Omni-directional rotary zipper head

An all-round, head-to-head technology, applied in the field of zippers, can solve the problems of good thermal conductivity, easy damage, and low strength of nylon sliders, and achieve the effects of low friction coefficient, preventing sliding, and improving the overall mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

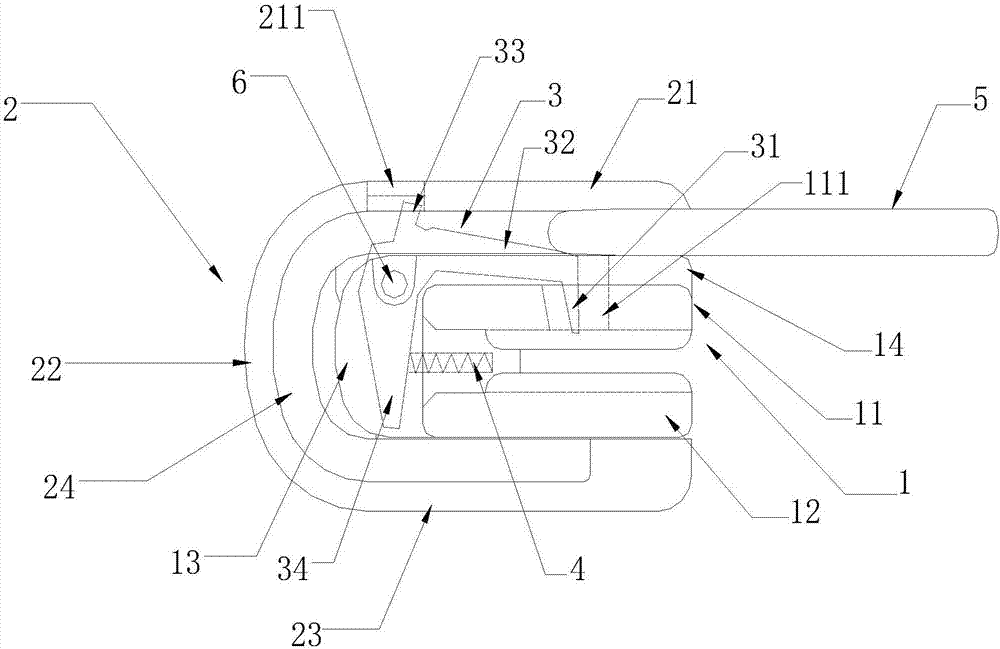

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

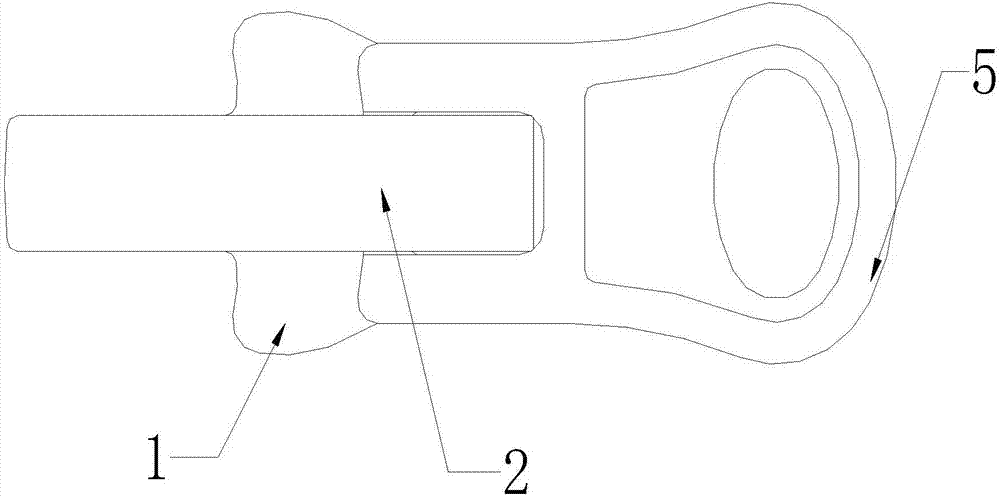

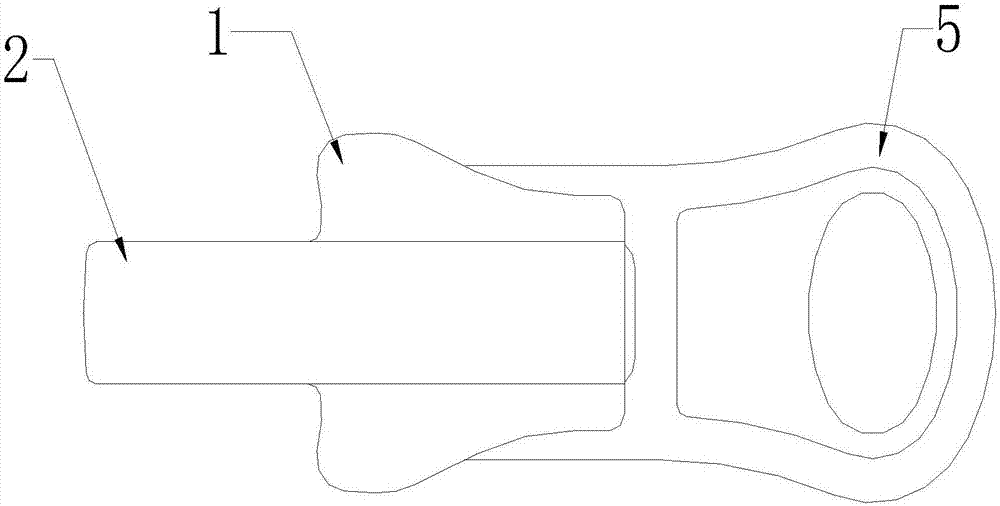

[0023] In order to achieve the above object, the technical scheme adopted by the present invention is as follows: a kind of omni-directional rotary slider, the slider includes the head 1, the multi-track structure 2, the locking structure 3, the spring structure 4 and the pull tab 5, the pull tab 5 is set There are two clamping ends and are clamped on the multi-track structure 2. The head 1 includes an upper plate 11 and a lower plate 12. The upper plate 11 and the lower plate 12 are connected by a front baffle 13, and the front baffle 13 is set At the front end of the head 1, the head 1 includes an inlet and an engagement port, and the front baffle 13 divides the inlet into two symmetrically; the multi-track structure 2 is vertically intersected with the head 1, and the multi-track structure 2 surrounds the head 1 is set in three directions, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com