Patents

Literature

68results about "Mechanical/acoustic circuit processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical backdrilling method for PCB

InactiveCN105025658AAvoid errorsAvoid the phenomenon that the surface copper thickness becomes largerMechanical/acoustic circuit processingPrinted element electric connection formationCopper platingTin plating

The invention discloses a mechanical backdrilling method for a PCB. The method comprises the following steps that through holes are drilled in the PCB; the inner wall of the through hole is electro-plated with a copper layer; resin is filled into the through hole whose inner wall is covered with the copper layer; depth-controlled backdrilling is carried out on the through hole into which the resin is filled; and copper scarps in the backdrilling hole are removed by etching. The mechanical backdrilling method can protect the copper layer at the inner wall of the through hole by filling the resin into the hole, the part, protected by the resin, of the copper layer is not influenced in the etching process, secondary copper and tin plating are not needed, the problem that the diameter of the through hole is decreased caused by twice copper electroplating at the inner wall of the through hole is solved, and the phenomenon that an electroplated tin layer cannot protect the copper layer, which should not be etched, in the hole is avoided. Mechanical backdrilling is carried out after the resin is filled, so that the depth-controlled tolerance of the mechanical drilling hole is strictly controlled within the range of + / -0.075mm, the production efficiency is improved, and the social competitiveness of enterprise is improved.

Owner:开平依利安达电子第五有限公司

Method for producing a radome and corresponding radome

ActiveUS20180269569A1Easy and inexpensive procedureLow production costTransparent/reflecting heating arrangementsRadiating element housingsEngineeringFlexible electronics

The invention relates to a method for producing a heatable radome, a flexible printed circuit board having a metallic structure being used. Said flexible printed circuit board is embossed and is back-molded with a thermoplastic material.

Owner:HELLA KG HUECK & CO

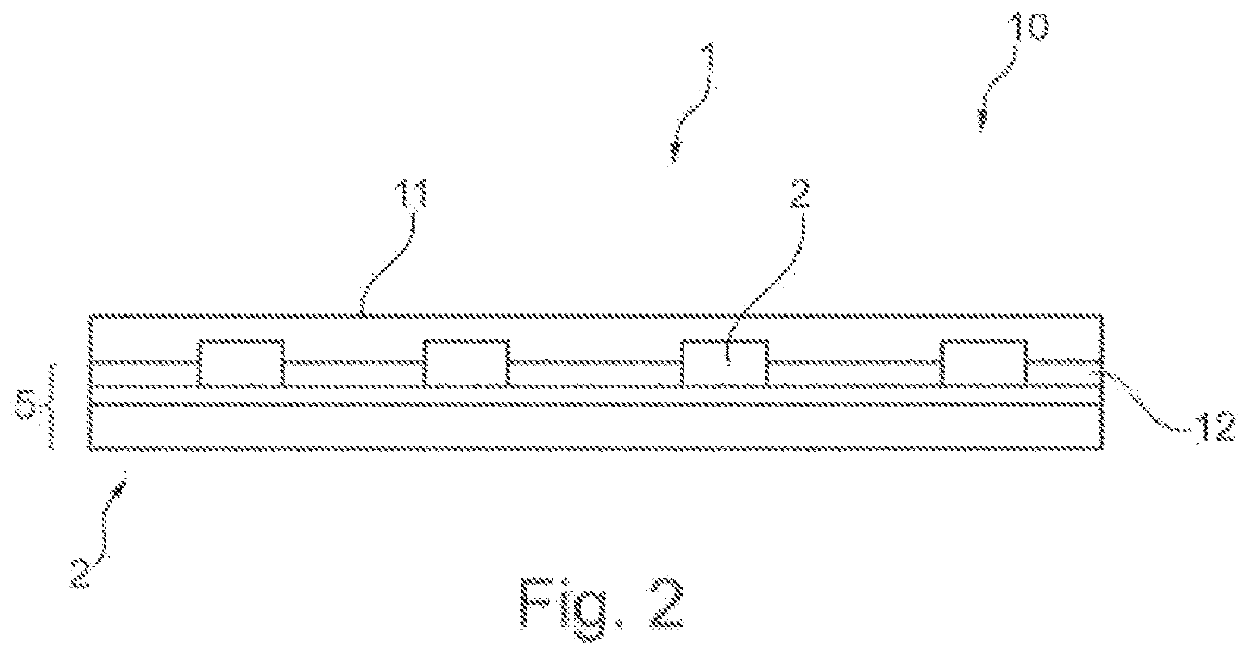

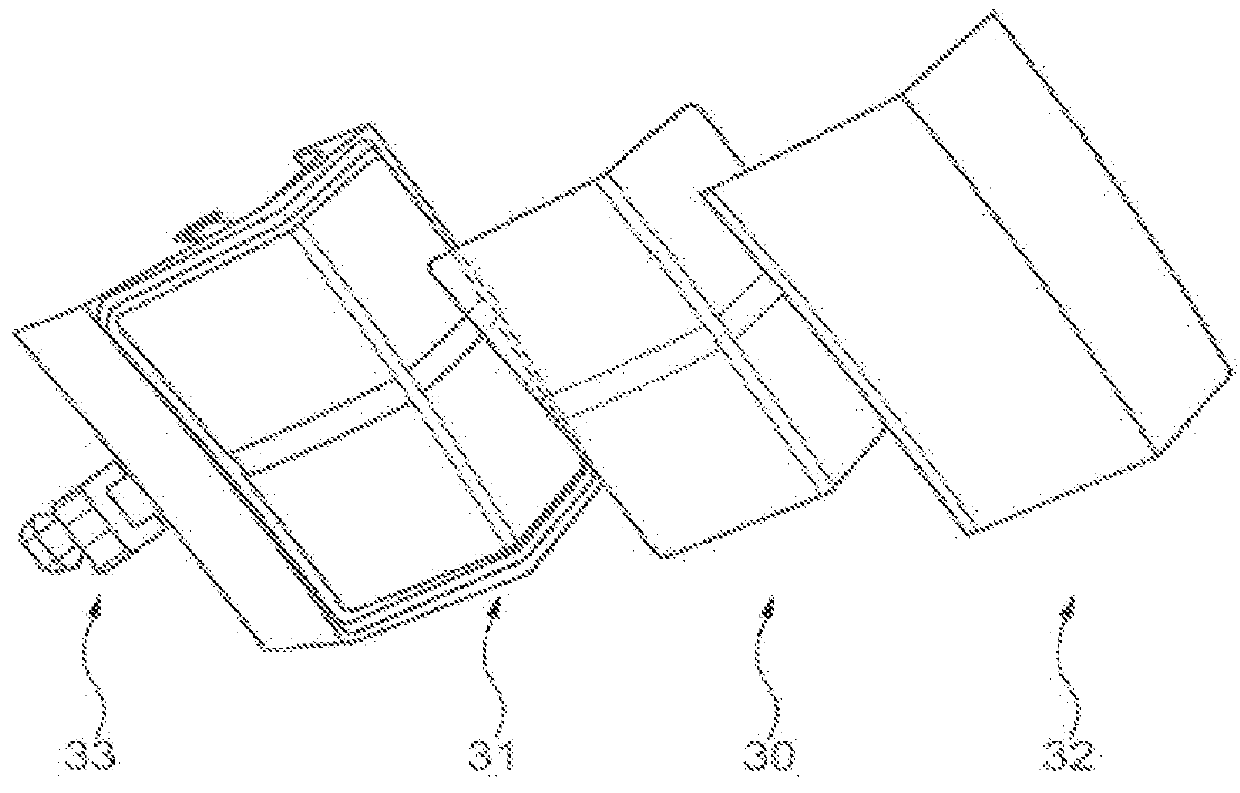

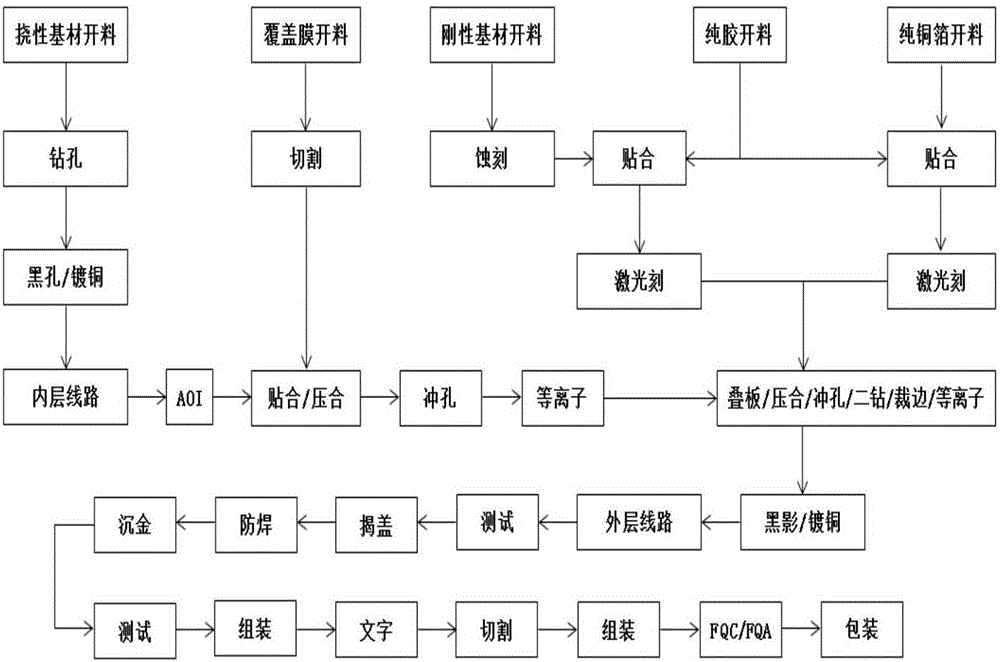

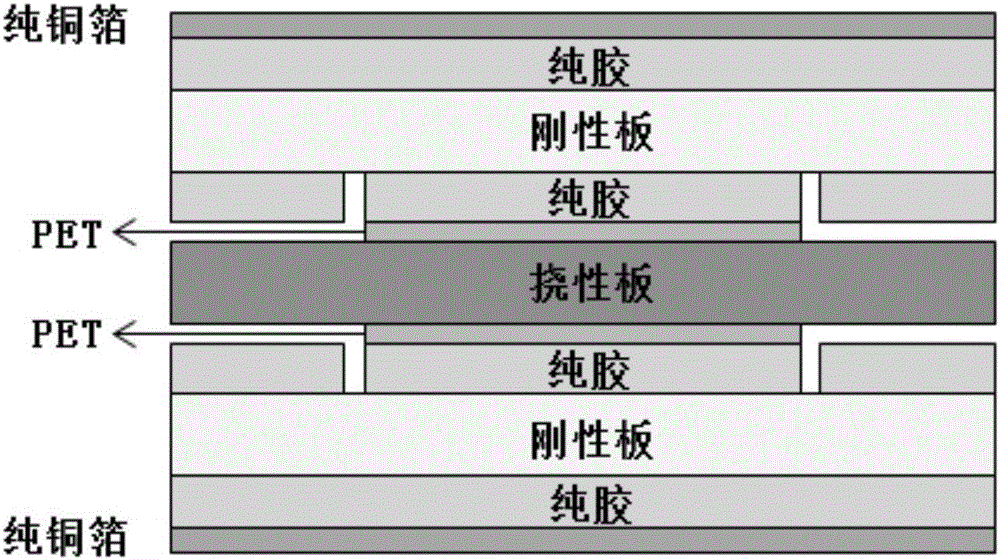

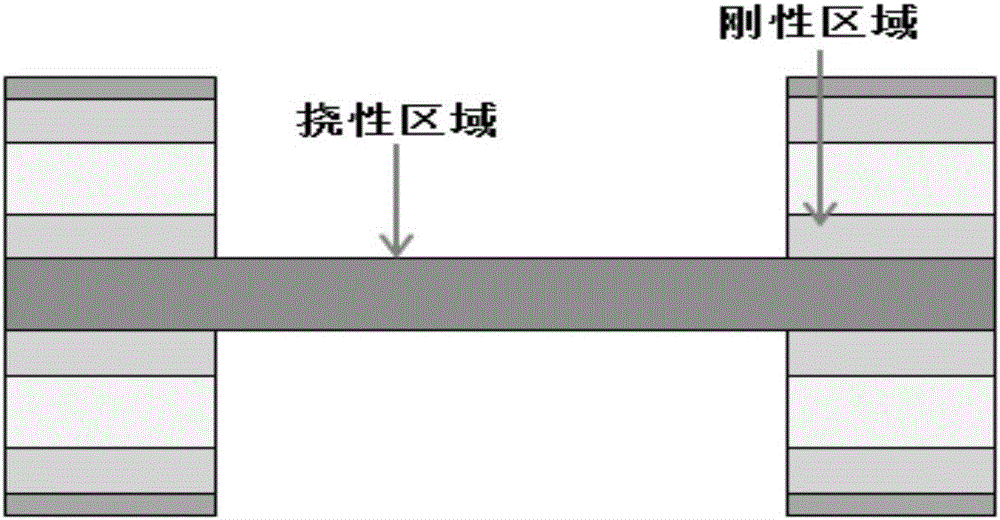

Method for producing rigid-flex PCB lid

InactiveCN106535510AWon't frackMechanical/acoustic circuit processingMultilayer circuit manufactureCopper platingPunching

The invention relates to a method for producing a rigid-flex PCB lid. The method comprises material cutting, flexible material treatment, rigid material treatment, integration, a shadow / copper plating, an outer layer, and punching and lid removing. According to the method for producing a rigid-flex PCB lid, an internal-layer circuit is produced in the rigid-flex PCB, anti-etching ink is not required to be printed after a coverage film is pressed. The flexible board, the rigid board and the pure copper foil can be combined at one time to complete the combination. The pure copper foil cannot be cracked when pressed. The method reduces production process and reduces production cost.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

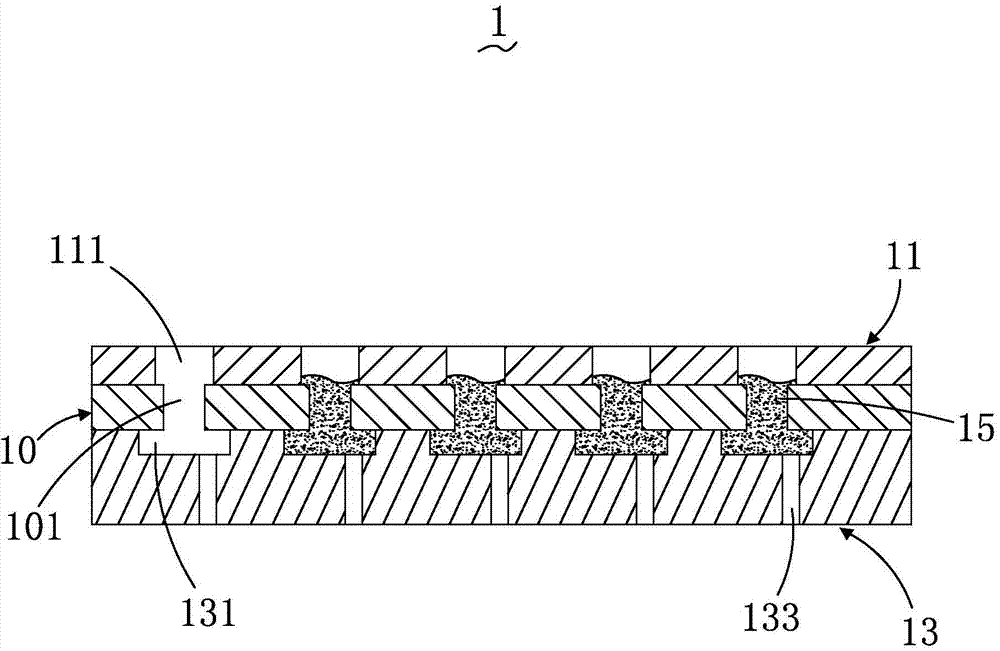

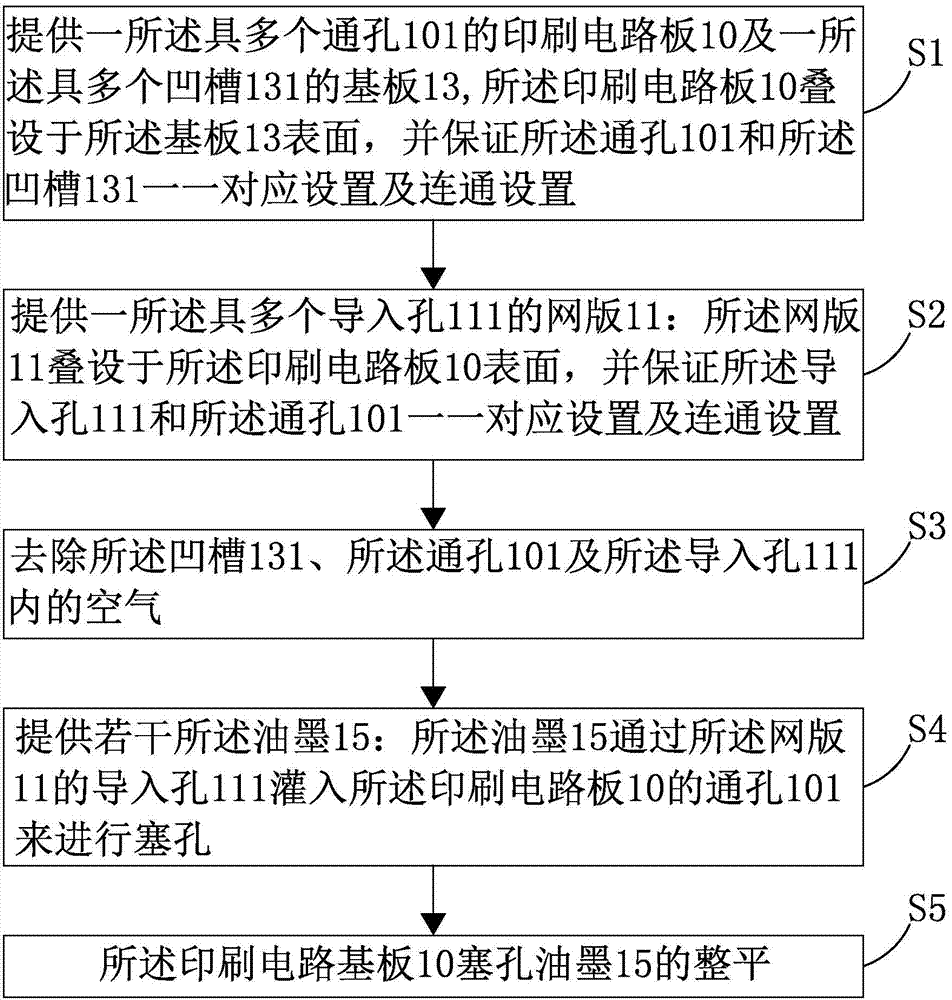

Circuit board jig and ink hole-plugging method

InactiveCN104519668APrevent protrudingPrevents the problem of not being easy to plug inMechanical/acoustic circuit processingPrinted element electric connection formationScreen printingBaseboard

The invention relates to a circuit board jig which is used for performing ink hole-plugging on a printed circuit board with multiple through holes. The circuit board jig comprises a screen printing plate, a baseboard and a lot of ink, the screen printing plate comprises multiple guide-in holes formed in a manner of penetrating the surface of the screen printing plate, the baseboard comprises multiple grooves formed in the surface of the baseboard, the screen printing plate is arranged on the surface of the printed circuit board, the guide-in holes, the through holes and the grooves are arranged in a one-to-one corresponding manner and in a mutually communicated manner, and the through holes are filled with the ink. The invention further relates to an ink hole-plugging method utilizing the circuit board jig.

