V-shaped valve for measuring and controlling flow

A flow measurement and valve plate technology, which is applied to safety valves, balance valves, valve devices, etc., can solve problems such as the inability to meet the accuracy of flow control in precise aeration systems, poor linearity of air conditioning, and failure to meet energy-saving requirements. To achieve the effect of good air conditioning linearity, large flow adjustment range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with accompanying drawing:

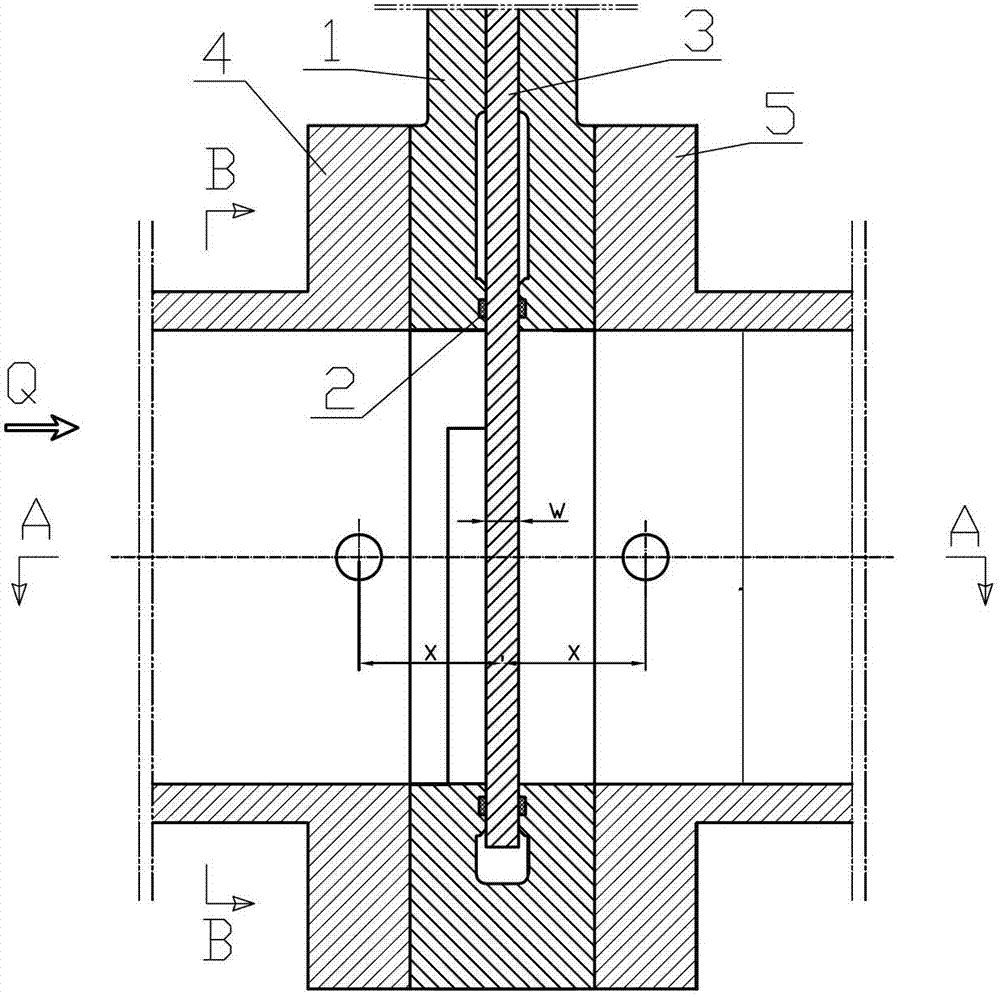

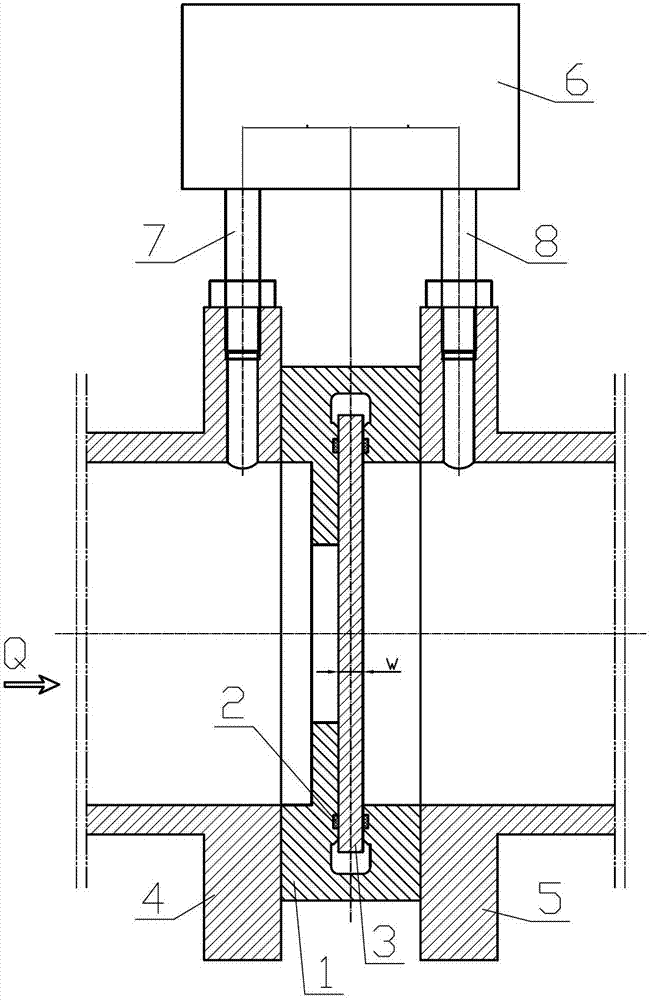

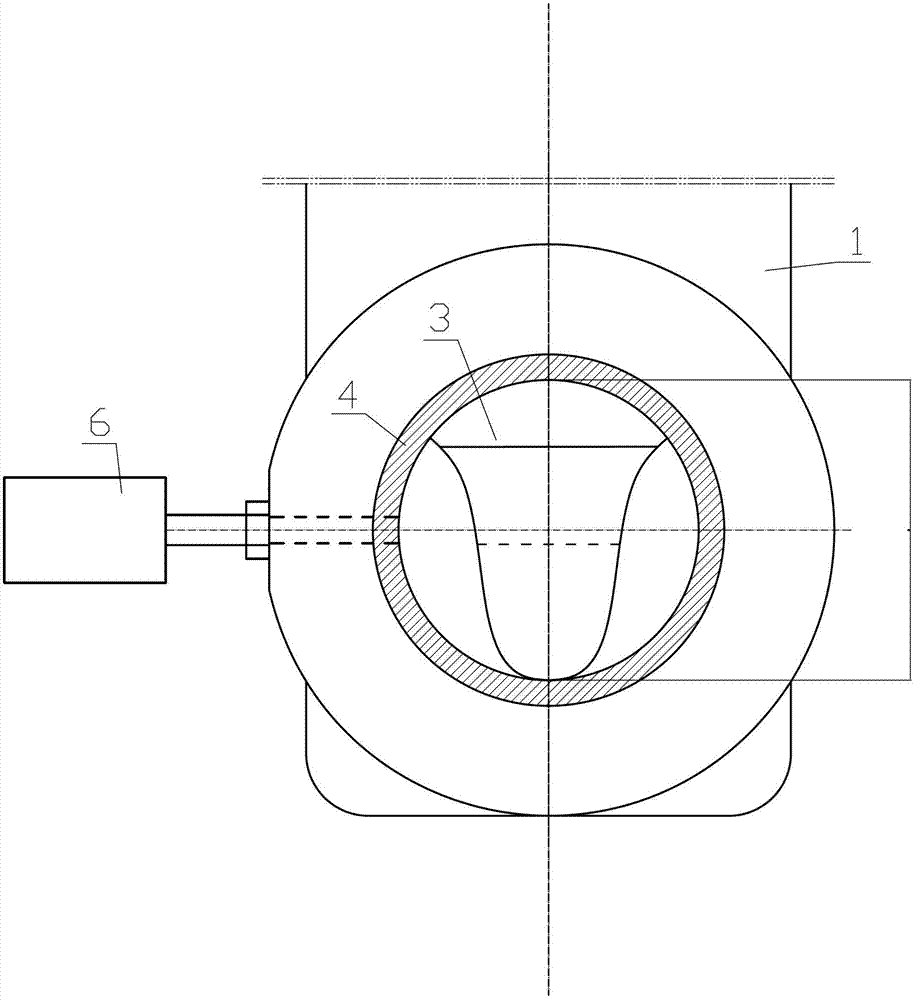

[0016] Such as figure 1 , figure 2 , image 3 As shown: it includes valve body 1, sealing ring 2, valve plate 3, valve front pipe 4, valve rear pipe 5, air differential pressure transmitter 6, positive pressure connecting pipe 7, negative pressure connecting pipe 8, etc.

[0017] The valve body 1 is equipped with a valve plate 3 , and a sealing ring 2 is arranged on the valve body 1 . The positive pressure interface of the air differential pressure transmitter 6 is connected to the inner cavity of the pipeline 4 before the valve through the positive pressure connecting pipe 7, and the negative pressure interface of the air differential pressure transmitter 6 is connected to the valve after the valve through the negative pressure connecting pipe 8. The inner cavity of the pipeline 5 is connected, the pipeline 4 before the valve is arranged at the front end of the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com