Method for making window on cover film of flexible circuit board

A technology for flexible circuit boards and cover films, which is used in printed circuits, printed circuit manufacturing, mechanical/acoustic circuit processing, etc., and can solve problems such as failure of automated equipment production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

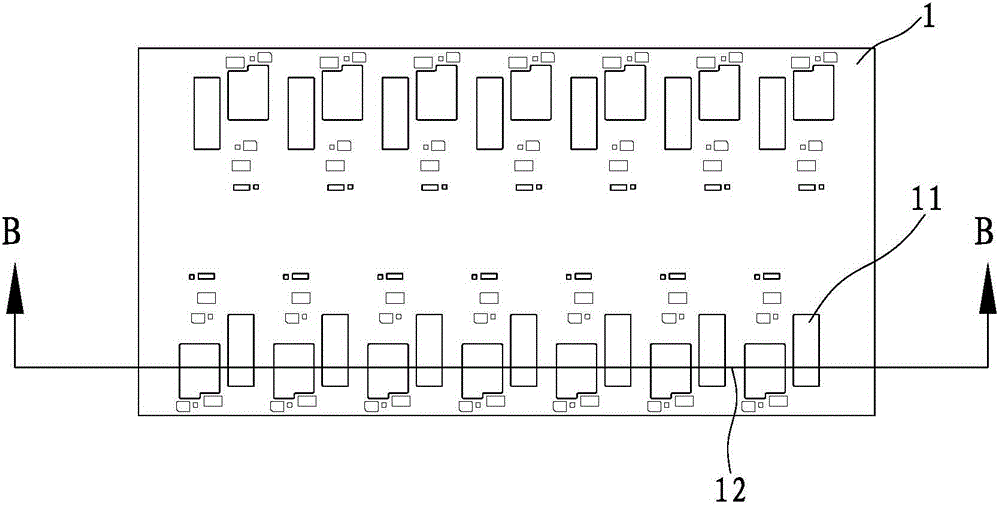

[0016] Such as figure 1 , figure 2 As shown, it is the first embodiment of the method for opening a cover film of a flexible circuit board in the present invention. The cover film 1 is composed of a cover film layer 2 and a release paper layer 3, and the cover film layer 2 is covered on the release paper layer. Pattern paper layer 3 surface.

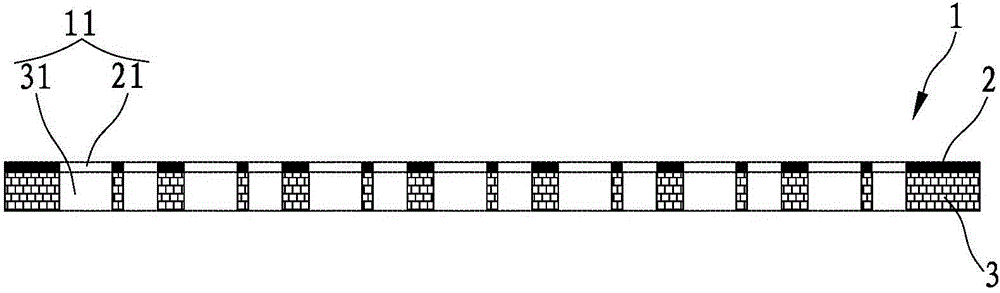

[0017] Such as image 3 As shown, it is the conventional window opening method of the cover film 1. Both the cover film layer 2 and the release paper layer 3 are punched with completely through grooves 21, 31 (or through holes), and the full cut (that is, completely through) is adopted. Way.

[0018] Such as Figure 4 As shown, the present invention only punches out the through groove 21 (or through hole) on the cover film layer 2, and the release paper layer 3 has no through groove (or through hole) opposite the cover film layer 2 through groove 21 (or through hole). hole), that is, by half-cut (partially through) method.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com