Patents

Literature

97results about How to "Reduce working errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

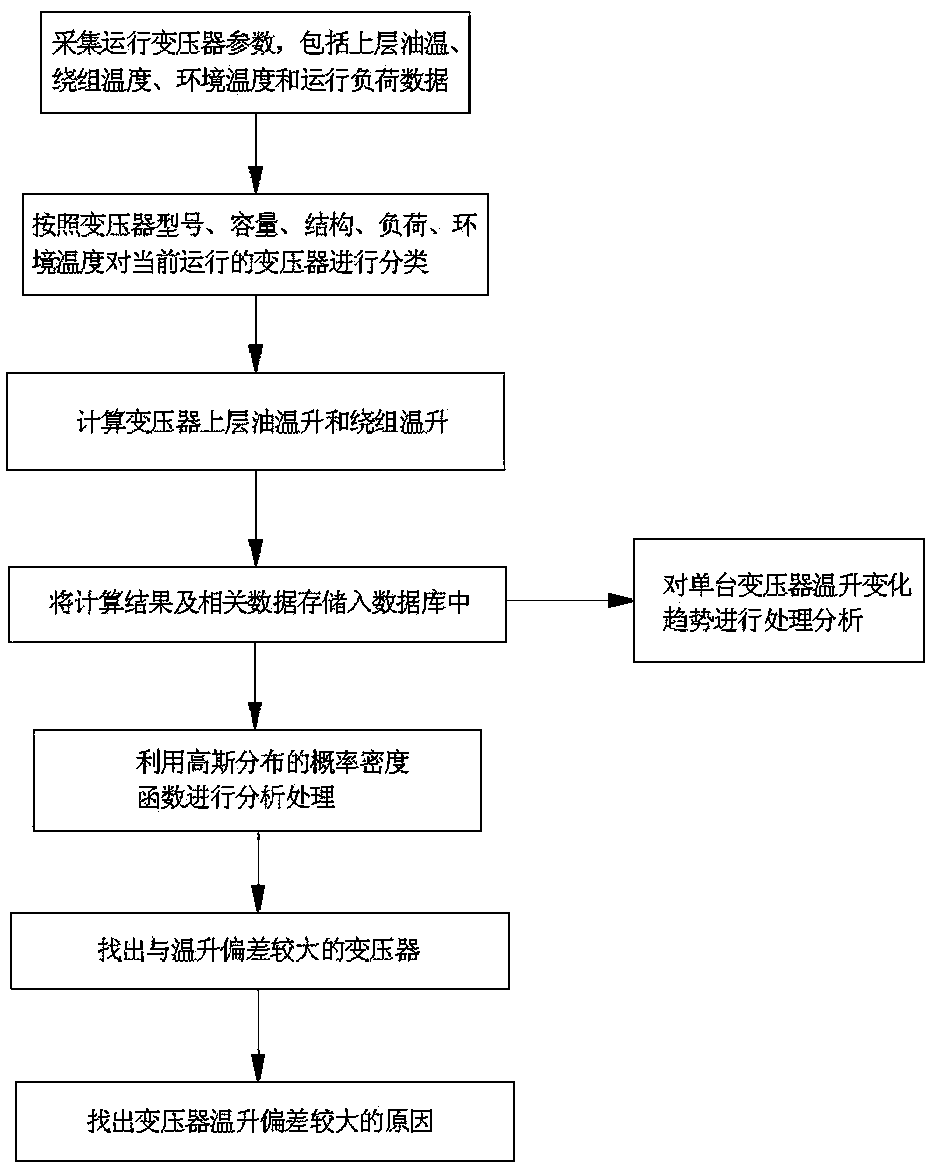

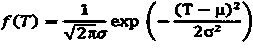

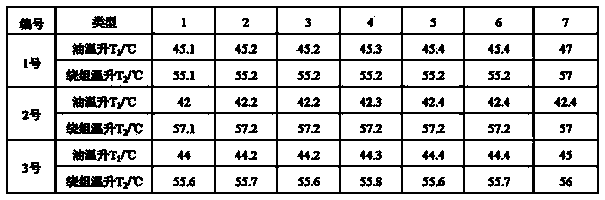

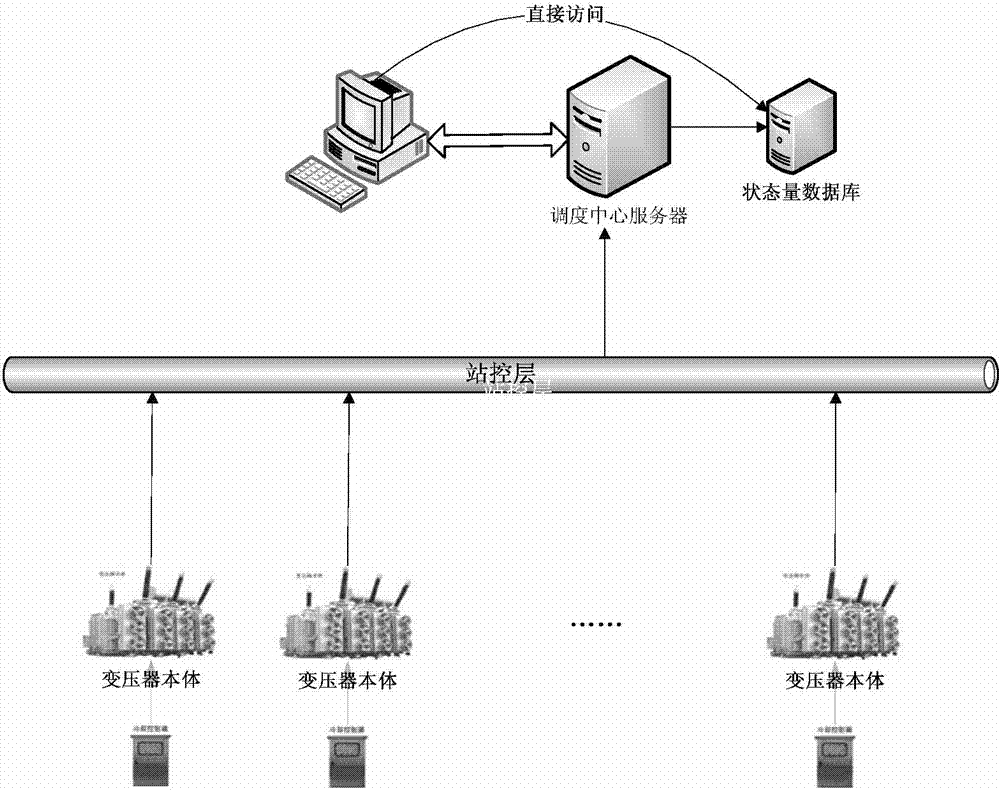

Transformer temperature rise abnormity monitoring and diagnosis method based on probability statistics

ActiveCN103592545ASolve the problem of evaluating abnormal temperature riseLoad capacity assessmentElectrical testingCapacitanceThermodynamics

The invention discloses a transformer temperature rise abnormity monitoring and diagnosis method based on probability statistics. Operation parameters of transformers are collected, wherein the transformers work with the same model, the same capacitance, the same structure, the same load and the same environmental temperature. The operation parameters comprise upper-layer oil temperature, winding temperature, environmental temperature and operation load data, the upper-layer oil temperature rise and the winding temperature rise of the transformers are calculated out, the method of probability statistics is used for processing two difference values and the transformer with a larger temperature difference is found out and determined as abnormal. Sequentially, the transformer is analyzed and the transformer which dissipates heat abnormally is found out. The application range is wide and the transformer temperature rise abnormity monitoring and diagnosis method is applicable to transformers of different voltage classes and different cooling manners. The transformer temperature rise abnormity monitoring and diagnosis method is high in reliability, low in cost and capable of carrying out real-time calculation with normal computers. Involvement of working personnel is relieved, working errors are reduced and the working efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

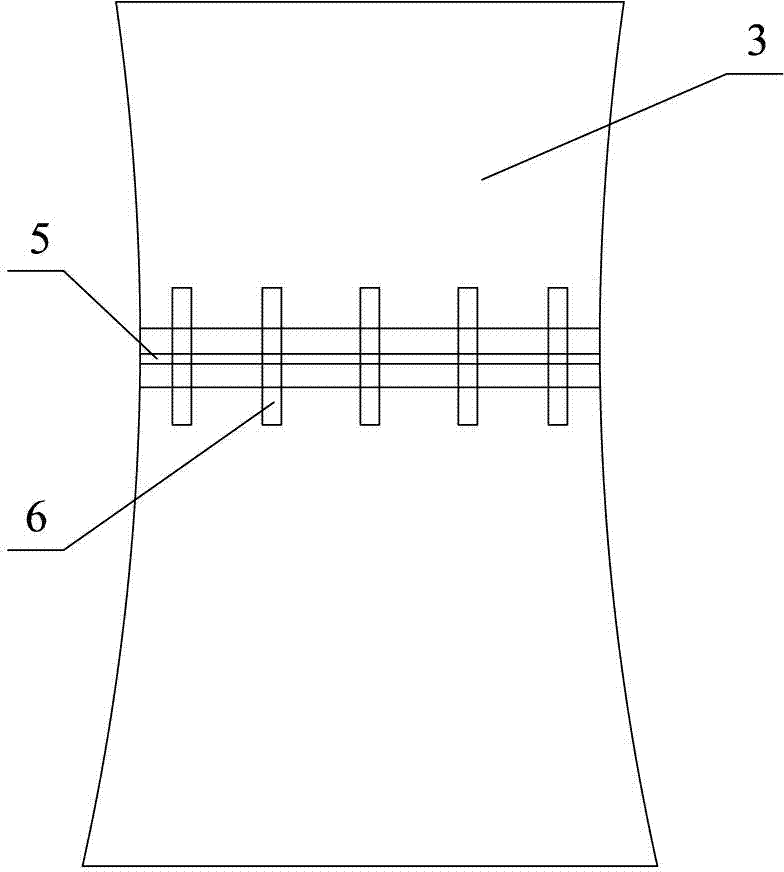

Radiographic testing method for welding beams under radioactive environment of nuclear power station

InactiveCN102759537AQuality improvementControlled absorbed doseMaterial analysis by transmitting radiationImaging qualityNuclear power

The invention relates to a radiographic testing method for welding beams under the radioactive environment of a nuclear power station. The radiographic testing method is used for testing the welding seams through rays under the radioactive environment. The radiographic testing method comprises three stages of preparation, operation and after-treatment, wherein the preparation of a tag system, the assembly of a hidden bag system, the debugging of an exposure system, the manufacture of an auxiliary accessory system and the budgeting of a data computing system are involved in the preparation stage; in the operation stage, a lead rule and a tag identification label are connected near the welding seams to locate the welding seams, the hidden bag system is fixed so as to cover the welding seams, and a spherical center exposure method or a central exposure method or a double-wall single image exposure method or a double-wall double-image exposure method is adopted for imaging on a photographic film; and in the after-treatment stage, the photographic film is processed into a negative film, and the negative film is evaluated. The radiographic testing method has the advantages that the working procedures and tools in the traditional radiographic testing processed are optimized, the accuracy is high, less time is consumed, the imaging quality is high, and the transillumination risk of workers in a high radiation region is effectively reduced.

