Perforating device for adding protection plate and pasting adhesive tape on PCB production line

A technology for printed circuit boards and punching devices, which is applied in the fields of printed circuits, printed circuit manufacturing, mechanical/acoustic circuit processing, etc. close together and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

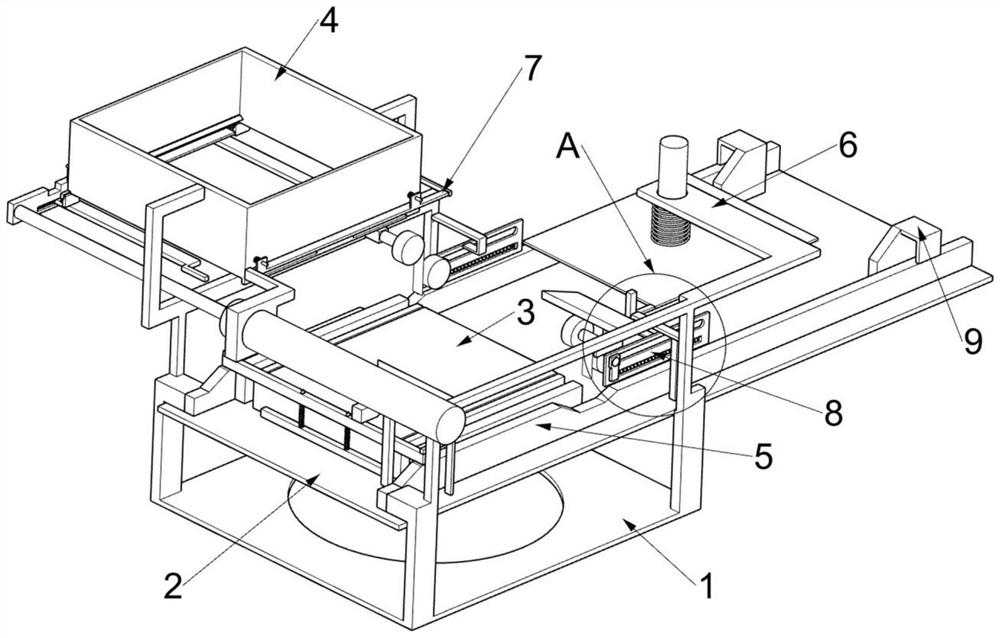

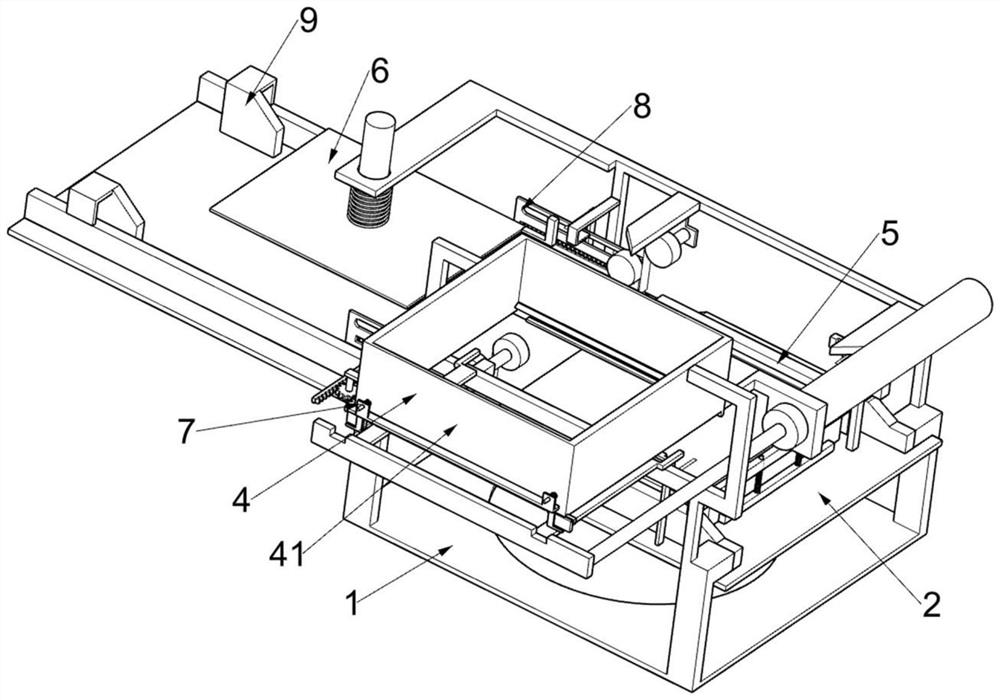

[0029] A punching device for adding a protective plate and pasting adhesive tape on a PCB printed circuit board production line, such as Figure 1-11 As shown, it includes a support frame 1, a conveyor belt 2, a placement plate 3, a lower plate mechanism 4, a glue cutting mechanism 5, and a punching mechanism 6. The conveyor belt 2 is set on the support frame 1, and the conveyor belt 2 is used to convey the circuit. Plate, the top of the conveyor belt 2 is provided with a placement plate 3, the lower plate mechanism 4 is set on the support frame 1, the lower plate mechanism 4 is used to intermittently put the protective plate, the glue cutting mechanism 5 is set on the support frame 1, and the glue The cutting mechanism 5 is used to paste the adhesive tape on the protective plate and peel off the adhesive tape. The punching mechanism 6 is arranged on the support frame 1 and is used to punch holes on the circuit board.

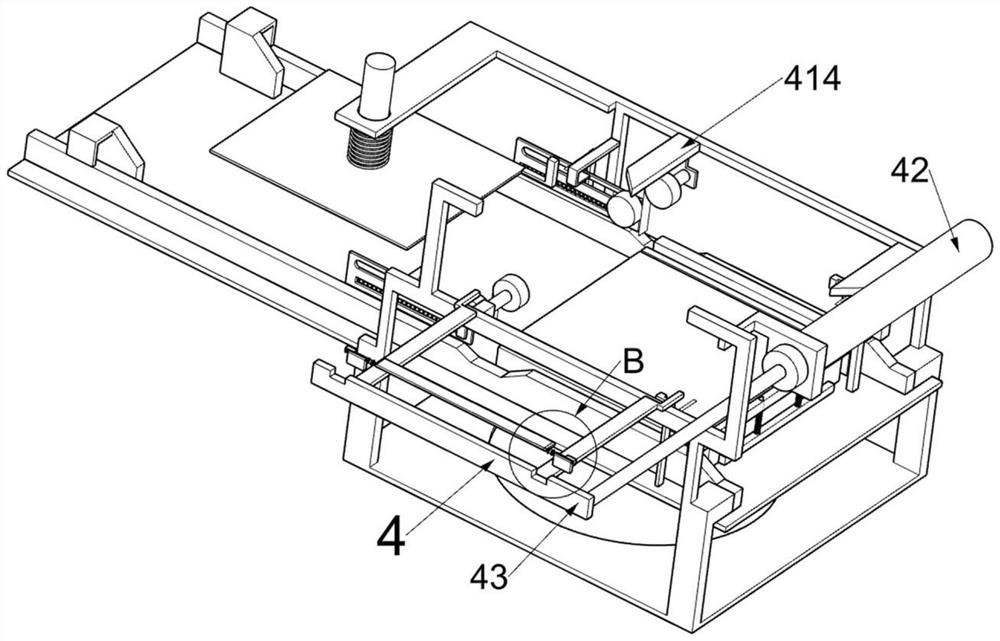

[0030]The lower plate mechanism 4 includes a protective p...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 9 As shown, a control board device 7 is also included, and the control board device 7 is arranged on the protection board frame 41. The control board device 7 includes a sliding frame 71, a second slide bar 72, a fourth return spring 