Owner:SHENZHEN WUZHU TECH

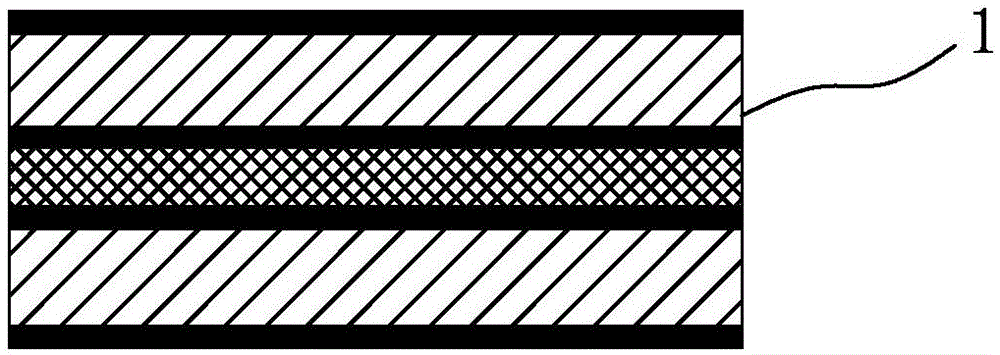

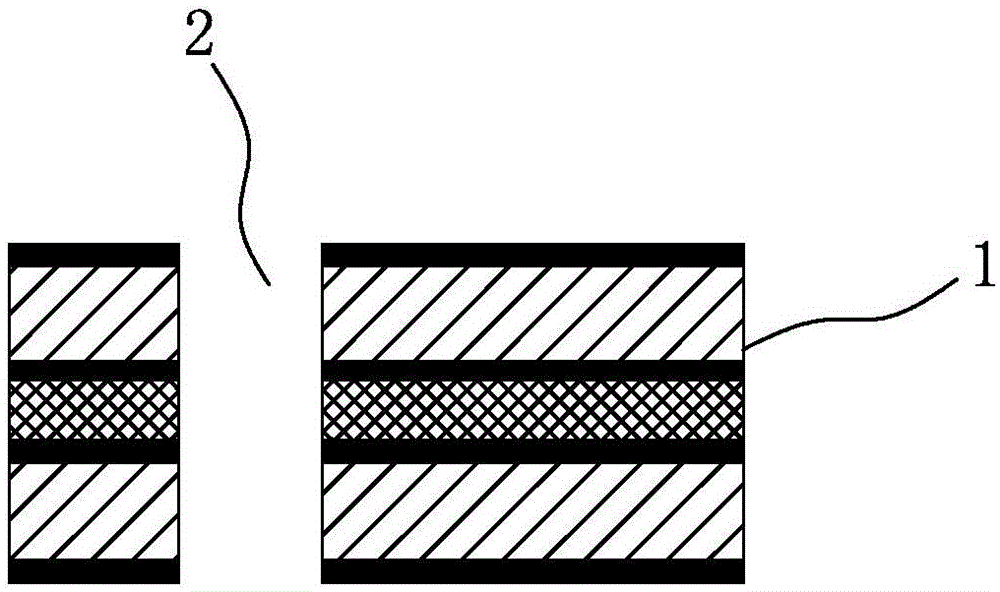

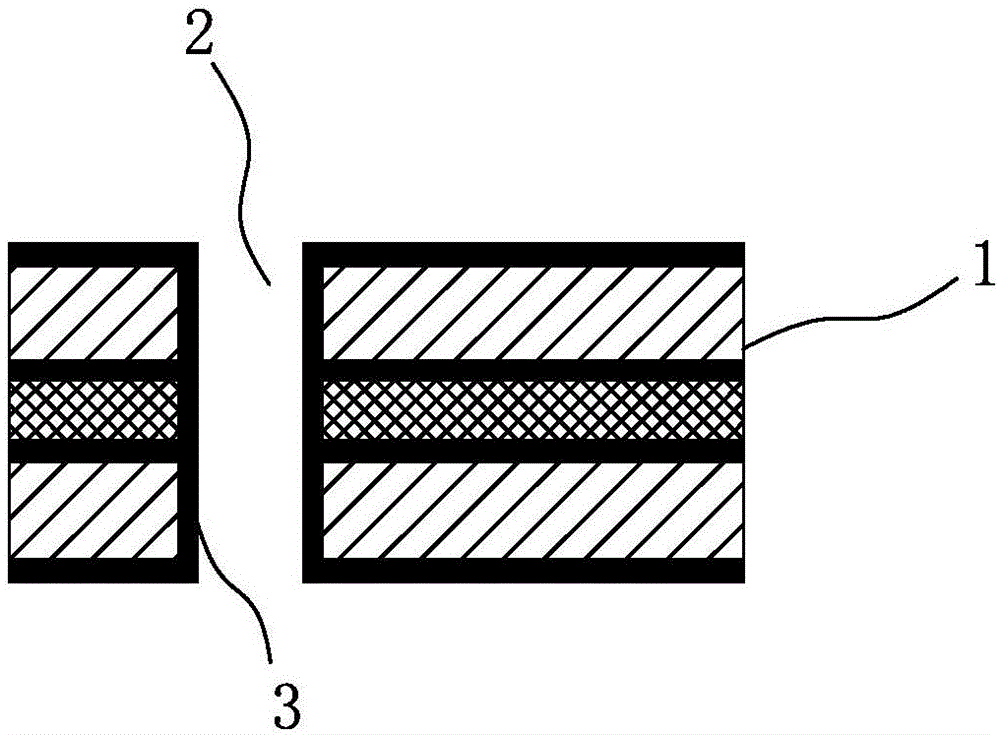

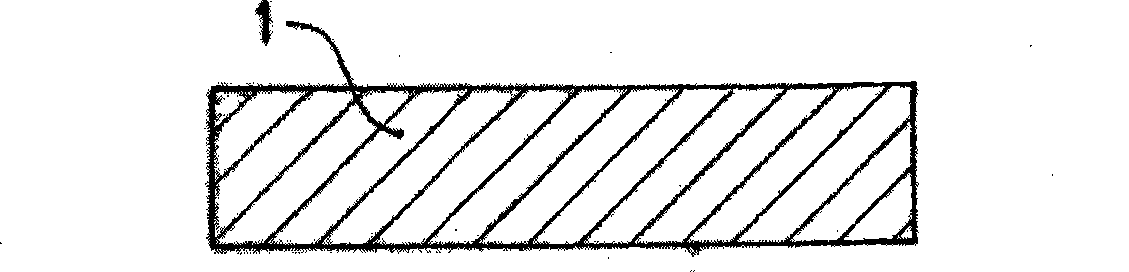

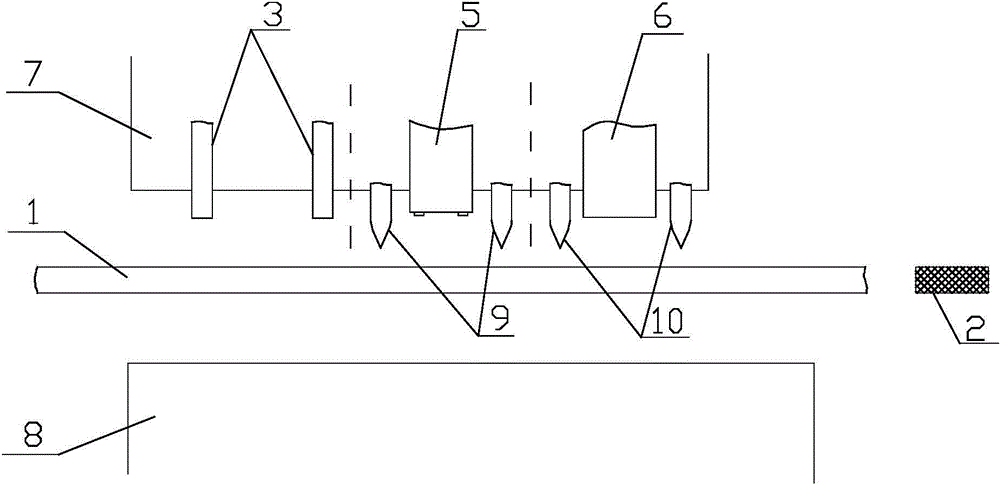

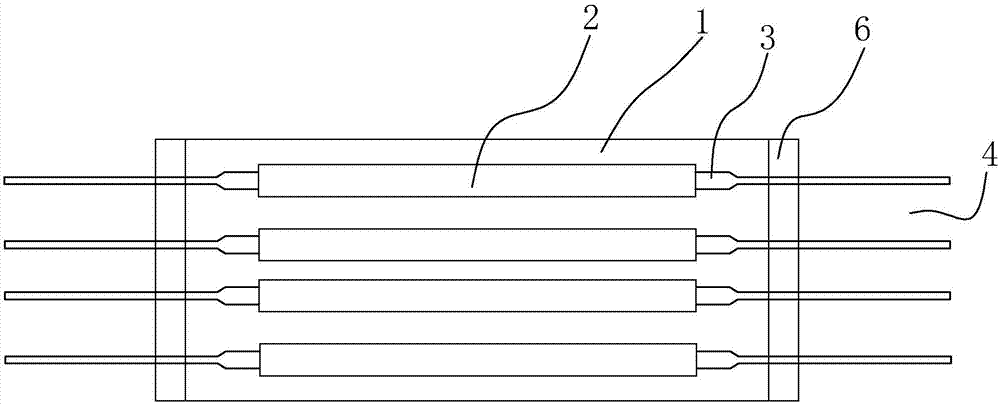

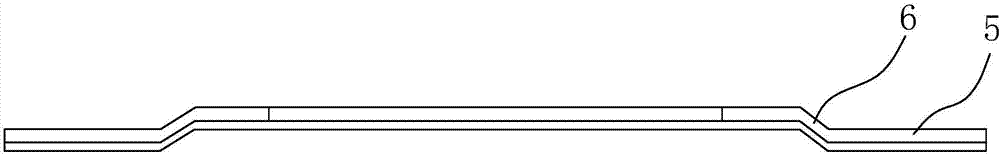

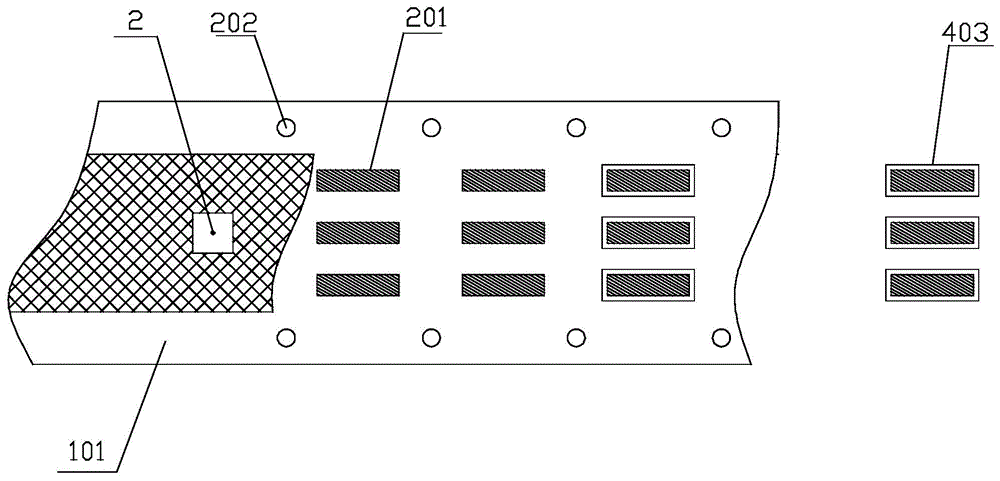

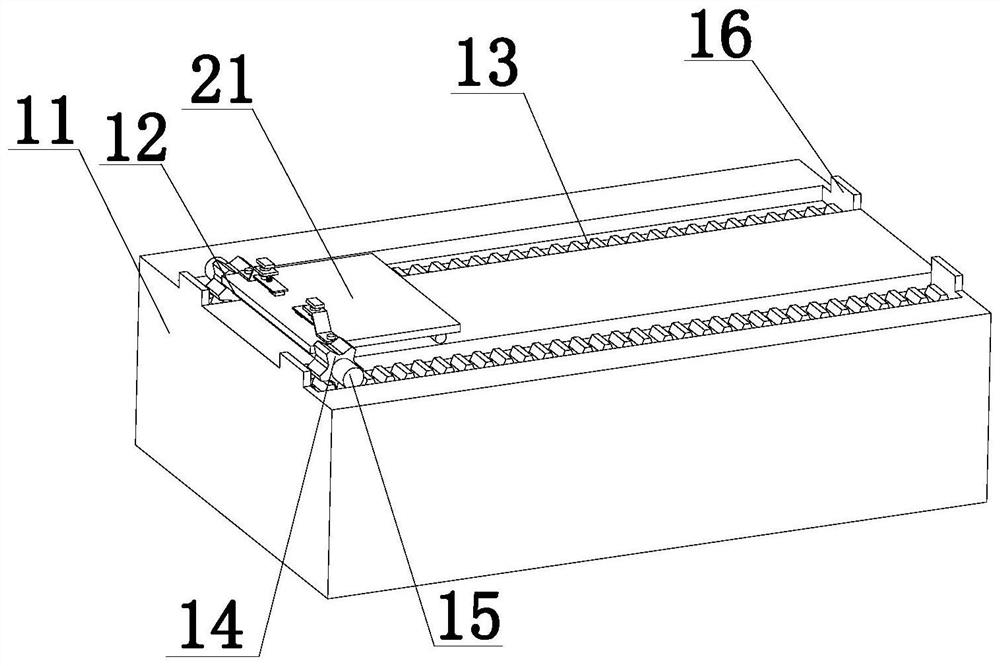

Production method of glue contraction reinforcing slice

InactiveCN104411096AIncrease productivityMechanical/acoustic circuit processingEngineeringSteel belt

The invention discloses a production method of a glue contraction reinforcing slice, and relates to the technical field of processing flexible printed circuit boards. The method comprises the following steps: die cutting a glue tape 1 which is continually transported with a first cutter 2 to form a die cutting glue shape and a glue tape positioning hole, removing waste materials through a material receiving mechanism, and then transporting the glue tape 1 to a cementing unit; and die cutting a glue tape 5 which is continually transported with a second cutter 6 to form a positioning hole, then transporting the glue tape 5 to the cementing unit, and the like.

Owner:SUZHOU MIDAS PRECISION ELECTRONICS

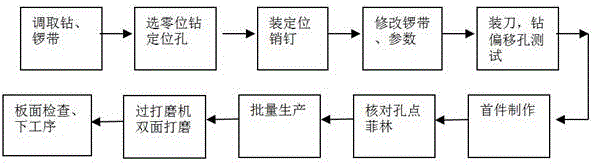

Processing and shaping method of PCB

InactiveCN106304637ASmall mechanical tolerancesQuick exclusionPCB positioning during processingInsulating layers/substrates workingHydrocarbon solventsEngineering

The present invention provides a processing and shaping method of a PCB. The method mainly comprises (1) a PCB feeding step the PCB; (2) a V-shaped groove making step of using a CNC automatic device to make a V-shaped groove, wherein the angle of the V-shaped groove is between 35 degrees and 90 degrees; (3) a PCB milling step of firstly adopting a CNC program to make, then milling the first board and inspecting the size until the size is qualified, then producing, cleaning the PCB and discharging; (4) a connecting finger bevel edge making step, wherein the included angle of the bevel edge and a horizontal line is between 15 degrees and 65 degrees, and the residual thickness is 1 / 3 of the thickness of the PCB; (5) a PCB cleaning step of firstly feeding the PCB, then using the hydrocarbon solvent PCB cleaning water to clean the surface of the PCB, wherein the temperature at cleaning is 30 DEG C, and cleaning time is 1-2 hours, and then carrying out the ultrasonic washing, blow-drying, drying and cooling operations, and discharging the PCB after cooling; (6) a discharging step.

Owner:安徽广德威正光电科技有限公司

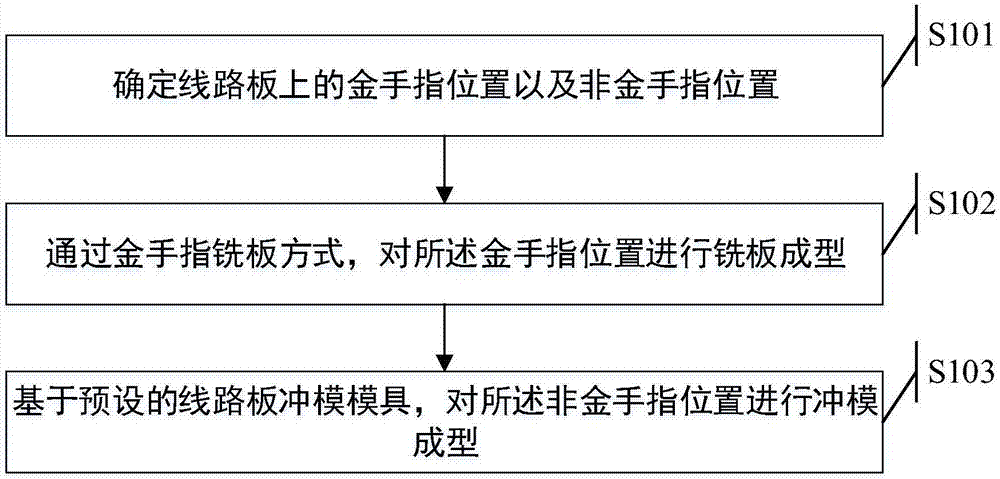

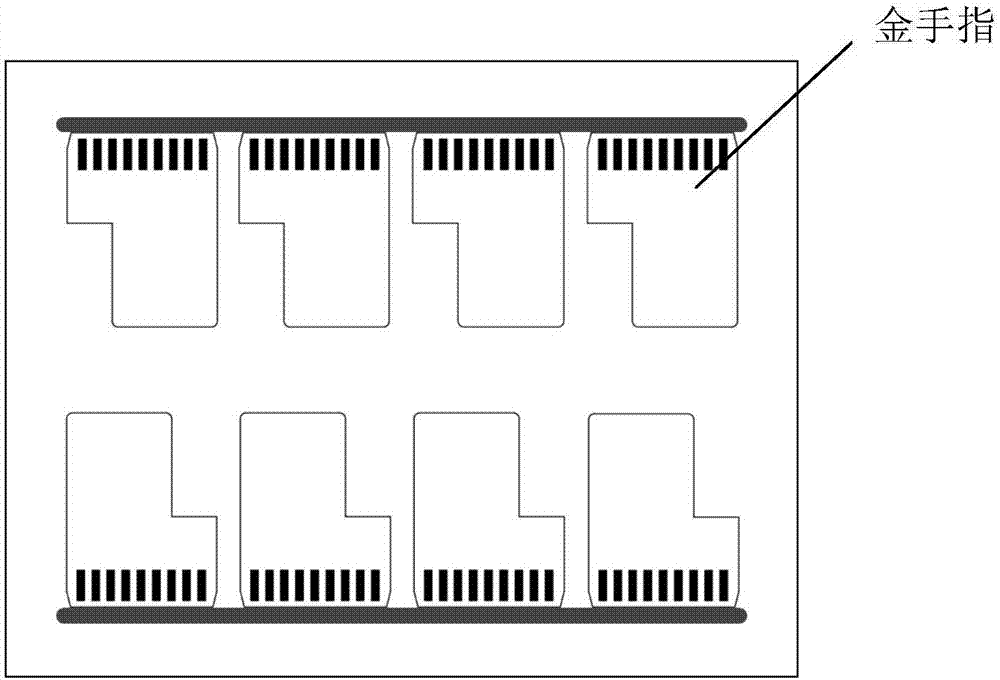

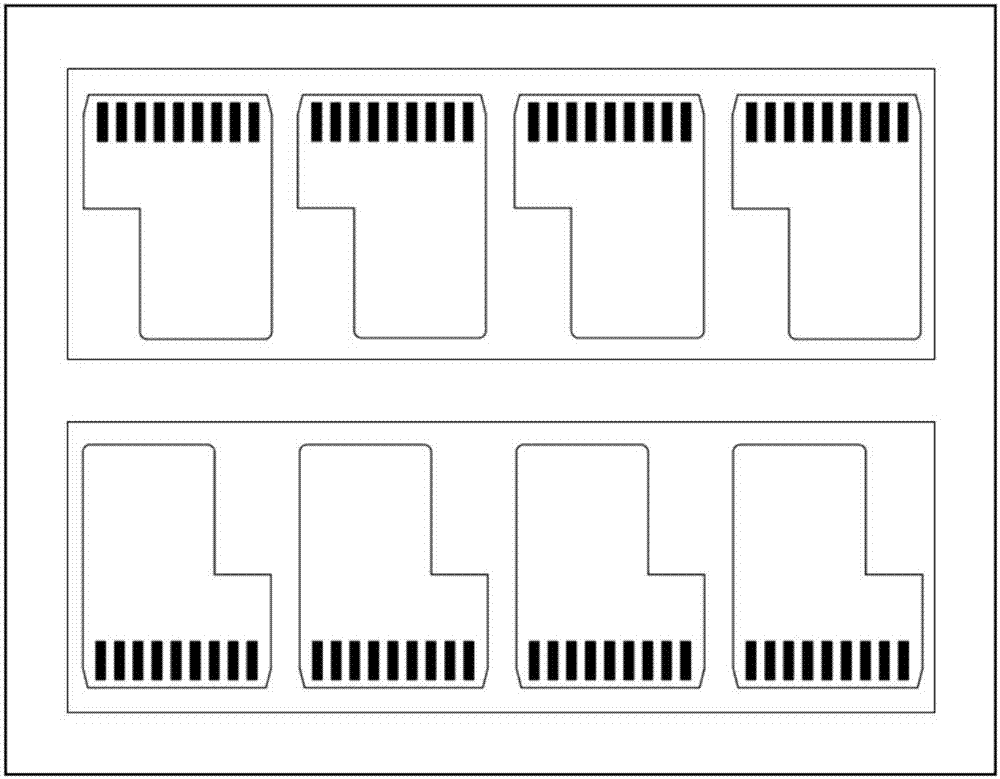

Method and device for preparing golden finger circuit board

ActiveCN107231763AShape processing improvementAvoid efficiencyMechanical/acoustic circuit processingPrinted element electric connection formationEngineeringMaterial resources

The invention discloses a method and device for preparing a golden finger circuit board. The advantages of both of a board milling process and a stamping process in a circuit board appearance processing manner are combined. By utilizing a method of sequentially performing local board milling and local stamping on the circuit board, the defects of low production efficiency and manpower and material resource material wasting due to the traditional process during board milling are avoided, and meanwhile, problems of relatively larger board edge burrs and white spot layering due to stamping are modified, especially appearance processing effects of high-grade golden finger circuit boards are improved.