Owner:CGNPC INSPECTION TECH +2

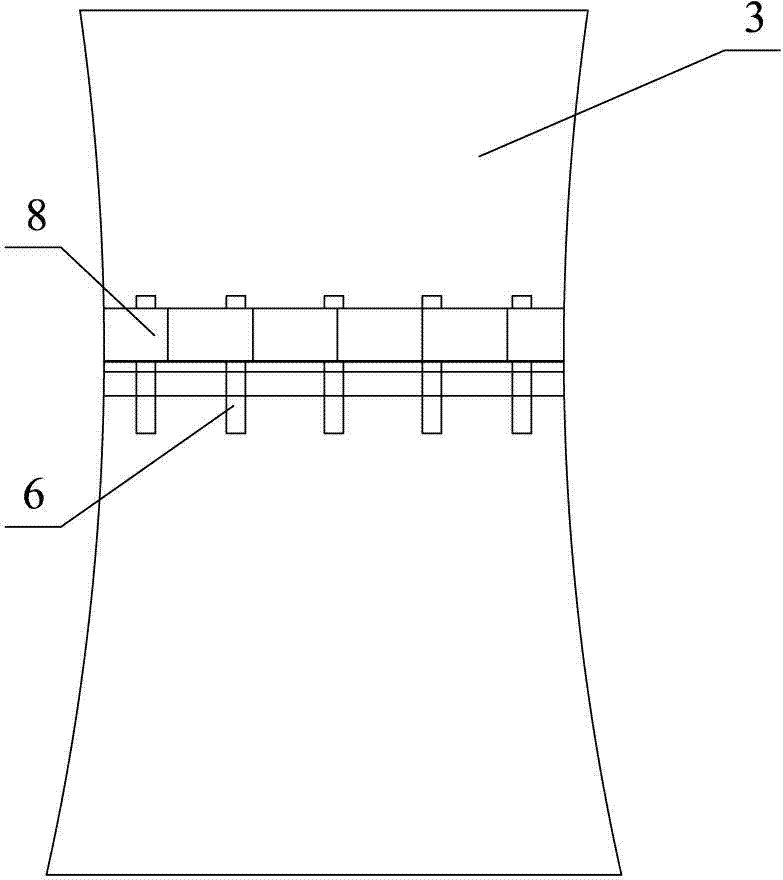

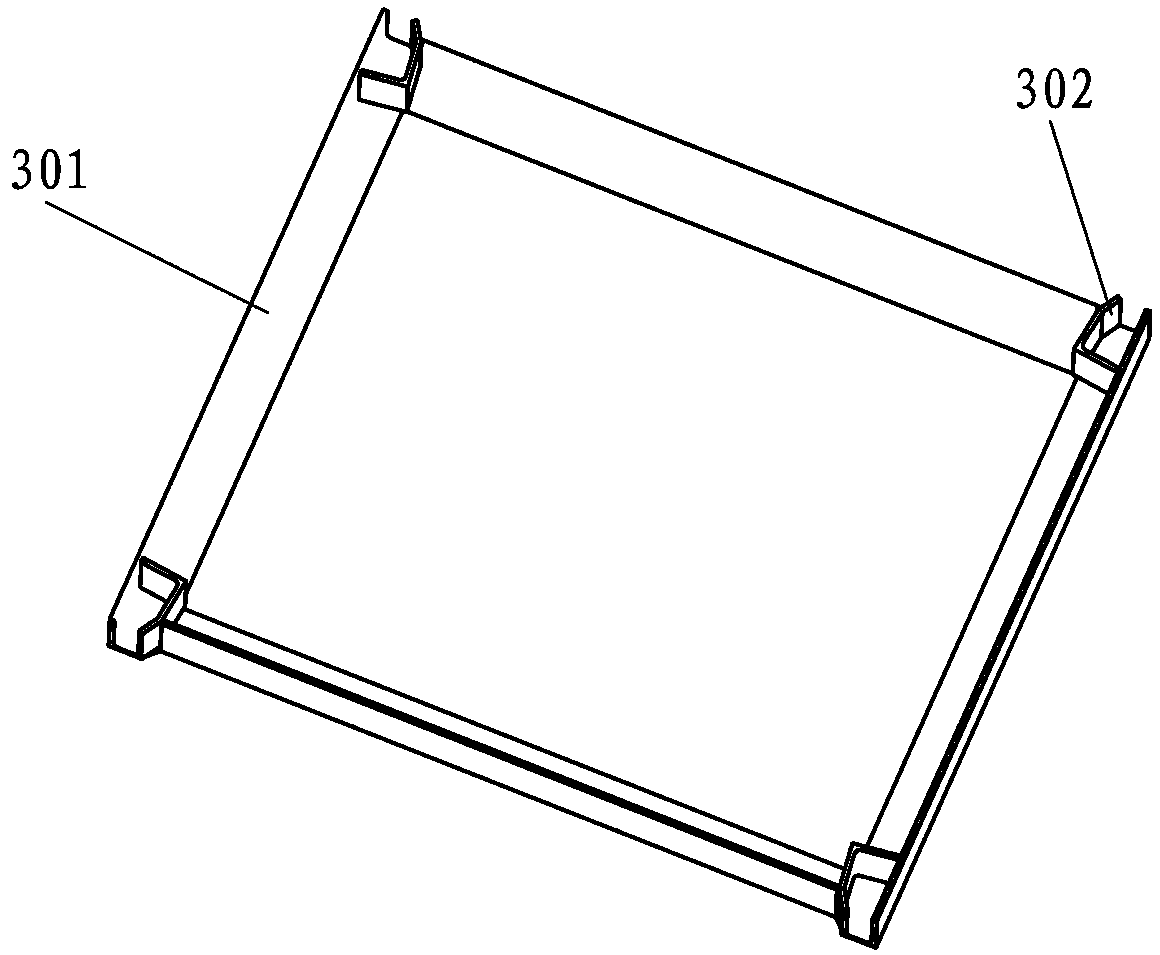

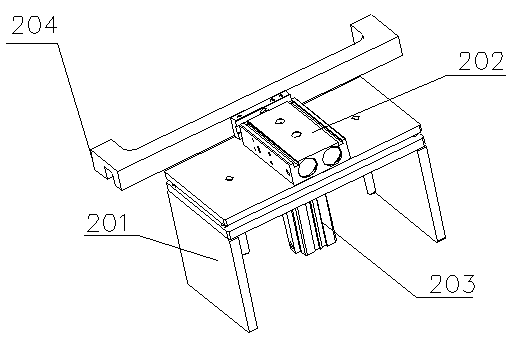

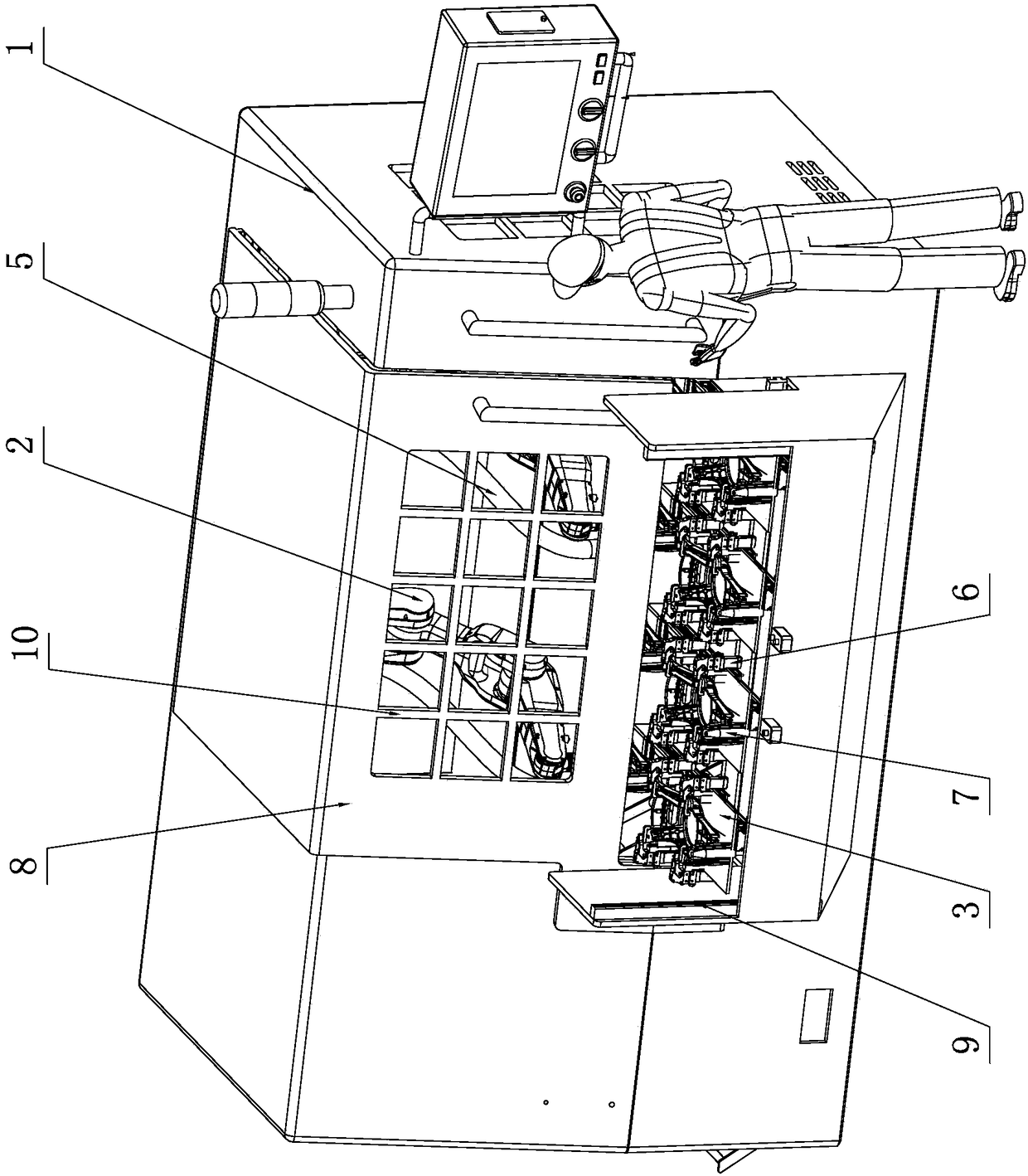

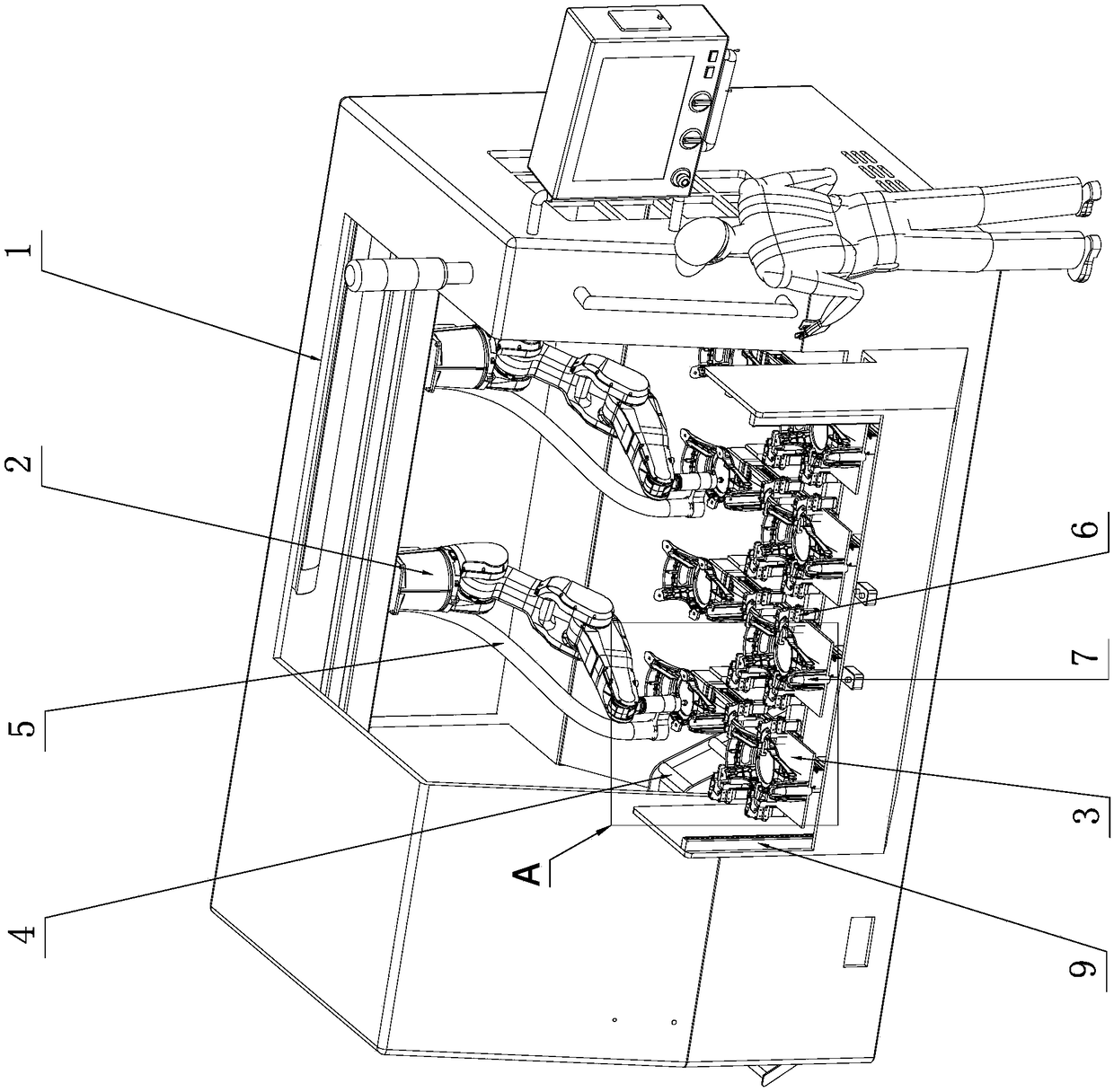

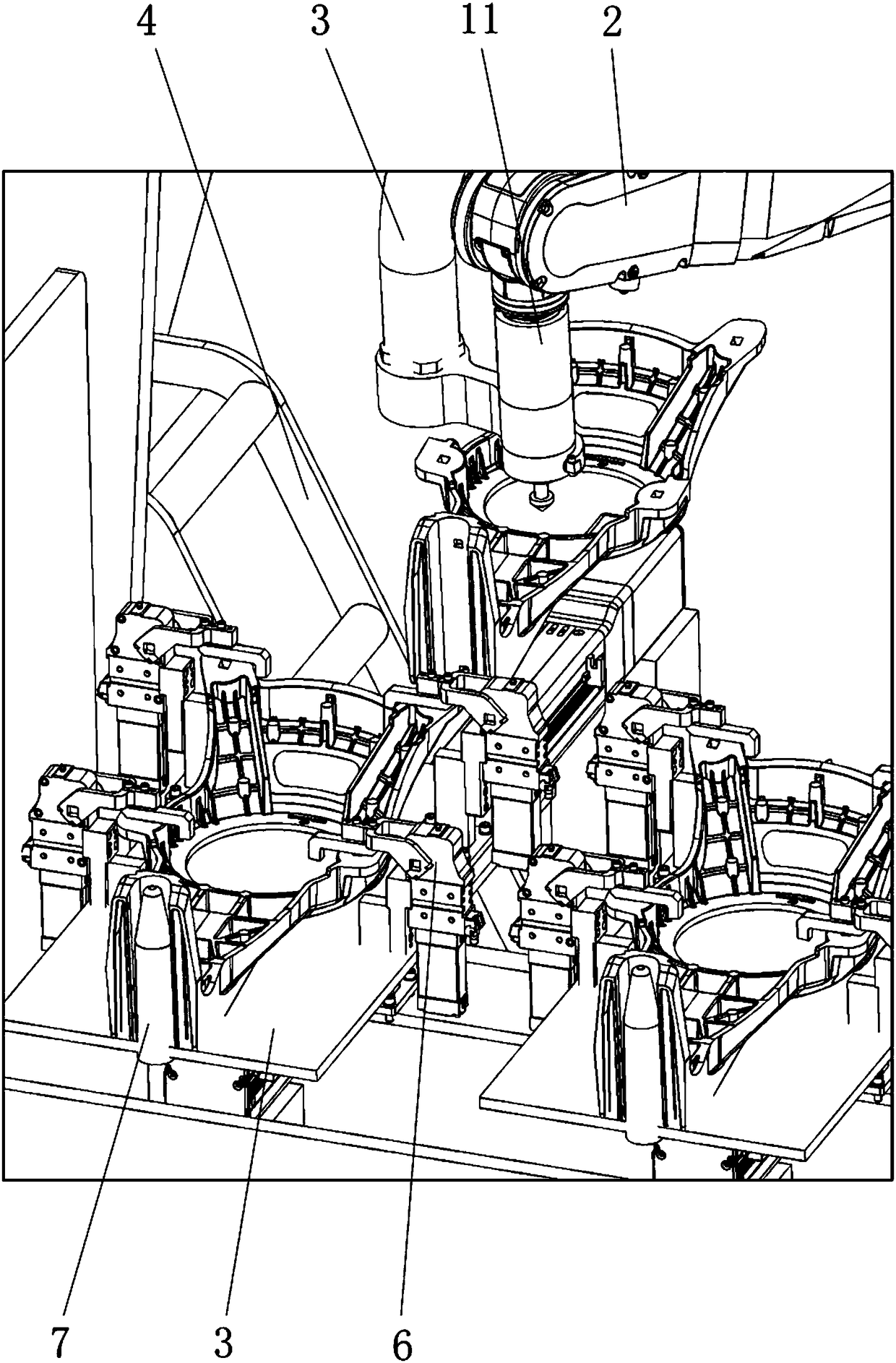

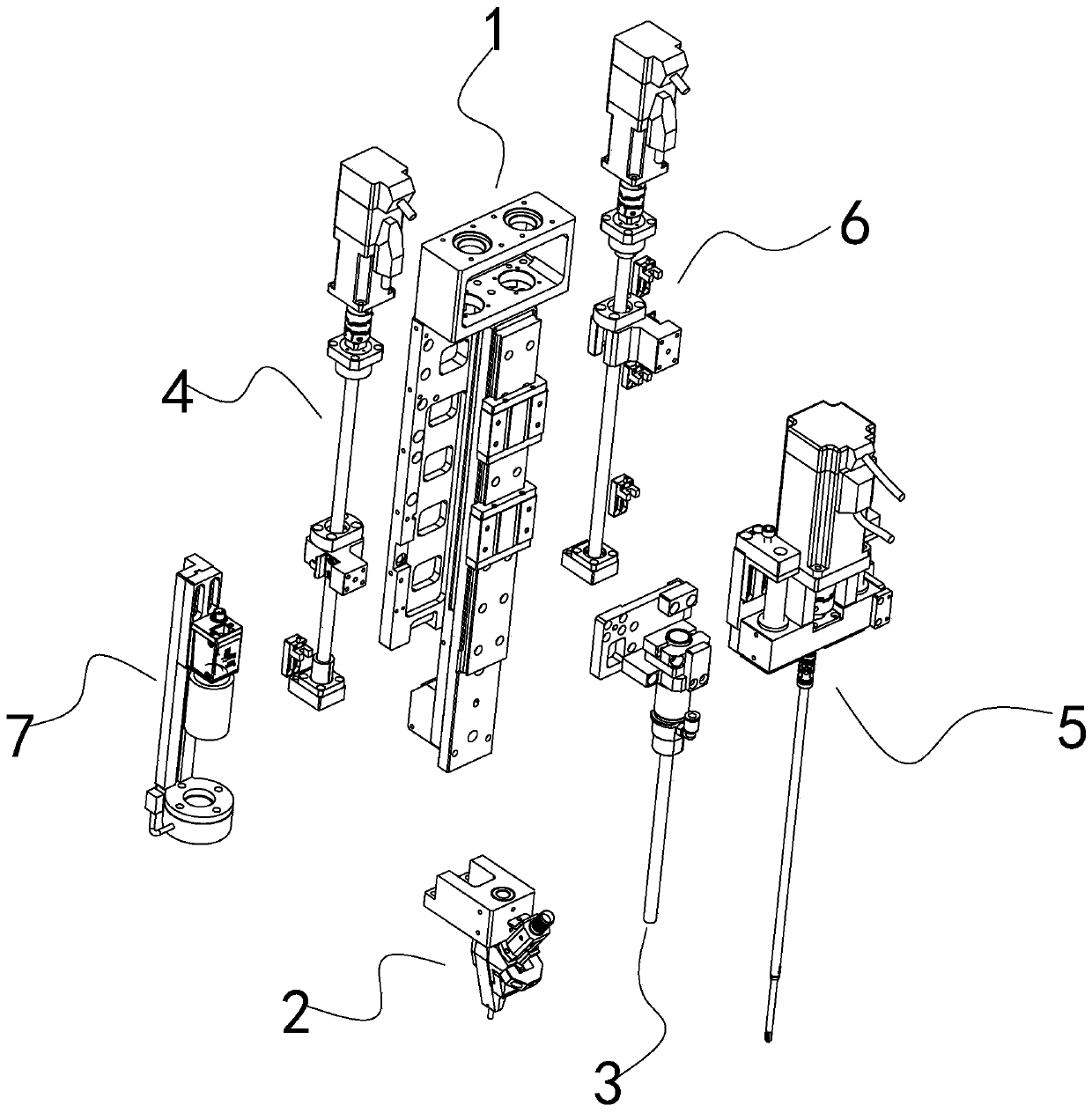

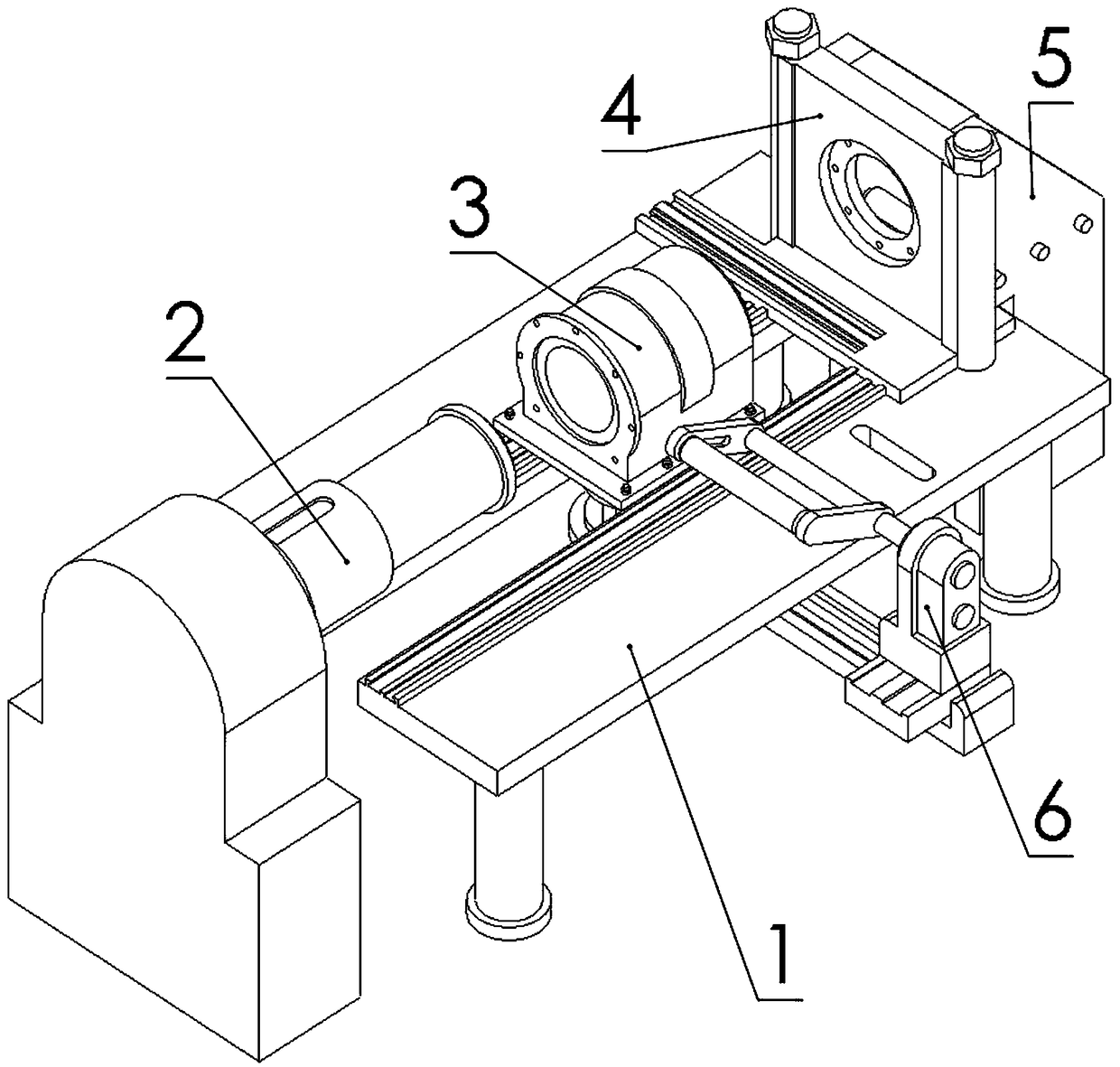

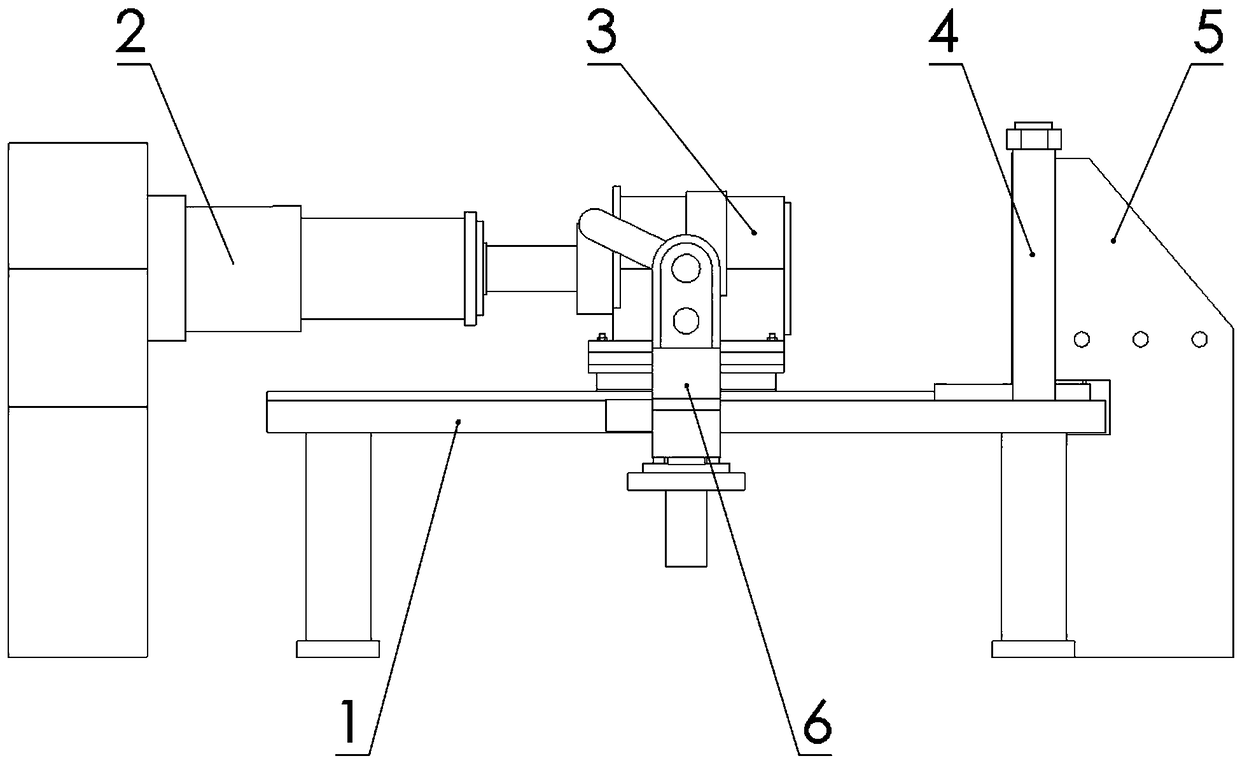

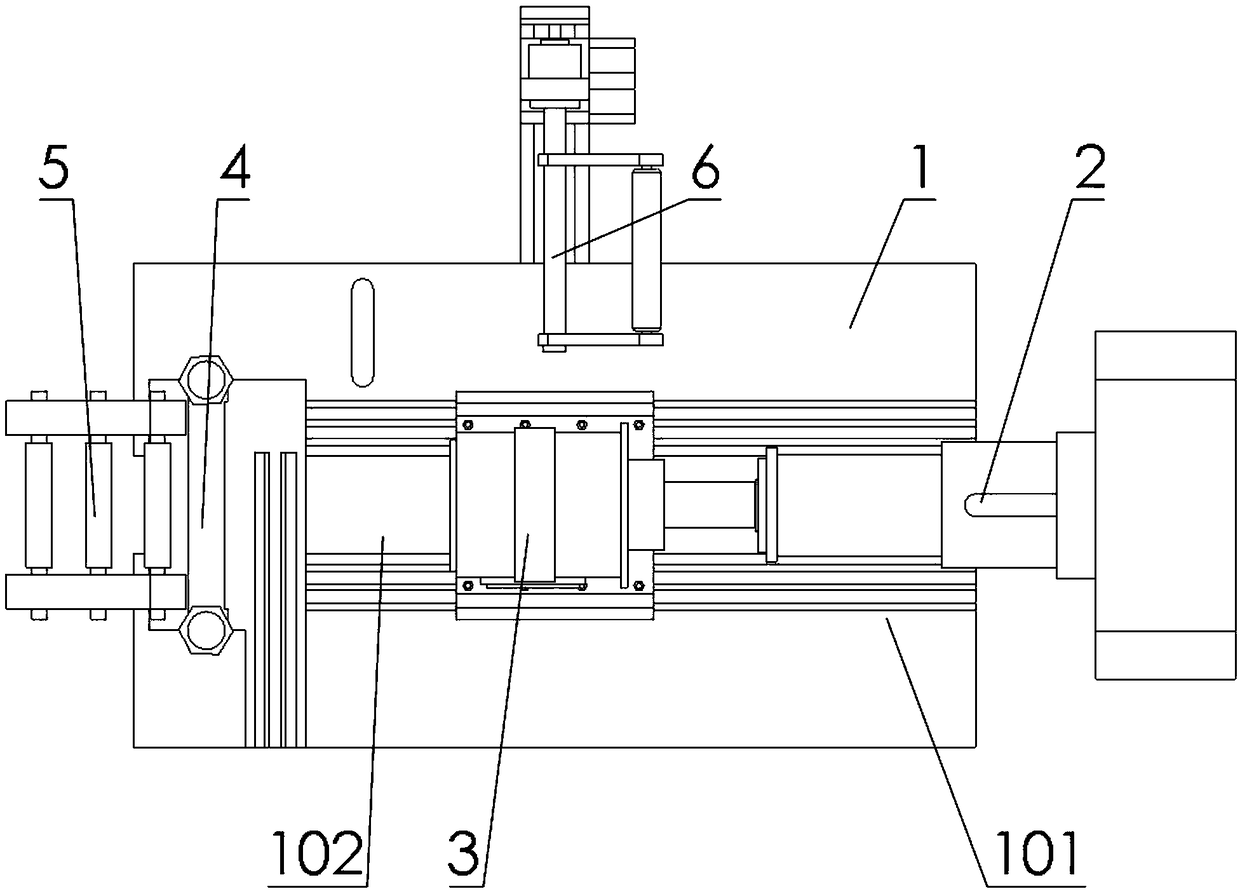

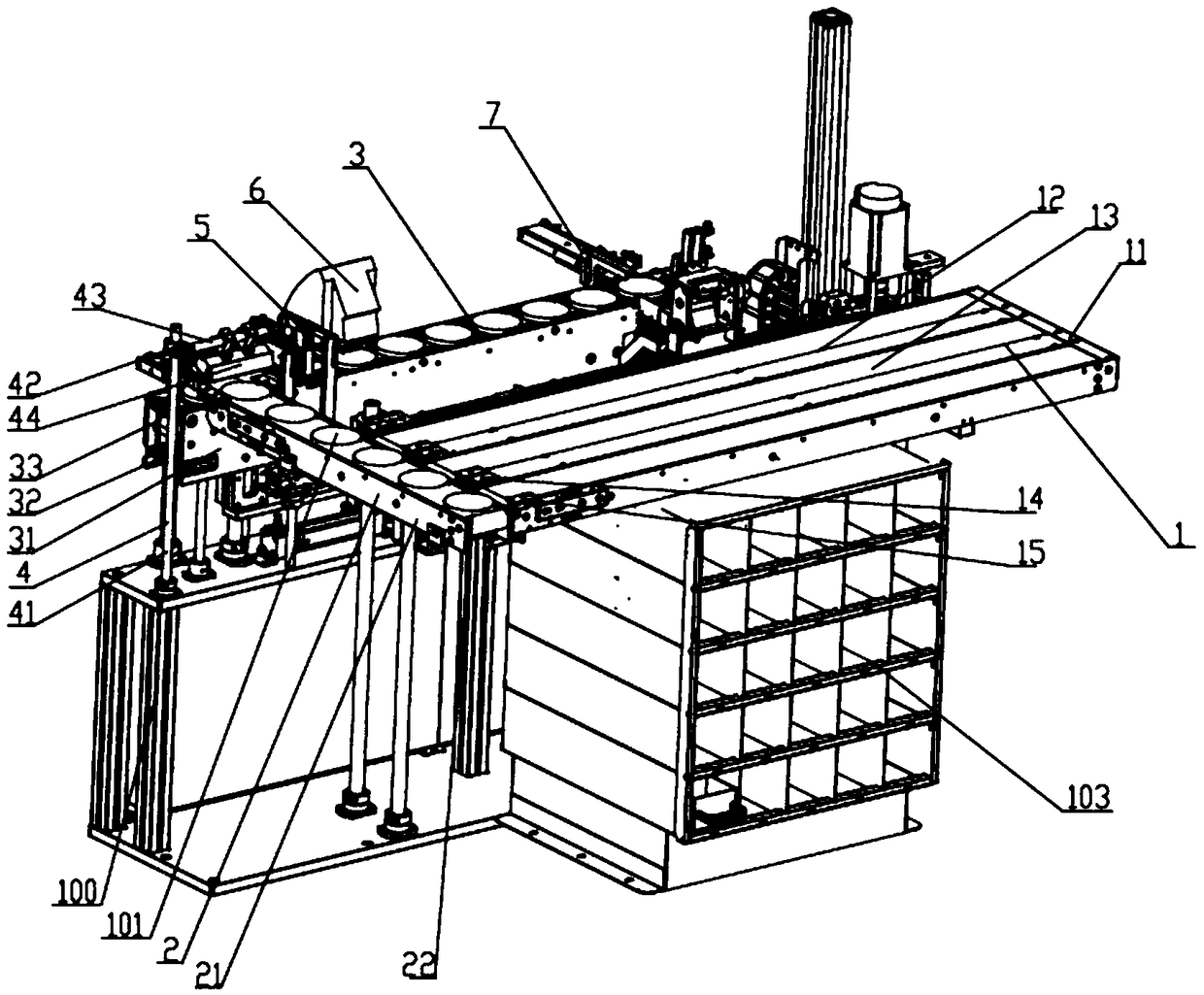

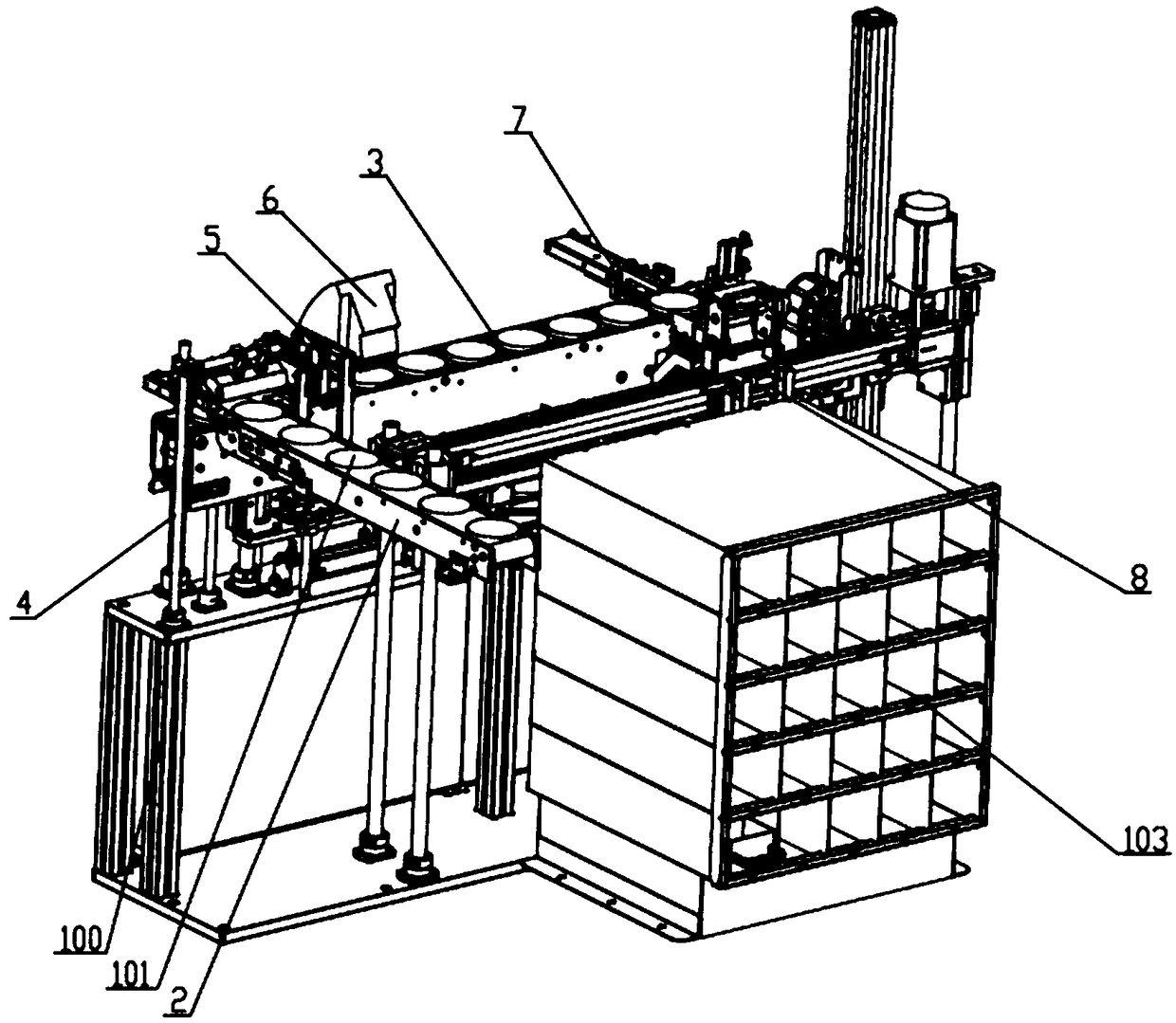

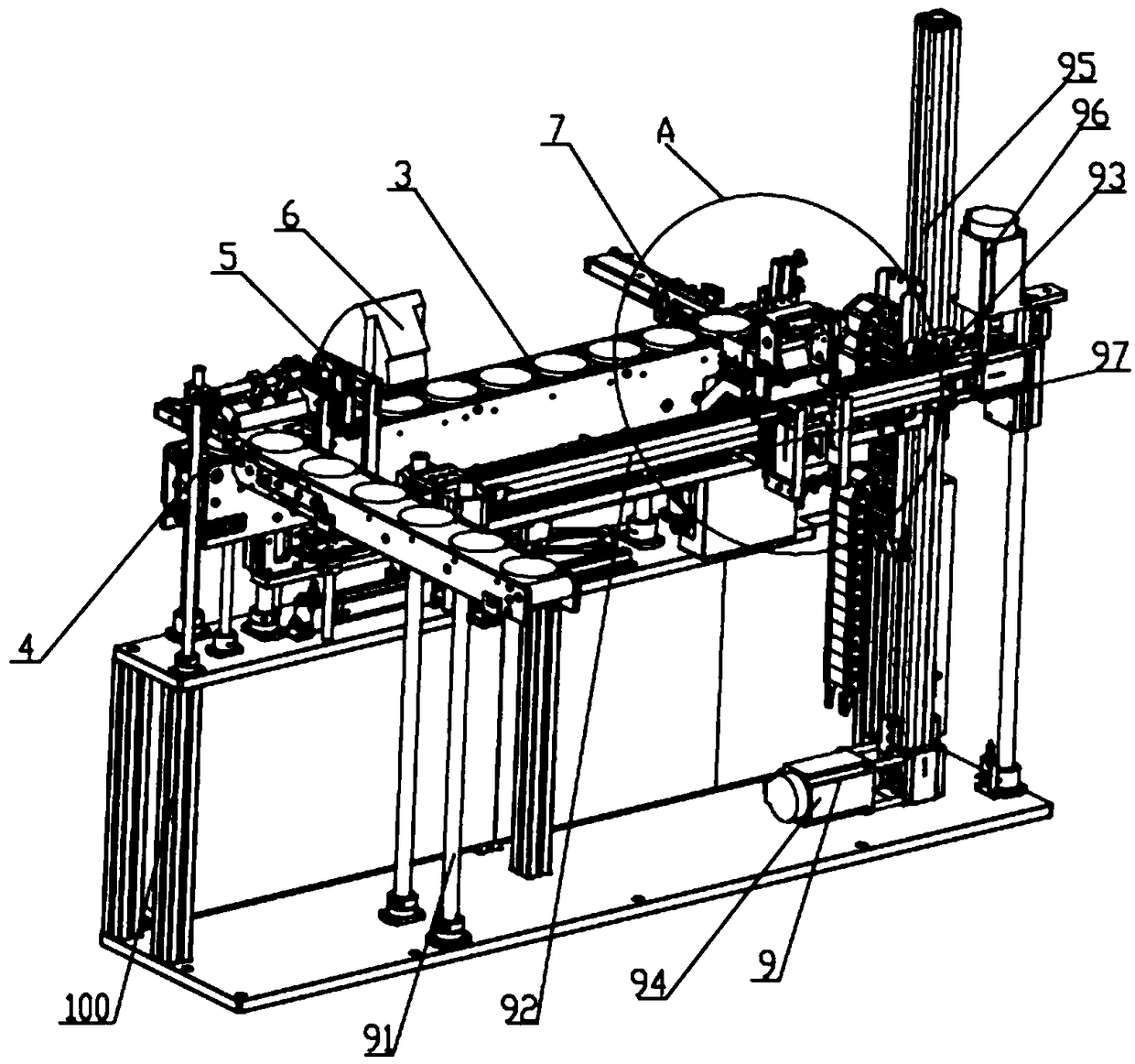

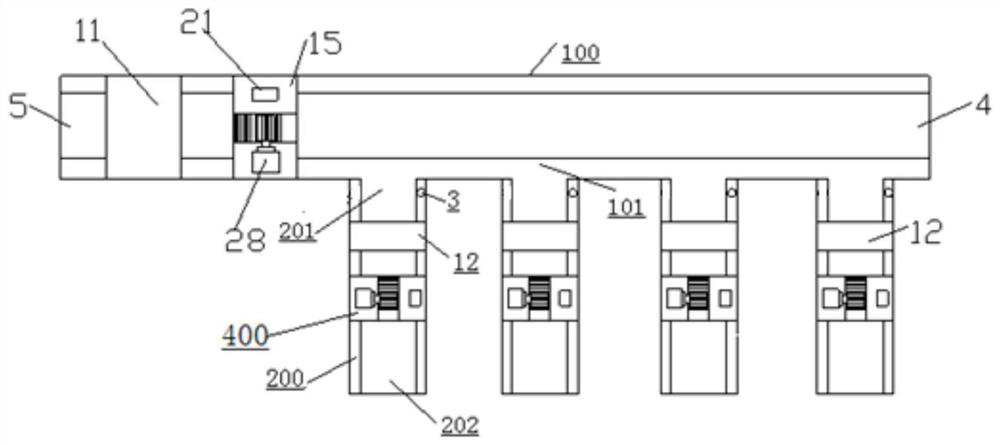

Tool mechanism for clamping frame workpiece of robot workstation

InactiveCN103350300AIngenious and reasonable structureImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesWorkstationBlock match

The invention discloses a tool mechanism for clamping a frame workpiece of a robot workstation. The mechanism comprises frame workpiece supports matched with the frame workpiece, wherein frame positioning blocks matched with workpiece frames are arranged on four frame supports; ejection air cylinders are arranged on inner sides of the frame positioning blocks; ejection rods of the ejection air cylinder are ejected, so that four frames of the frame workpiece are fixed and positioned stably in positions corresponding to the frame positioning blocks; and workpiece ejection mechanisms are arranged corresponding to the frames of the frame workpiece on the frame supports. The tool mechanism for clamping the frame workpiece of the robot workstation is ingenious and reasonable in structure; and the four scattered frames of the frame workpiece are directly positioned and fixed on the frame workpiece supports through arrangement of the ejection air cylinders and the frame positioning blocks, so that a complex underneath electric welding process in which positioning errors are prone to occur is not required, the workpice supports can be directly fixed and welded, the work efficiency is greatly improved, and the work errors are also greatly reduced.

