Equipment and process for manufacturing flexible circuit board

A flexible circuit board and equipment technology, applied in printed circuit manufacturing, printed circuit, mechanical/acoustic circuit processing, etc., can solve the problems affecting the accuracy of product stamping, high environmental requirements, increase costs, etc., to reduce work errors, reduce Equipment investment and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

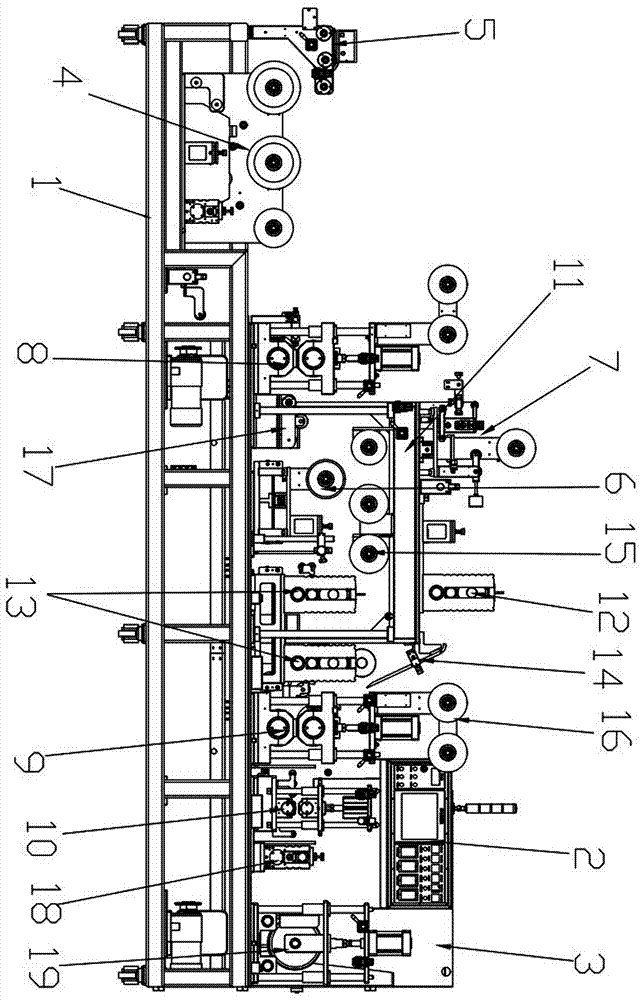

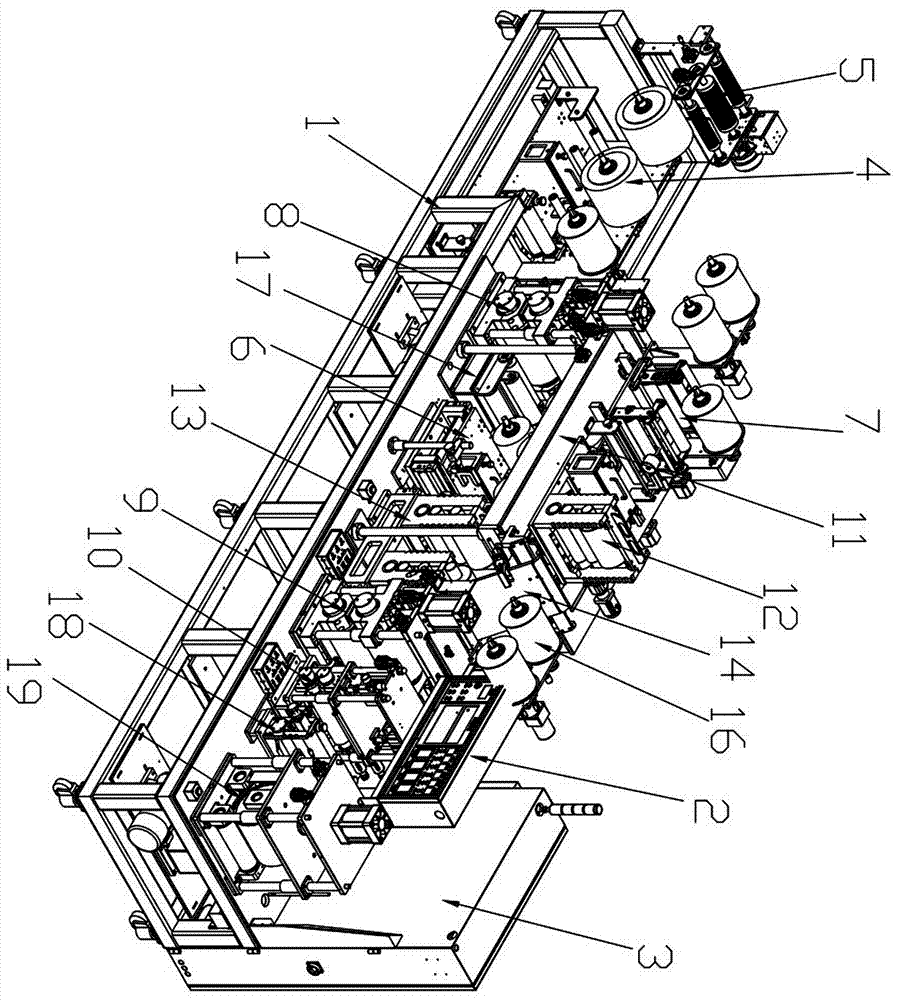

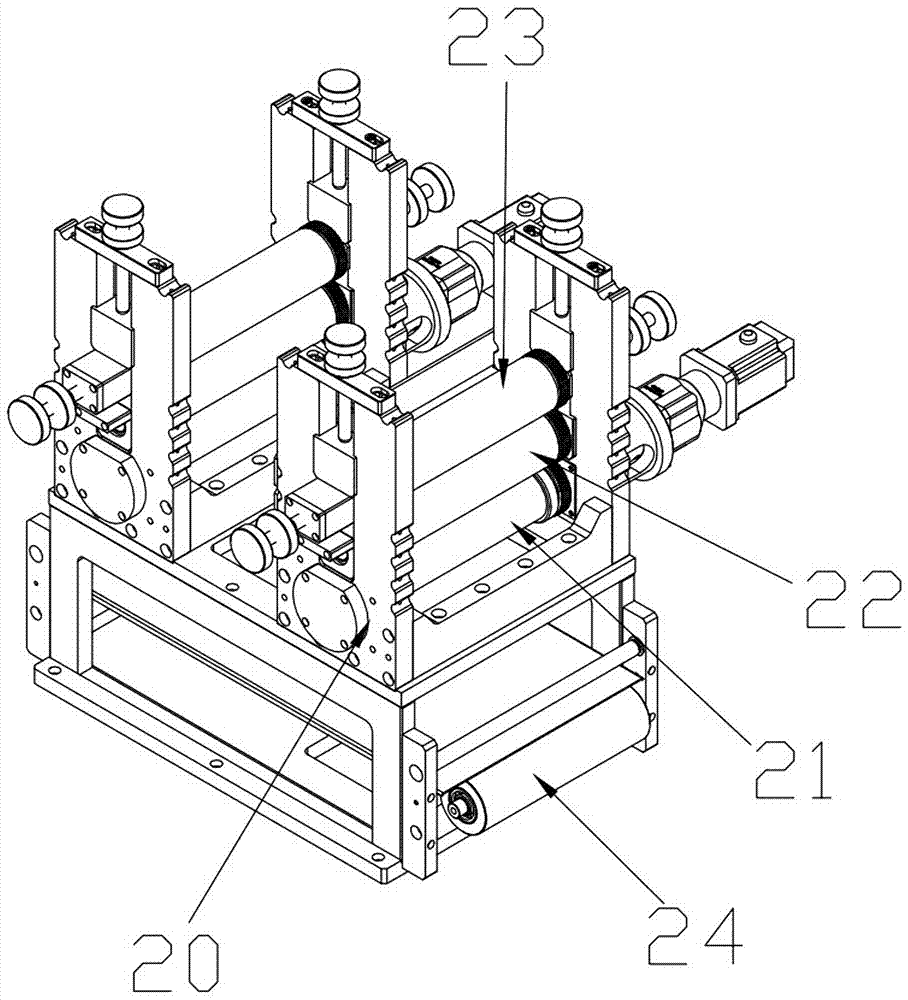

[0030] In this embodiment, refer to Figure 1 ~ Figure 4 The equipment for manufacturing flexible circuit boards specifically implemented includes a strip-shaped frame-type body 1, and the top of the frame-type body 1 is an automatic operation platform, which includes a control panel 2, an automatic feeding part, an automatic pressing part, an automatic The rolling cutting part, the slitting mechanism 18, the traction mechanism 19 and the winding mechanism (not shown), the control panel 2 are connected with the main control electric box 3.

[0031] The automatic feeding part includes the bottom film feeding mechanism 4, the strip conductor feeding mechanism 5, the laminating middle film feeding mechanism 6 and the cover film feeding mechanism 7, and the automatic pressing part includes the first pressing mechanism 8 and the second press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com