Owner:珠海杰赛科技有限公司 +1

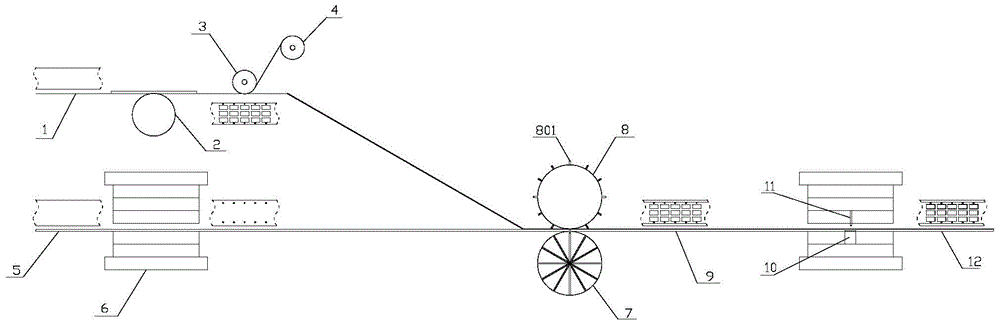

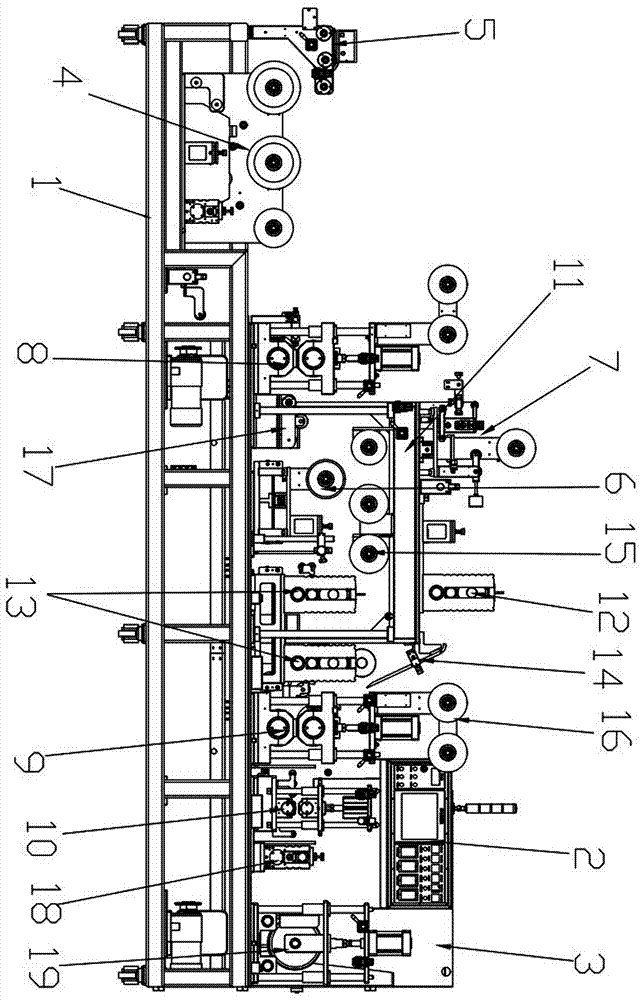

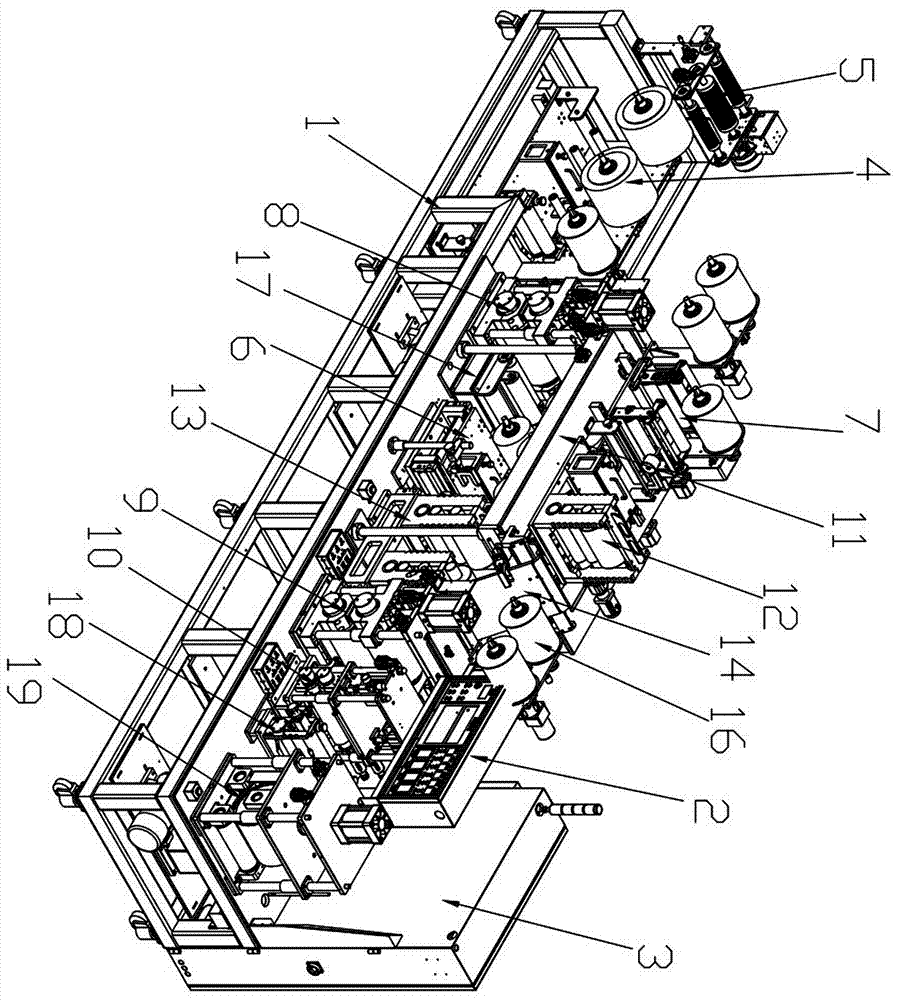

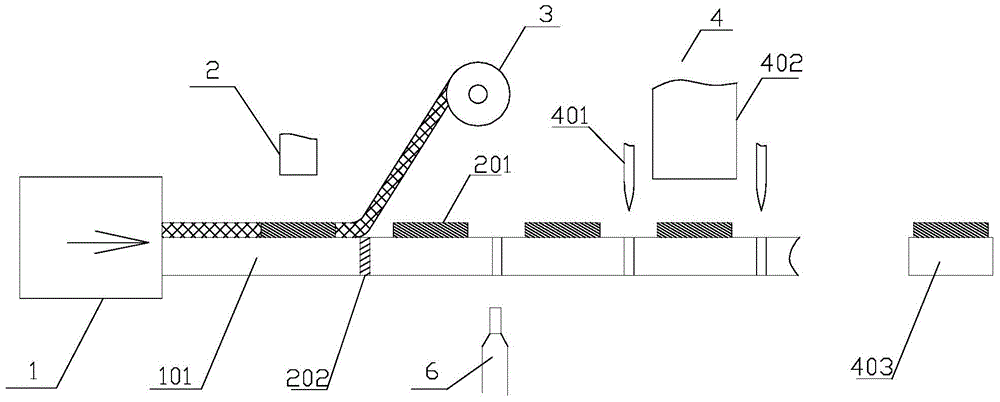

Equipment and process for manufacturing flexible circuit board

ActiveCN107241865AIncrease rateHigh precisionConductive material mechanical removalMechanical/acoustic circuit processingElectrical conductorFlexible circuits

The invention relates to equipment and process for manufacturing a flexible circuit board in the technical field of manufacturing of an electronic circuit board. The equipment comprises an elongate framework type machine body, wherein an automatic operating platform is arranged at a top part of the framework type machine body and comprises a control panel, an automatic feeding part, an automatic lamination part, an automatic rolling cutting part, a splitting mechanism, a traction mechanism and a winding mechanism, the automatic feeding part comprises a bottom membrane feeding mechanism, an elongate conductor feeding mechanism, a combination medium membrane feeding mechanism and a cover membrane feeding mechanism, the automatic lamination part comprises a first lamination mechanism and a second lamination mechanism, and the automatic rolling cutting part comprises an upper rolling cutter mechanism and a lower rolling cutter mechanism. Compared with a traditional punching or etching process, the process employing rolling cutting has the advantages that an irregularly-shaped cross section and a clearance hole can be synchronously cut in a rolling way, the rolling cutting efficiency is high, no stop is needed during the rolling cutting process, assembly line type processing can be directly completed, so that the production working efficiency of a product can be improved, labor investment is greatly reduced, and the qualified rate and the accuracy of a finished product are improved.

Owner:广东力兹微电气技术有限公司

Method for improving groove-making burrs before copper plating

ActiveCN106332456AMeet sizeFulfil requirementsMechanical/acoustic circuit processingCopper platingEngineering

The invention provides a method for improving groove-making burrs before copper plating. Low-cost input and high-quality output are realized, the problem of the groove-making burrs before copper plating is effectively solved, the scrap rate of the groove-making burrs is greatly reduced, the appearance and the quality of the product are improved, and the product quality is improved to meet the demand of customers.

Owner:广东喜珍电路科技有限公司

Metal semi-hole forming production technology

InactiveCN110446348AReduce the situation of forced inward extrusionIncrease the areaMechanical/acoustic circuit processingMilling cutterPore diameter

The invention relates to the technical field of metal semi-hole machining, and discloses a metal semi-hole forming production technology. The metal semi-hole forming production technology comprises the following steps of 1) preparing a tool; 2) forming a knife hole; 3) performing semi-hole forming processing; 5) determining a forming knife-feeding scheme and carrying out knife feeding; and 5) finally carrying out testing and verifying. According to the metal semi-hole forming production technology, by means of the design of a milling cutter and layout, the distance of the line layers is Min 0.2mm, the distance of anti-welding layer is Min 0.25mm; the copper area outside the board is increased, and the stress of the hole ring is reduced to be extruded inwards; meanwhile, a double-V-shaped two-way walking method is used for forming the cutter path, so that the copper Burr phenomenon caused by the stress problem of the metal half-hole edge when the board thickness is greater than or equalto 0.8MM, the hole diameter is greater than or equal to 0.5MM, and the hole spacing is greater than or equal to 0.45MM (the hole central distance is 0.95mm) can be solved; the effect of no copper Burr and burrs in the forming process is achieved, and the whole process of the production technology is simplified, so that the problem that part of raw copper slag and burrs are generated and the processing quality is influenced when the PCB is milled through half-hole forming and the like is effectively solved.

Owner:重庆科迈电子科技有限公司

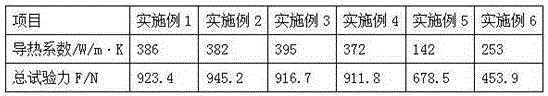

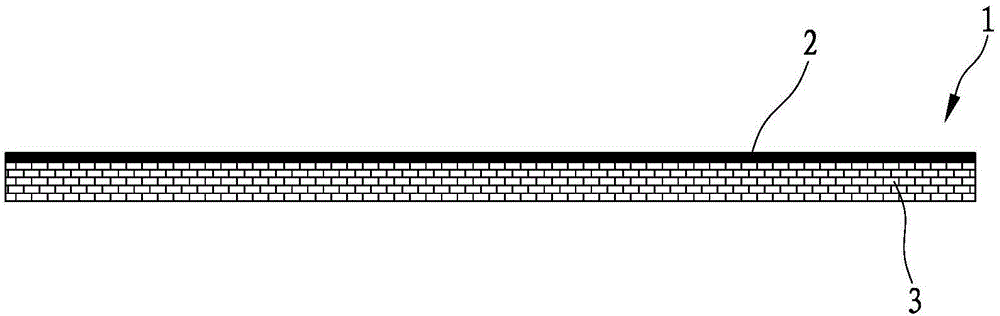

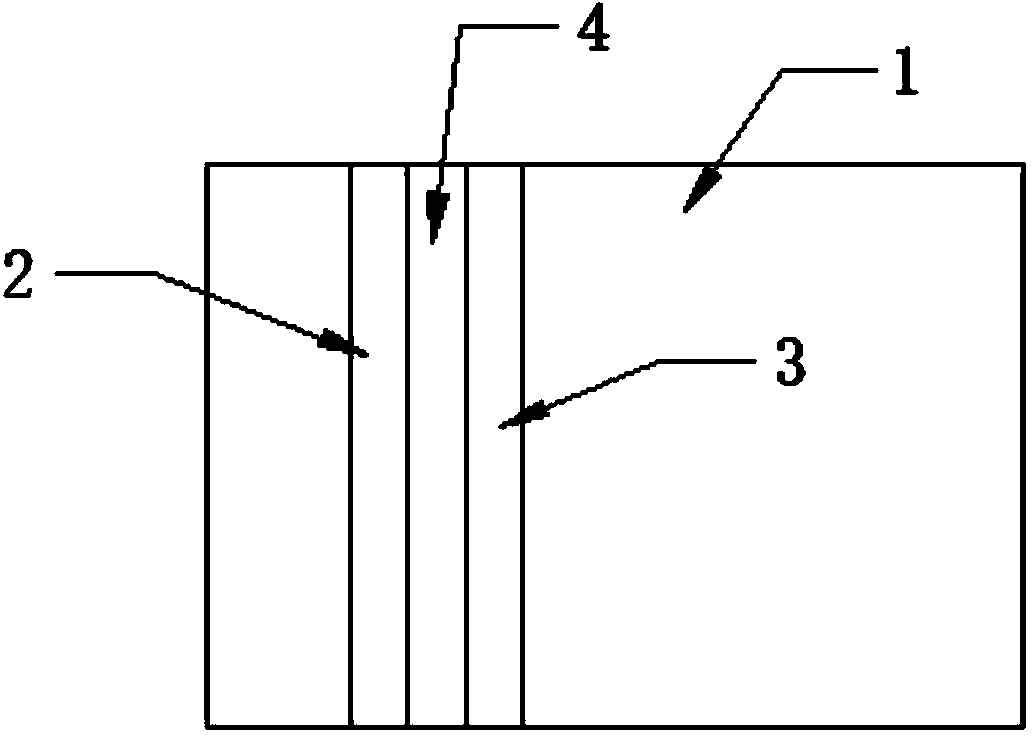

Method for manufacturing printed circuit board using base material of high thermal conductivity suitable for being inserted into non-surface component

InactiveCN101466202AImprove cooling effectEnsure proper insulationMechanical/acoustic circuit processingCircuit susbtrate materialsPrinting pressPrinted circuit board

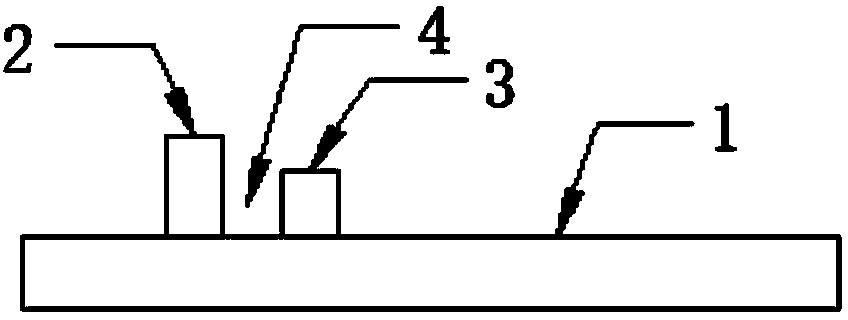

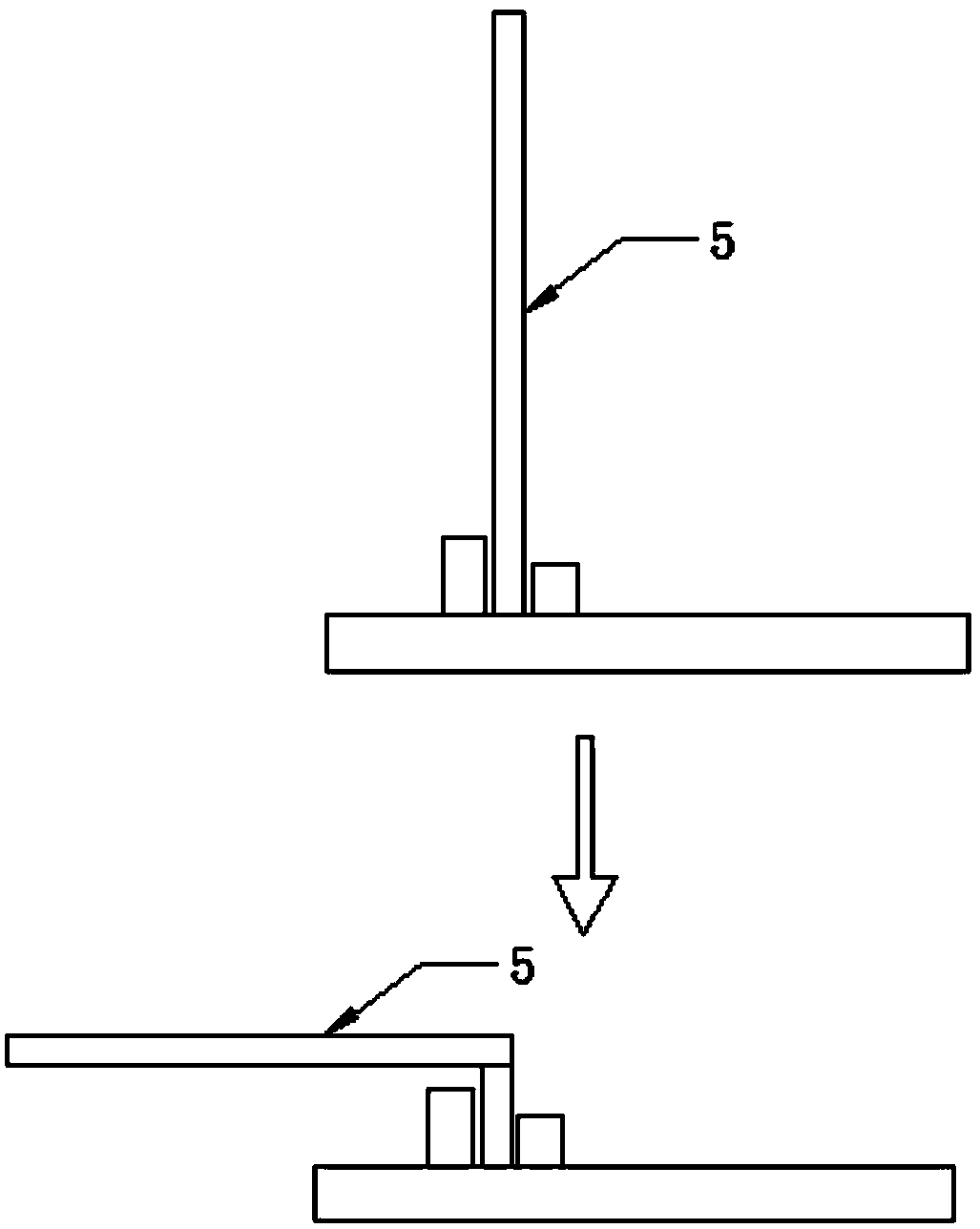

The invention relates to a method for producing a printing circuit board by using a high heat conductivity substrate material suitable for inserting in a non-surface component comprising the following steps: molding a metal plate (1) to get a drilling (2) with enough number and position to insert in the surface component, arranging the metal substrate (1) on an aspiration formwork (3) which has an aspiration hole (4) corresponding to the drilling (2) so that an injection head (5) of a conventional printing machine falls on the metal substrate (1), filling an insulation resin (7) by an injection hole (6), simultaneously pumping the air from the drilling (2) by the aspiration hole (4), and molding the obtained component to get an insertion mould (12) with a diameter less than that of the corresponding initial drilling (2).

Owner:EUROCIR

Method for making window on cover film of flexible circuit board

InactiveCN105188264AWithout sacrificing panel utilizationRealize automated productionMechanical/acoustic circuit processingPunchingFlexible circuits

The invention discloses a method for making a window on a cover film of a flexible circuit board. The cover film is composed of a cover film layer and a release paper layer, and the cover film layer covers the surface of the release paper layer. Through slots or through holes are arranged on the cover film layer through punching, and the release paper layer has no through slots or through holes in positions corresponding to the through slots or through holes of the cover film layer. Cover film half-cutting making, cover film full-cutting making or cover film half-cutting and full-cutting making can be selected according to the cover film window making requirements of different products in order to increase connecting ribs after cover film window making, improve the tensile ability of coil cover films and enable more products to be imported to automation equipment.