Owner:上海气焊机厂有限公司

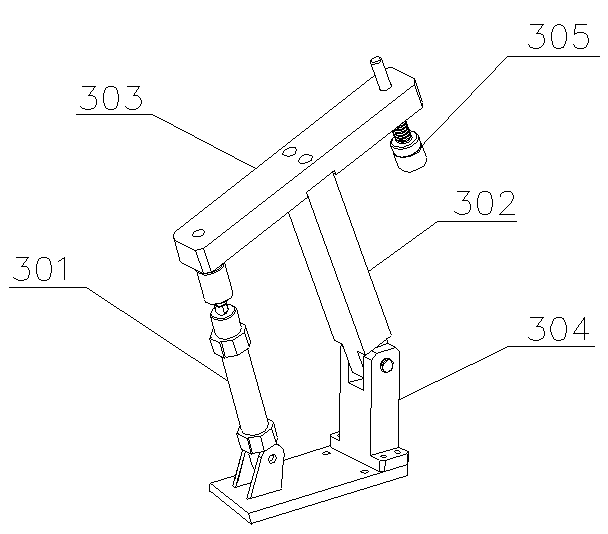

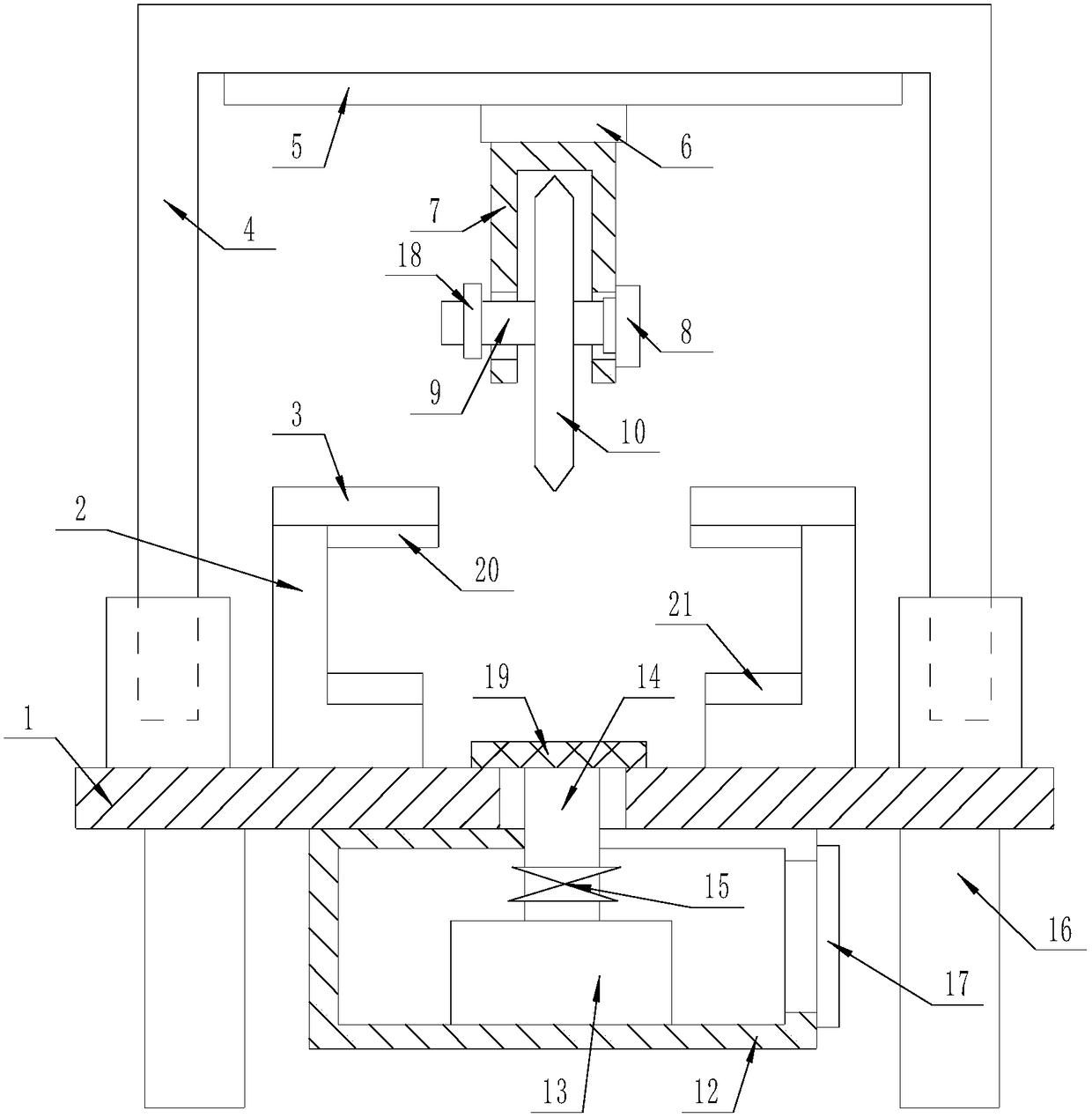

Full-automation grinding machine

InactiveCN103158051AKeep healthyImprove work efficiencyGrinding drivesGrinding machinesRotary stageShortest distance

The invention discloses a full-automation grinding machine which comprises a base plate, a working table, a grinding device, a locating device and a pressing device. A rotary table is arranged on the working table. A driving device which is used for driving the rotary table to rotate is arranged below the working table. The grinding device comprises a grinding wheel, a transmission device and a displacement adjusting device, wherein the transmission device is used for providing a driving force for the grinding wheel, and the displacement adjusting device is used for adjusting the position of the grinding wheel. The full-automation grinding machine further comprises an electric control device which is used for controlling the working table to rotate and adjusting feed amount of the grinding wheel. The electric control device controls the driving device to transfer the driving force to the rotary table. After grinding of one side, close to the grinding machine, of a workpiece is finished, the grinding position can be adjusted through rotation of the rotary table. Manual replacement and adjustment are not needed, and the purpose of full-automatic grinding of the workpiece is achieved. Due to the fact that full-automatic grinding of the workpiece is adopted, working efficiency is improved, working errors are reduced, product quality is improved, and production cost is lowered. Due to the fact that short-distance operation is avoided, fitness of operators is ensured.

Owner:YIHE PRECISION IND SUZHOU

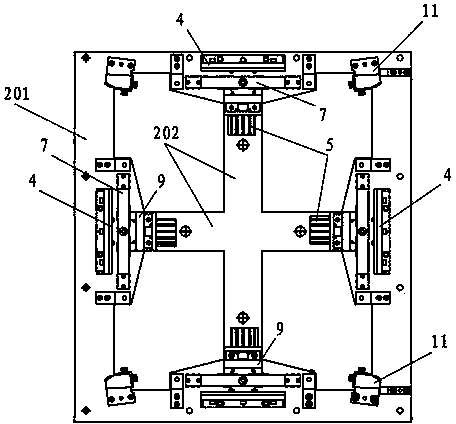

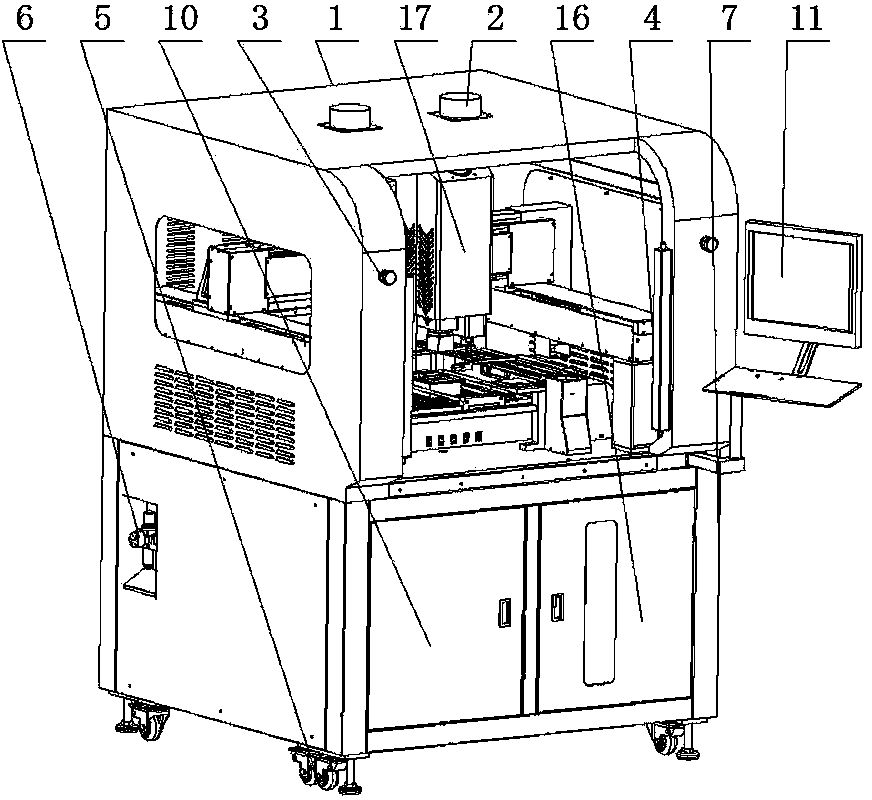

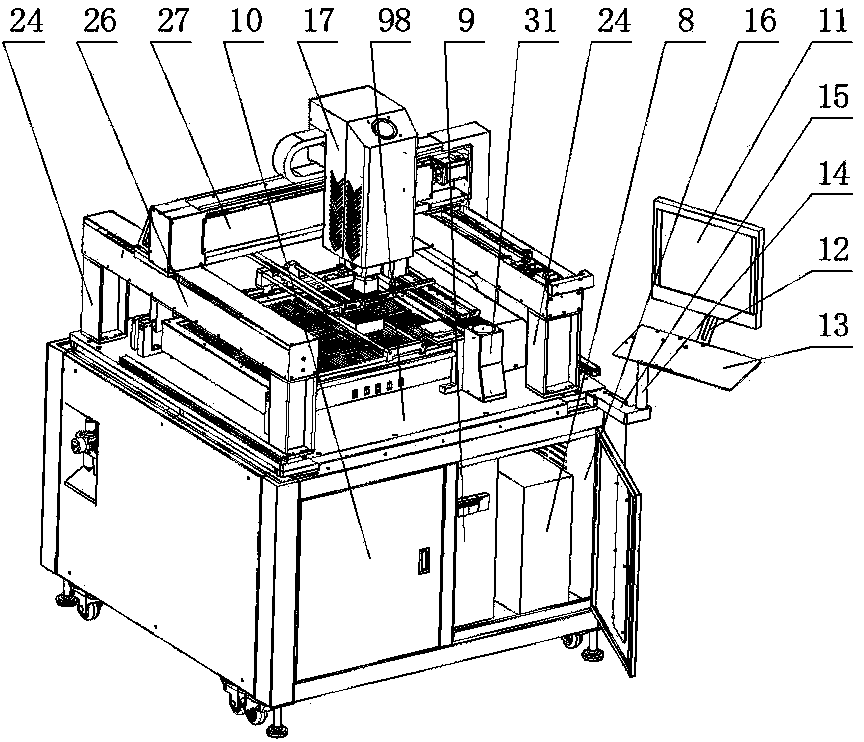

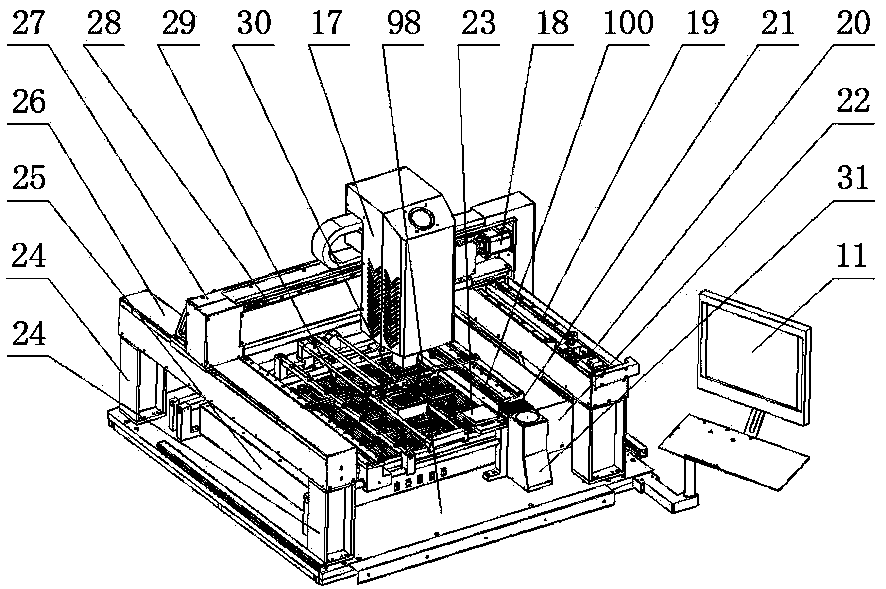

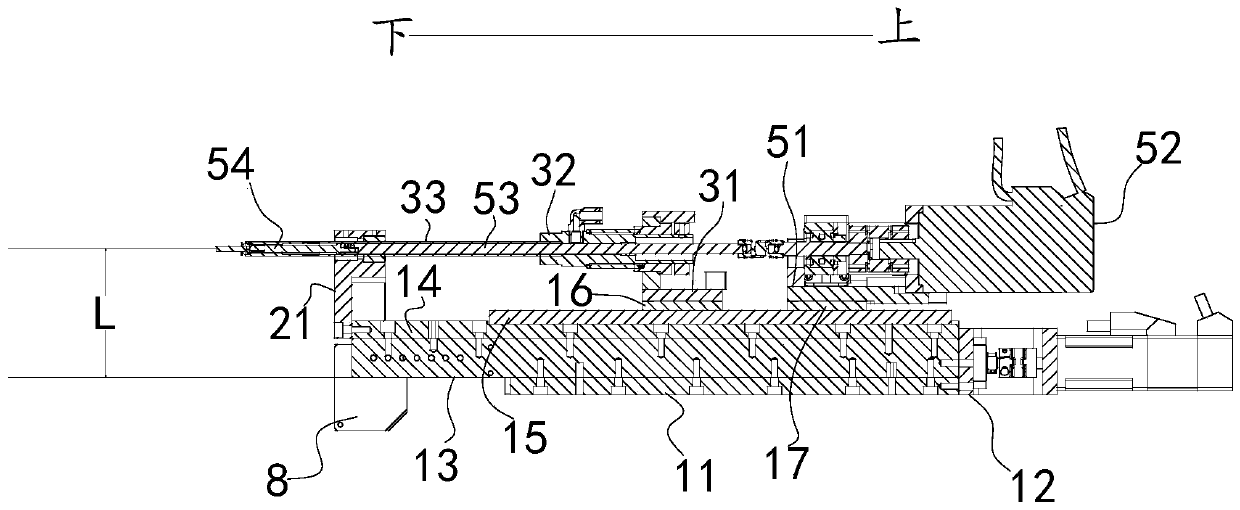

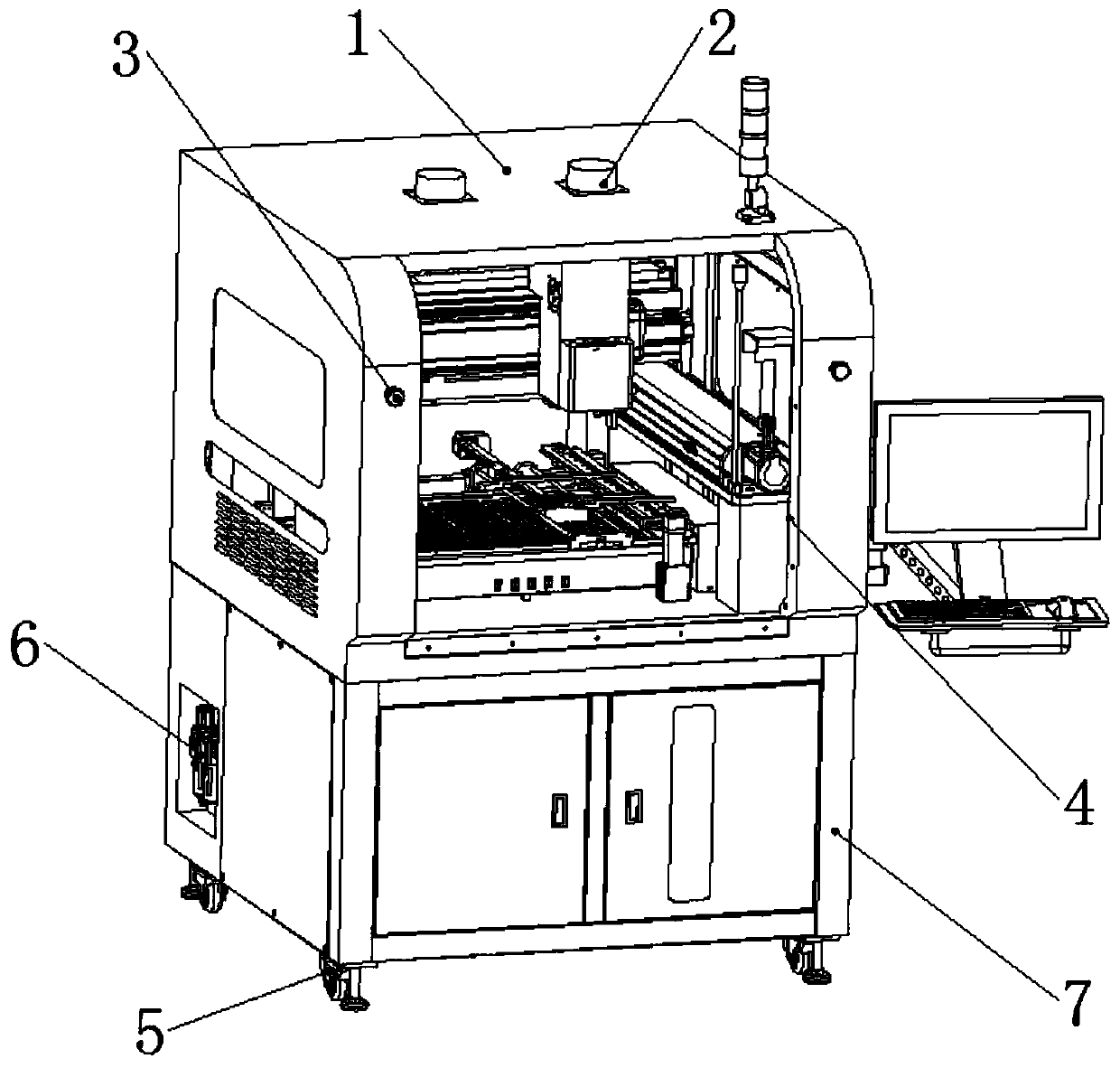

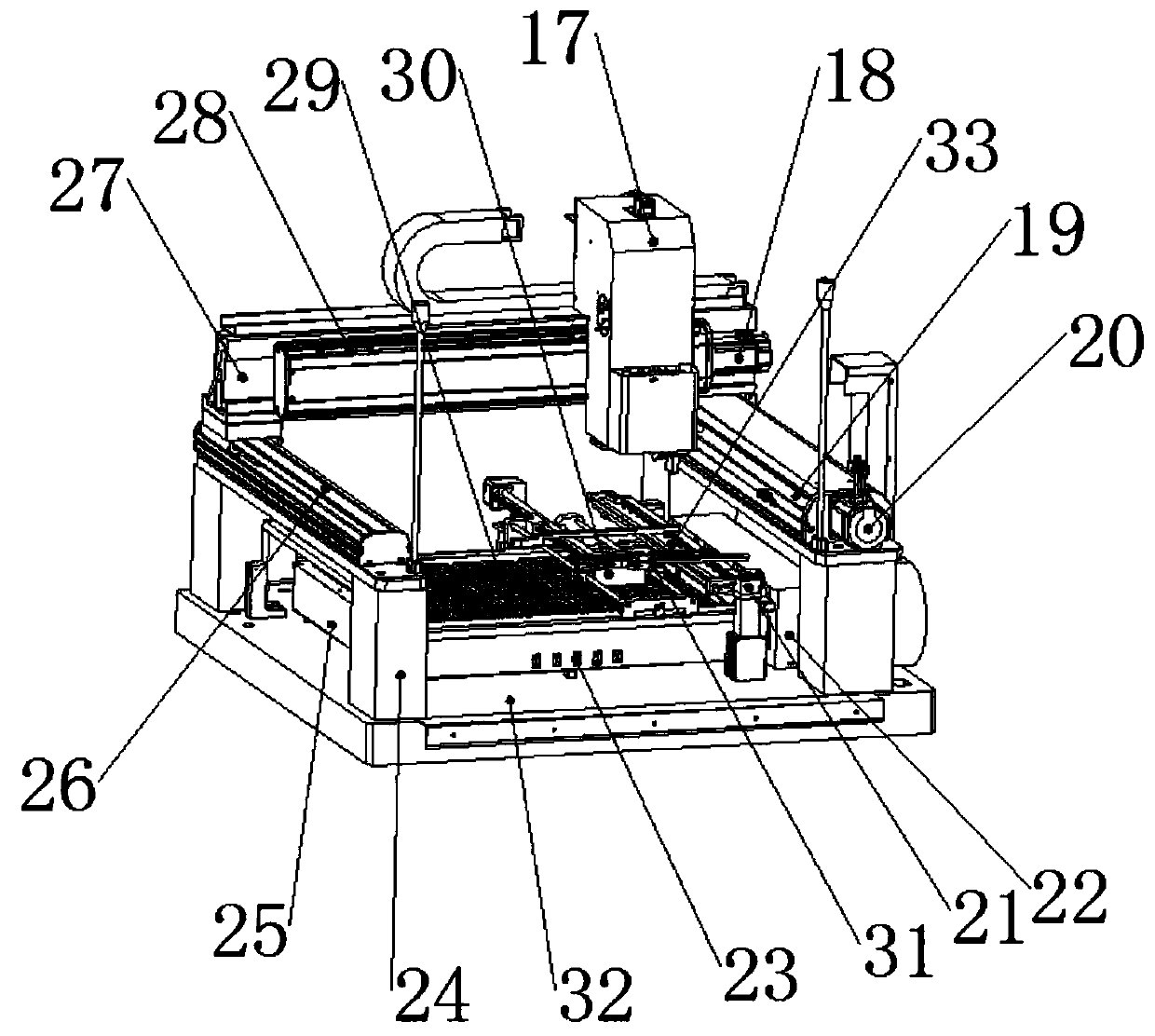

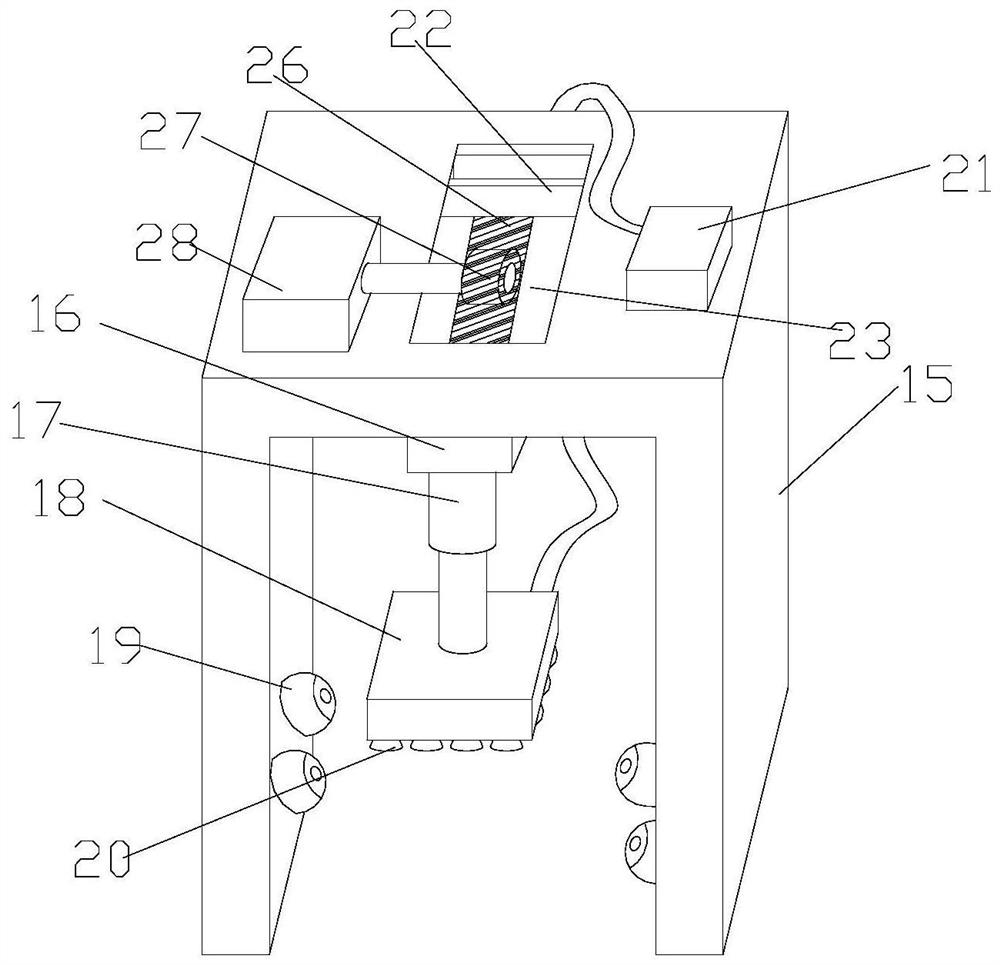

High-precision full-automatic BGA repair workbench

ActiveCN103874343AAvoid uncertaintyReduce rework and scrap ratePrinted circuit assemblingSurface mountingImage processing software

The invention provides a high-precision full-automatic BGA repair workbench. The high-precision full-automatic BGA repair workbench comprises a handpiece portion mechanism, an X-axis motor, an X-axis sliding rail, a Y-axis sliding rail, a Y-axis motor, a picking-up mechanism, a PCB supporting device, a cooling device, a feeding mechanism, a preheating box, an X shaft, a Y shaft, a datum base plate, a preheating device, a lower hot-air mechanism, a lower CCD vision mechanism, an upper machine body cover and a lower machine body cover. The handpiece portion mechanism is arranged on the X-axis sliding rail and comprises a handpiece fixing base, a surface mounting mechanism, an upper heating mechanism, an upper CCD vision mechanism, a headpiece cover, a heating motor, a surface mounting motor, a heating motor fixing base, a surface mounting motor fixing base, a coupler, a lead screw fixing base, a lead screw and a Z-axis sliding rail. According to the high-precision full-automatic BGA repair workbench, a vision automatic alignment system is adopted, image capturing and locating are conducted on a PCB and a BGA through a CCD, accurate alignment and surface mounting are achieved through analysis and deviation rectification by image processing software, and the surface mounting precision can reach + / -0.025 mm; in this way, the consistency of work quality is guaranteed, and high-end precise electronic products are easily processed.

