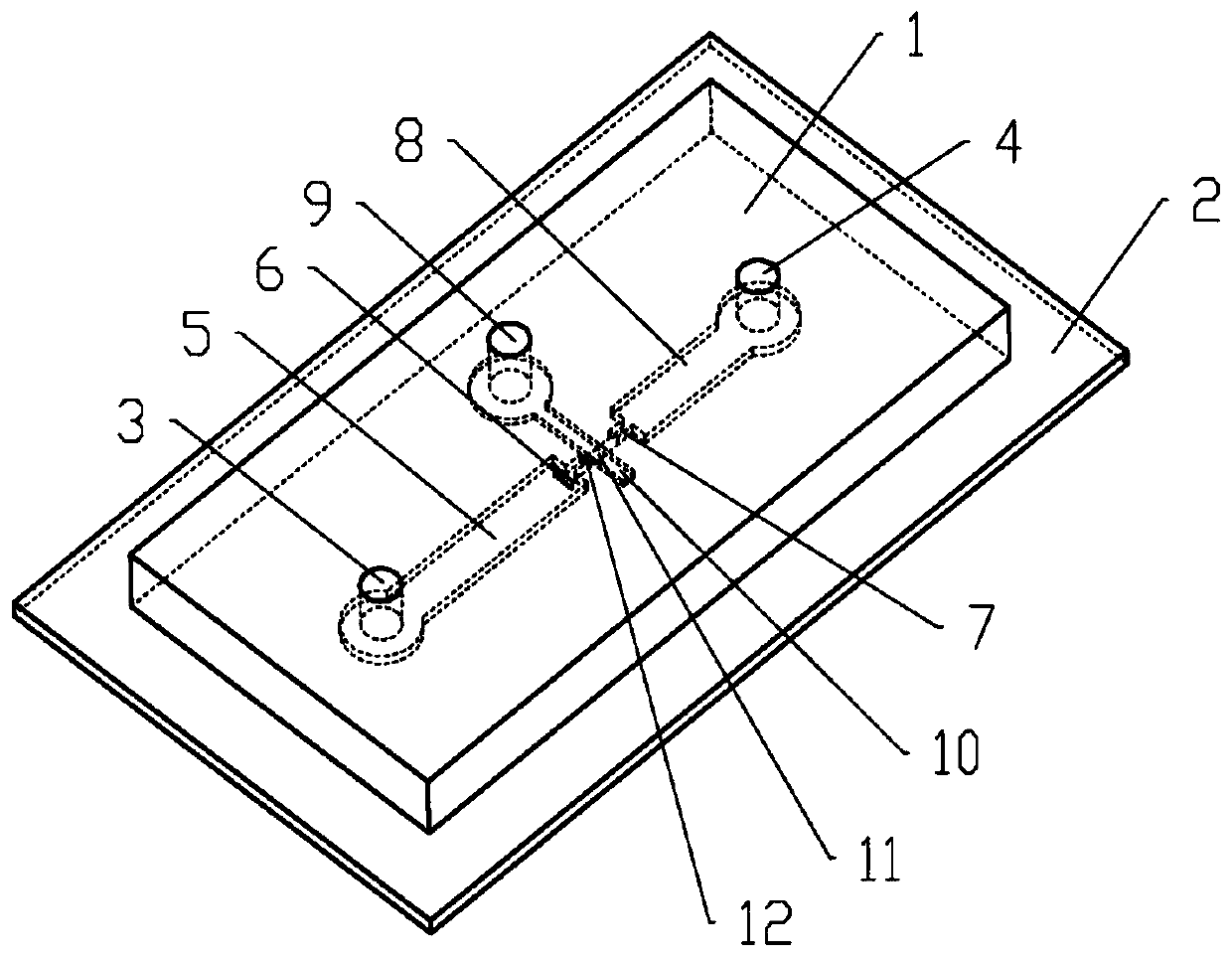

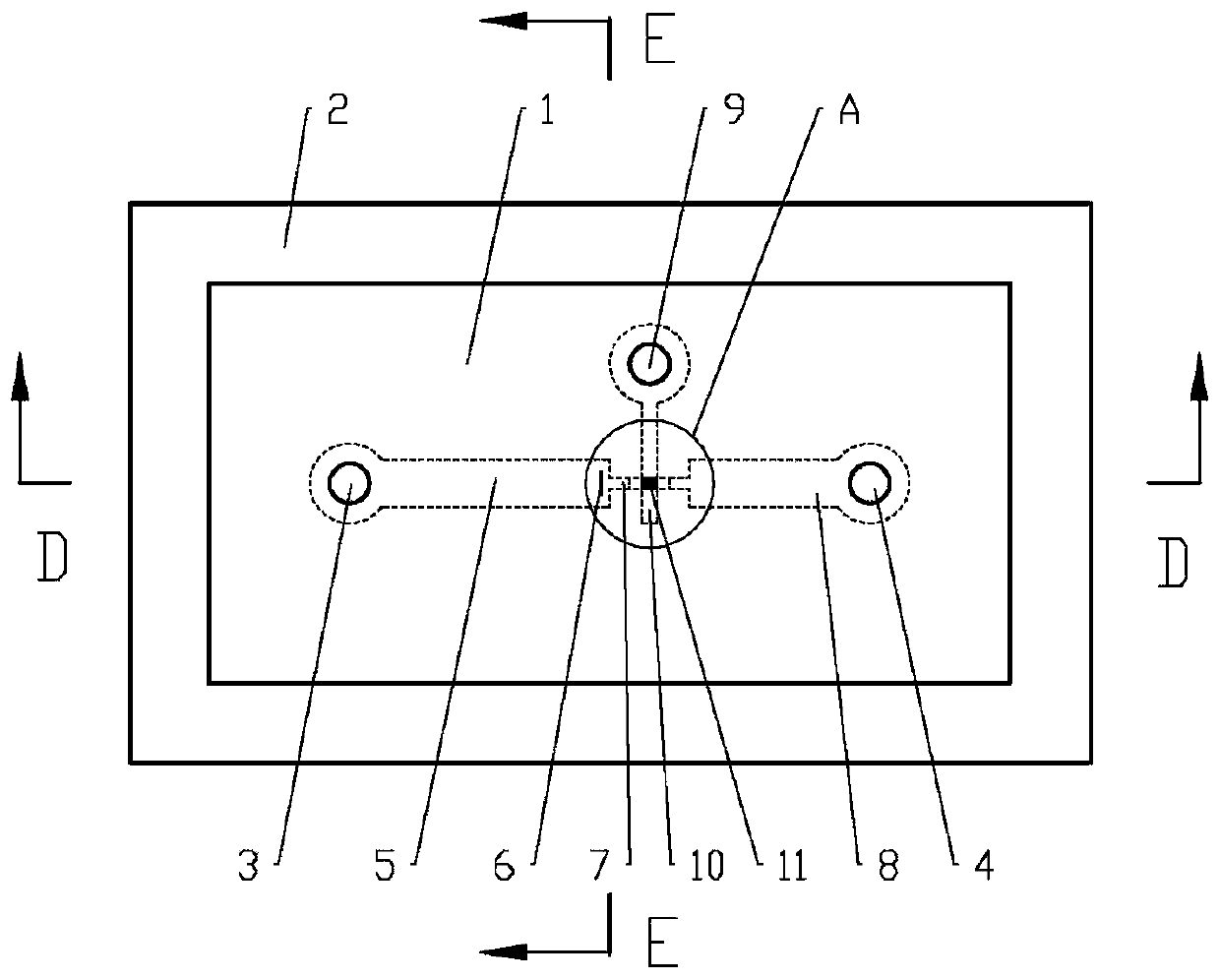

[0036] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

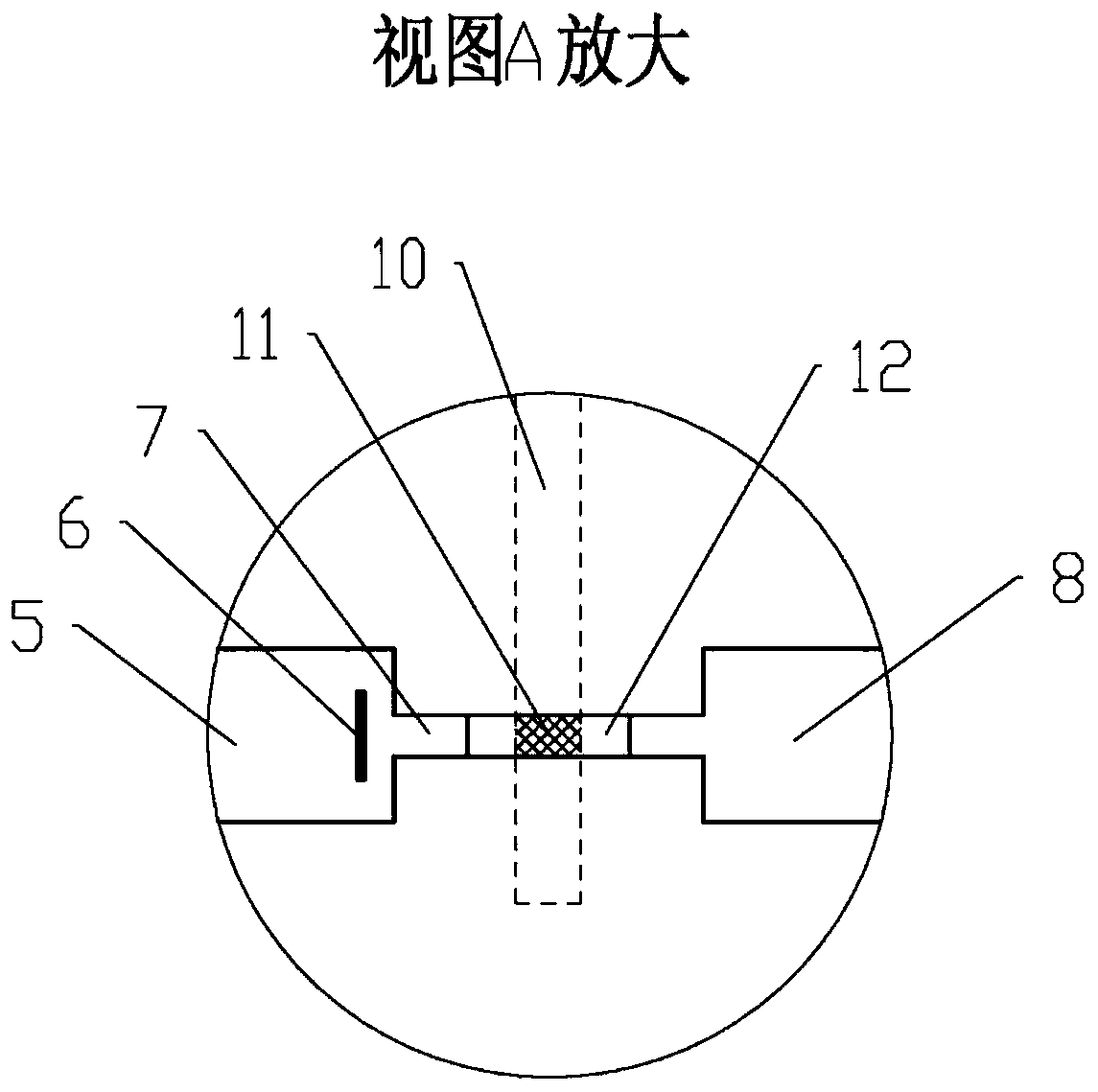

[0037] A microfluidic control valve in the present invention uses the lateral deformation of the flow regulating film 6 in the inlet main channel 5 to be impacted by the liquid to adjust the microfluid entering the contraction channel 7, and automatically adjusts the flow resistance of the microvalve and compensates The change of inlet liquid pressure achieves the purpose of precise control of microfluidic flow. At the same time, the cut-off film 11 in the control flow channel 10 is subjected to the pressure of the compressed gas to make the film elastically deform, close to and close the curved surface flow channel 12, and realize the cut-off control of the microfluid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com