Owner:XIAMEN HONGXIN ELECTRON TECH

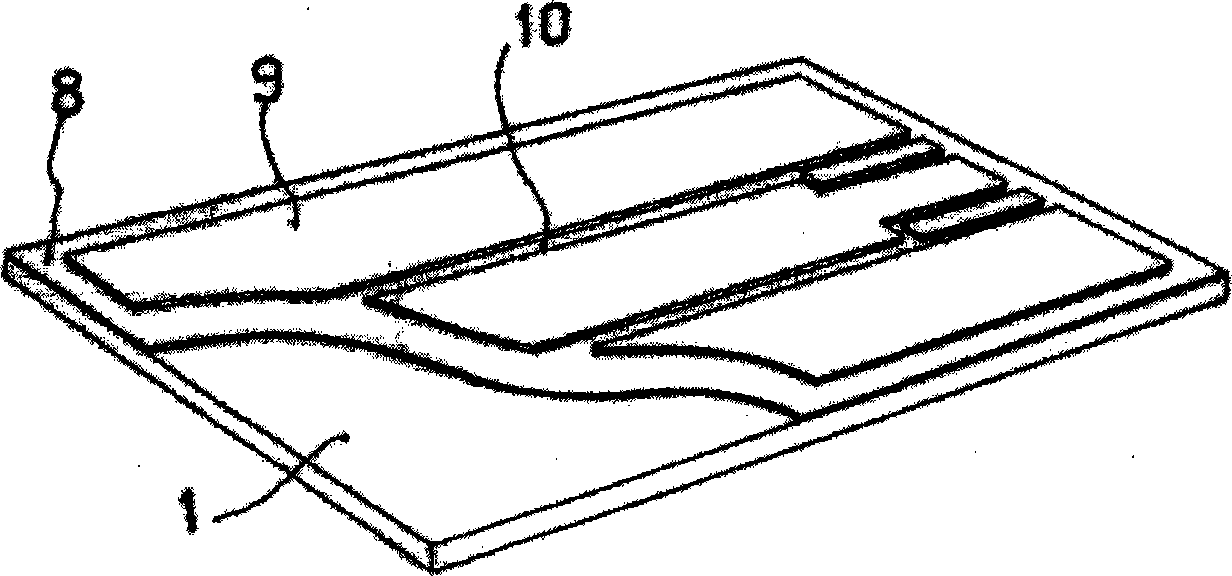

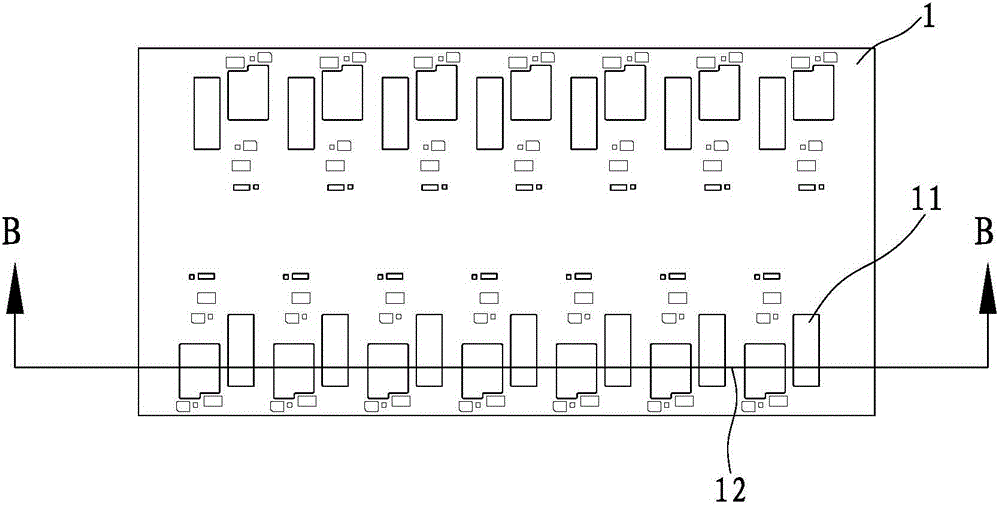

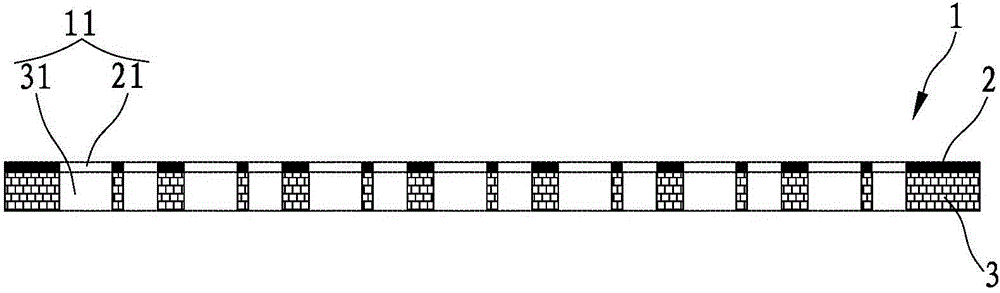

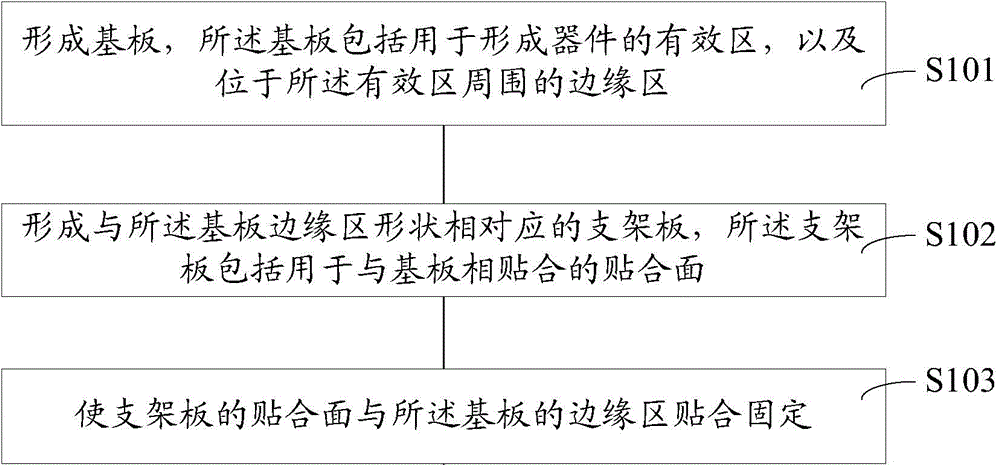

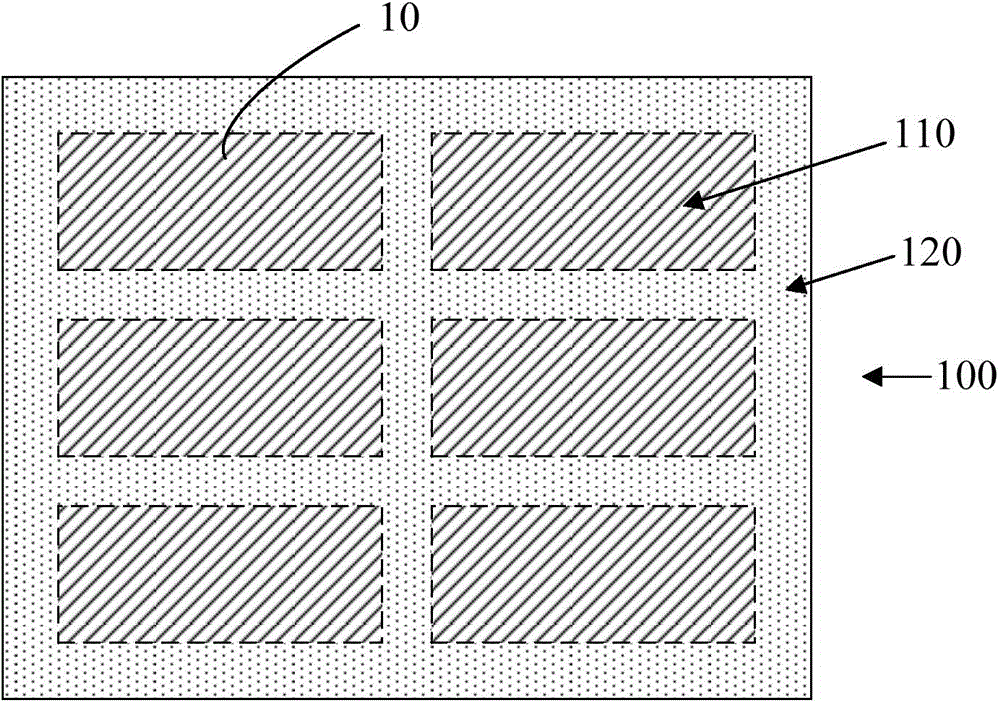

Making method of substrate with support

InactiveCN104411100AAvoid warpingAvoid damageMechanical/acoustic circuit processingCooling/ventilation/heating modificationsState of artEngineering

Owner:NANTONG FUJITSU MICROELECTRONICS

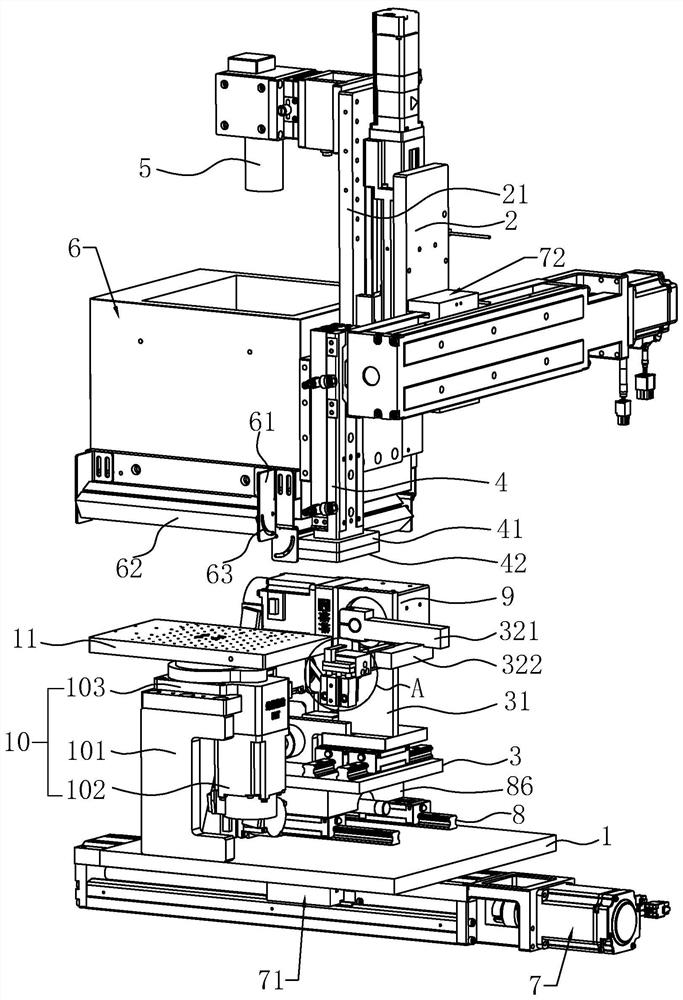

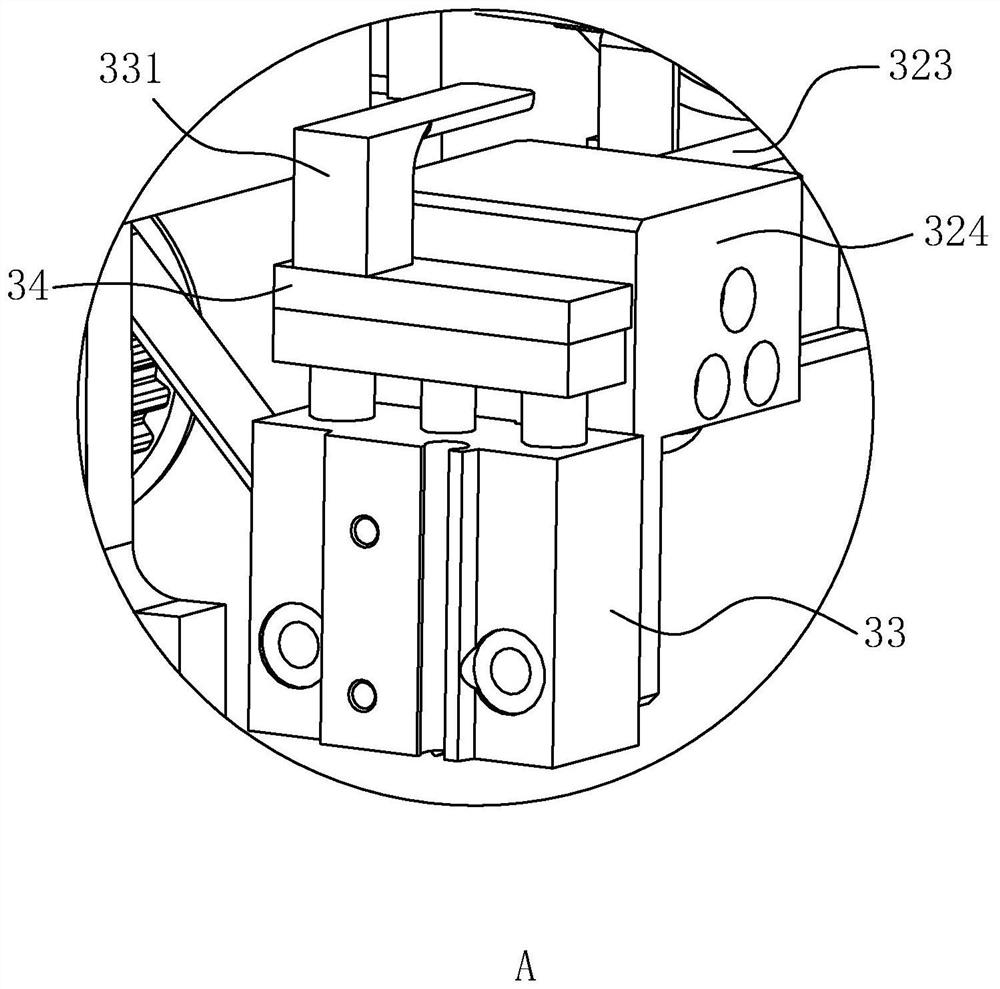

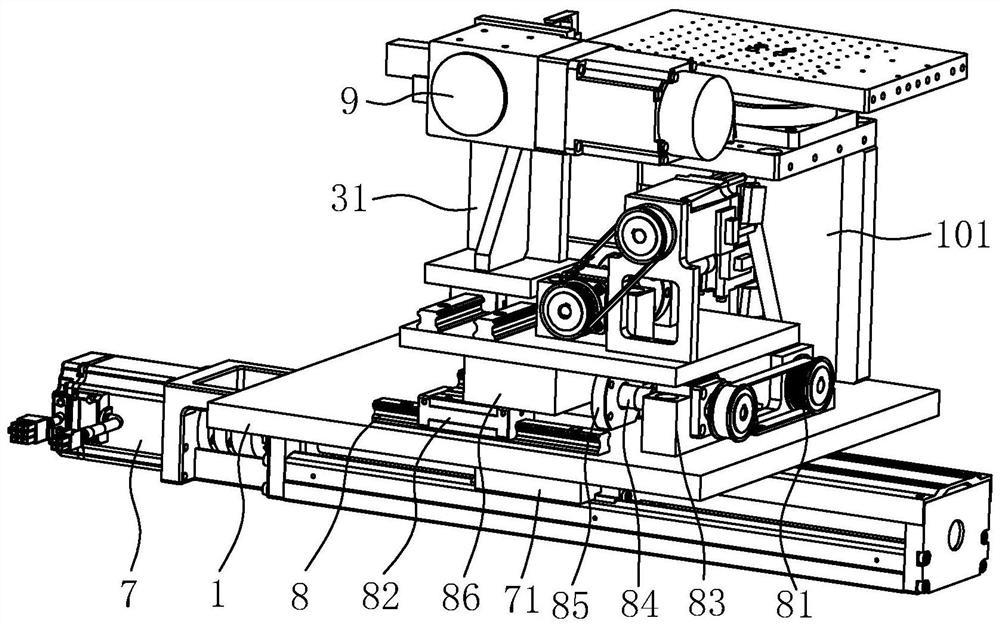

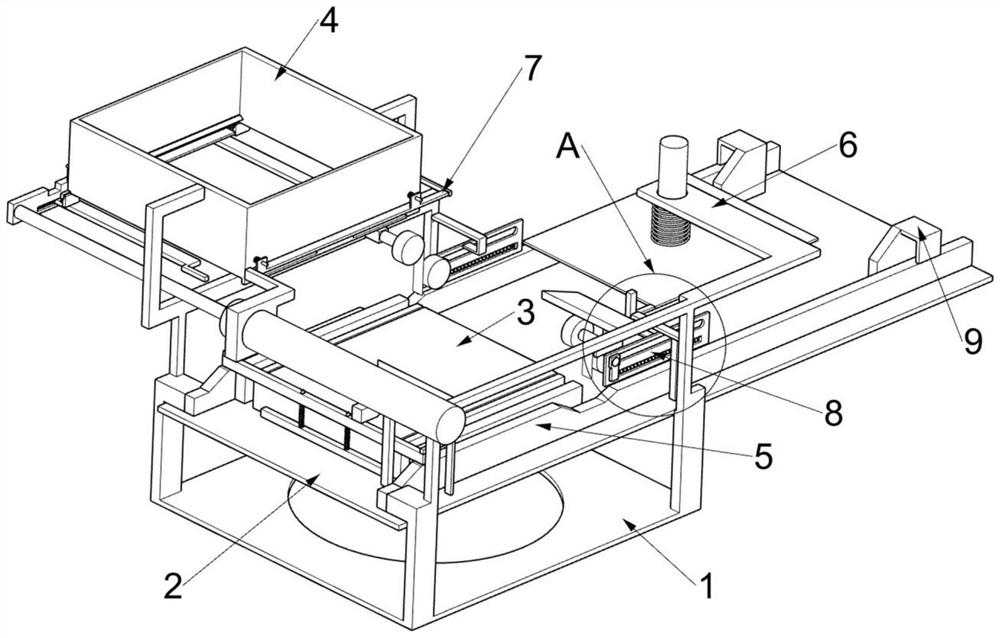

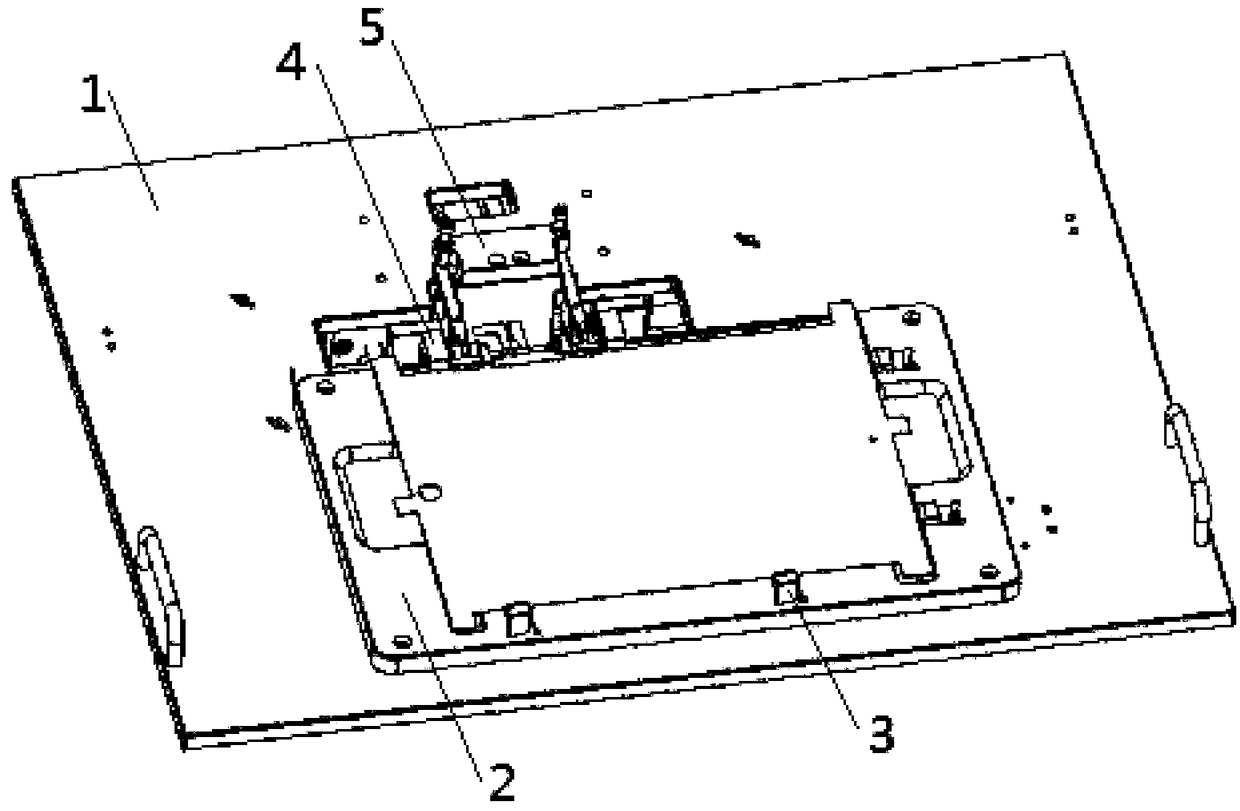

Reversely folding equipment for FPC of LED screen

ActiveCN113038712AReal-time shooting and positioningImprove the accuracy of reflexionFlexible printed circuitsCircuit board tools positioningControl systemSlide plate

The invention relates to reversely folding equipment for a FPC of an LED screen, belonging to the technical field of bending equipment. According to a main scheme, the reversely folding equipment comprises: a rotating platform mounted on a sliding plate bearing surface; an X-axis driving mechanism installed on a frame and used for driving a sliding plate to slide in a horizontal preset direction; an adsorption plate mounted on the rotating platform and connected with the adsorption end of an adsorption device; a Y-axis driving mechanism mounted on the frame; a moving frame mounted at the output end of the Y-axis driving mechanism through a sliding seat; a shooting device mounted on the moving frame and used for shooting the LED screen and the FPC on the bearing surface of the adsorption plate; a reversely folding mechanism mounted on the bearing surface of the sliding plate and used for clamping and reversely folding the FPC extending out of the adsorption plate; and an abutting mechanism installed on the moving frame and used for abutting against reversely-folded FPC, wherein the rotating platform, the X-axis driving mechanism, the Y-axis driving mechanism, the shooting device, the reversely folding mechanism and the abutting mechanism are all electrically connected with a control system. When the reversely folding equipment is used, the reversely folding equipment can replace manual work to effectively improve the reverse folding precision and reverse folding efficiency of the FPC and enhance product quality.