Owner:SHENZHEN ZHUO MAO TECH

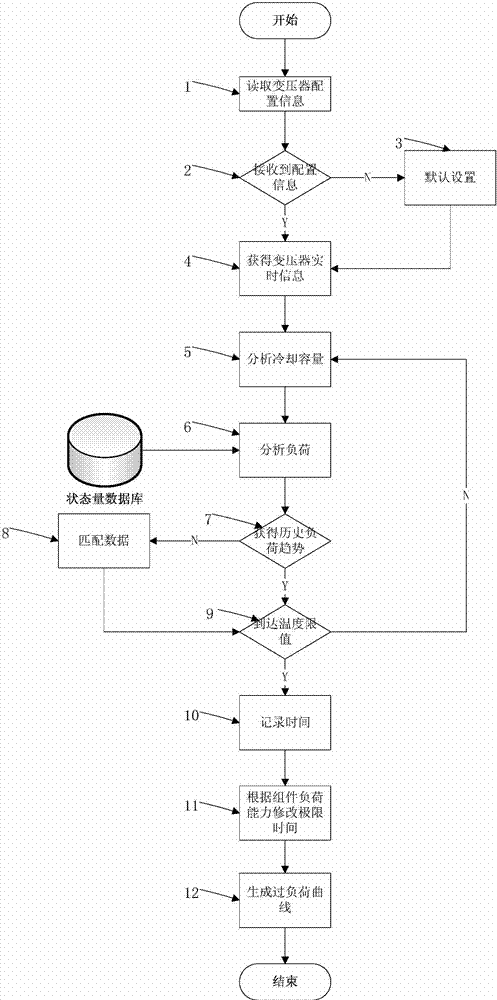

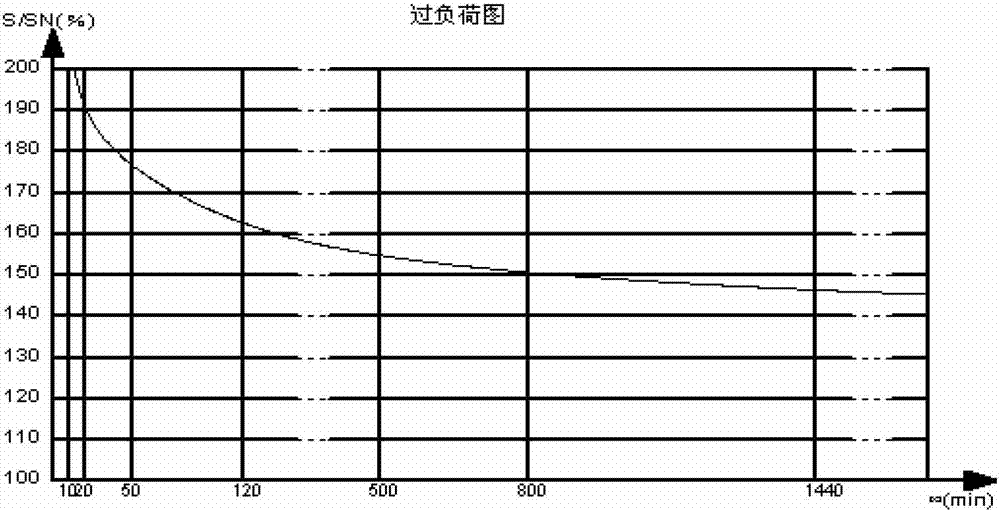

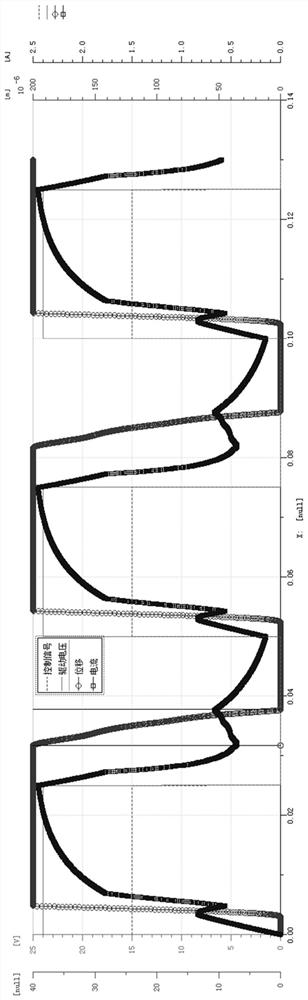

Method for determining dynamic overload curves of transformers based on operating data

ActiveCN103543352AForecasting future loadFully tap the overload capacityElectrical testingReal-time dataTransformer

The invention discloses a method for determining dynamic overload curves of transformers based on operating data. The method includes: A), adapting basic configuration subjected to overload curve calculation according to basic configuration information of the transformers to the transformers different in types and cooling ways; B), reading real-time operating data of the transformers to complete preparation for real-time data of the transformers; C), calculating cooling capacity of the transformers and initiating cooing power of the transformers; D), analyzing historical load trend of the transformers and forecasting future loads of the transformers; E), calculating hot-limit time of the transformers according to the winding hot-spot temperature of the transformers; F), modifying the hot-limit time of the transformers according to overload capacity tables of initialized transformer tables; G), matching the overload curves by adopting a Bezier grid to complete and determine dynamic overload curve graphs of the transformers. Since the dynamical overload curve graphs can be generated by the method, scientific and effective reference can be provided for load control.

Owner:STATE GRID CORP OF CHINA +2

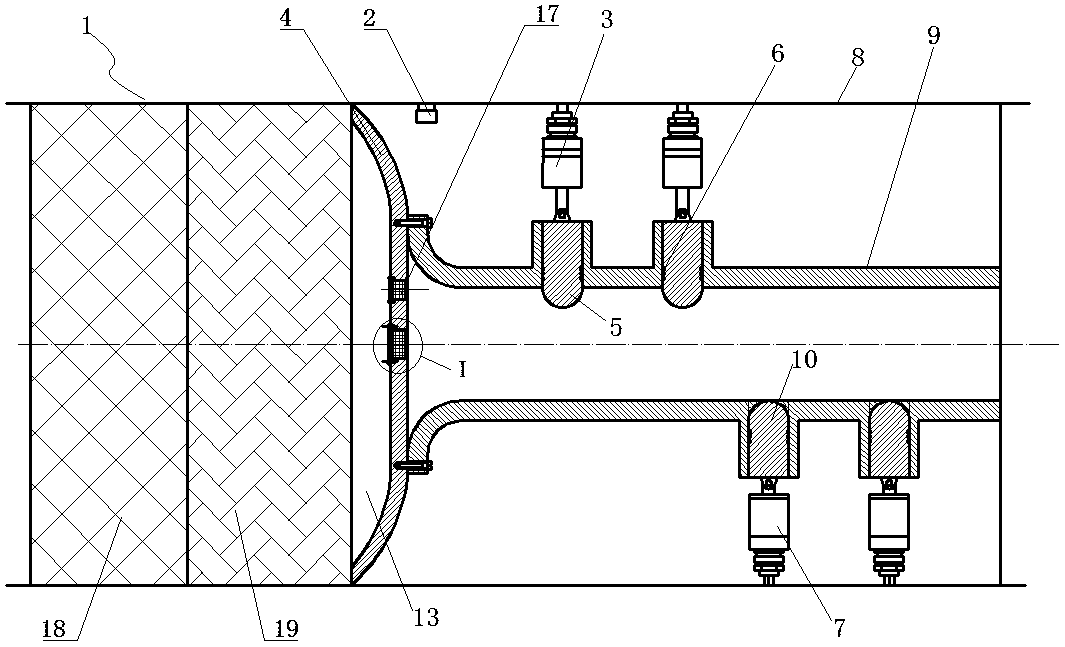

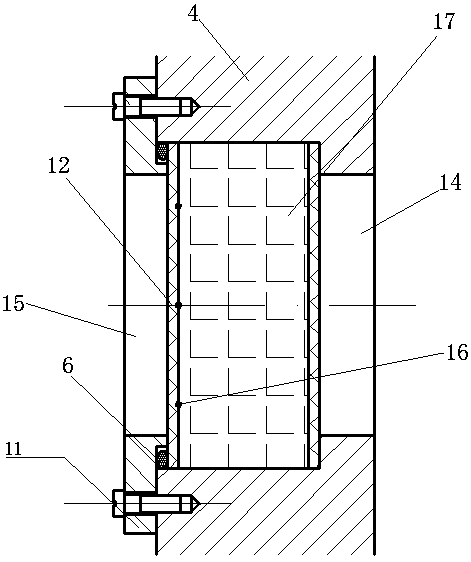

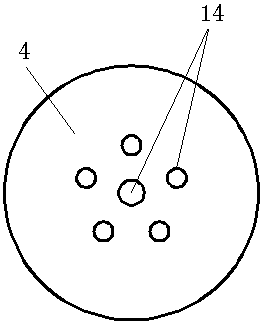

Solid rocket ramjet engine gas flow adjusting device

PendingCN107795409ALarge flow adjustment rangeChange trafficRocket engine plantsRam jet enginesRamjetElastomer

The invention discloses a solid rocket ramjet engine gas flow adjusting device. The solid rocket ramjet engine gas flow adjusting device comprises a master controller, a projectile body, a gas generator and a spraying pipe; the spraying pipe comprises a sealing plate and a hollow pipe, an unthreaded hole is formed in the wall of the pipe in the direction vertical to the pipe axis direction, a plunger sliding valve is installed in the unthreaded hole in a sealed manner, and a driving device is arranged on the plunger sliding valve; N through air inlet holes are formed in the sealing plate, theair inlet holes are distributed within the pipe diameter scope, plugging covers capable of sealing and plugging the air inlet holes are arranged in N-1 air inlet holes, and detonation devices capableof detonating the plugging covers are arranged on the plugging covers; and a pressure sensor is installed in a cavity between the pipe outer wall and the projectile body and is electrically connectedwith the master controller, and the master controller is electrically connected with the driving device; and the pressure sensor is electrically connected with the detonation devices. By means of thesolid rocket ramjet engine gas flow adjusting device, a larger flow adjusting scope can be achieved under the non-jamming state and the jamming state of a solid rocket ramjet engine, and the beneficial effects of being low in price, accurate and reliable in work and the like are achieved.

Owner:湖南宏大日晟航天动力技术有限公司

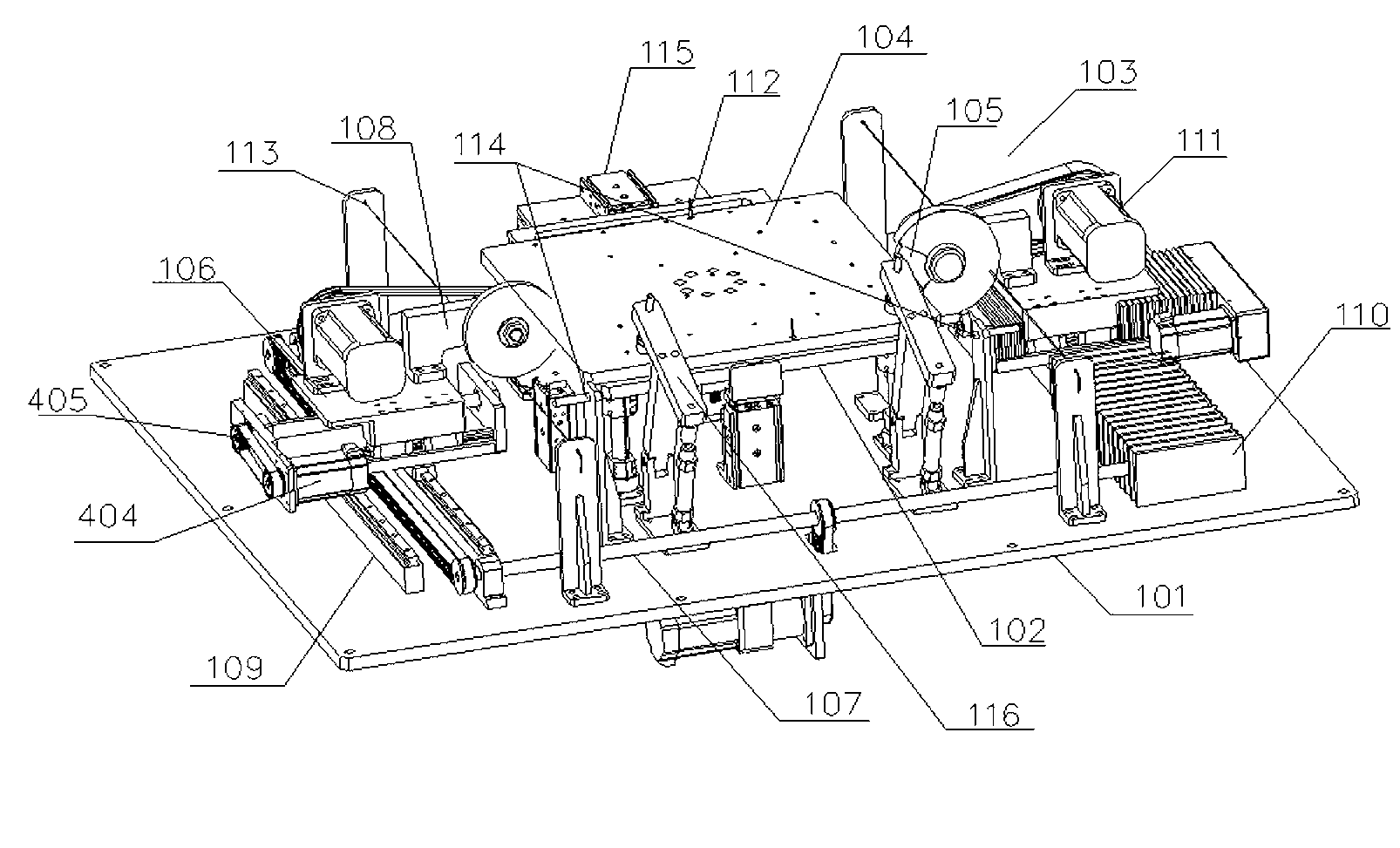

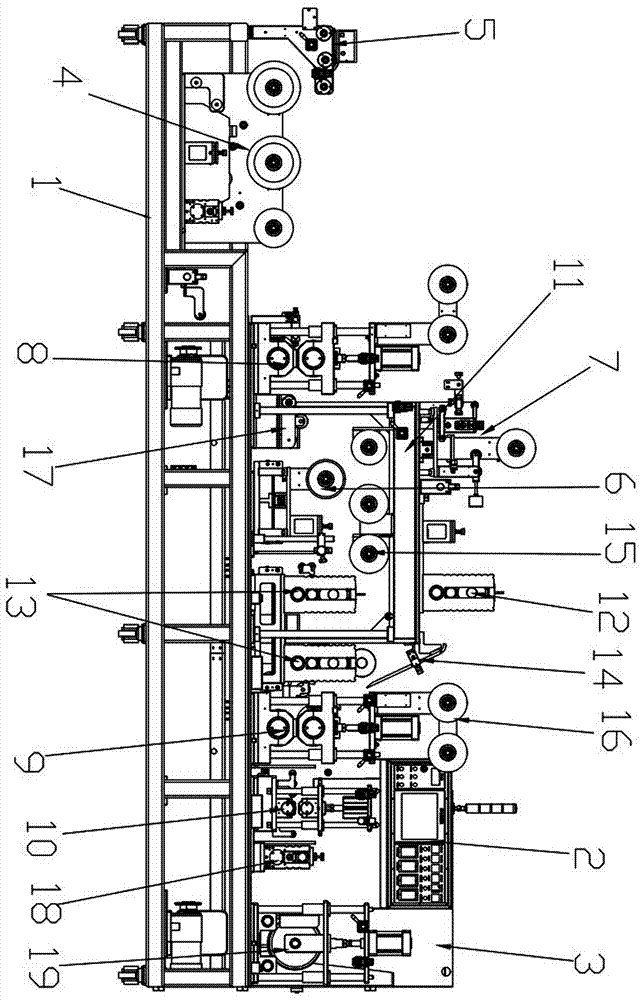

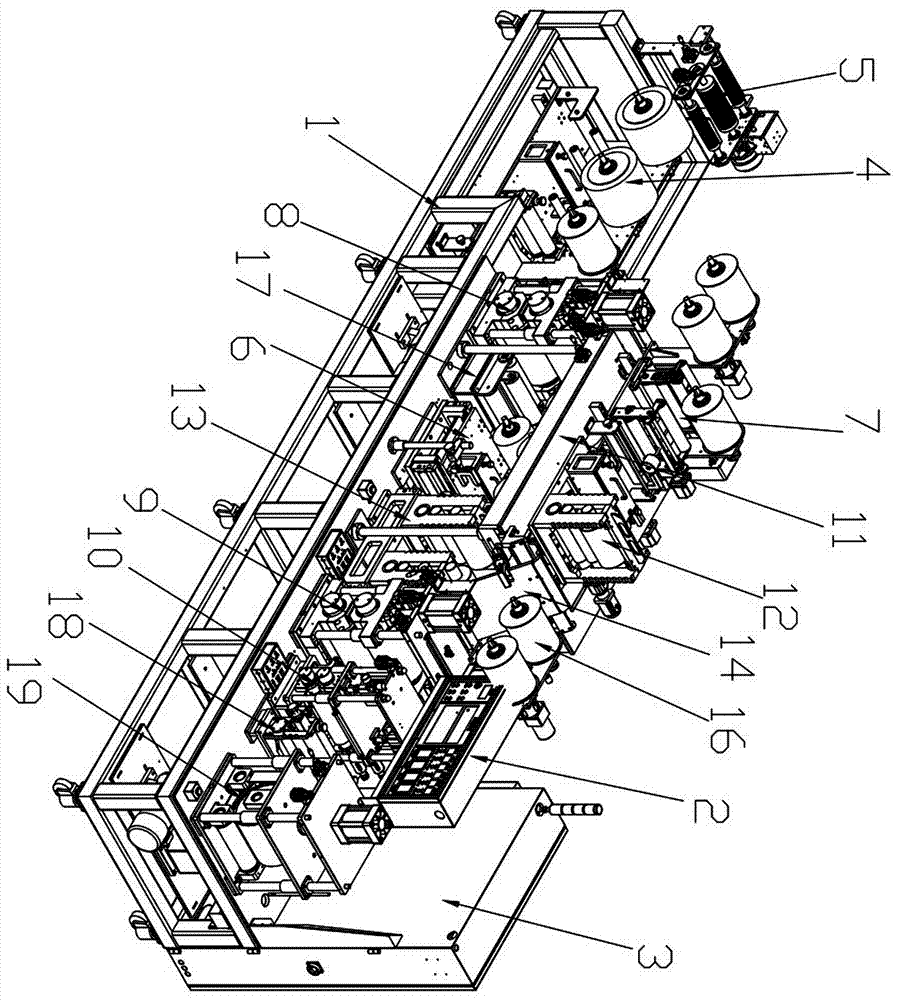

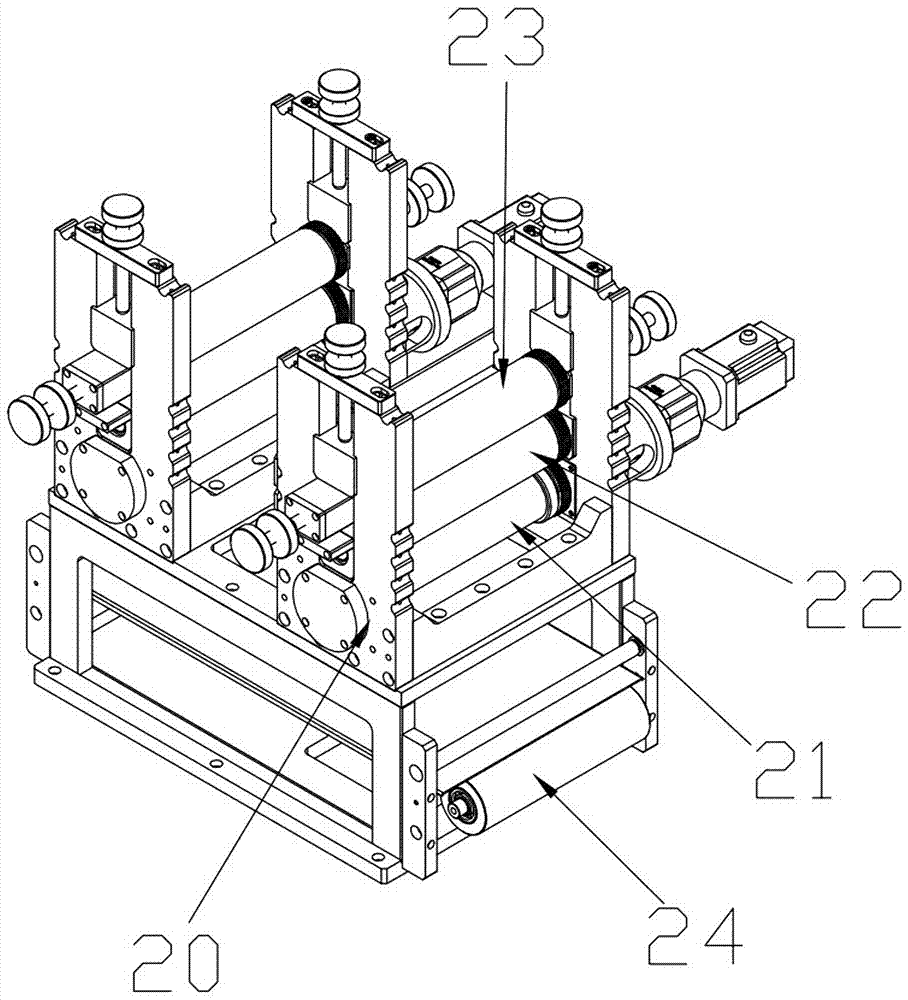

Equipment and process for manufacturing flexible circuit board

ActiveCN107241865AIncrease rateHigh precisionConductive material mechanical removalMechanical/acoustic circuit processingElectrical conductorFlexible circuits

The invention relates to equipment and process for manufacturing a flexible circuit board in the technical field of manufacturing of an electronic circuit board. The equipment comprises an elongate framework type machine body, wherein an automatic operating platform is arranged at a top part of the framework type machine body and comprises a control panel, an automatic feeding part, an automatic lamination part, an automatic rolling cutting part, a splitting mechanism, a traction mechanism and a winding mechanism, the automatic feeding part comprises a bottom membrane feeding mechanism, an elongate conductor feeding mechanism, a combination medium membrane feeding mechanism and a cover membrane feeding mechanism, the automatic lamination part comprises a first lamination mechanism and a second lamination mechanism, and the automatic rolling cutting part comprises an upper rolling cutter mechanism and a lower rolling cutter mechanism. Compared with a traditional punching or etching process, the process employing rolling cutting has the advantages that an irregularly-shaped cross section and a clearance hole can be synchronously cut in a rolling way, the rolling cutting efficiency is high, no stop is needed during the rolling cutting process, assembly line type processing can be directly completed, so that the production working efficiency of a product can be improved, labor investment is greatly reduced, and the qualified rate and the accuracy of a finished product are improved.

