Solid rocket ramjet engine gas flow adjusting device

A technology of gas flow regulation and ramjet, which is applied to rocket engine devices, ramjet engines, combined engines, etc., and can solve the problem that it is difficult to adjust the gas flow in a large range, the self-regulation method cannot meet the requirements, and the range of self-regulation is limited and other problems, to achieve the effect of light weight, small working error and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

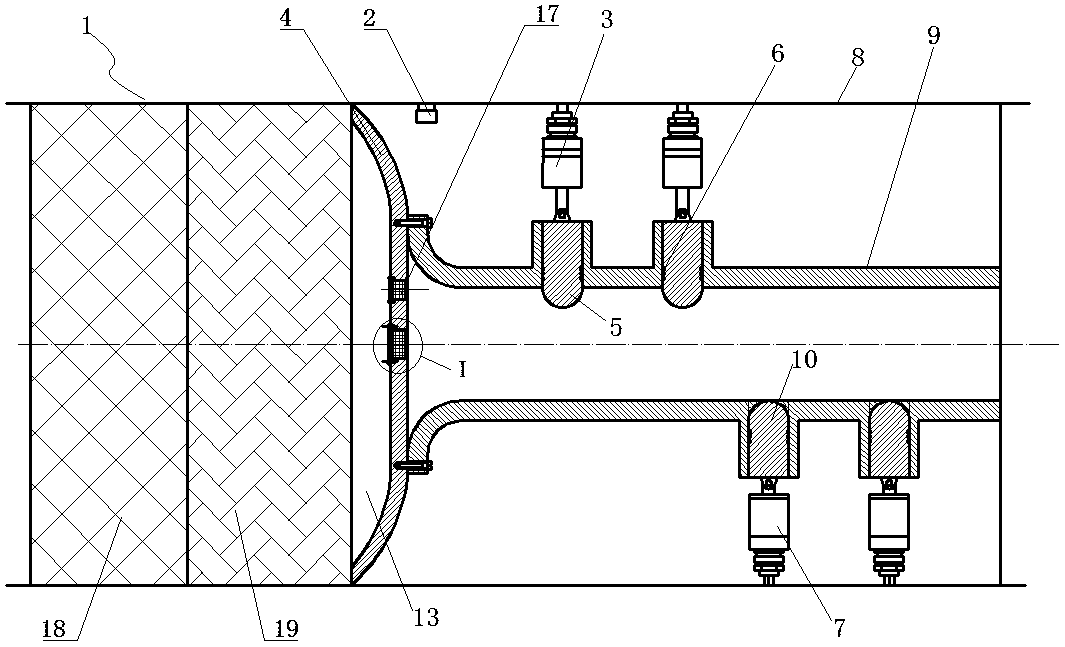

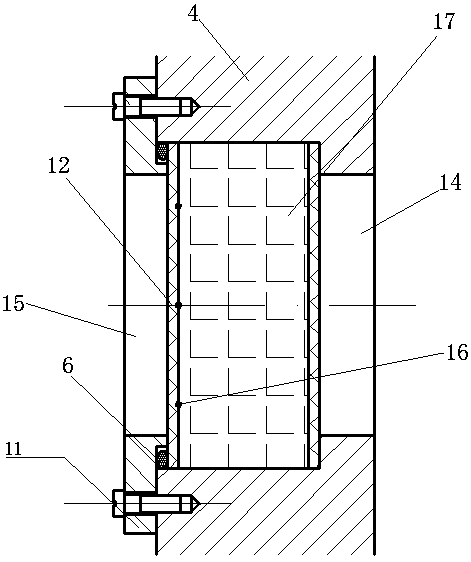

[0044] like Figure 1~5 As shown, a solid rocket ramjet gas flow regulating device includes a main controller, a hollow body 8, a gas generator 1 arranged in the body 8, and the gas generator 1 and the gas generator 1 are arranged in the body 8. The nozzle connected to the supplementary combustion chamber, the nozzle includes a sealing plate 4 sealing the fuel chamber 13 of the gas generator 1, a hollow pipe body 9 sealingly connected with the sealing plate 4, and the axis of the pipe body 9 is perpendicular to the sealing plate 4 .

[0045] The fuel chamber 13 is provided with a low burning rate solid fuel 18 and a high burning rate solid fuel 19 in sequence, and the high burning rate solid fuel 19 is close to the sealing plate 4 .

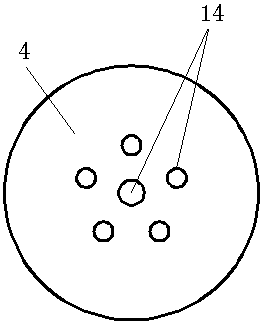

[0046] A light hole is provided on the wall of the tube body 9 perpendicular to the axial direction of the tube body 9 . The light hole includes at least one first through hole and at least one second through hole. The first through hole is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com