Owner:SHENZHEN HISMART IND ROBOT CO LTD

Gold finger manufacturing method without lead residue

InactiveCN107484354AReduce usageReduce quality risksPrinted circuit aspectsMechanical/acoustic circuit processingProcess qualityEngineering

The width of a gold finger lead is enabled to be consistent with that of a gold finger in manufacturing of the gold finger lead. The width of the gold finger lead increases so that the gold finger lead can be directly removed by using a mechanical bevel edge method without using the etching mode, a lot of processes and use of liquid medicine, ink and dry films can be reduced, the manufacturing flow can be shortened, processing quality management and control of each manufacturing process are facilitated, the quality hidden trouble can be reduced, the probability of contamination of the surface of the circuit board can be effectively reduced by reduction of use of the liquid medicine, the ink and the dry films and the product quality of the circuit board can be enhanced.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

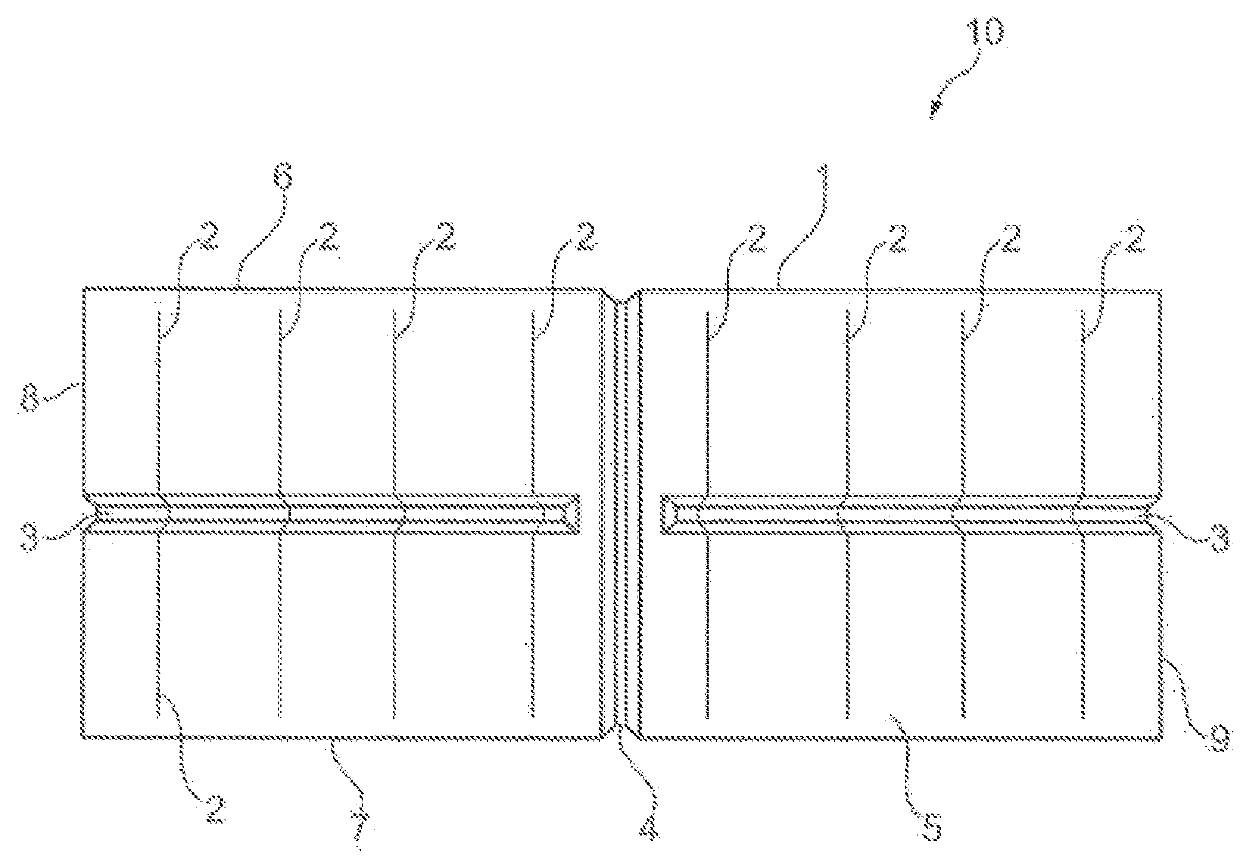

Production method of reinforcing sheet with mark

ActiveCN104411092AFast processingAccurate locationMechanical/acoustic circuit processingPunchingFlexible circuits

The invention discloses a production method of a reinforcing sheet with a mark, and relates to the field of a flexible circuit board processing technology. The method comprises the following steps: a metal material plate conveyer belt 1 moving forward by one step pitch D and then stopping conveying, wherein the parameter of the step pitch D is arranged according to such concrete conditions as product size, the row number of a reinforcing sheet molding knife 2 and the like; and an upper mold 7 stamping a metal material plate, hole molding knives 3 punching out of positioning holes, and the like.

Owner:南通瑞特照明电器有限公司

Perforating device for adding protection plate and pasting adhesive tape on PCB production line

ActiveCN113038708AImprove work efficiencyEasy to punchMechanical/acoustic circuit processingMetal working apparatusAdhesive beltMechanical engineering

The invention relates to a perforating device, in particular to a perforating device for adding a protection plate and pasting an adhesive tape on a PCB production line. The device comprises a supporting frame, a conveying belt, a containing plate, a plate discharging mechanism and the like, wherein the conveying belt is arranged on the supporting frame, the containing plate is arranged at the top of the conveying belt, the plate discharging mechanism is arranged on the supporting frame, an adhesive tape cutting mechanism is arranged on the supporting frame, and a perforating mechanism is arranged on the supporting frame. According to the invention, through mutual cooperation of an adhesive tape cutting mechanism, a rolling device and an adhesive tape uncovering block, an adhesive tape on an adhesive tape roll can be cut after a certain length is reserved, and then the adhesive tape pasted on a protection plate is uncovered through the adhesive tape uncovering block, so that a PCB is conveniently perforated, and the purposes of automatically pasting the adhesive tape on the protection plate, cutting the adhesive tape, uncovering the pasted adhesive tape and intermittently putting the protection plate are achieved.

Owner:湖北瀚鼎电路电子有限公司

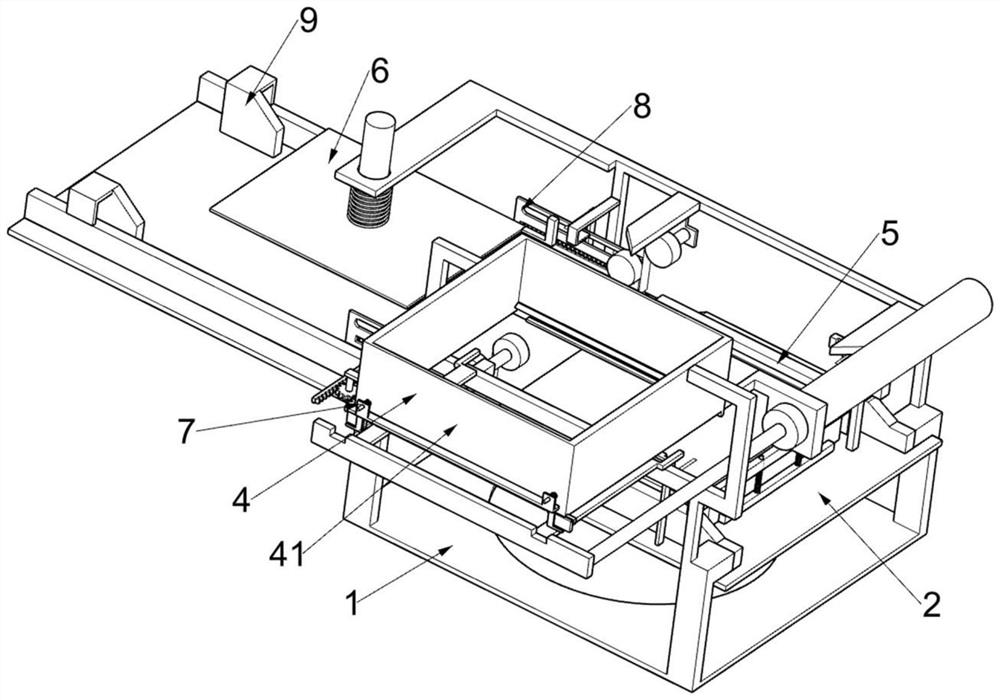

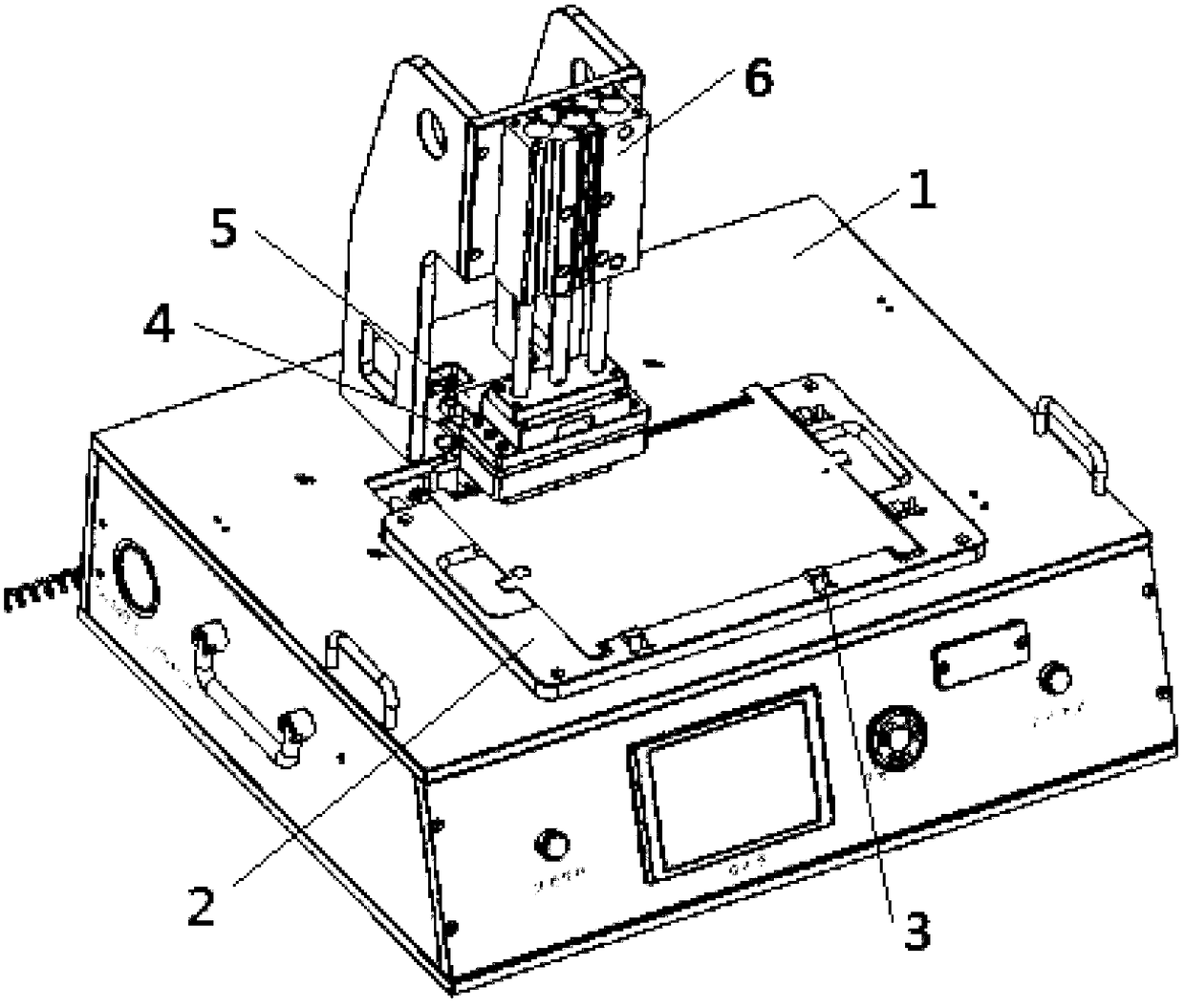

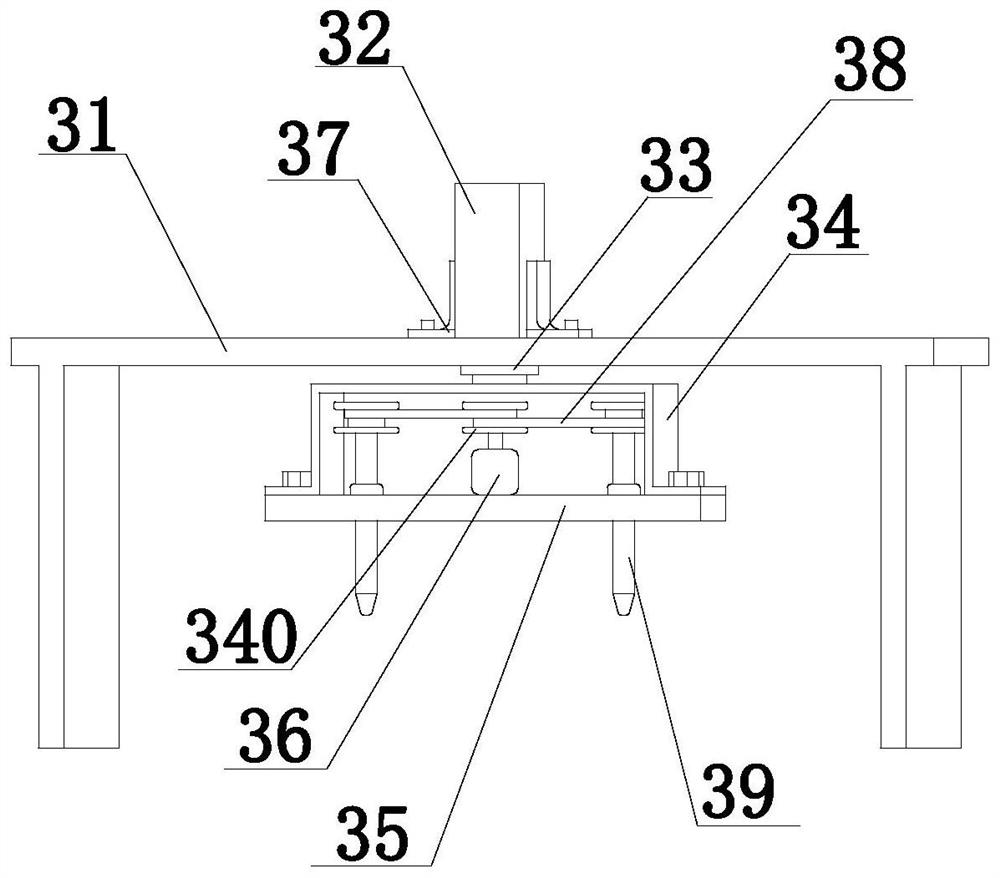

Small dimension FPC bending mechanism and bending method thereof

PendingCN108521716ARealize automatic processingImprove bending accuracyMechanical/acoustic circuit processingEngineeringElectric control

The invention relates to a small dimension FPC bending mechanism which comprises an electric control box body, a carrier device, a positioning device, a round pin device, a roller device and a pressing device, wherein the carrier device is fixedly arranged at one end of the upper surface of the electric control box body; the positioning device is arranged on two adjacent edge of the carrier device; the round pin device and the roller device are arranged in parallel on one side of the carrier device, and the pressing device is arranged at the other end of the upper surface of the electric control box body and is located above the round pin device and the roller device; the carrier device is used for placing a product, the roller device is used for bending the product, the round pin device is used for moving to two ends of the FPC to form a bending reference, the roller device is used for bending the FPC around the round pin device, and the pressing device is used for pressing and attaching the FPC to the surface of a screen. The mechanism provided by the invention achieves automatic processing of FPC, so that the bending precision and the production precision are improved greatly, the human resources are reduced, and the production cost is lowered greatly.

Owner:深圳市星威恒科技有限公司

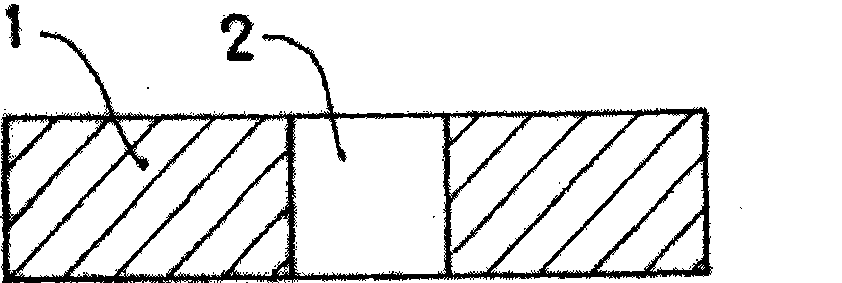

Flexible board cover plate for processing flexible circuit board and technological process of flexible board cover plate

InactiveCN110121241AHigh hardnessImprove wear resistanceMechanical/acoustic circuit processingEngineeringDrill bit

The invention discloses a flexible board cover plate for processing a flexible circuit board. The flexible board cover plate comprises a base material body and a resin board body, wherein the resin plate body is a plate body formed by curing fine particles, and the base material body comprises a cold punching plate or kraft paper or aluminum. During use, as the resin plate body can enable the small drill points to be stabilized instantly when the small drill points are in contact with the surface of the resin plate body during drilling, the deflection is reduced; and meanwhile, the cutting powder generated after the drill bit is cut by the small drill bit is converted into dust to be sucked away, so that the optimal hole position precision can be provided for drilling in the drilling process, and therefore, on the premise that the hole position precision of drilling is met, the problem of needle breakage happening in the processing of 0.075-0.10 mm micro drill needles is improved on the premise that the hole position precision of drilling is met. In addition, the flexible board cover plate is convenient for processing, is easy and convenient.