73, and a first rack 74. , the fourth fixed plate 75, gear 76, the second rack 77 and the fifth fixed plate 78, both sides of the protective plate frame 41 are provided with two second slide bars 72, wherein the two second slide bars 72 are jointly slidably connected There is a sliding frame 71, and a fifth fixed plate 78 is slidably connected to the other two second sliding bars 72. Through the mutual cooperation between the sliding frame 71 and the fifth fixed plate 78, the protective plate falls to the second rotating plate, so that A fourth return spring 73 is connected between the sliding frame 71 and the protection plate frame 41, and the fourth return spring 73 is used to drive the sliding f...

Embodiment 3

[0039] On the basis of Example 2, such as Figure 11 As shown, a rolling device 8 is also included, and the rolling device 8 is used to make the adhesive tape on the protection board and the protection board more fit, the rolling device 8 is arranged on the support frame 1, and the rolling device 8 includes a fixed frame 81 , slide block 82, second fixed rod 83, turning roller 84 and the 5th back-moving spring 85, support frame 1 is provided with fixed mount 81, on the fixed mount 81 sliding type is connected with the second fixed rod 83, the second fixed rod 83 One end is fixedly connected with a slide block 82, and the slide block 82 is used to drive the second fixed rod 83 and its upper device to move towards the direction close to the rubber stripping block 9. The other end of the second fixed rod 83 is rotatably connected with a rotating roller 84, and the rotating roller 84 is used for pressing the adhesive tape on the protective plate, and the fifth return spring 85 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com