Owner:广东力兹微电气技术有限公司

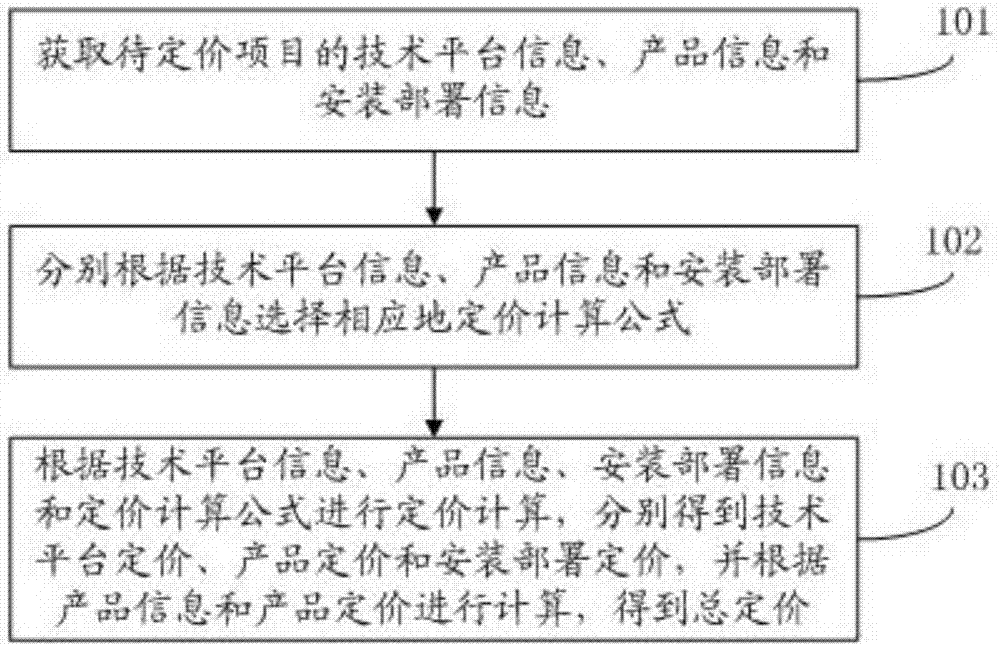

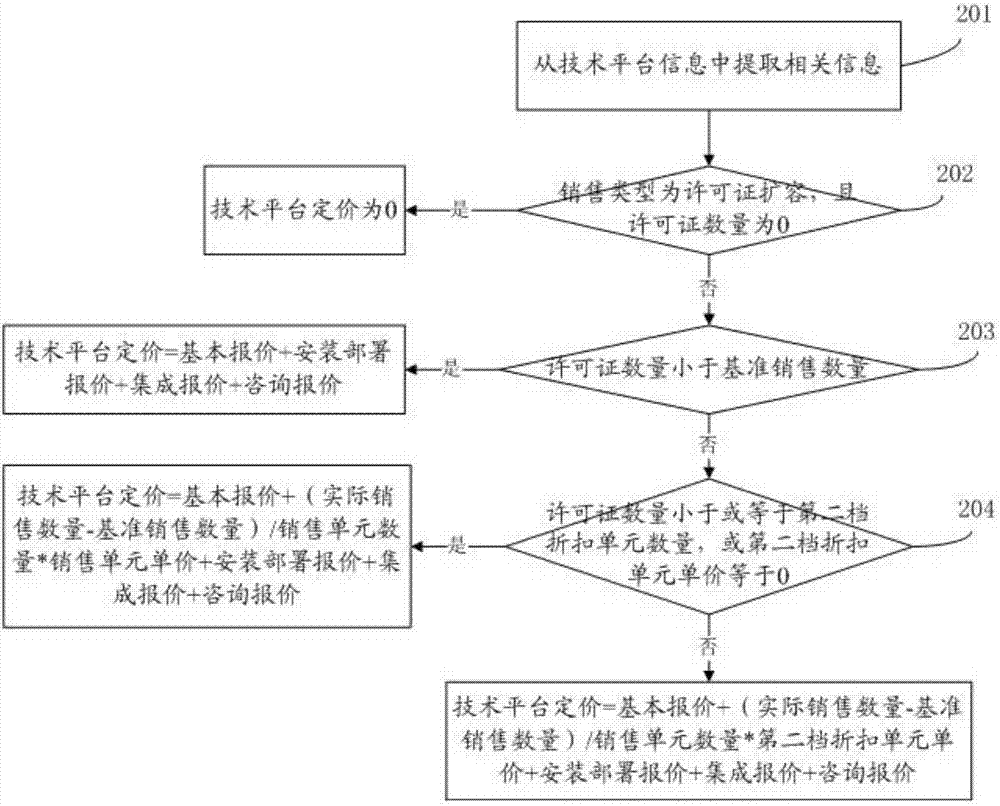

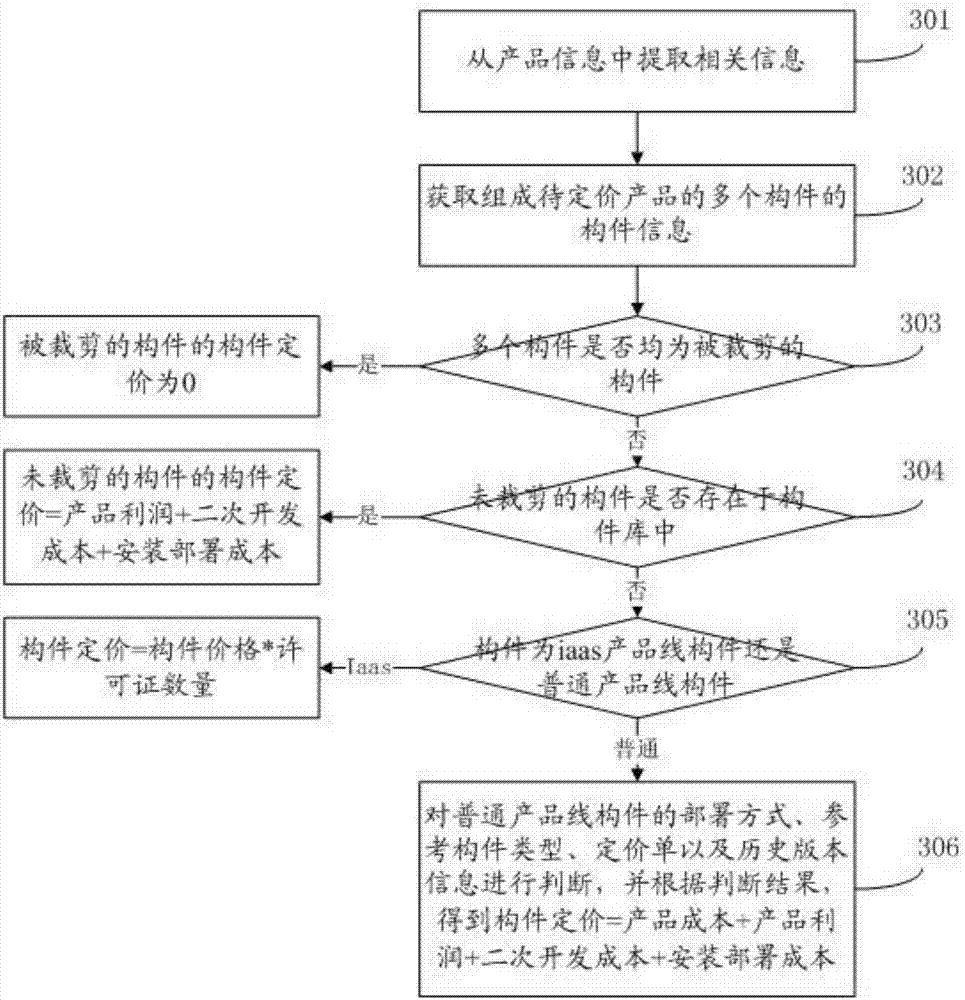

Pricing method and system

InactiveCN107038607AAccurateIncreased quotation accuracyMarket predictionsProduct appraisalCalculation errorTotal price

The present invention relates to a pricing method and system. The method comprises the following steps: acquiring technical platform information, product information and installation and deployment information of items to be priced; and selecting corresponding pricing calculation formulas respectively according to the technical platform information, product information and installation and deployment information ; Perform pricing calculations based on technology platform information, product information, installation and deployment information, and pricing calculation formulas to obtain technology platform pricing, product pricing, and installation and deployment pricing, and calculate based on product information and product pricing to obtain the total pricing. The pricing method and system provided by the invention increase the quotation accuracy and reduce the work cost and error of manual calculation.

Owner:北京思特奇信息技术股份有限公司

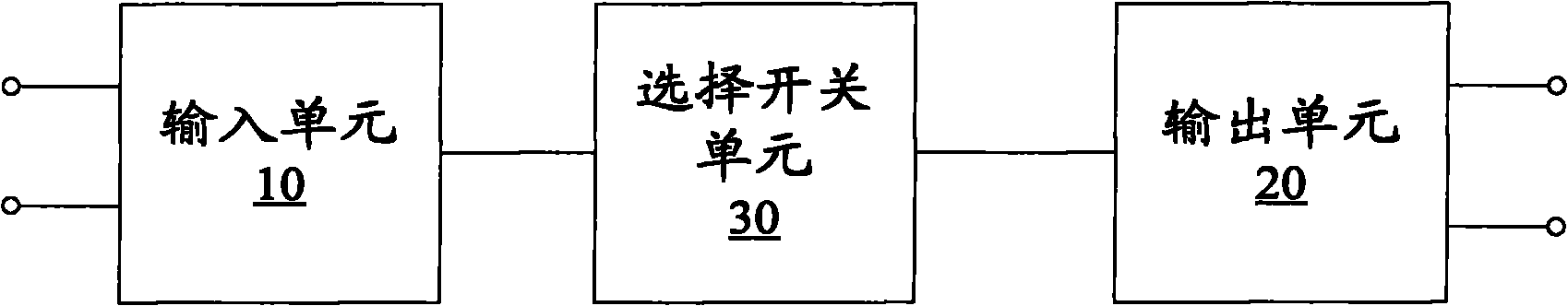

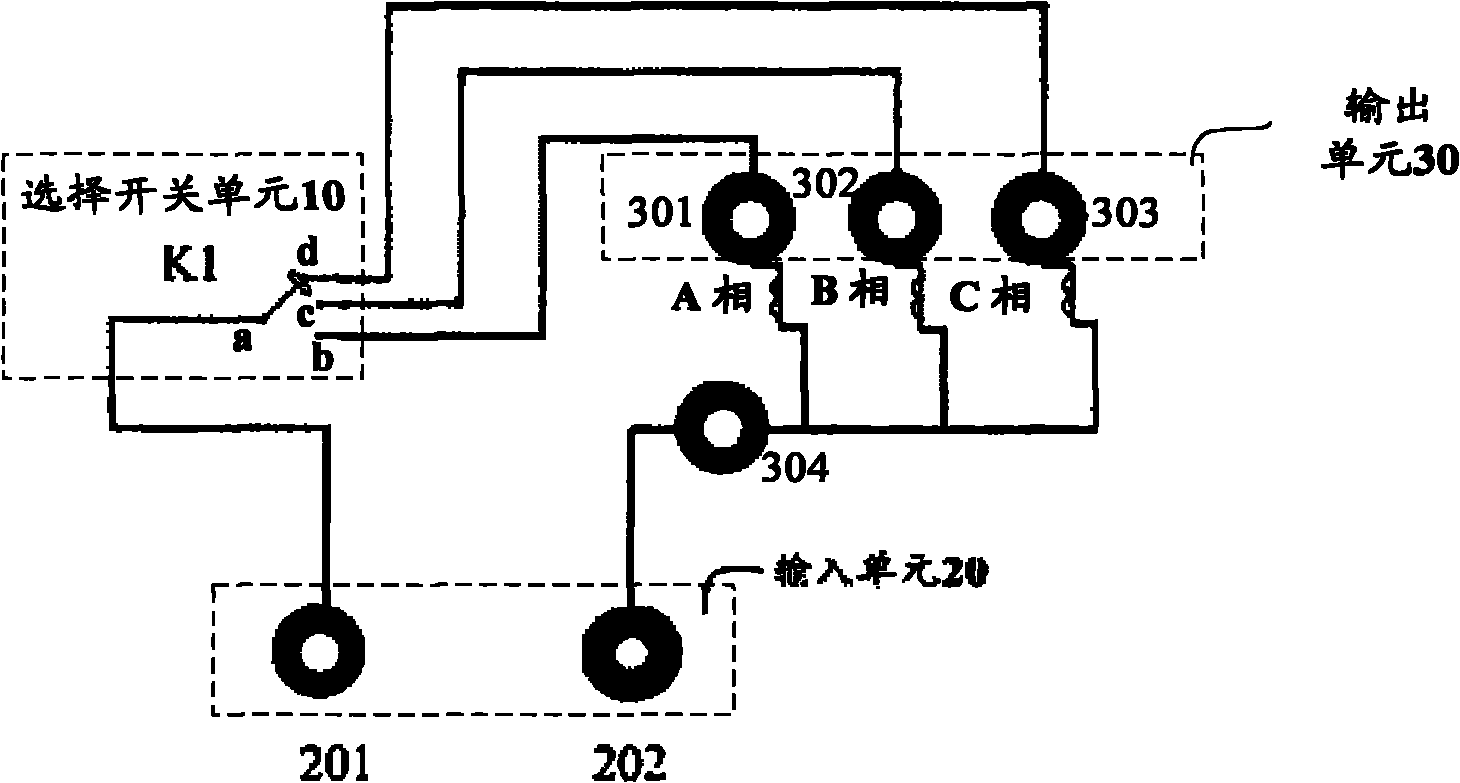

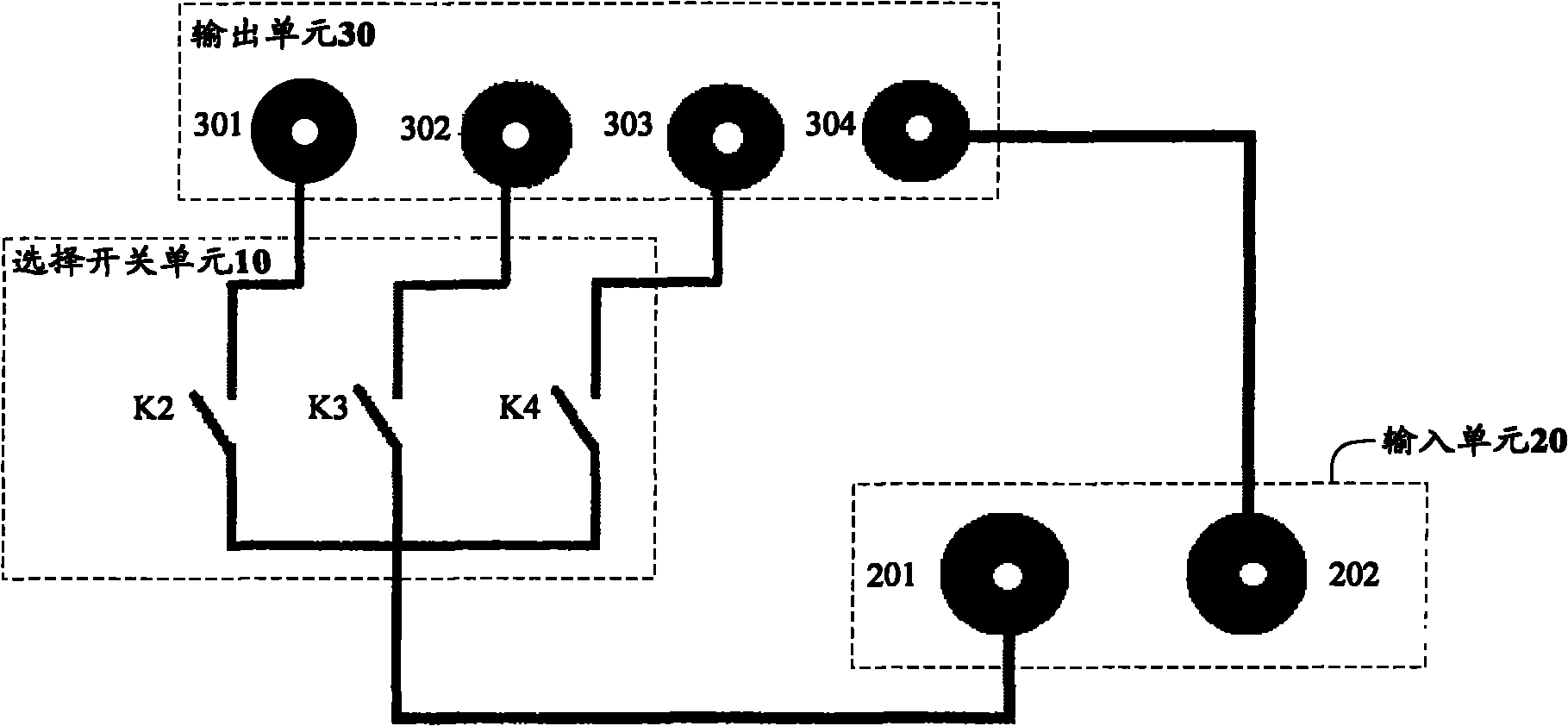

Wiring device and current mutual inductance testing system

ActiveCN102095899AIncrease work intensityReduce the number of wiringElectrical measurement instrument detailsElectrical testingPilot systemEngineering

The invention provides a wiring device and a current mutual inductance testing system. The wiring device comprises an input unit, an output unit and a select switch unit, wherein the input unit is electrically connected with a relay protection three-phase tester; the output unit is electrically connected with the A phase, B phase and C phase of a current mutual inductor; the select switch unit isrespectively connected to the input unit and the output unit and used for receiving test current from the relay protection three-phase tester and selectively outputting the test current to the A phase, the B phase or the C phase by means of the output unit. According to the invention, the wiring times and the possibility of working errors can be reduced, the working efficiency is improved, the labor intensity is lowered, the power failure time caused by test wiring can be shortened, and the power supply reliability is improved.

Owner:STATE GRID CORP OF CHINA +1

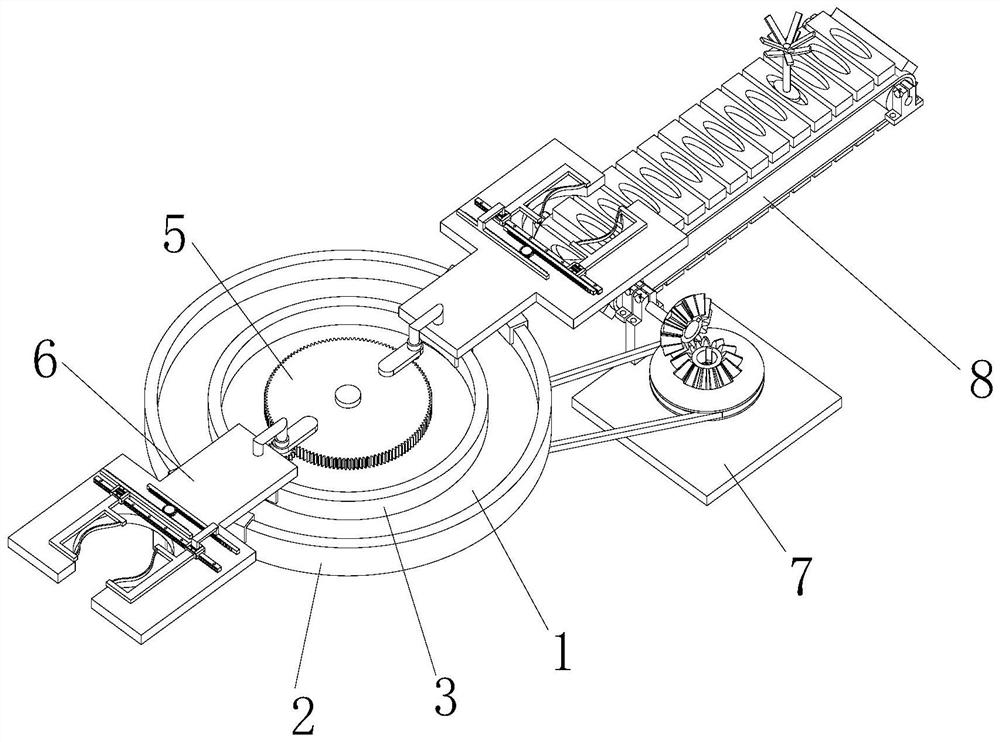

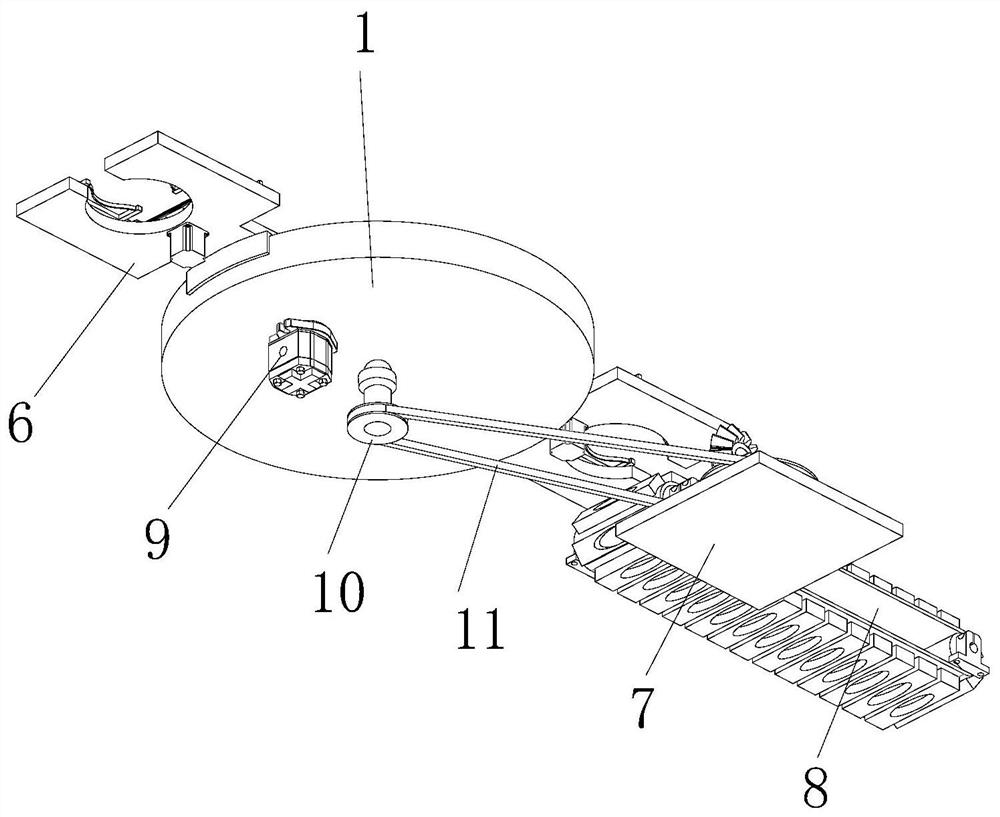

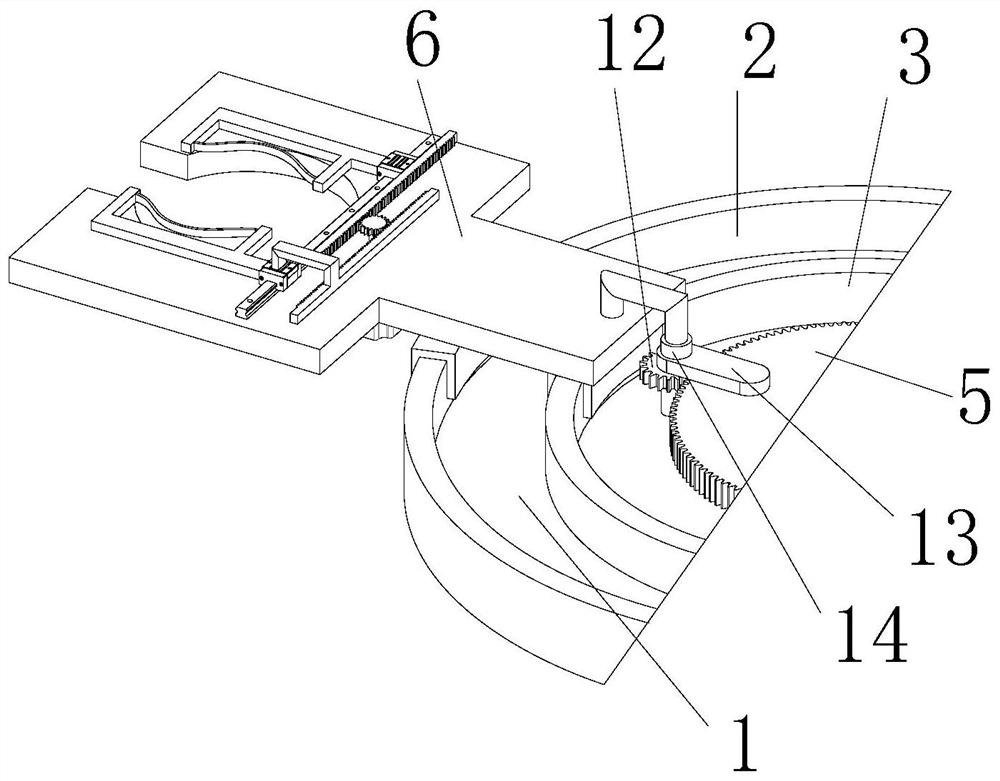

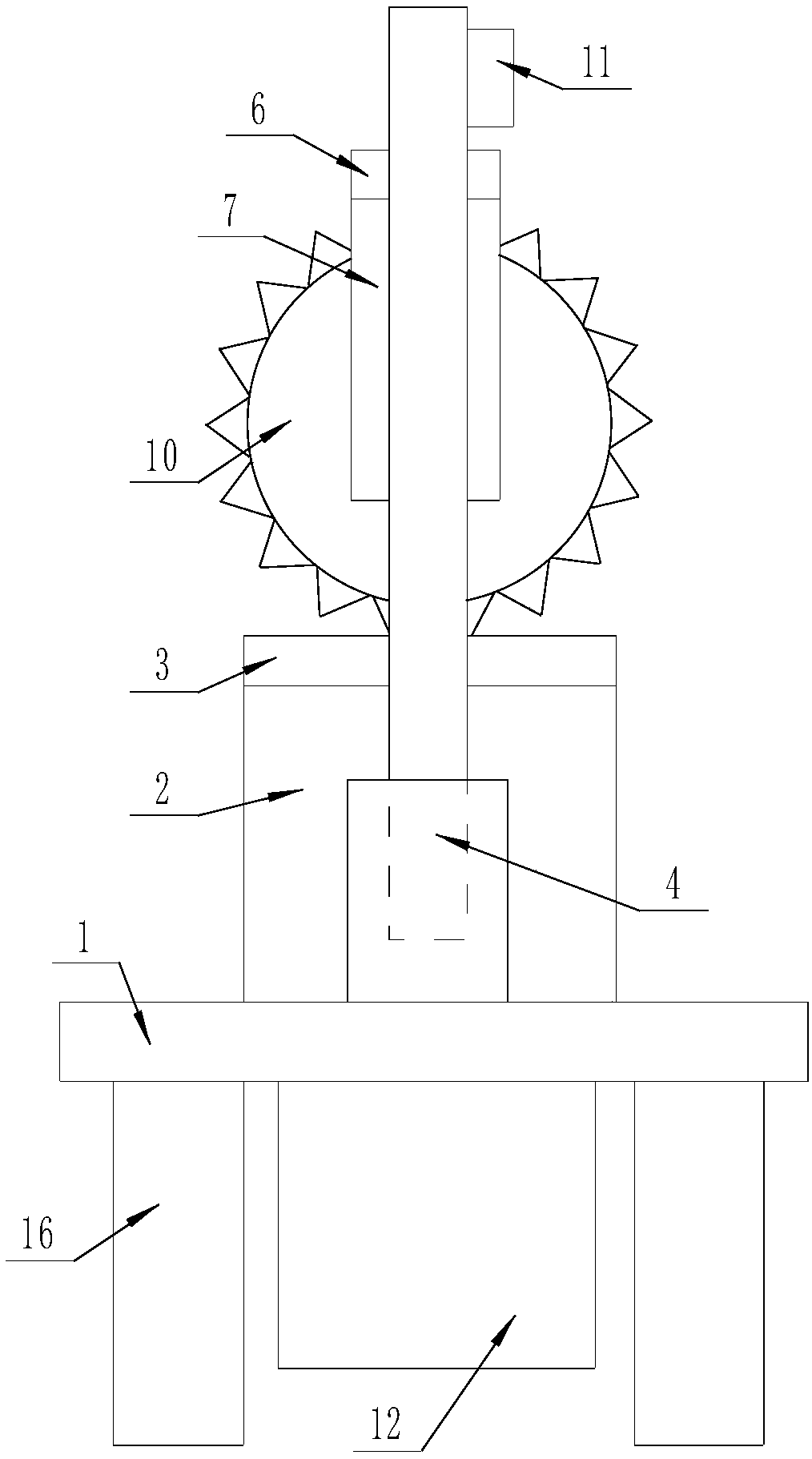

Cherry tree planting equipment

ActiveCN111742810ARealize the function of automatic feedingReduce working errorsForestryFixed bearingGear wheel

The invention relates to cherry tree planting equipment. The cherry tree planting equipment comprises a circular bottom plate, wherein an outer circular ring is mounted at the top end of the circularbottom plate; an inner circular ring is mounted on the circular bottom plate on the inner side of the outer circular ring; a gear disk is mounted at the middle part of the inner circular ring; a circular rod is arranged at the bottom end of the gear disk; a fixing bearing is mounted on the circular rod in a sleeving manner; an outer ring of the fixing bearing is fixedly connected with the circularbottom plate; an opening which is matched with the circular rod is formed in the middle part of the circular bottom plate; the circular rod penetrates through the upper side and the lower side of thecircular bottom plate; connecting blocks are arranged on two sides of the top end of the gear disk; a circular sleeve is mounted at one end of each connecting block; a second gear is mounted on the circular bottom plate on one side of the gear disk; the second gear and the gear disk are mutually meshed; the second gear is mounted at the output end of a stepping motor; the stepping motor is fixedto the bottom end of the circular bottom plate; and the inner circular sleeve and the inner circular ring are in sliding connection. Two clamping assemblies are arranged, so that seedlings can be clamped separately, and operation time is saved.