Owner:SHENZHEN HONGYUHUI TECH CO LTD

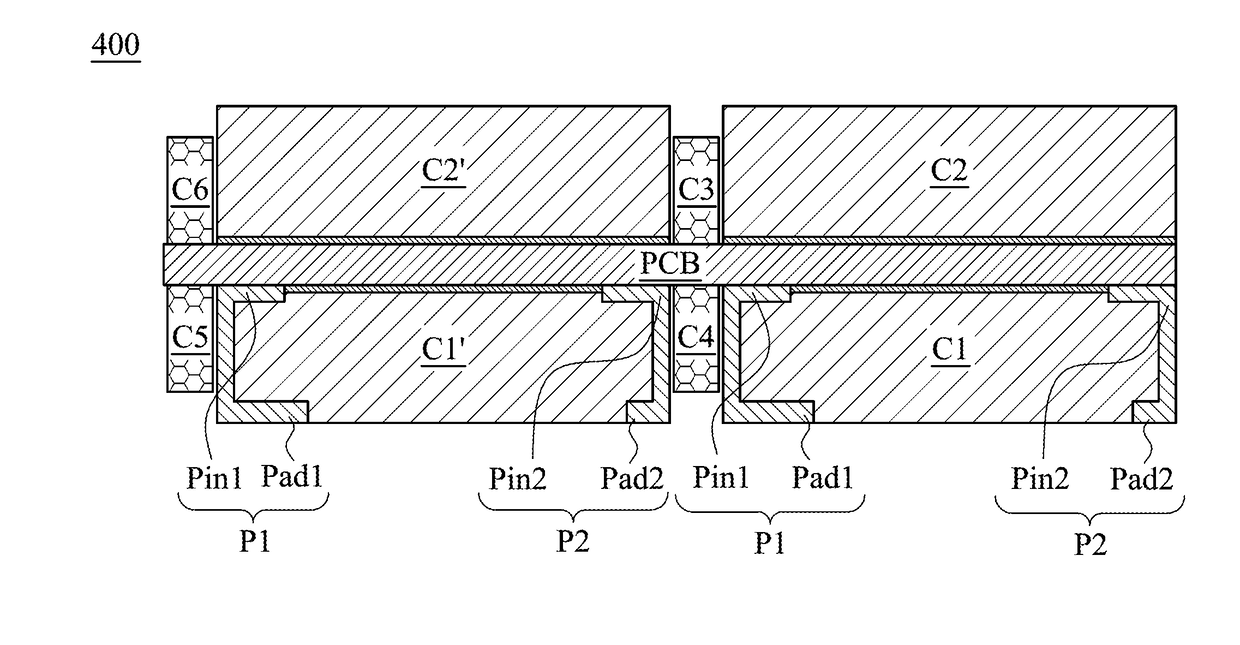

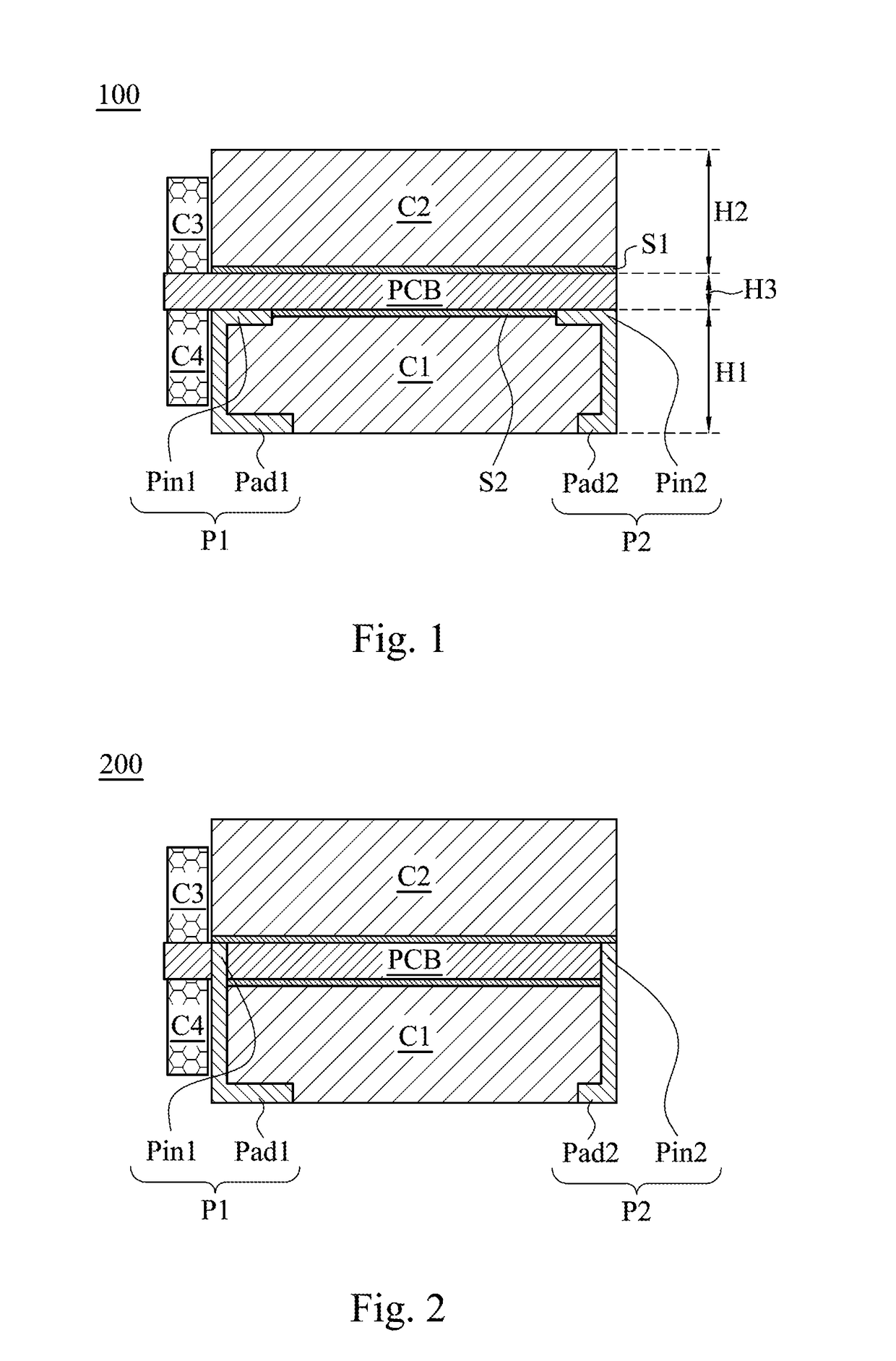

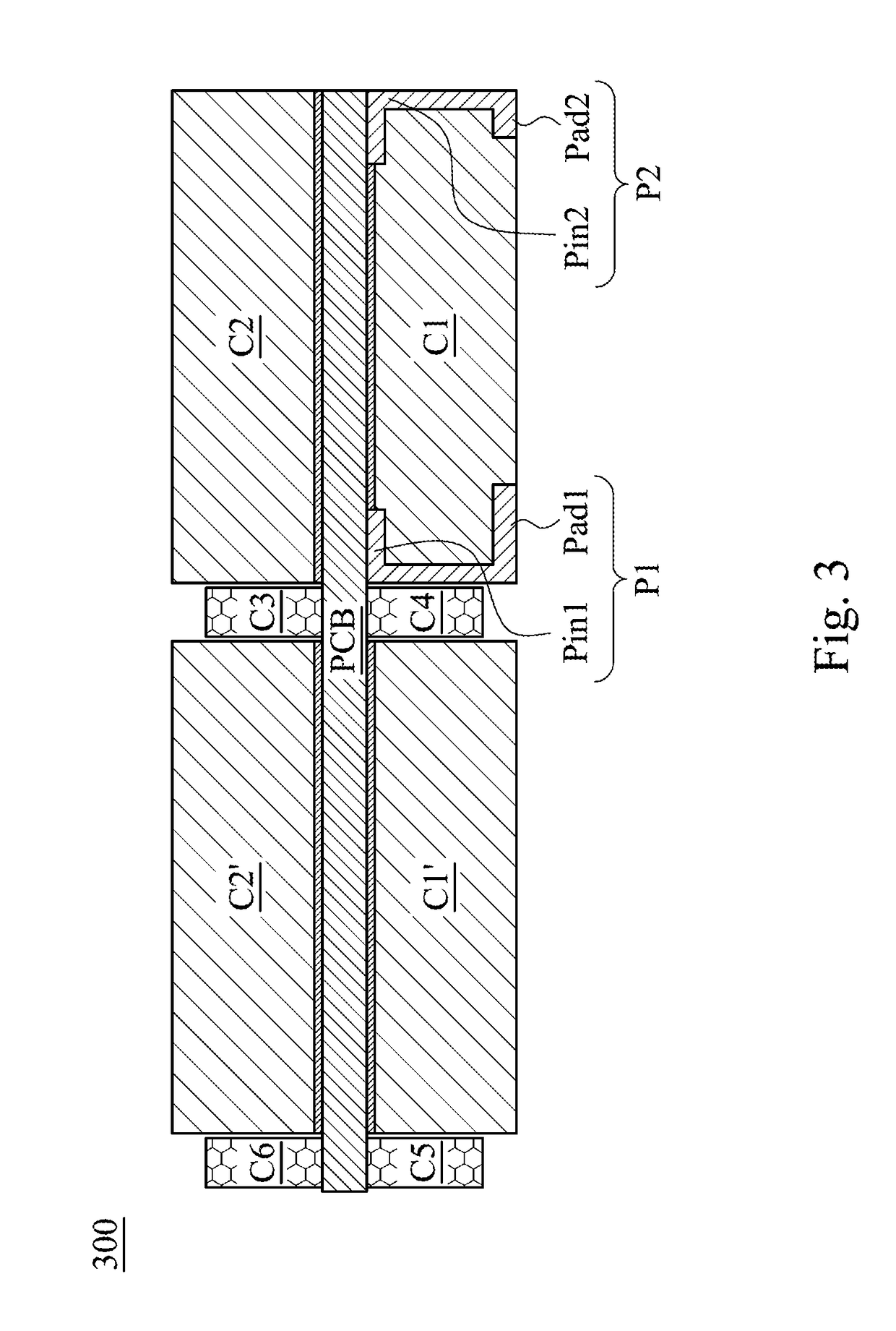

Power converter and method for manufacturing the same

ActiveUS20170104410A1Small sizeLow costSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsEngineering

A power converter includes a carrier, a first electronic component, a second electronic component, and a connection part. The first electronic component is disposed on the bottom surface of the carrier. The second electronic component is disposed on the top surface of the carrier. A first terminal of the connection part is coupled to the top surface or the bottom surface of the carrier. A second terminal of the connection part is a bonding pad and attached to the first electronic component's surface apart from the carrier. The carrier is disposed at ⅓ to ⅔ of a height of the power-converter. The connection part is fabricated by mechanical support of the first electronic component.

Owner:DELTA ELECTRONICS INC

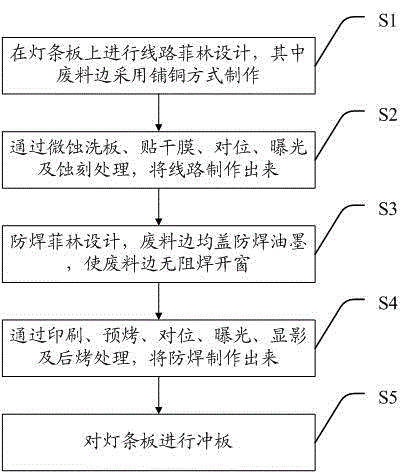

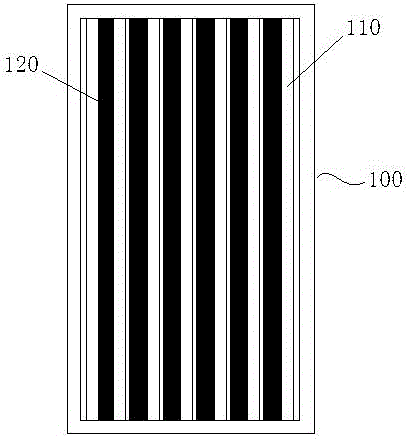

Method for improving wire dropping of punching dielectric layer of light bar plate

ActiveCN105025659AHigh hardnessImprovement of wire drop problemInsulating layers/substrates workingMechanical/acoustic circuit processingEtchingPunching

The invention discloses a method for improving the wire dropping of a punching dielectric layer of a light bar plate, and the method comprises the steps: A, carrying out circuit film design on the light bar plate, wherein a waste edge is prepared in a mode of copper laying; B, enabling a circuit to be manufactured through miniature etching and washing of the plate, dry film pasting, alignment, exposure and etching; C, carrying out solder mask film design, enabling the waste edge to be covered by solder mask ink, and enabling the waste edge to achieve windowing without soldering resistance; E, manufacturing a solder mask through printing, pre-baking, alignment, exposure, development, and post-baking; F, carrying out the punching of the light bar plate. According to the invention, the circuit waste edge is manufactured in a mode of copper laying, thereby improving the hardness of the waste edge, enabling the wire dropping to be improved greatly, and reducing the risk of crushed scraping caused by that a dielectric layer falls to a desk top.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

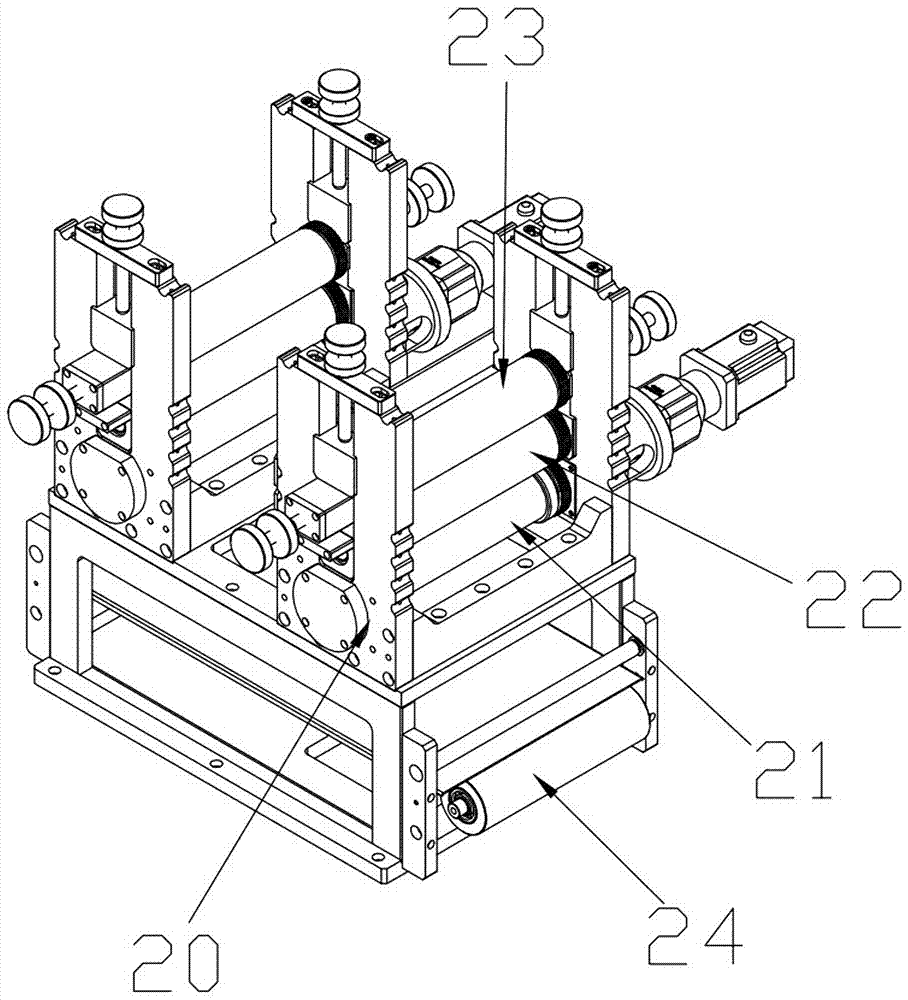

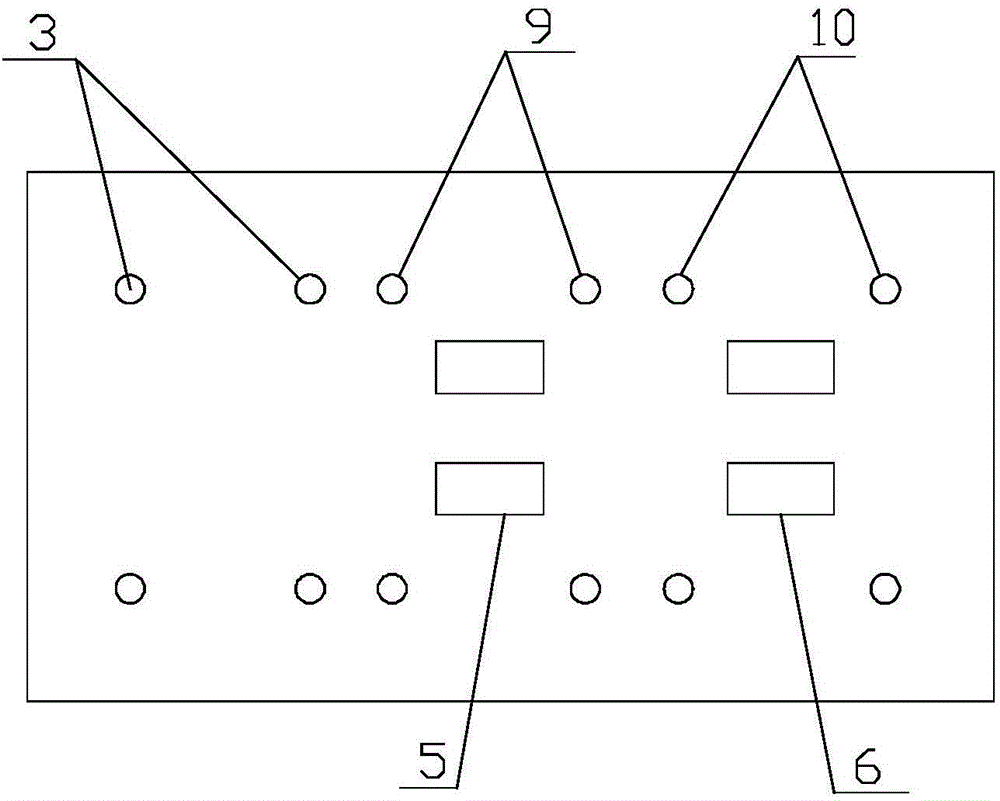

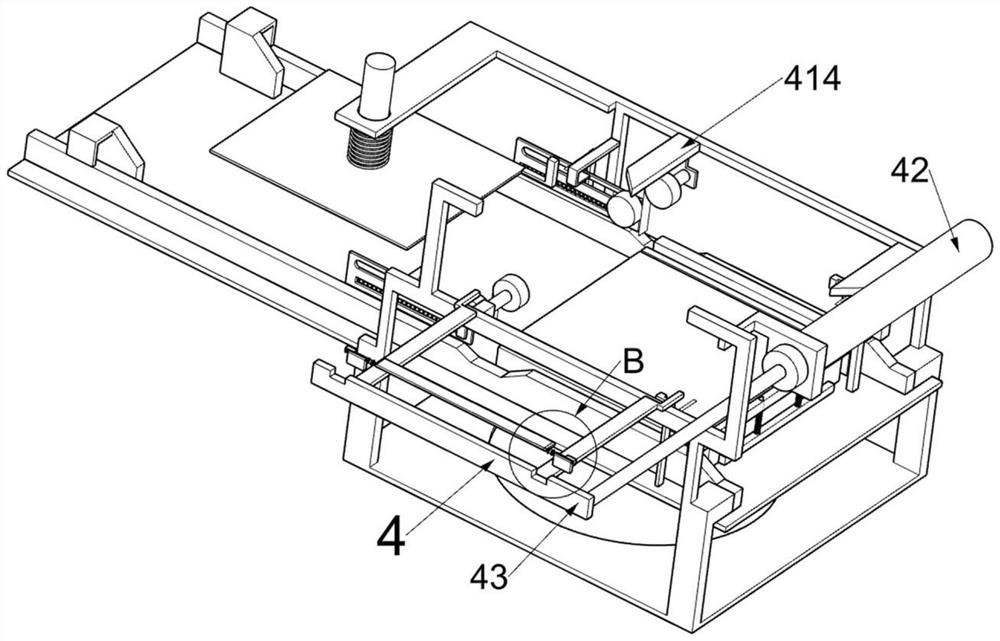

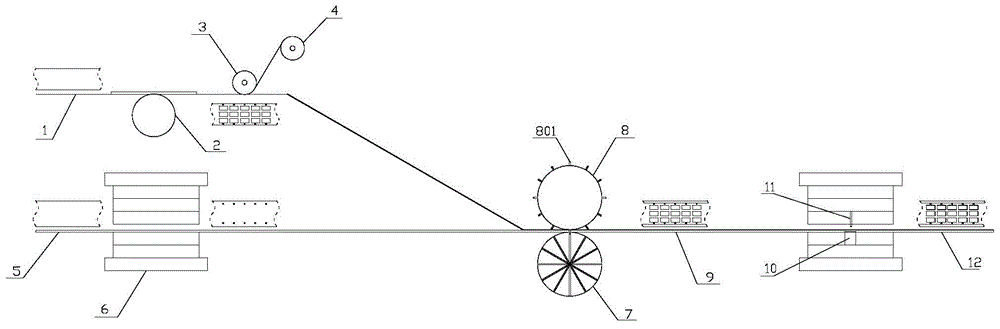

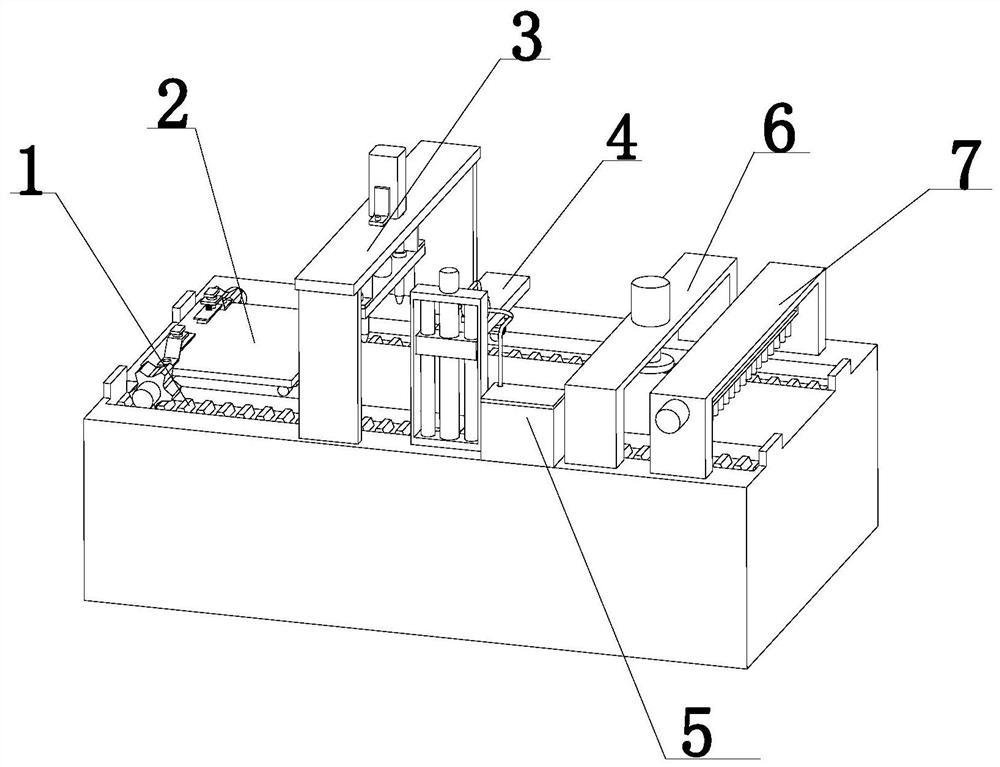

Production equipment for glue indentation reinforced panel

InactiveCN104470219AIncrease productivityMechanical/acoustic circuit processingPunchingFlexible circuits

The invention discloses production equipment for a glue indentation reinforced panel, and relates to the technical field of flexible circuit board processing. The production equipment comprises a die cutting glue punching unit, a steel strip punching unit, a gluing unit and a product punching unit. The die cutting glue punching unit is provided with a first cutter used for hole forming and glue forming of adhesive tape and a material collecting mechanism used for removing waste materials. The adhesive tape continuously penetrates through the first cutter. The steel strip punching unit is provided with a second cutter used for hole forming of a steel strip, and the steel strip continuously penetrates through the second cutter. The gluing unit is provided with a pair of compression rollers with a first guide column, and the adhesive tape and the steel strip both penetrate through the gluing unit and are attached to each other to form a glue-coated steel strip. The product punching unit is provided with a third cutter used for punching the outlines of products and a second guide column. The glue-coated steel strip penetrates through the product punching unit.

