Method for improving groove-making burrs before copper plating

A gong groove and sinking copper technology, which is applied in mechanical/acoustic circuit processing, electrical components, printed circuit manufacturing, etc., to reduce scrapping problems, meet customer needs, and reduce scrapping rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

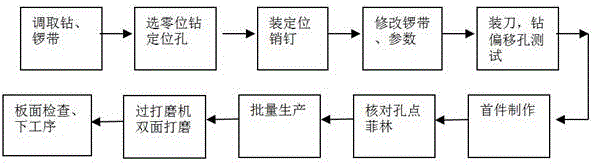

[0022] This embodiment provides a method for improving the front edge of the gong groove before sinking copper, including the following steps:

[0023] S1. Select the material number of the gong groove in front of sinking copper to retrieve the corresponding drill and gong data;

[0024] S2. Select the zero position to drill the positioning hole to ensure that there are no repeated holes and half holes;

[0025] S3. Install a positioning pin 0.05mm smaller than the hole diameter on the drilled hole;

[0026] S4. Adopt split-knife production, the first gong knife gong slot compensation goes to the upper limit, and the second gong knife repair and batch front compensation goes to the lower limit;

[0027] S5. Drill offset test holes, and drill holes at 200mm in the X and Y directions of the direction holes to confirm the offset status;

[0028] S6. After the first piece is finished, use the hole point film to confirm the position of the gong groove and the condition of the gon...

Embodiment 2

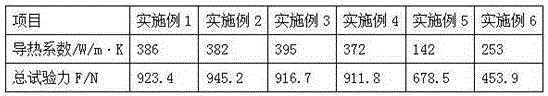

[0038] The method for improving the front edge of the gong groove in the present embodiment is consistent with that of Embodiment 1. The difference is that in the present embodiment, the composition of the cladding layer is C 16 parts, Si 7 parts, Mg 3 parts, Cr 2 parts, Ni 9 parts, Al 10 parts, Ti 8 parts, Cu 12 parts.

[0039] Through the cladding layer, the heat generated by the gong knife during processing can be effectively conducted to avoid overheating of the processing part and damage to parts. At the same time, the cladding layer has high rigidity, which can effectively resist the impact during processing and prevent the wear of the tool.

Embodiment 3

[0041] The method for improving the front edge of the gong groove in the present embodiment is consistent with that of embodiment 1, the difference is that in the present embodiment, the composition of the cladding layer is calculated in parts by weight: 16 parts of C, 7 parts of Si, 9 parts of Mg, 5 parts of Cr, 9 parts of Ni, 15 parts of Al, 8 parts of Ti, and 12 parts of Cu.

[0042] Through the cladding layer, the heat generated by the gong knife during processing can be effectively conducted to avoid overheating of the processing part and damage to parts. At the same time, the cladding layer has high rigidity, which can effectively resist the impact during processing and prevent the wear of the tool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com