Owner:奉节县铭恒农业科技有限公司

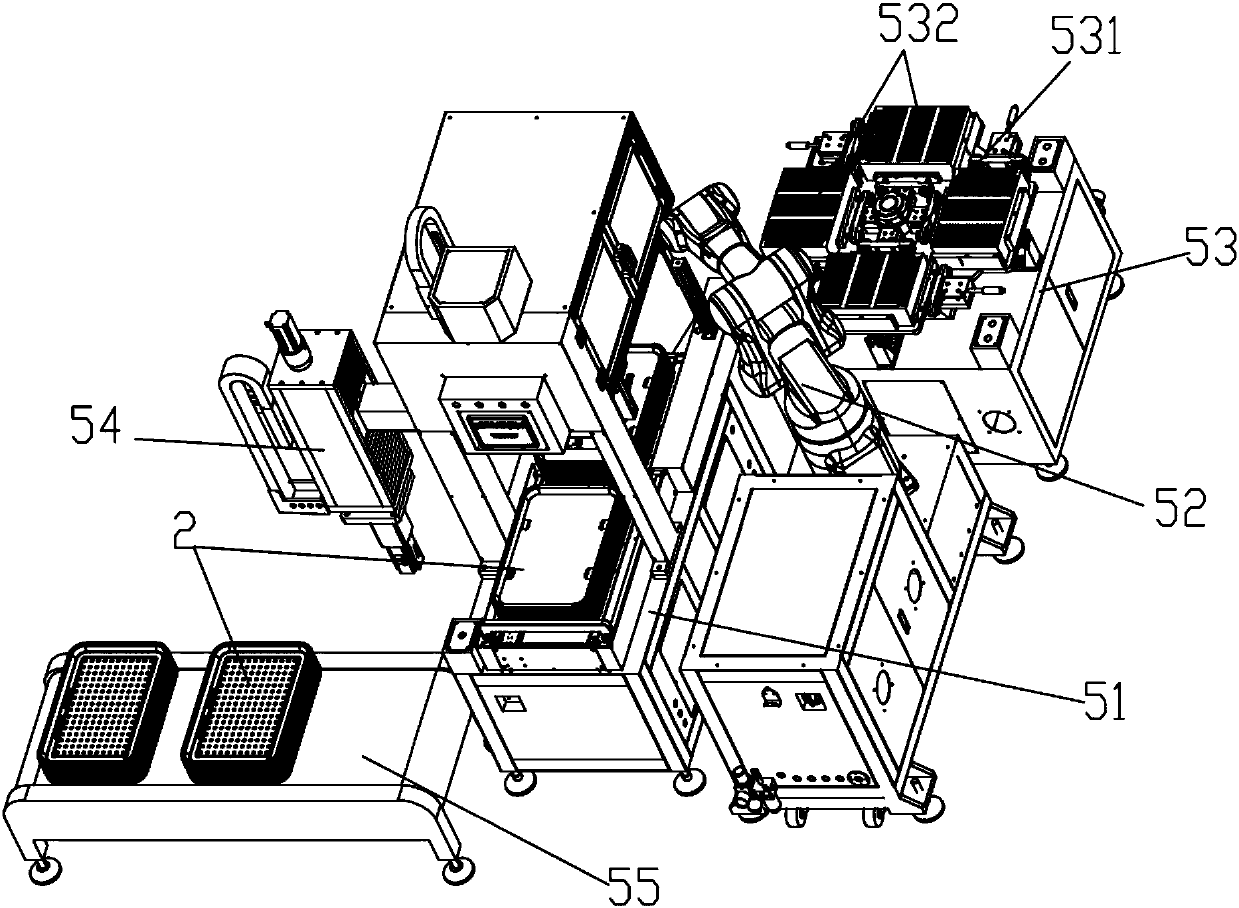

Intelligent production line for searching positions and inserting mobile phone touch screens in cages

PendingCN107901042AImprove recognition rateHigh degree of automationProgramme-controlled manipulatorProduction linePollen

The invention provides an intelligent production line for searching the positions and inserting mobile phone touch screens in cages. The intelligent production line comprises a position searching machine, a six-axis robot, a four-axis mechanical arm, a conveying belt and a material cage transfer station. The six-axis robot and the four-axis mechanical arm are arranged on the two sides of the position searching machine correspondingly, the conveying belt is arranged on one side of the four-axis mechanical arm, and the material cage transfer station is arranged within a working range of the six-axis robot. The intelligent production line has the following beneficial effects that 1, the automation degree is high, specifically, through automatic recognition and position searching of the position searching machine, automatic loading and unloading of the six-axis robot and the four-axis mechanical arm and conveying of the conveying belt and the material cage transfer station, the charging and conveying processes of the touch screen can be automatically completed; and 2, a working error is small, specifically, the mobile phone touch screens placed in a charging tray disorderly are photographed and recognized through a CDD industrial camera, then data analysis and real-time reporting of a production situation are conducted, meanwhile division of a working area and a material loading area of a material conveying mechanism is clear, mutual interference is avoided, the recognition rate, to the mobile phone touch screens, of the position searching machine for the mobile phone touch screens is greatly increased, and the working error is decreased.

Owner:广州泰行智能科技有限公司

Full-automatic grinding machine

InactiveCN108436663ASmall footprintEfficient collectionEdge grinding machinesAutomatic grinding controlEngineeringMechanical engineering

The invention discloses a full-automatic grinding machine. The grinding machine comprises a grinding chamber, grinding robots and moving platforms, wherein the grinding robots are inversely hung in the grinding chamber, and the moving platforms can carry a workpiece to move in and out of the grinding chamber; hand portions of the grinding robots are connected with floating deburring main shafts, and the floating deburring main shafts are connected with grinding cutters; and at least one grinding robot is arranged, each grinding robot is at least correspondingly provided with the two groups ofmoving platforms, and the two groups of moving platforms of each grinding robot alternately enter and exit the grinding chamber for workpiece grinding and workpiece feeding and discharging. Accordingto the grinding machine, the workpiece is machined fully automatically, so that the working efficiency is improved, the working error is reduced, the product quality is improved, and the production cost is reduced.

Owner:JIANGSU BVM INTELLIGENT TECH

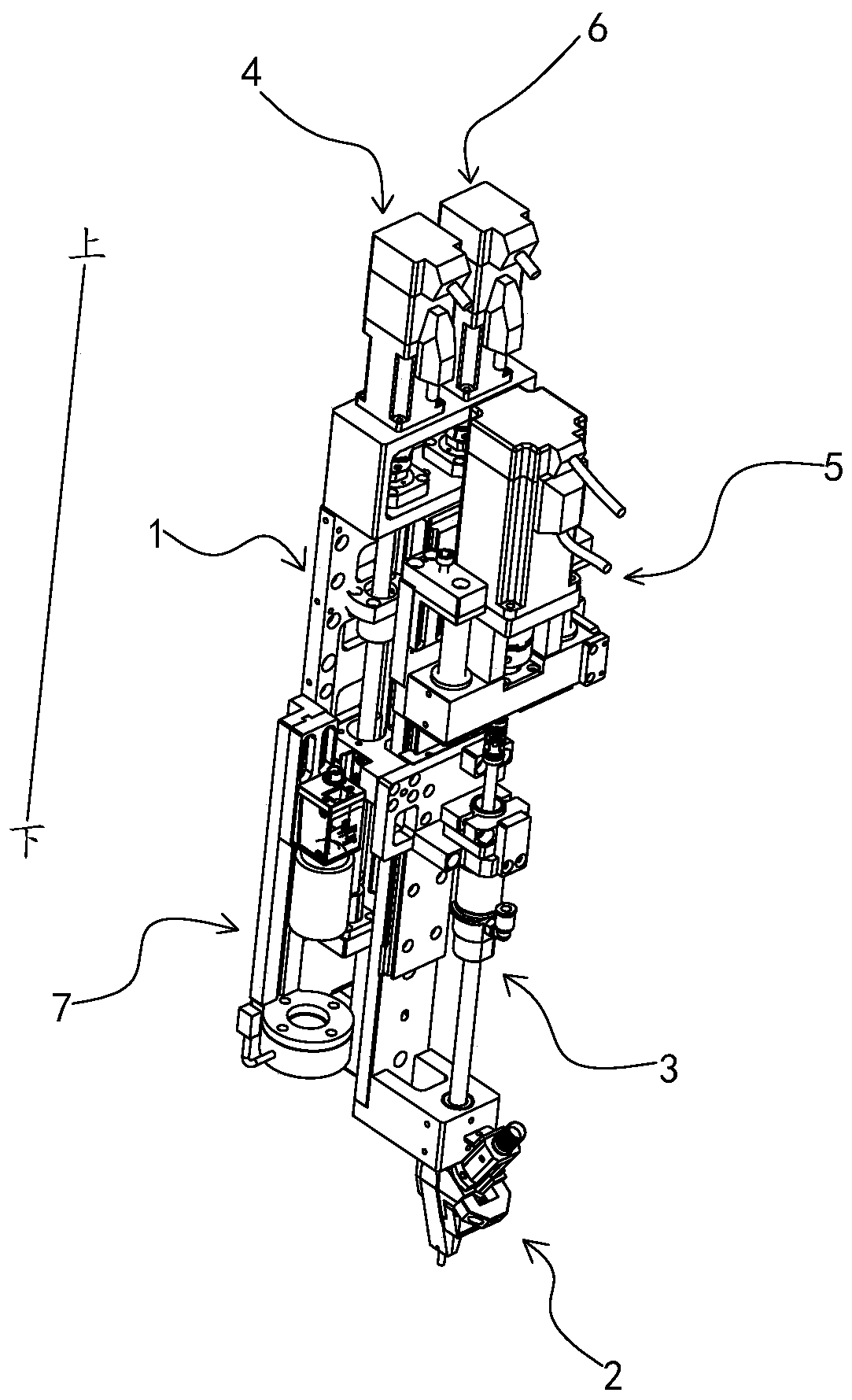

Automatic locking device and method

ActiveCN110315328AReduce installation errorsReduce working errorsMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic locking device and method. The automatic locking device comprises a conveying chuck for feeding, a taking assembly for taking materials from the conveying chuck, afirst driving assembly for driving the taking assembly to drive, a locking assembly for carrying out locking and a second driving assembly for driving the locking assembly to move. The taking assembly and the first driving assembly are connected, and the locking assembly and the second driving assembly are connected. The taking assembly is located between the conveying chuck and the second driving assembly. According to the automatic locking device, the first driving assembly and the second driving assembly drive the taking assembly and the locking assembly to lock the product, the mounting error and the work error of the automatic locking device are reduced, and the locking precision is high.

Owner:深圳市宏锦电子有限公司

Building brick shape-fixing cutting equipment

InactiveCN108189247ALow costEasy to useWorking accessoriesStone-like material working toolsBrickFixed frame

The invention discloses building brick shape-fixing cutting equipment. The building brick shape-fixing cutting equipment comprises an installation seat; the two ends of the upper surface of the installation seat are fixedly connected with a pair of L-shaped positioning plates; the upper surface of each L-shaped positioning plate is fixedly connected with a fixed pressing plate; the upper surface of the installation seat is fixedly connected with an electrically-controlled telescopic door-shaped frame; the lower surface of a transverse beam of the electrically-controlled telescopic door-shapedframe is fixedly connected with a transverse slide rail; an electrically-controlled movable slide block is arranged on the lower surface of the transverse slide rail, and the lower surface of the electrically-controlled movable slide block is fixedly connected with a door-shaped fixed frame; installation holes are machined in supporting legs of the door-shaped fixed frame, and a cutting motor of which the driving end is in the horizontal direction is embedded in one of the installation holes; the rotary end of the cutting motor is fixedly connected with a connection shaft stretching out through the other installation hole, and the connection shaft is sleeved with a cutting saw web. The building brick shape-fixing cutting equipment has the beneficial effects of being simple in structure andhigh in practicality.

Owner:魏敏生

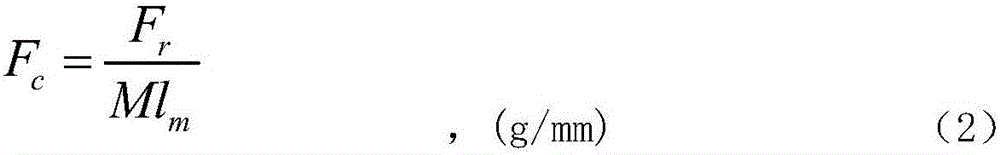

Method for evaluating risk of short circuit and damage of transformer

ActiveCN106295176ALow input costReduce participationInformaticsSpecial data processing applicationsPower flowLow voltage

The invention relates to a method for evaluating the risk of short circuit and damage of a transformer. The method is characterized by comprising the following steps: (1) evaluating the degree of the short circuit and damage of the transformer from short-circuit current according to a formula; (2) calculating the probability of tripping of single main transformer circuit every year according to a formula; (3) calculating the proportion of damaged transformers in recent ten years to transformers tripped at outlets according to a formula; (4) calculating the probability of the short circuit and damage at the low-voltage side of single transformer according to a formula; (5) evaluating the quantity P of the transformers damaged by short circuit every year according to a formula. The method is wide in application range, high in reliability and low in cost, can be used for evaluating the risk of the short circuit and damage of the transformer, and can be applicable to evaluation on the risk of the short circuit and damage of multiple transformers with different voltage levels and different cooling modes.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

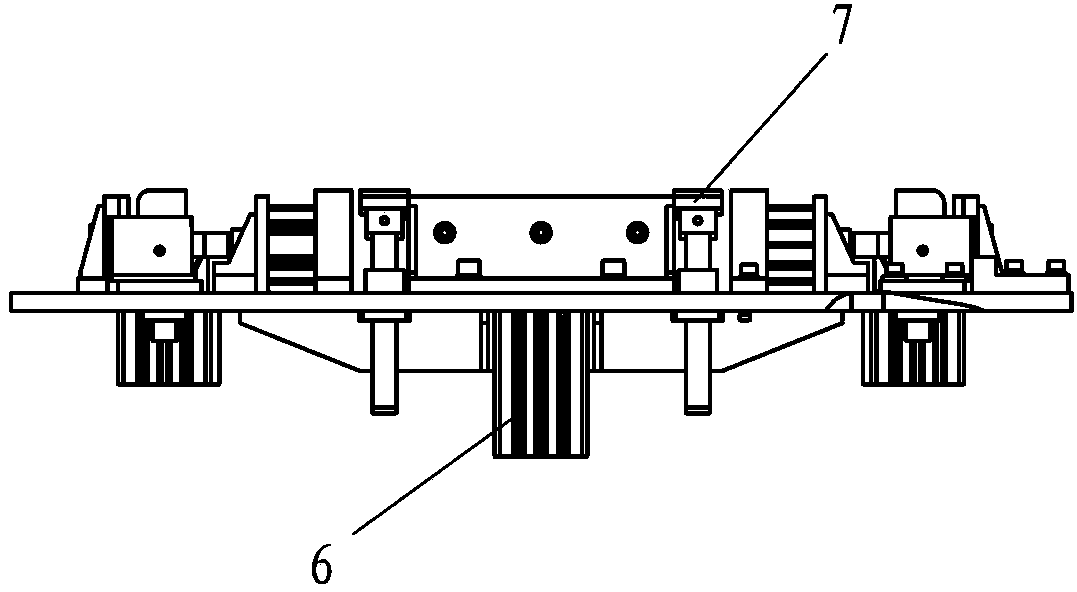

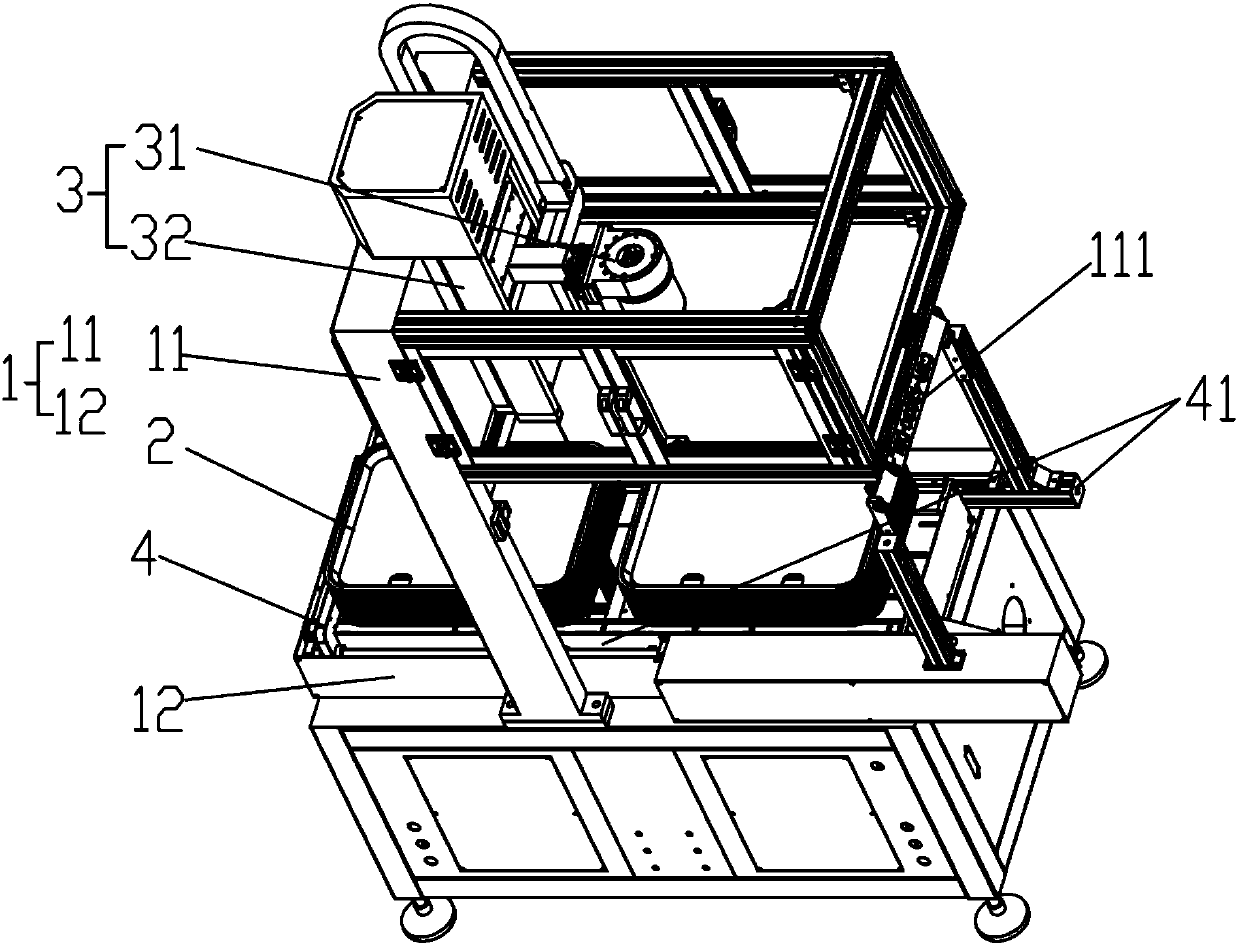

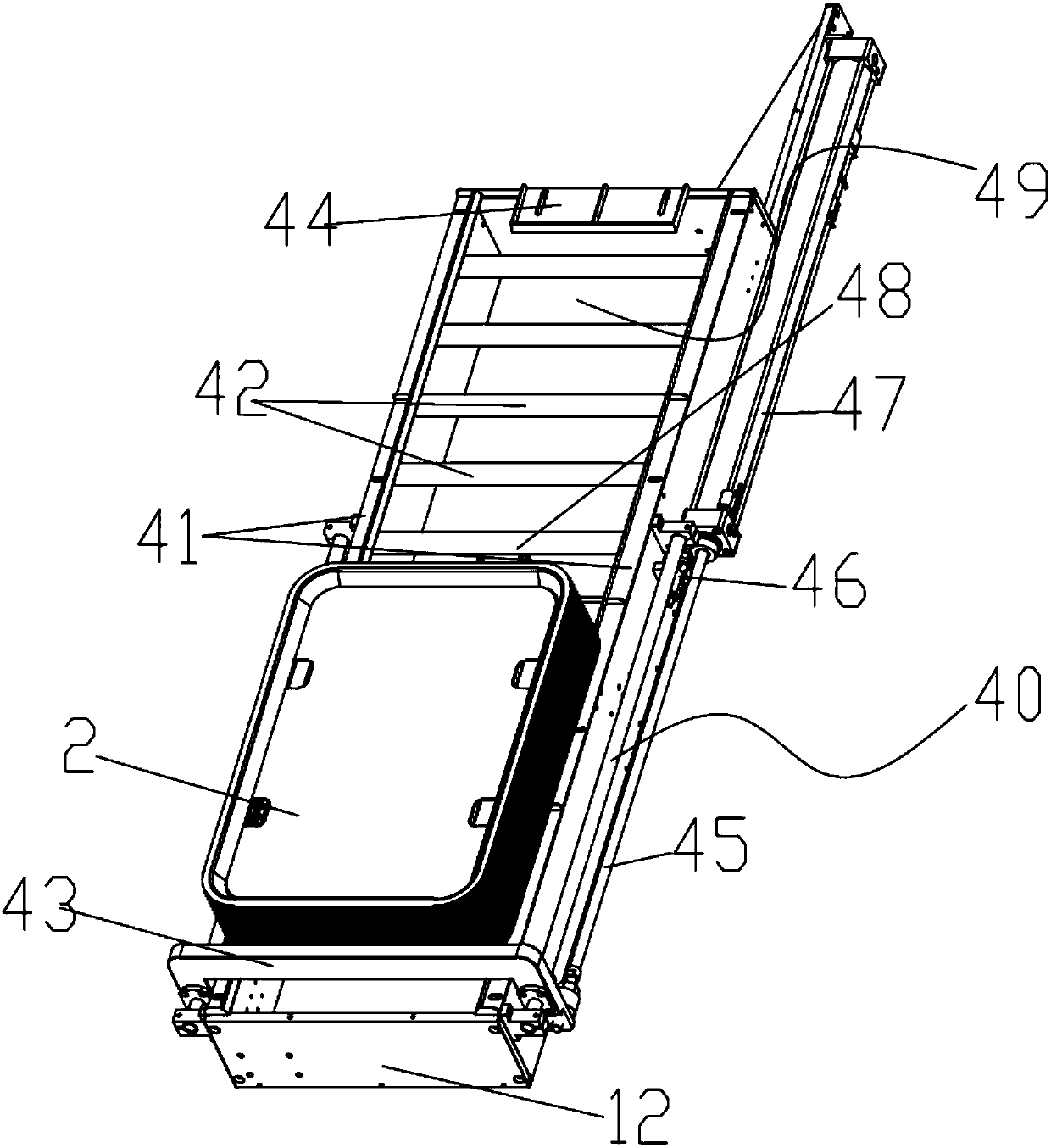

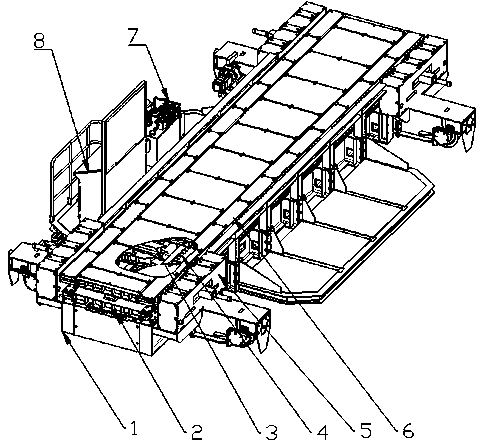

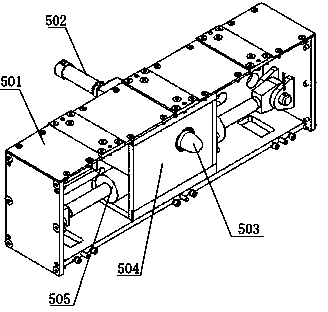

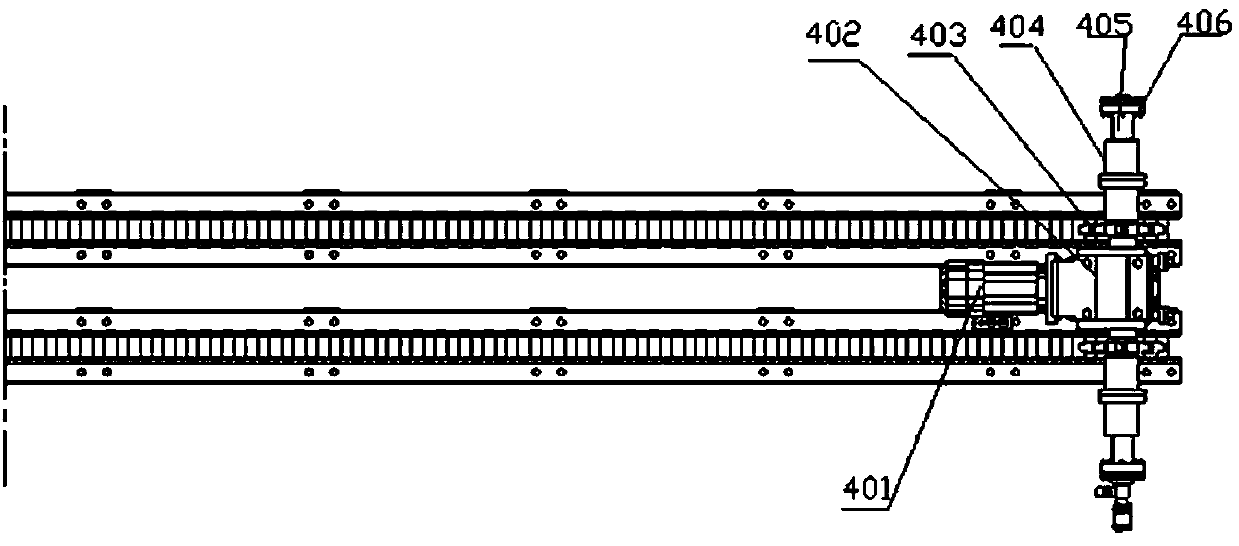

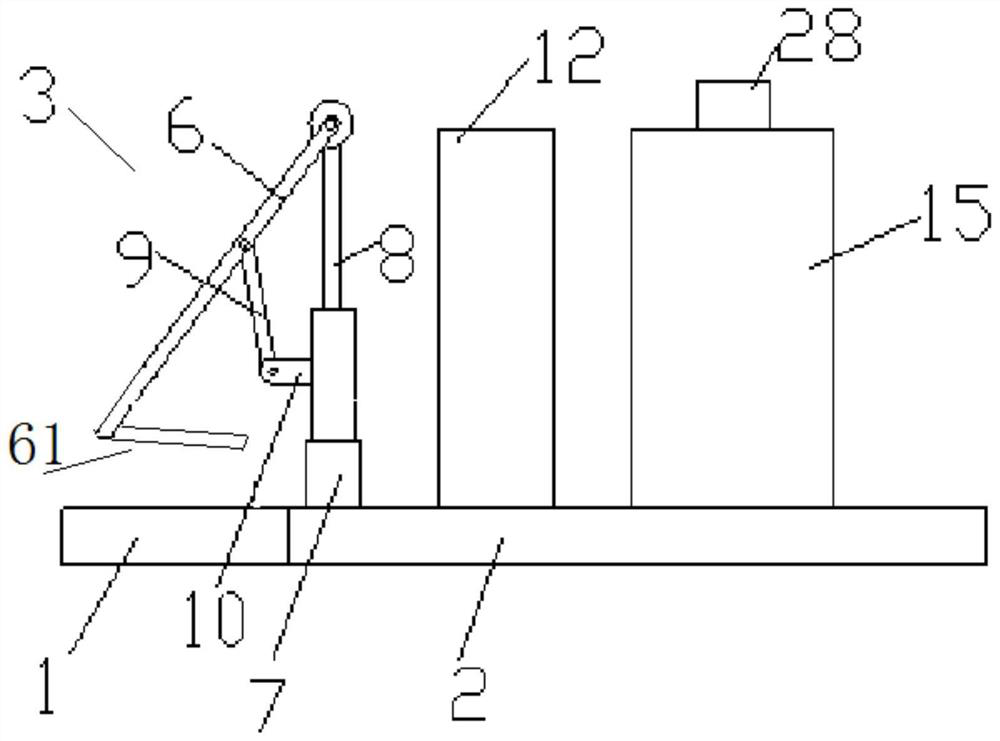

Automatic material loading and unloading vehicle

The invention relates to an automatic material loading and unloading vehicle. The automatic material loading and unloading vehicle comprises a bogie, a flatcar, a lift car and a material platform, wherein the bogie is located on a bogie running rail, the flatcar is located above the bogie, the lift car is located above the flatcar, the material platform is located above the lift car, and V-shaped blocks which are in contact with wheels of the lift car are arranged on the lower end face of the material platform. The automatic material loading and unloading vehicle further comprises a driving transmission device, a lift sliding mechanism, a lift orientation mechanism and a bogie locking mechanism, wherein the driving transmission device is used for driving the flatcar to horizontally move relative to the bogie, the lift sliding mechanism is used for driving the lift car to horizontally move so as to drive the material platform to be lifted, the lift orientation mechanism is used for orientating the lifting of the material platform, and the bogie locking mechanism is fixedly arranged on the bogie. The automatic material loading and unloading vehicle has the advantages that the problems in the prior art are improved and optimized, and the automatic material loading and unloading vehicle is safe and reliable and is long in service life, convenient in repair, low in cost and efficient in work.