Owner:SUZHOU MIDAS PRECISION ELECTRONICS

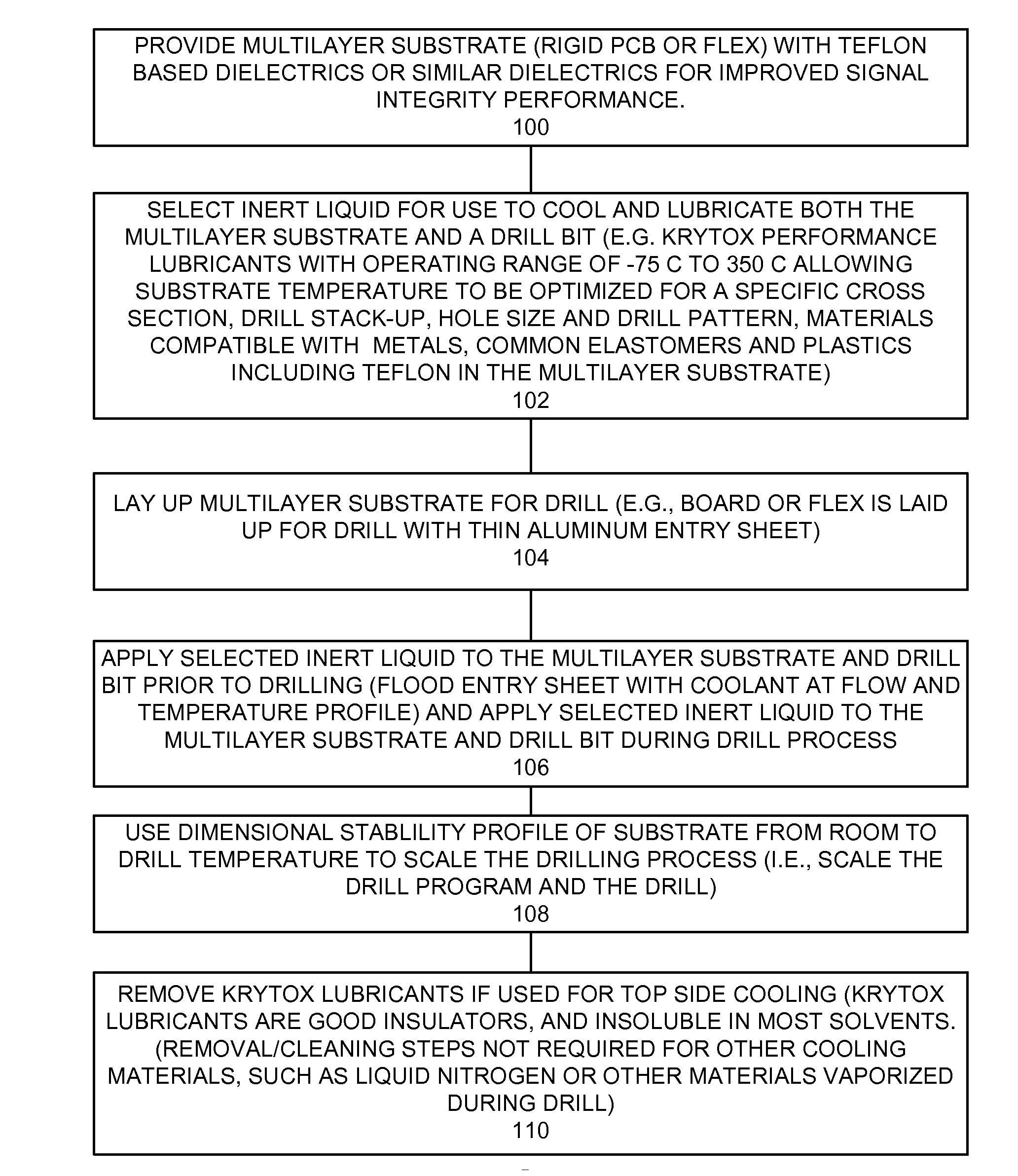

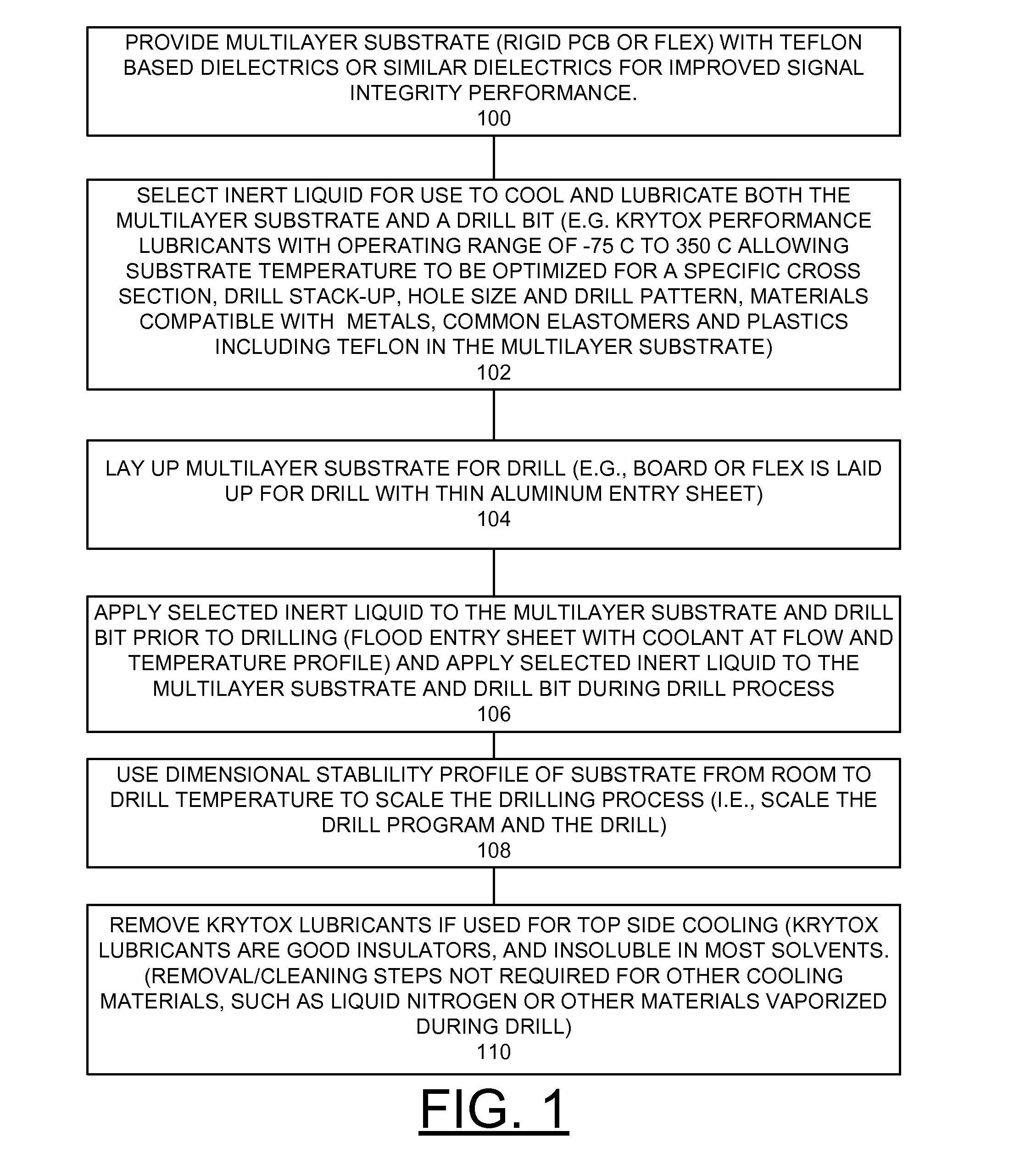

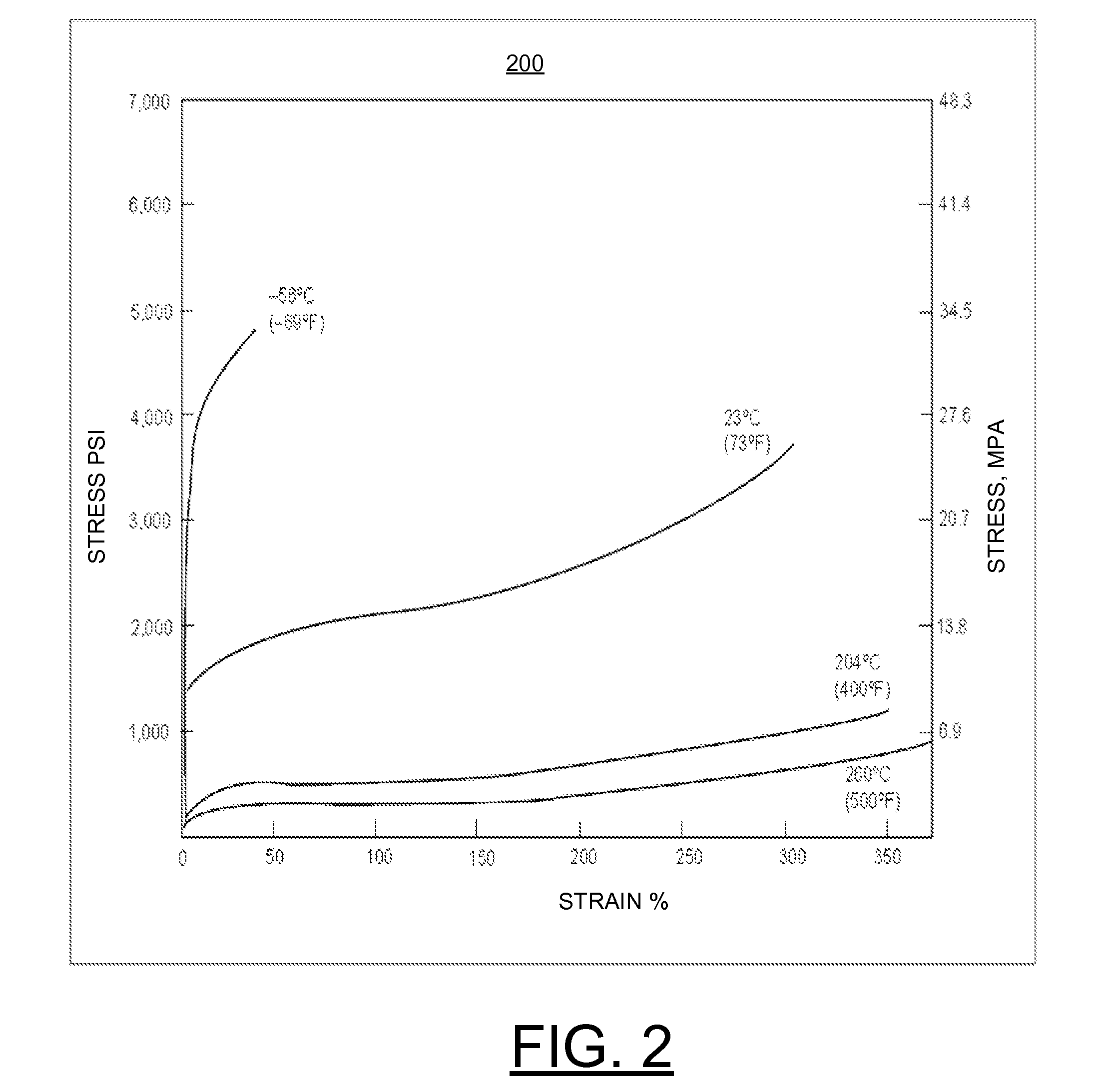

Implementing reduced drill smear

InactiveUS20150030402A1Minimize and eliminate needReduction of drill smearDielectric materialsWorkpiecesPrinted circuit boardDrill bit

A method is provided for implementing reduction of drill smear in drilling a multilayer substrate such as a rigid printed circuit board or flex to minimize or eliminate the need to remove drill smear and for improved via and interconnect reliability. An inert liquid is applied to the multilayer substrate and a drill bit prior to and during the drill process to cool and lubricate the multilayer substrate and the drill bit to reduce drill smear.

Owner:GLOBALFOUNDRIES INC

Thick copper foil shape correcting FPC having pierced gold fingers and manufacturing technology thereof

PendingCN107172810ANot easy to expandThose who are not easy to shrink and deformPrinted circuit aspectsElectrical connection printed elementsManufacturing technologyStructural engineering

The invention discloses a thick copper foil shape correcting FPC having pierced gold fingers and a manufacturing technology thereof. The FPC comprises base material and copper foil lines and the gold fingers which are printed on the base material. The gold fingers are arranged at the two sides of the base material. The gold fingers are provided with internal ends which are connected with the lines and external ends which extend to the edge of the base material. The FPC is provided with concave steps which are formed in the gold finger regions through stamping. The internal ends of the gold fingers are partially reserved on the internal side base material of the concave steps. The concave steps are formed on the gold finger regions of the two sides of the FPC through stamping so that the stress of the FPC is released to perform shape correction, the thick copper FPC is enabled not to expand or contract or deform and poor connection caused by welding point spraining of the product in the use process of different environments can be avoided, and the product reliability can be enhanced, the cost can be saved and the customer credit degree can be enhanced.

Owner:鹤山市中富兴业电路有限公司

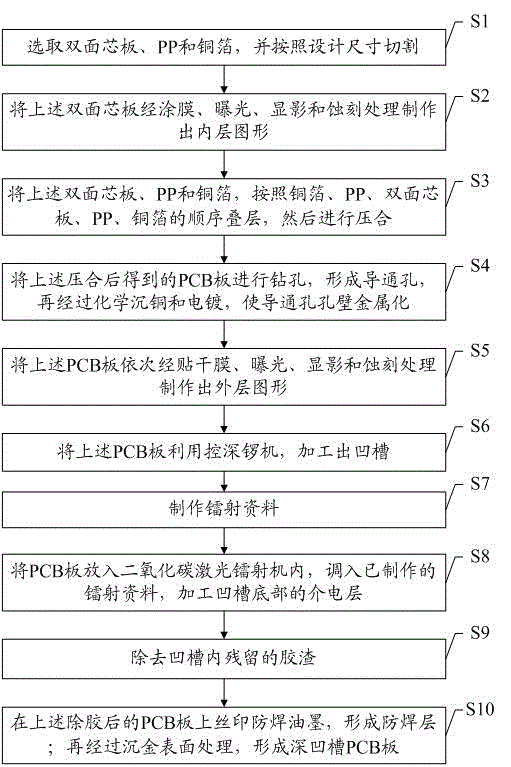

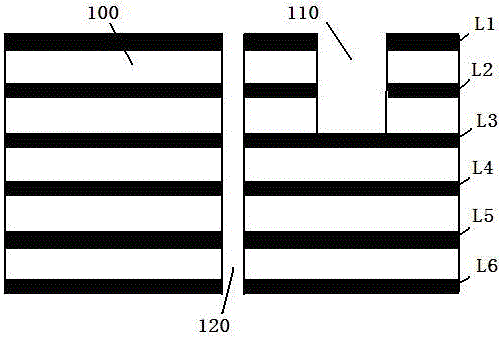

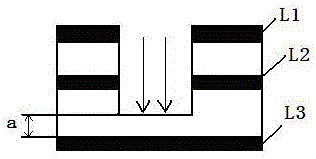

Deep-groove PCB board and processing method thereof

InactiveCN106413291AImprove machining accuracyAvoid damageMechanical/acoustic circuit processingMultilayer circuit manufactureSolder maskSlag

The invention discloses a deep-groove PCB board and a processing method thereof. The method comprises the following steps: step E, manufacturing an outer graph; orderly pasting a dry film, exposing, developing and etching on a PCB board to manufacture the outer graph; F, groove gonging: processing a groove on the PCB board by use of a depth-controlling gong machine; G, manufacturing laser document: manufacturing the laser document; H, forming the groove: placing the PCB board in a carbon dioxide laser machine, invoking the manufactured laser document to process a dielectric layer on the groove bottom; I, removing adhesive: removing residual adhesive slag in the groove; J, solder masking and surface processing: silk-printing solder-masking printing ink on the adhesive-removed PCB board to form a solder masking layer; and then forming a deep-groove PCB board through gold-immersion surface processing. Through the adoption of the method disclosed by the invention, the groove processing precision of the PCB board is improved to prevent a copper layer from being damaged in the groove processing procedure of the PCB board; and meanwhile, the processing efficiency is improved to prevent the groove side warping phenomenon from occurring.

Owner:SHENZHEN KINWONG ELECTRONICS

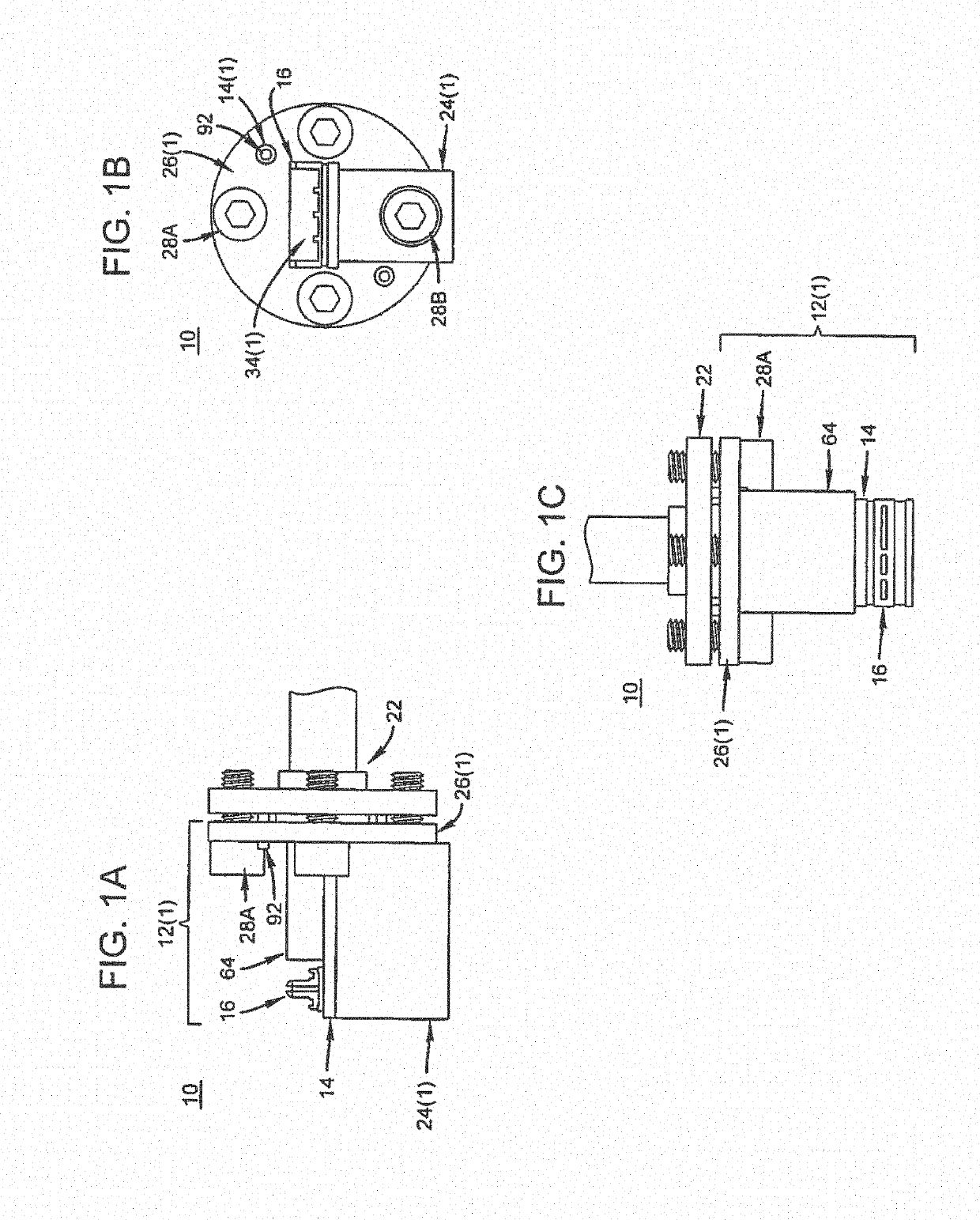

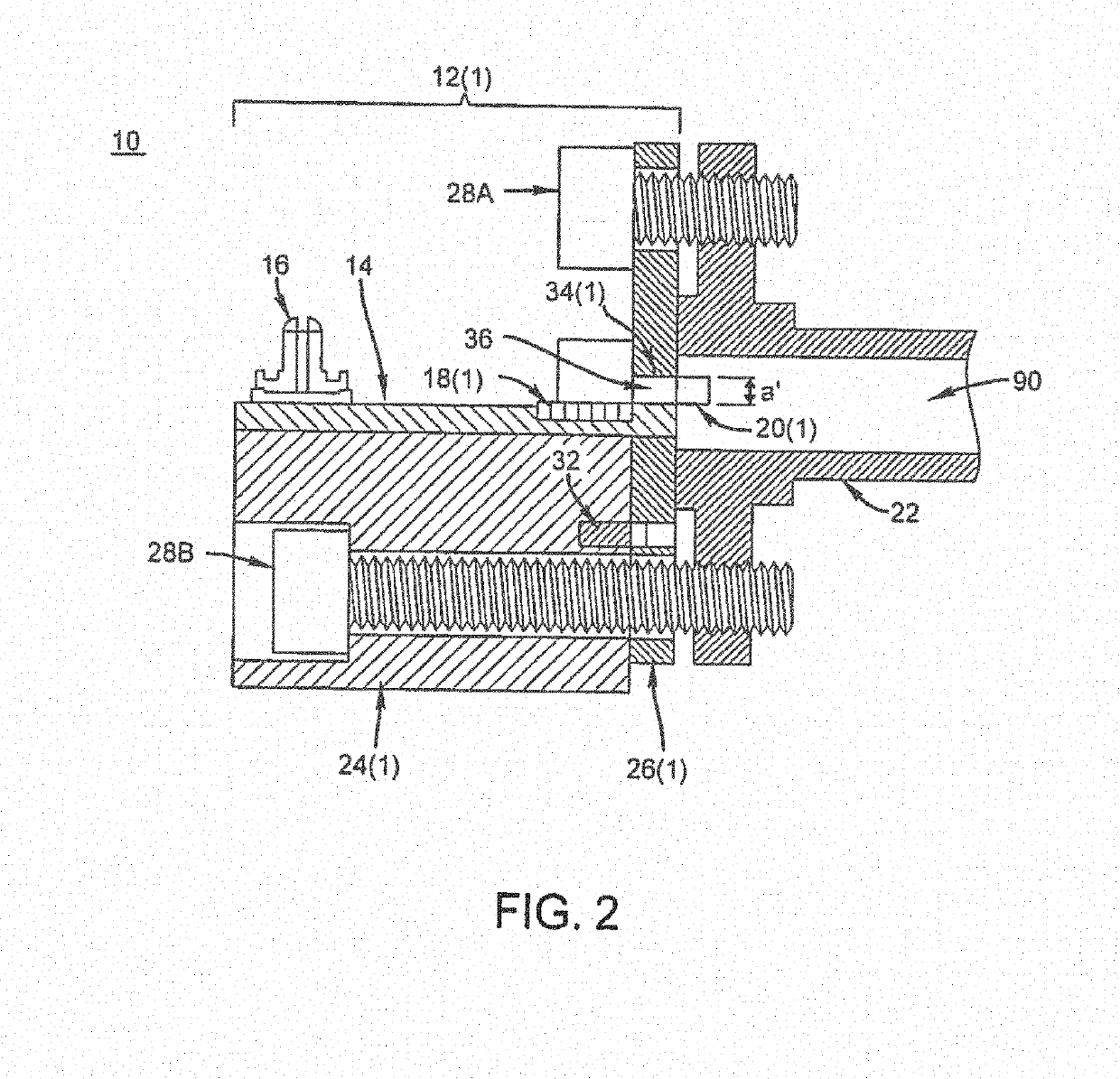

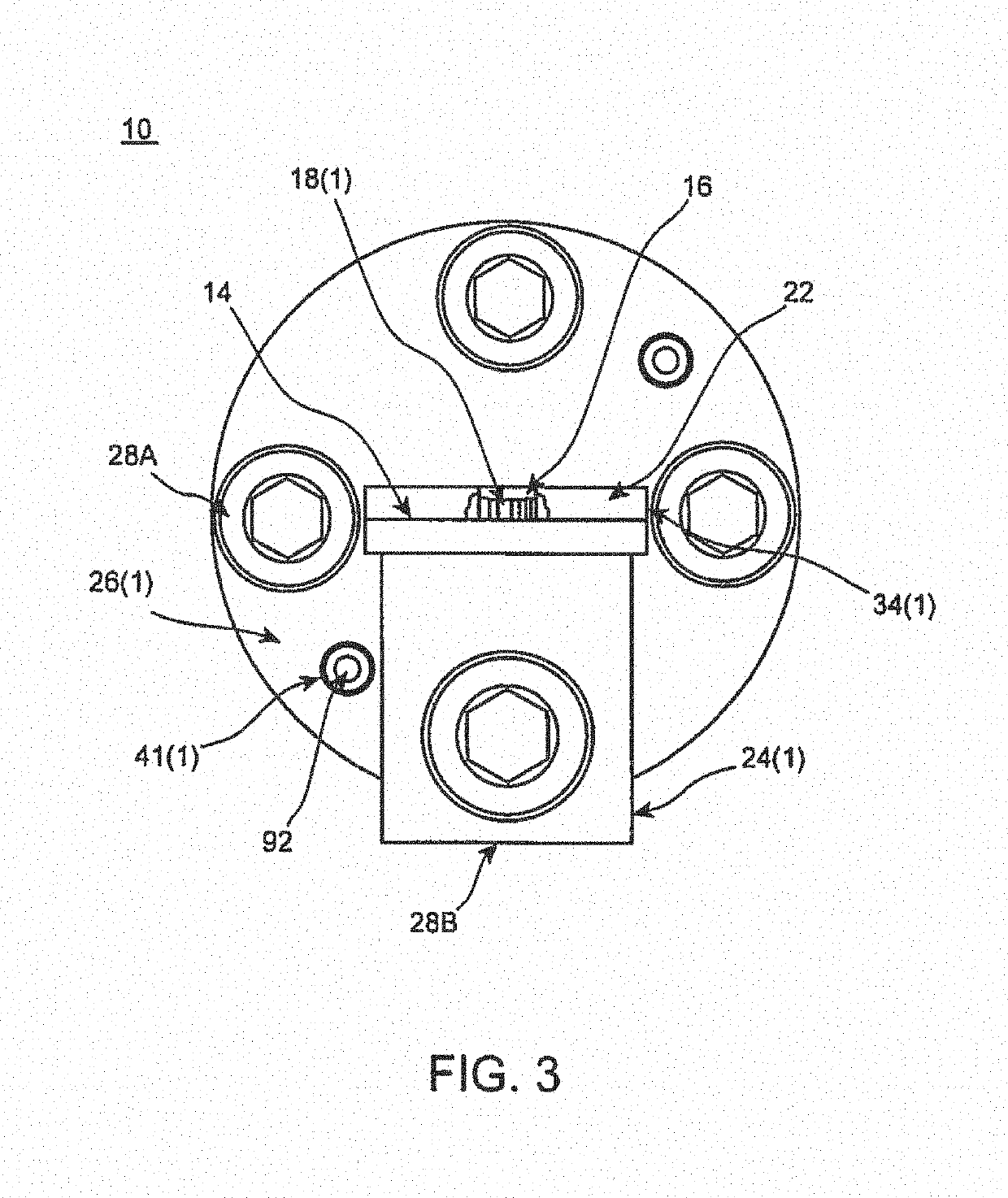

Waveguide interface and printed circuit board launch transducer assembly and methods of use thereof

ActiveUS20190207283A1Eliminate needHigh frequency circuit adaptationsSolid-state devicesTransducerEngineering

A printed circuit board assembly comprising a plurality of layers. At least one of the plurality of layers is formed of a dielectric material and has an extended portion extending beyond the other layers in the plurality of layers. A first metallic layer is located on at least a portion of the extended portion of the dielectric layer. The first metallic layer and the dielectric layer are configured to form a launch transducer comprising one or more transmission lines and a transducer element coupled to the one or more transmission lines. The transducer element is configured to propagate millimeter wave frequency signals.

Owner:VUBIQ

Inward-shrinking glue reinforcing sheet production device

The invention discloses an inward-shrinking glue reinforcing sheet production device and relates to the technical field of flexible printed circuit board processing. The device comprises a glue-coated steel strap conveying unit, a laser cutter, a waste reeling unit and a product punching unit. A glue-coated steel strap is continuously conveyed through the glue-coated steel strap conveying unit, the laser cutter is aligned with the glued face of the glue-coated steel strap and used for cutting forming glue pieces and a locating hole, the waste reeling unit is located behind the laser cutter and used for reeling waste of the forming glue pieces, the product punching unit is located on the rear side of the waste reeling unit and provided with a guide column and cutters, the guide column is used for being inserted in the locating hole of the glue-coated steel strap for guidance, and the cutters are used for cutting the glue-coated steel strap into the shape of products.

Owner:SUZHOU MIDAS PRECISION ELECTRONICS

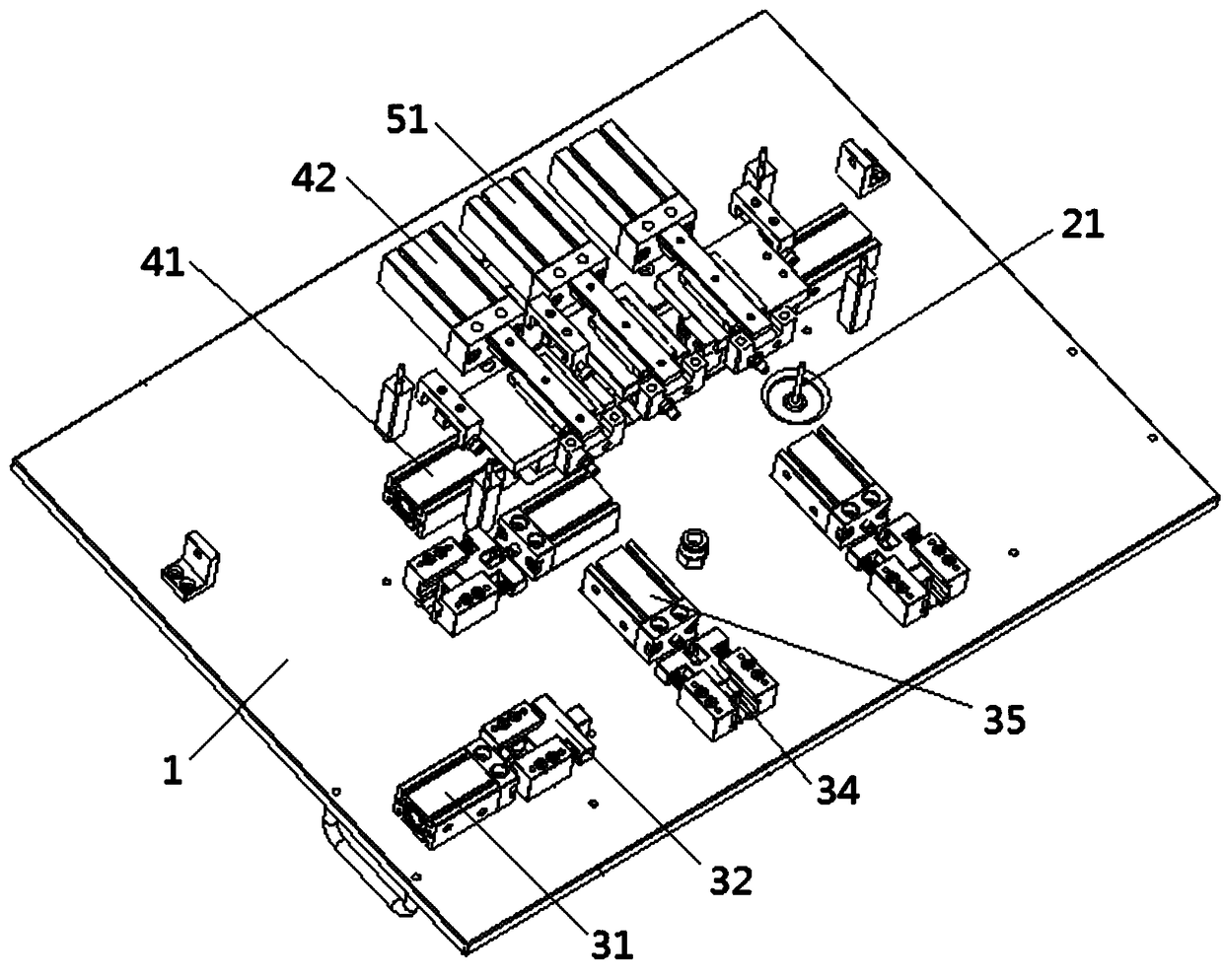

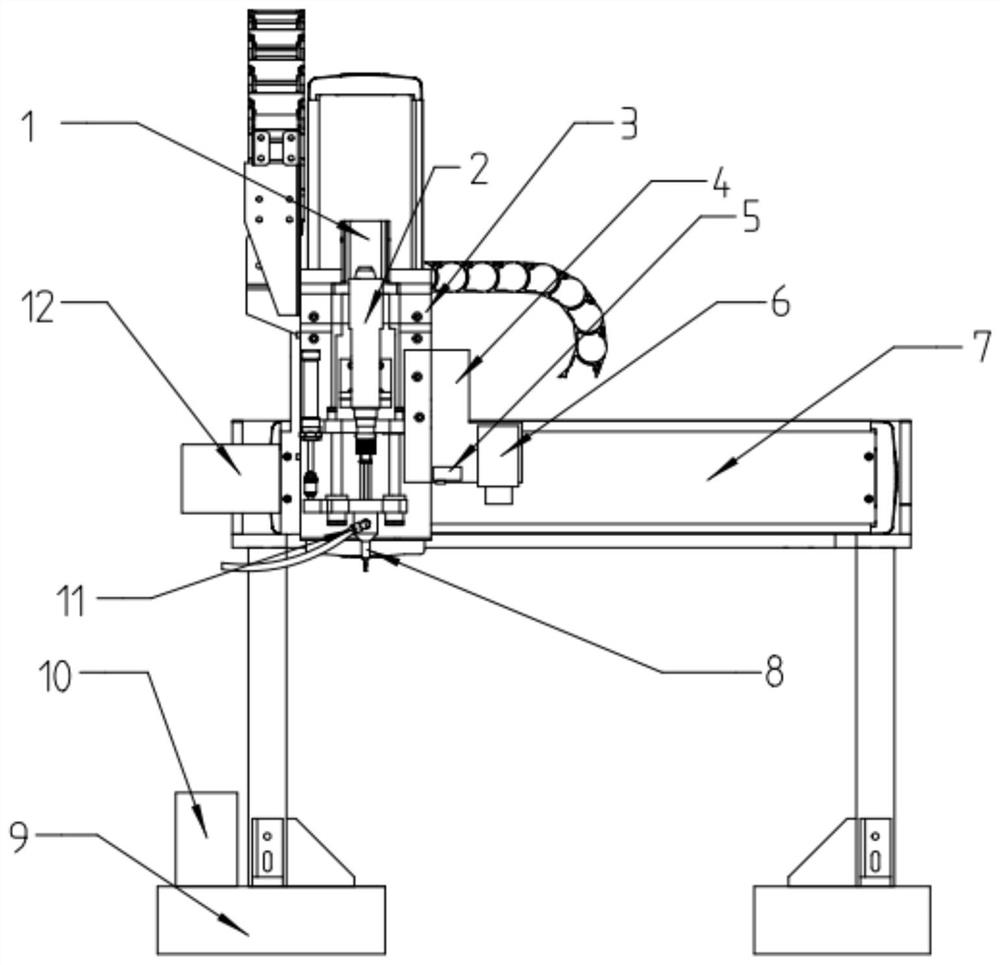

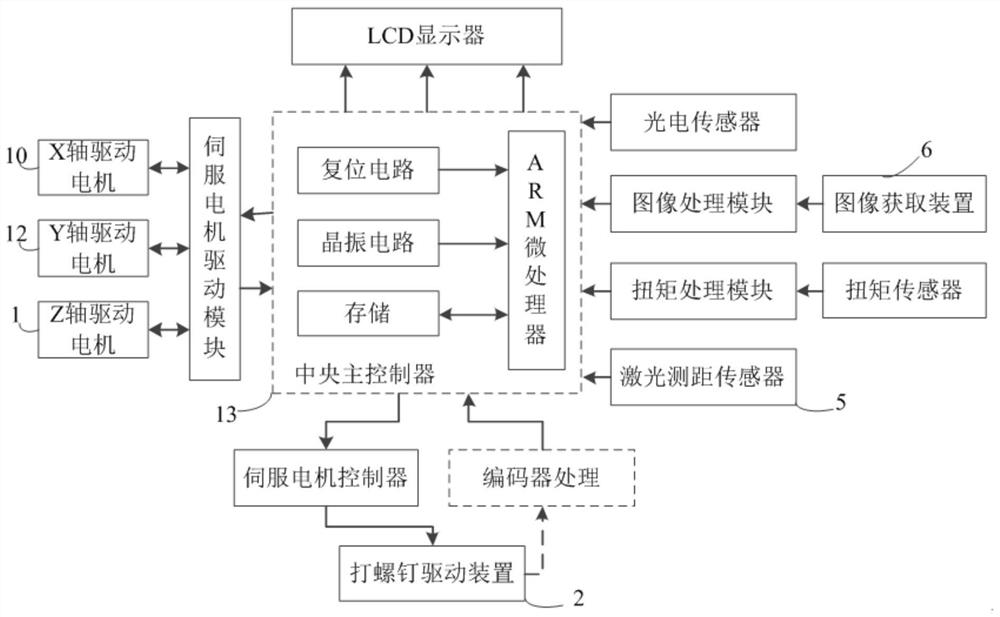

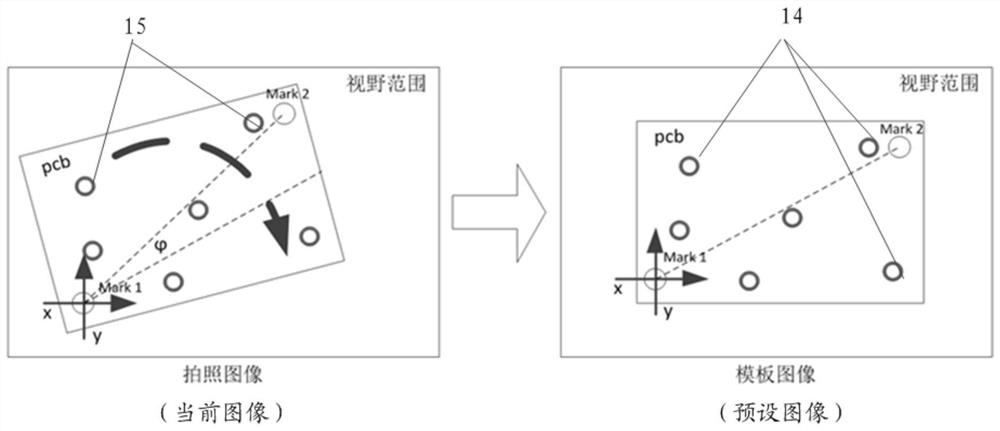

Circuit board screw driving method and system

ActiveCN112312666AIncrease productivityGuaranteed accuracyMechanical/acoustic circuit processingControl engineeringMechanical engineering

The invention discloses a circuit board screw driving method and system, and the method comprises the steps: obtaining a current image of a current circuit board, comparing the current image with a preset image of the circuit board, obtaining a coordinate deviation value relative to the preset image with a preset screw driving coordinate; and obtaining a target screw driving coordinate according to the coordinate deviation value and a preset screw driving coordinate, and controlling to carry out screw driving operation on the target screw driving coordinate on the current circuit board. The circuit board screw driving method provided by the invention is a vision-based position compensation method and is matched with the positioning of a tool carrier, by obtaining a primary image, comparingthe primary image with the set preset screw hole position, and determining the specific screw hole position of the current circuit board, and the method can match all position points only by obtaining the primary image. The production efficiency can be obviously improved, and the accuracy of the screw driving position is ensured.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

PCB splitting jig

InactiveCN104411102AReduce glitchesImprove Fragmentation EfficiencyInsulating layers/substrates workingMechanical/acoustic circuit processingEngineeringPrinted circuit board

The invention discloses a PCB splitting jig. The PCB splitting jig is composed of a working panel, a left side plate and a right side plate; the working panel is a flat panel arranged horizontally; the left side plate and the right side plate both are fixed on the upper surface of the working panel and are parallel to each other, a gap is formed between the left side plate and the right side plate to form a slot, and the width of the slot is greater than the thickness of a joint printed circuit board; the upper surface of the left side plate is higher than the upper surface of the right side plate and the height different is 2-5mm; the thickness of the left side plate is small than the length and the width of a single PCB. The PCB splitting jig is capable of splitting the small single PCBs on the joint printed circuit board row by row, and therefore, the splitting efficiency is greatly improved and burrs at the edges of the boards are reduced; the PCB splitting jig is simple in structure and easy to implement.

Owner:竞陆电子(昆山)有限公司

Integrated circuit board machining device

InactiveCN112770510APrevent secondary cleaningReduce workloadInsulating layers/substrates workingMechanical/acoustic circuit processingDust controlElectric machinery

The invention discloses an integrated circuit board machining device, and belongs to the technical field of integrated circuit boards. The integrated circuit board machining device comprises a moving device, a fixing device, a drilling device, a cutting device, a cleaning device, a polishing device and a dust removal device, the moving device is horizontally arranged on the ground, the fixing device is installed at the top of the moving device, the drilling device is installed at the top of the moving device, the cutting device is installed at the top of the moving device, the cleaning device is installed at the top of the moving device, the cleaning device is installed at the top of the cutting device, the polishing device is installed at the top of the moving device, and the dust removal device is installed at the top of the moving device. A second motor moves to drive a connecting column to rotate, the connecting column rotates to drive a polishing disc to rotate, a cut circuit board is polished, the circuit board can be smoother and more attractive, the cut circuit board has a dust removal function through movement of an air pump and a third motor, and the workload of people is greatly relieved.

Owner:合肥高地创意科技有限公司

Popular searches

De-icing/drying-out arrangements Non-metallic protective coating application Radio wave reradiation/reflection Circuit thermal arrangements Electronic waste recycling Boring/drilling machines Metal core circuit manufacture Conductive pattern reinforcement Transformers/inductances magnetic cores Inductances/transformers/magnets manufacture

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com