Owner:LUOYANG SIGMA FURNACE

Method for estimating probability of short circuit damage risk of large-sized transformer

ActiveCN106295216AWide range of applicationsImprove reliabilitySpecial data processing applicationsInformaticsTechnical supportCurrent transformer

The invention discloses a method for estimating the probability of short circuit damage risk of a large-sized transformer. The method comprises the following steps: acquiring structure parameters of the transformer, checking the short circuit withstand capacity of the transformer, classifying a checking result and factors such as the operation environment and a low-voltage side configuration condition of the transformer, setting scores, endowing weights, quantifying the probability of the short circuit damage risk of the transformer according to information of a happened short circuit fault of the transformer, and performing grading. A worker can learn about the damage risk of the current transformer, and a technical support can be supplied to taking of targeted treatment measures in the future. The method is wide in application range, and can be applied to estimation of the probability of short circuit damage to various transformers with different voltage levels and different capacities. The method is high in reliability and low in cost; a common computer can be used for performing real-time computing, so that participation of a worker is reduced, the working error is reduced, and the working efficiency is improved.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

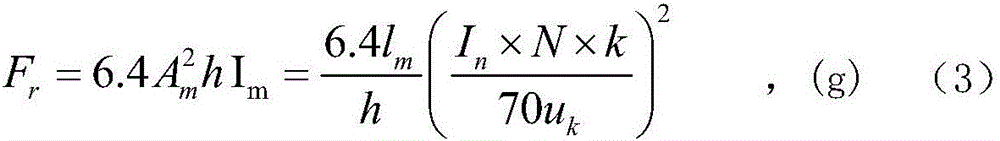

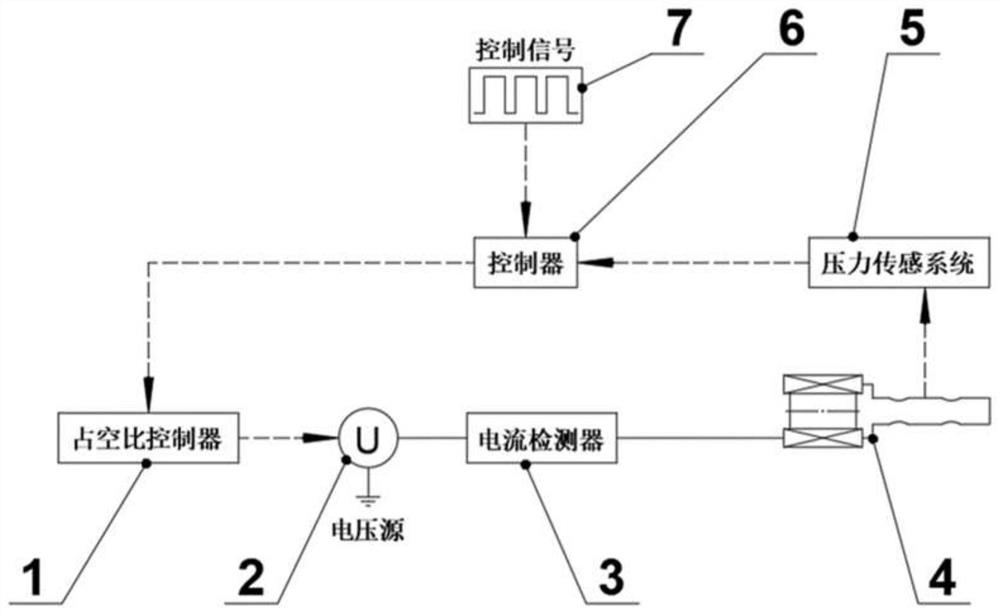

Electromagnetic valve high-dynamic high-frequency response control method based on voltage pulse width modulation technology

ActiveCN111810698AIncrease rate of ascentShort timeOperating means/releasing devices for valvesVoltage pulseAverage current

The invention discloses an electromagnetic valve high-dynamic high-frequency response control method based on a voltage pulse width modulation technology. A single working period of an electromagneticvalve is divided into a preloading excitation stage, a preloading maintaining stage, an opening stage, a reverse excitation stage, an opening maintaining stage, a closing stage and a closing maintaining stage. A single voltage source is adopted, the voltage source modulated by a high-frequency square wave signal with the duty ratio of 100% is adopted for excitation in the preloading stage, the current rising rate is higher, the current rises to the preloading current state faster, and the time consumed in the preloading excitation stage is shorter; and the current is then maintained in a preloaded current state. According to the method, in a reverse excitation stage, the voltage source modulated by the high-frequency square wave signal with the duty ratio of -100% is adopted for excitation, and the current is rapidly reduced to a maintaining current; and according to the electromagnetic valve, the average current in the working period is reduced, the electromagnetic energy consumptionis reduced, and the electromagnetic valve can adapt to a better opening and closing working condition.

Owner:ZHEJIANG UNIV OF TECH

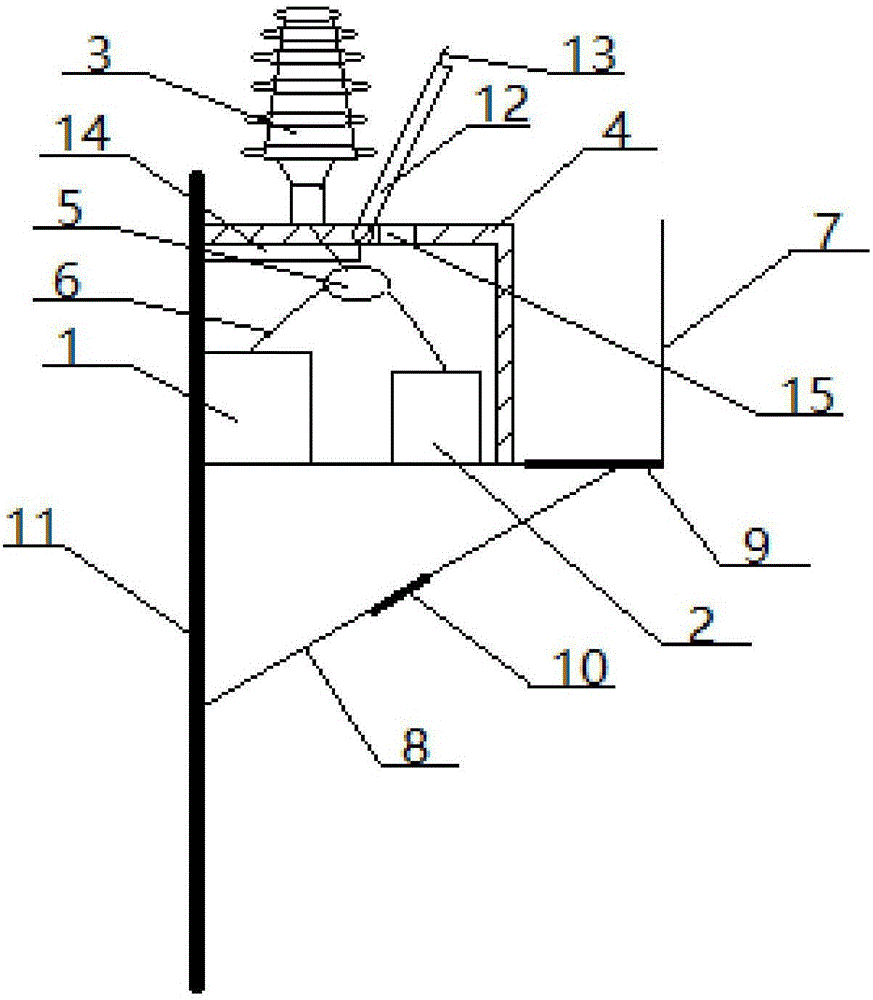

Outdoor high-voltage intelligent vacuum circuit breaker

InactiveCN106252148ARealize intelligent managementImprove the quality of workHigh-tension/heavy-dress switchesAir-break switchesAviationTransformer

The invention discloses an outdoor high-voltage intelligent vacuum circuit breaker, relating to the technical field of electrical automation. The high-voltage intelligent vacuum circuit breaker comprises a circuit breaker body, an intelligent controller, an external voltage transformer, a supporting frame and a protective box in a use process. The circuit breaker body is a vacuum circuit breaker. The circuit breaker body, the intelligent controller and external voltage transformer are electrically connected through an aviation socket and an outdoor sealing cable, and the circuit breaker body and the intelligent controller are installed in the protective box. In the use process of the outdoor high-voltage intelligent vacuum circuit breaker, a triangular structure is formed by the mounting base and the fixed rod of the high-voltage intelligent vacuum circuit breaker, a tool box can be placed on the fixed rod, and convenience is brought to work.

Owner:ANHUI XIGAO ELECTRIC EQUIP

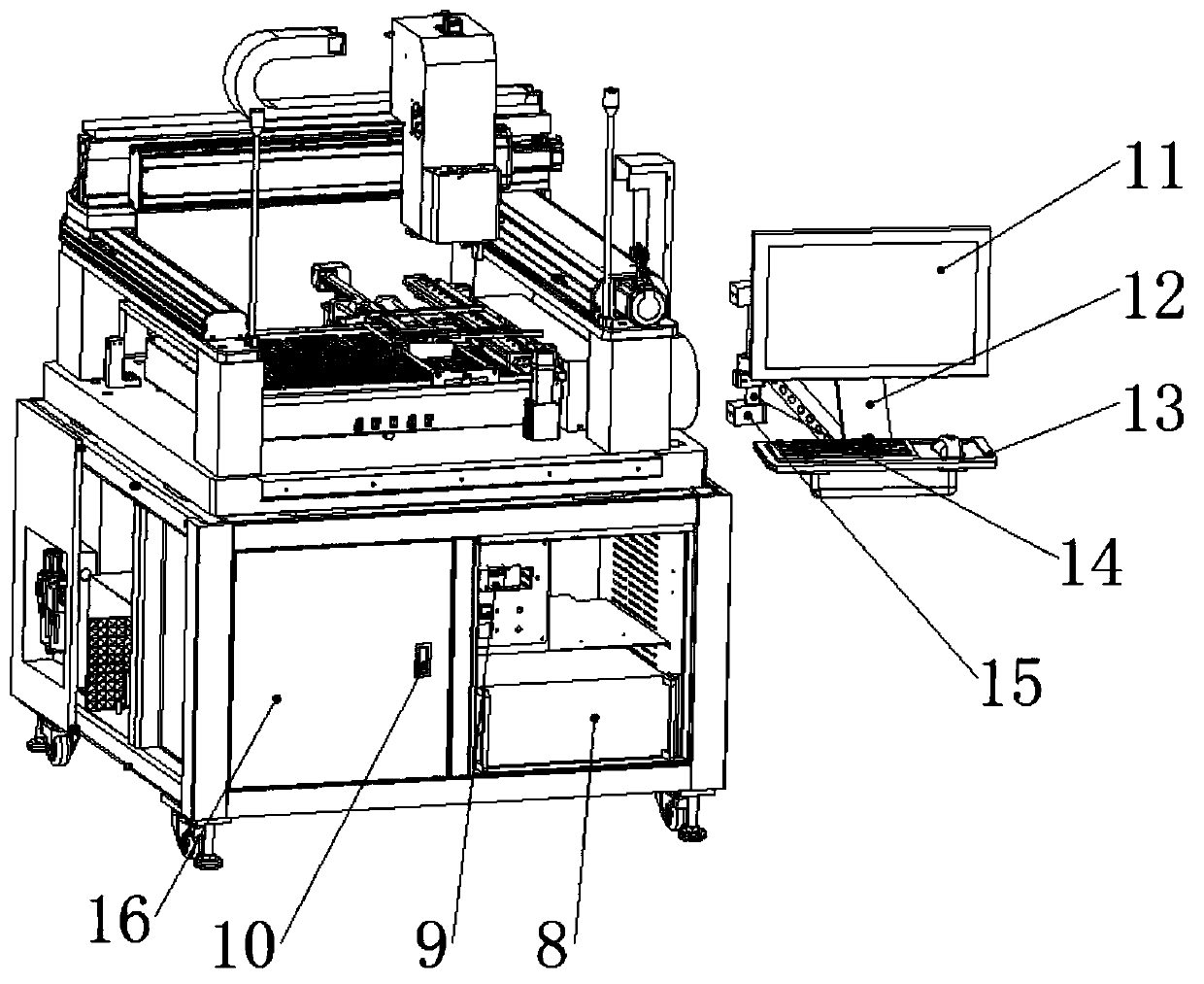

Full-automatic non-contact type detinning equipment

InactiveCN110076410ARealize automatic alignmentAutomatic identification of tin removal heightHeating appliancesSoldering auxillary devicesGratingDisplay device

The invention discloses full-automatic non-contact type detinning equipment which comprises a machine body upper cover and a machine body lower cover, wherein the bottom of the machine body upper cover is fixedly connected with the top of the machine body lower cover; a waste gas pumping system is arranged at the top of the machine body upper cover; emergency stop switches are arranged on the outer surface of the front side of the machine body upper cover in bilateral symmetry; a grating protecting system is arranged at the left end of the emergency stop switch at the right end; castor footedglass is arranged at the bottom of the machine body lower cover; an oil mist separator is arranged on the rear side of the outer surface of the left side of the machine body lower cover; an industrialpersonal computer is arranged in the lower right part of the machine body lower cover; and a displayer, a displayer fixing plate, a keyboard placement plate, a displayer swirling shaft and a displayer swirling column are sequentially arranged at the front right part of the machine body upper cover from top to bottom. The full-automatic non-contact type detinning equipment can precisely control counterpoint and heating and has the functions of automatic counterpoint, intelligent motion, automatic identification of detinning height and automatic detinning.

Owner:SHENZHEN ZHUO MAO TECH

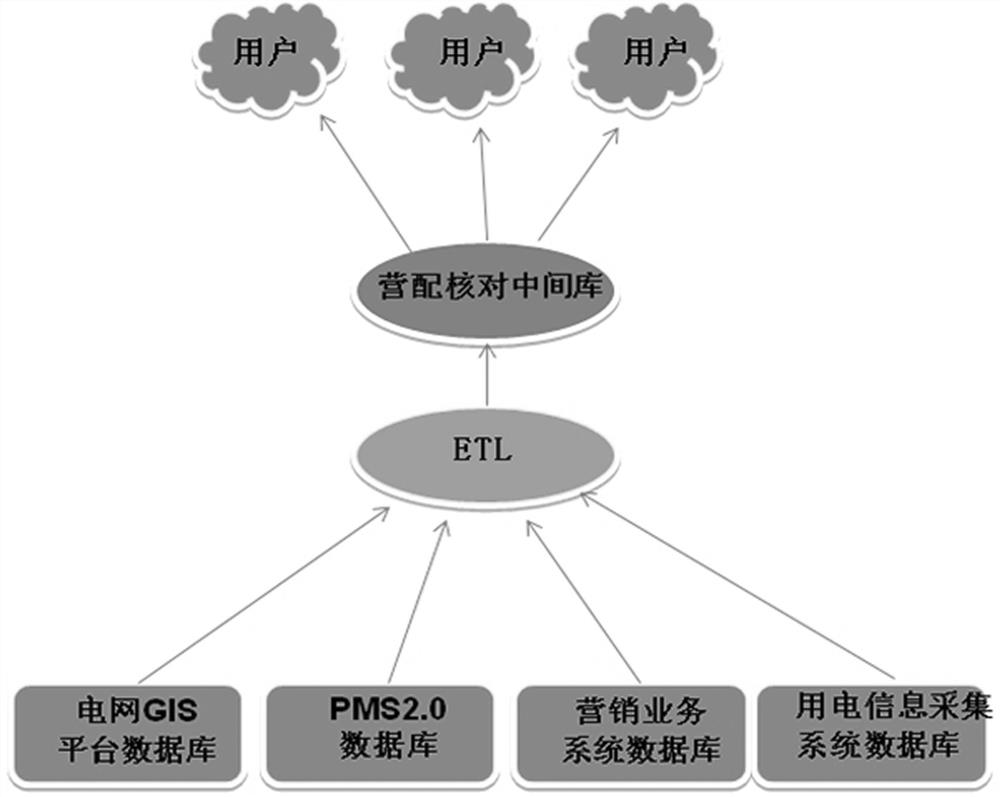

Power grid enterprise power equipment marketing and distribution through data acquisition and processing method

PendingCN112100223AAutomated Statistical AnalysisImproving the Statistical Effectiveness of IndicatorsDatabase management systemsGeographical information databasesLow voltageTransformer

The invention belongs to the technical field of data acquisition and processing, and particularly relates to a power grid enterprise power equipment marketing and distribution through data acquisitionand processing method. Through investigation and analysis of marketing and distribution through acquisition application conditions of basic units of Liaoning Company, marketing and distribution checkdata acquisition processing methods and devices are applied, cross-platform marketing, distribution and dispatching data checking management and control are realized. A marketing and distribution checking tool technology is applied to realize space information and attribute information checking management and control of bureau operation and inspection professional equipment such as low-voltage overhead equipment, low-voltage cables, low-voltage station buildings, low-voltage stations, low-voltage wall brackets and user access points and marketing and distribution through equipment such as user special lines, special transformers, metering equipment, terminal equipment and service websites; correlation between user equipment and power grid equipment such as a transformer substation, a lineand a transformer is established, a unified power grid equipment model, a customer information model, basic data and a topological relation are constructed, and cross-department and cross-professional data sharing and service fusion are realized.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +3

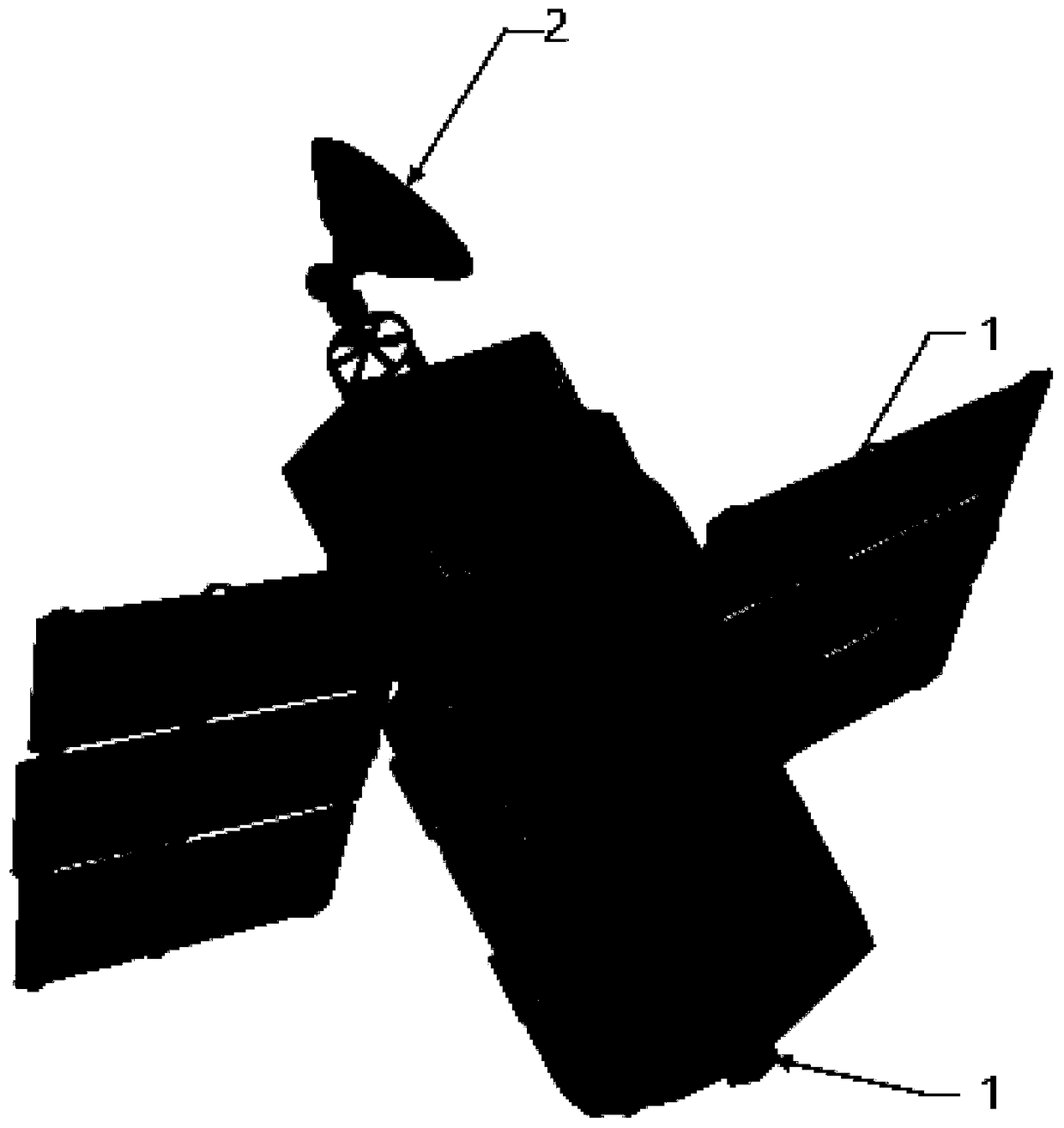

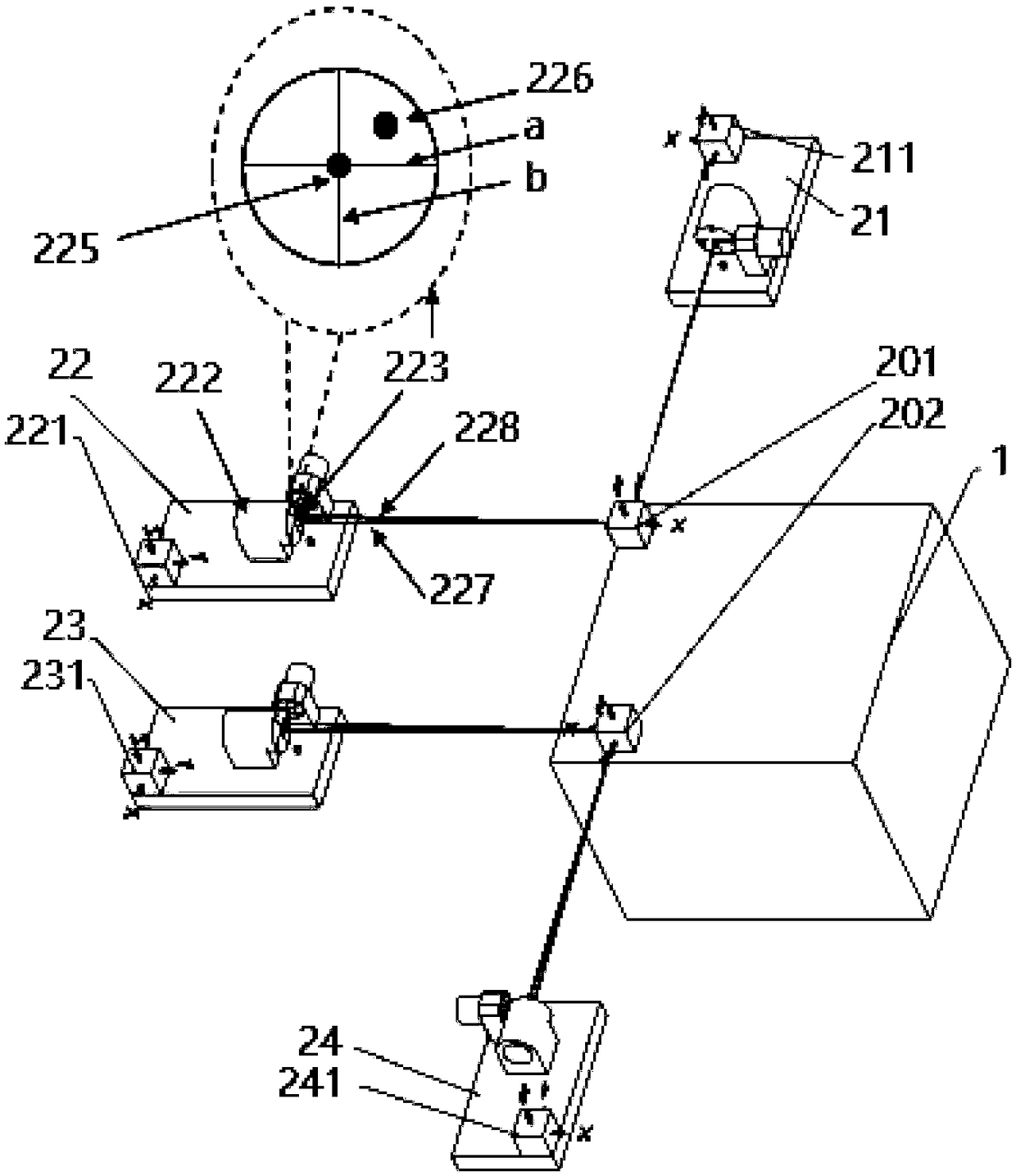

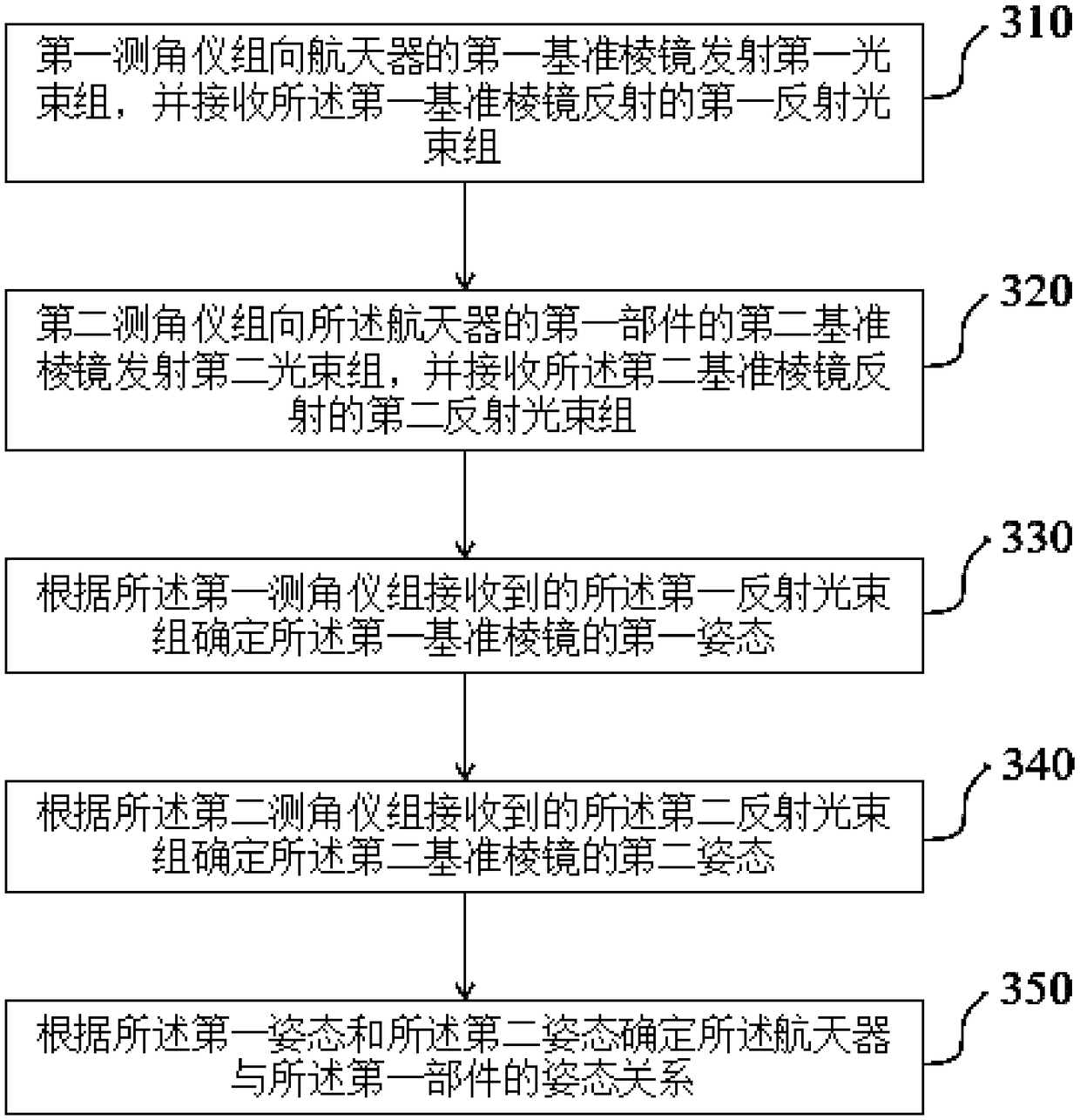

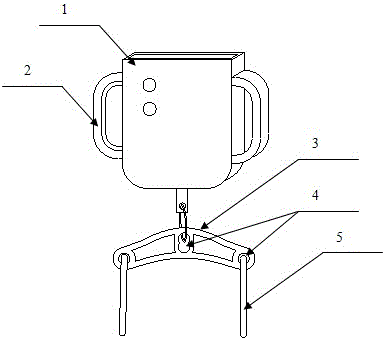

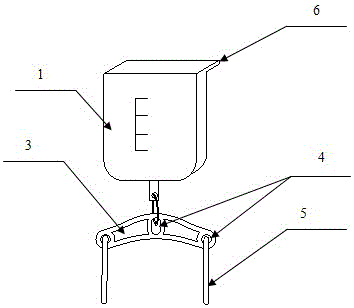

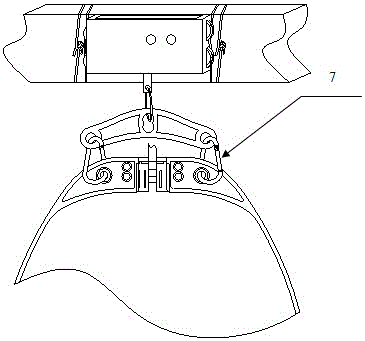

System and method for determining attitude relation between spacecraft and part

A system for determining the attitude relation between a spacecraft and a part may comprises a first angle measuring group, a second angle measuring group and a processor. The first angle measuring group can be used to measure the spatial attitude of a reference prism of the spacecraft. The second angle measuring group can be used to measure the spatial attitude of a reference prism of the spacecraft part. The processor can determine the attitude relation between the spacecraft and the part according to the spatial attitudes. The system can determine the attitude of the spacecraft and the partthereof automatically via the angle measuring groups, the relation therebetween is constructed by the processor instead of manually, the working efficiency can be improved greatly, and the working errors and reliability decrease caused by artificial factors are reduced.

Owner:银河航天(北京)通信技术有限公司

Medical scale

PendingCN106821648AReduce work intensity and errorsSmooth drainageIntravenous devicesNursing bedsHandrailDrainage bags

The invention discloses a medical scale. The medical scale comprises a body. The medical scale is characterized in that the body is a part of a bed or an infusion support; or the body is suitable for being hung or fixed to a transverse fixing rod of a fence handrail fixed to the side face / side faces of a bed frame or a bed edge and the bed frame / the bed edge; a hanging fixing device for hanging or fixing a drainage container is arranged or connected below the body. The medical scale can precisely weigh the weight or volume of liquid in a drainage bag, automatically add up the weight or volume of liquid in the common drainage bags and display and record use time. The medical scale can serve as a universal drainage container hanging device which is convenient and rapid to operate, achieves hanging fixing on multiple portions of the nursing bed in multiple modes, especially is hung and fixed on an installing fixing rod of a transverse handrail fence fixed to the side edge of the nursing bed and the side face of the nursing bed at the same time, can be rapidly installed and moved and is suitable for various drainage patients and wards.

Owner:常熟市精亮微医疗器械科技有限公司

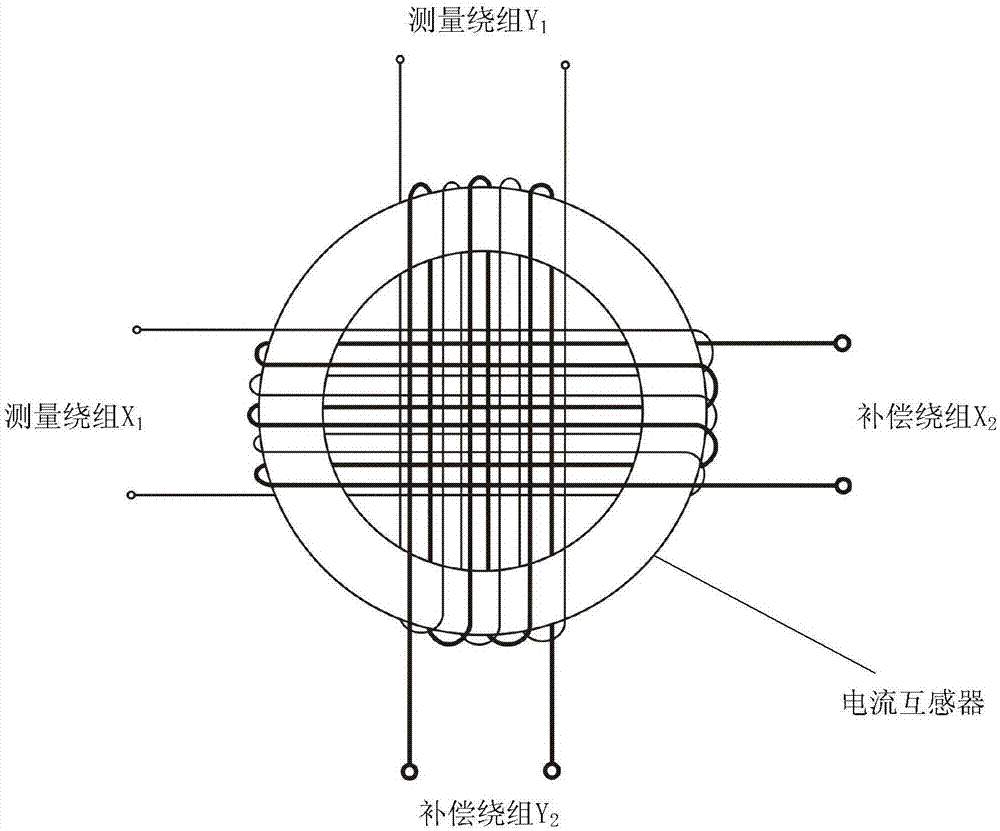

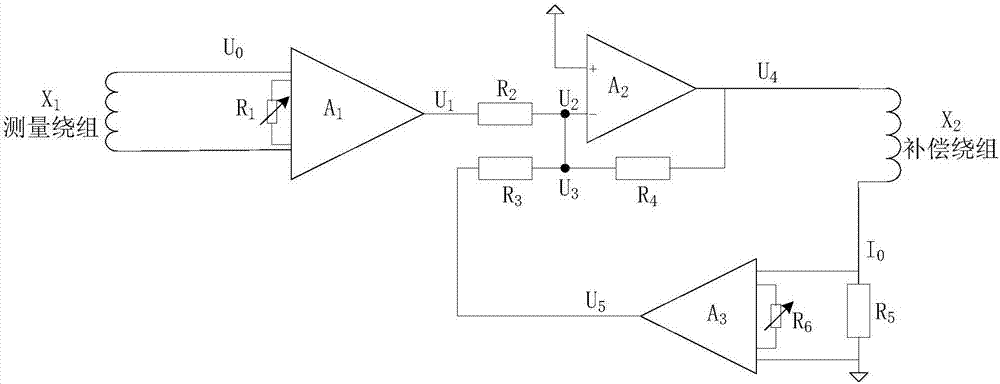

Current transformer based on active-compensation external magnetic field

InactiveCN106908635AReduce working errorsImprove stabilityInstrument screening arrangementsCurrent measurements onlyConductor CoilActive compensation

The invention relates to a current transformer based on an active-compensation external magnetic field. The technical characteristics are as follows: two pairs of measurement windings and compensation windings orthogonal to each other, namely, a measurement winding and a compensation winding in the X-axis direction and a measurement winding and a compensation winding in the Y-axis direction, are wound outside the current transformer; the two pairs of measurement windings and compensation windings are equal in number of turns and opposite in direction; and the two pairs of measurement windings and compensation windings respectively constitute an external magnetic field active compensation circuit in the X-axis direction and an external magnetic field active compensation circuit in the Y-axis direction. According to the invention, two pairs of measurement windings and compensation windings orthogonal to each other are wound outside the current transformer. Through the external magnetic field active compensation circuit between the two windings, the influence of an external magnetic field can be compensated actively. Therefore, the work error of the current transformer caused by the influence of an external magnetic field is reduced greatly, the stability of the current transformer is improved, the immunity to interference of an external magnetic field and precision of equipment are improved, and the effect of magnetic shielding is improved greatly.

Owner:国网天津节能服务有限公司 +3

Cleaning device for aluminum alloy extrusion forming

The invention discloses a cleaning device for aluminum alloy extrusion forming. The cleaning device comprises a workbench, an ejecting mechanism, a forming mechanism, a mold base, a discharging mechanism and an extruding barrel cleaning mechanism, wherein a through groove is longitudinally formed in the middle of the workbench, and sliding rails are arranged on the upper surface of the workbench along both sides of the through groove; the forming mechanism is arranged above the sliding rails, and a lifting base which is used for bearing the forming mechanism and can rotate is arranged below the center of the bottom of the forming mechanism; the ejecting mechanism is arranged on one end of the workbench and comprises an extruding oil cylinder and a hydraulic ejecting shaft which is arrangedon the front end of the extruding oil cylinder and faces towards the forming mechanism; the mold base is arranged on the other end of the workbench; the discharging mechanism is arranged on the otherend of the mold base; and the extruding barrel cleaning mechanism is arranged on one side of the forming mechanism. The cleaning device has an adaptive extruding barrel cleaning function, and a freeswitching mode of backward and forward extrusion during operation of aluminum alloy profile forming can be realized.

Owner:湖南千源铝业有限公司

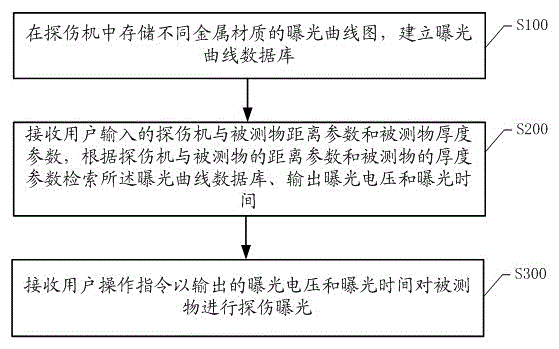

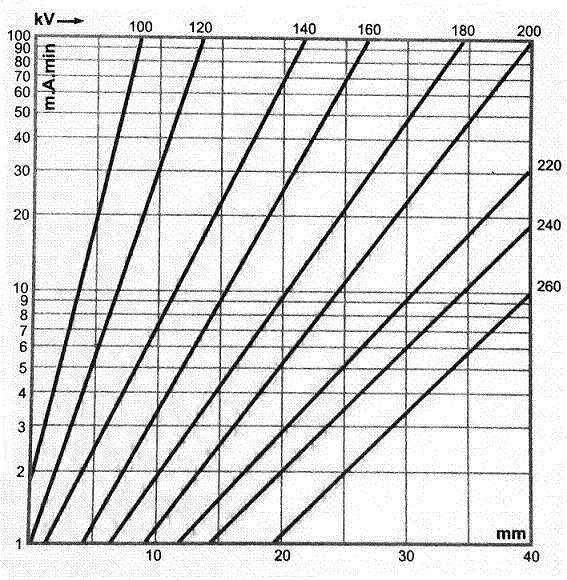

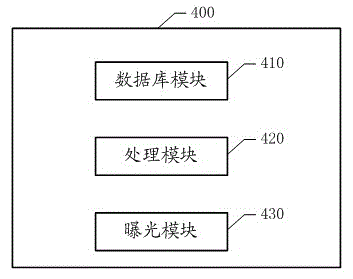

Detection apparatus and automatic exposure method and system for high frequency X-ray radial detection apparatus

ActiveCN105044135AEasy to useImprove accuracyMaterial analysis by transmitting radiationDistance parameterVoltage

The invention discloses a detection apparatus and an automatic exposure method and system for a high frequency X-ray radial detection apparatus. The method comprises the following steps of storing exposure curve charts of different metal materials in the detection apparatus, establishing an exposure curve database, receiving the distance parameter of the detection apparatus and a to-be-detected object and the thickness parameter of the to-be-detected object, which are input by a user; retrieving the exposure curve database, output exposure voltage and exposure time according to the distance parameter of the detection apparatus and the to-be-detected object and the thickness parameter of the to-be-detected object, and receiving a user operation command so as to carry out flaw detection exposure on the to-be-detected object by using the output exposure voltage and exposure time. According to the invention, only the thickness of the to-be-detected object is input, then the distance of the detection apparatus and the to-be-detected object can be exposed accurately, the operation and use are simple, the degree of accuracy is high, the parameter set steps of the traditional detection apparatus are simplified, the error and workload of the workers are reduced and the detection work efficiency is improved.

Owner:深圳市中昌探伤器材有限公司

Full-automatic lens sorting and packaging machine

PendingCN109110170AReduce work intensityReduce working errorsShock-sensitive articlesSortingEngineeringUltimate tensile strength

The invention discloses a full-automatic lens sorting and packaging machine. The full-automatic lens sorting and packaging machine at least comprises a machine frame and a feeding conveyance assemblyarranged on the machine frame. A lens on the feeding conveyance assembly is conveyed to a driving conveyance assembly through a connection conveyance assembly. The machine frame is further provided with an anti-static assembly, a lens centering and thickness detecting assembly and a focal power detecting assembly, wherein the anti-static assembly, the lens centering and thickness detecting assembly and the focal power detecting assembly are located above the connection conveying assembly or the driving conveyance assembly. One side of the tail end of the driving conveyance assembly is providedwith a packaging assembly used for packaging the lens on the driving conveyance assembly. The lens packaged by the packaging assembly is classified and pushed into a collecting frame by a pushing assembly. The full-automatic lens sorting and packaging machine has the beneficial effects of being simple in structure, ingenious in design, organically combines multiple kinds of equipment, achieves full-automatic detection, packaging and sorting, can greatly improve the production efficiency, lower the work intensity of workers and lower the product measurement error.

Owner:苏州申科谱自动化科技有限公司

Logistics conveying device used for warehousing system

PendingCN112027615AAvoid congestionImprove efficiencySortingConveyor partsLogistics managementProcess engineering

The invention relates to a logistics conveying device, in particular to a logistics conveying device used for a warehousing system. The logistics conveying device comprises a main conveying device, flow-dividing conveying devices, a material shifting device, a first portal frame which is used for identifying flow-dividing information, a second portal frame which is used for identifying commodity information, a first re-inspection portal frame which is used for identifying flow-dividing information again and a second re-inspection portal frame which is used for identifying commodity informationagain. When products are conveyed to corresponding discharging openings, the material shifting devices shift and convey the corresponding products to the corresponding flow-dividing conveying devices, and the products are conveyed to the corresponding storage areas through the flow-dividing conveying devices. According to the logistics conveying device, flow-dividing is automatically carried outon to-be-warehoused commodities, the to-be-warehoused commodities after flow-dividing are transmitted to the corresponding storage areas, and meanwhile, the technical problem of missing recording of the to-be-warehoused commodity information is solved.

Owner:NANJING INST OF MECHATRONIC TECH

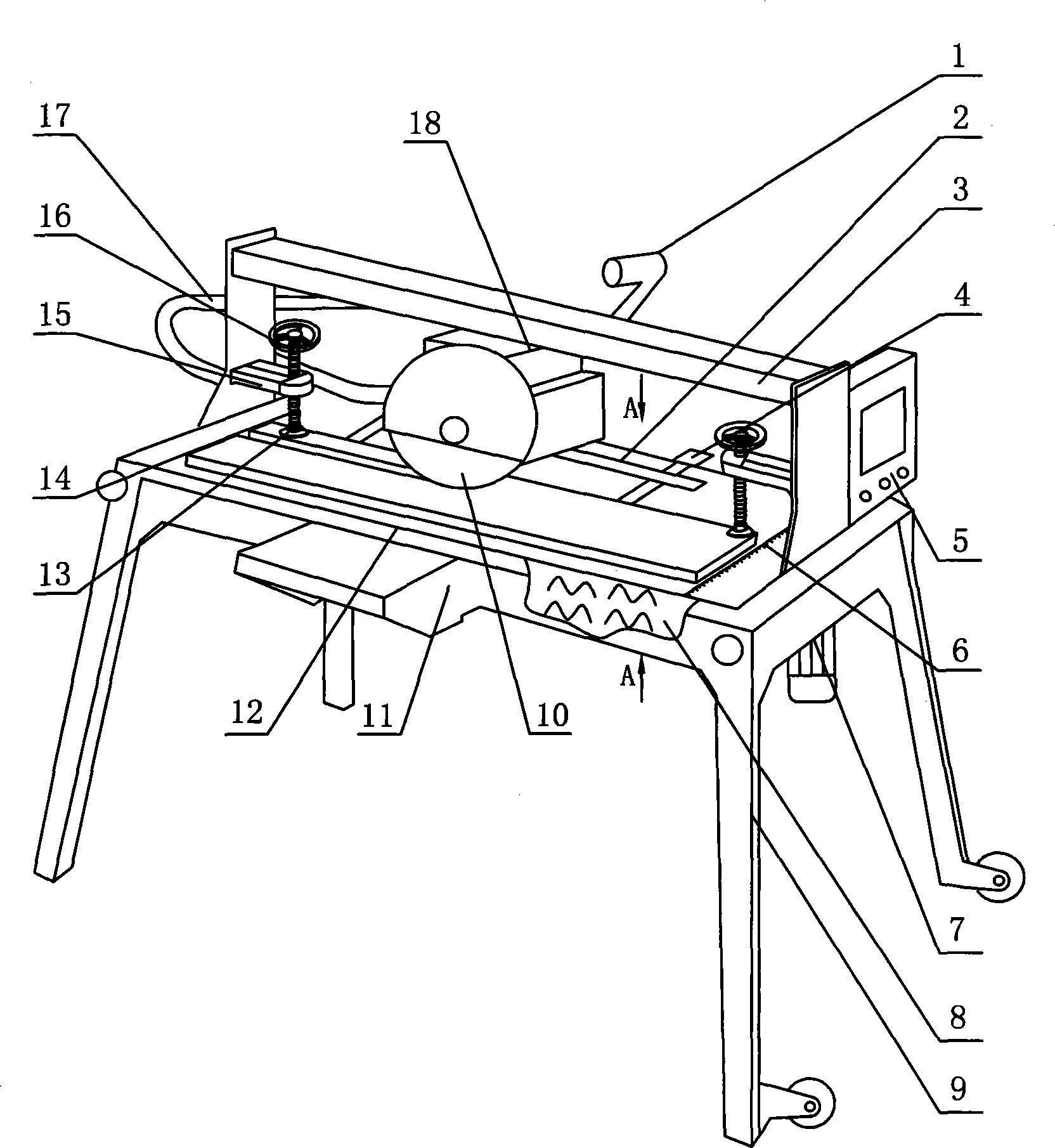

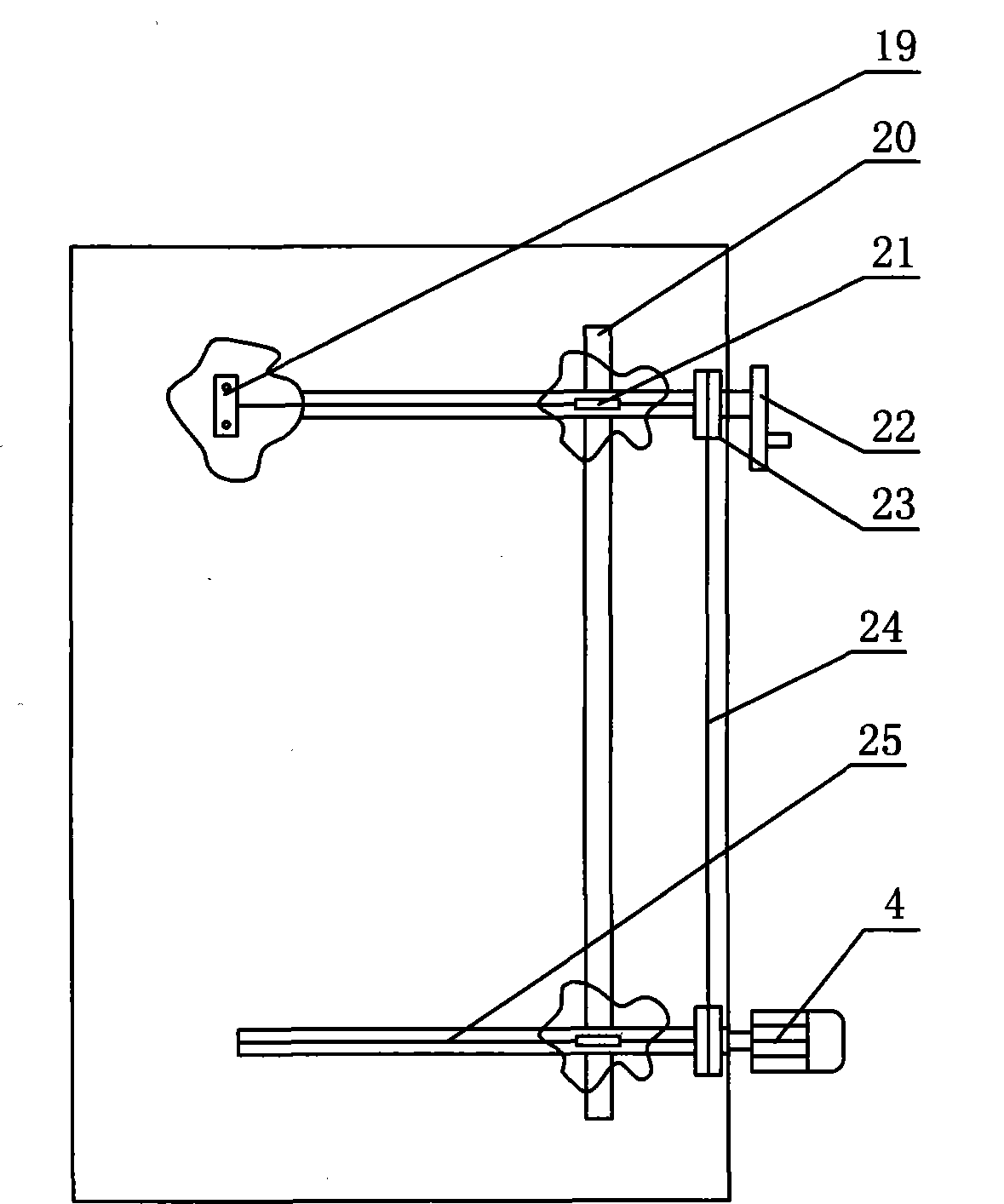

Intelligent novel water groove cutting machine

ActiveCN104275748AEffectively fixedSmooth incisionWorking accessoriesStone-like material working toolsAutomatic controlProgrammable logic controller

The invention provides an intelligent novel water groove cutting machine and relates to the field of electric tools. The cutting machine is reasonable in structure; a PLC (Programmable Logic Controller) program is used for controlling a movable box, an automatic feeding device and a water pump, so that digital automatic cutting and automatic cooling procedures are realized; the automation degree is high and the performance is safe and reliable. According to the cutting machine, hold-down mechanisms are arranged at the two ends of an I-shaped bracket; a working tabletop is provided with the automatic feeding device and manual control and automatic control can be realized. Each hold-down mechanism is composed of a small supporting frame, a hold-down hand wheel, a screw rod and a rubber compression disc; all types of workpieces can be effectively held down and the workpieces are not damaged. The automatic feeding device can be used for automatically adjusting cutting positions of the workpieces, so that the labor intensity of workers is alleviated, the working errors are reduced, and the product quality and the working efficiency are improved.

Owner:YANCHENG BAODING POWER TOOLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com