Patents

Literature

109results about How to "Minimize and eliminate need" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

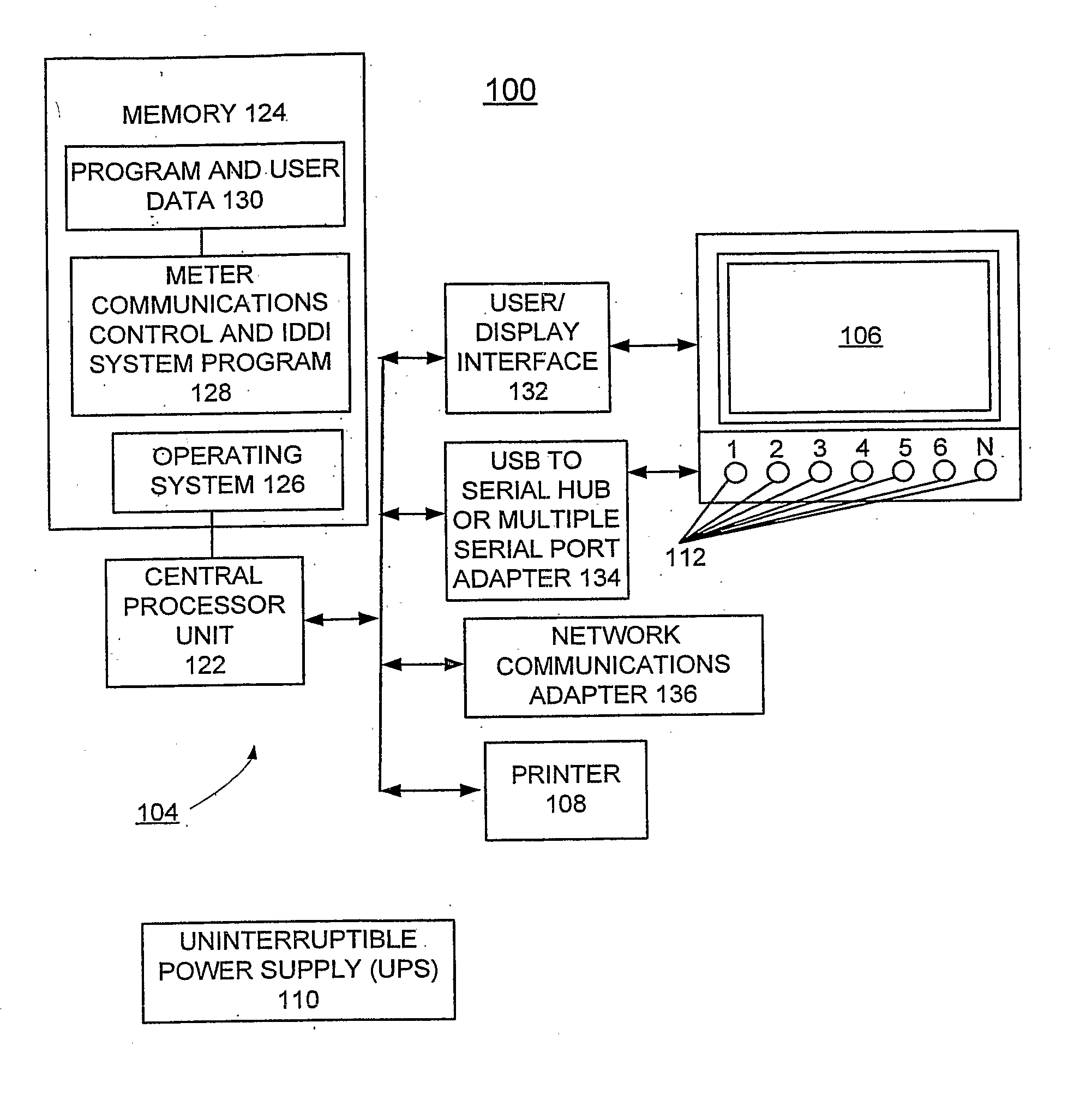

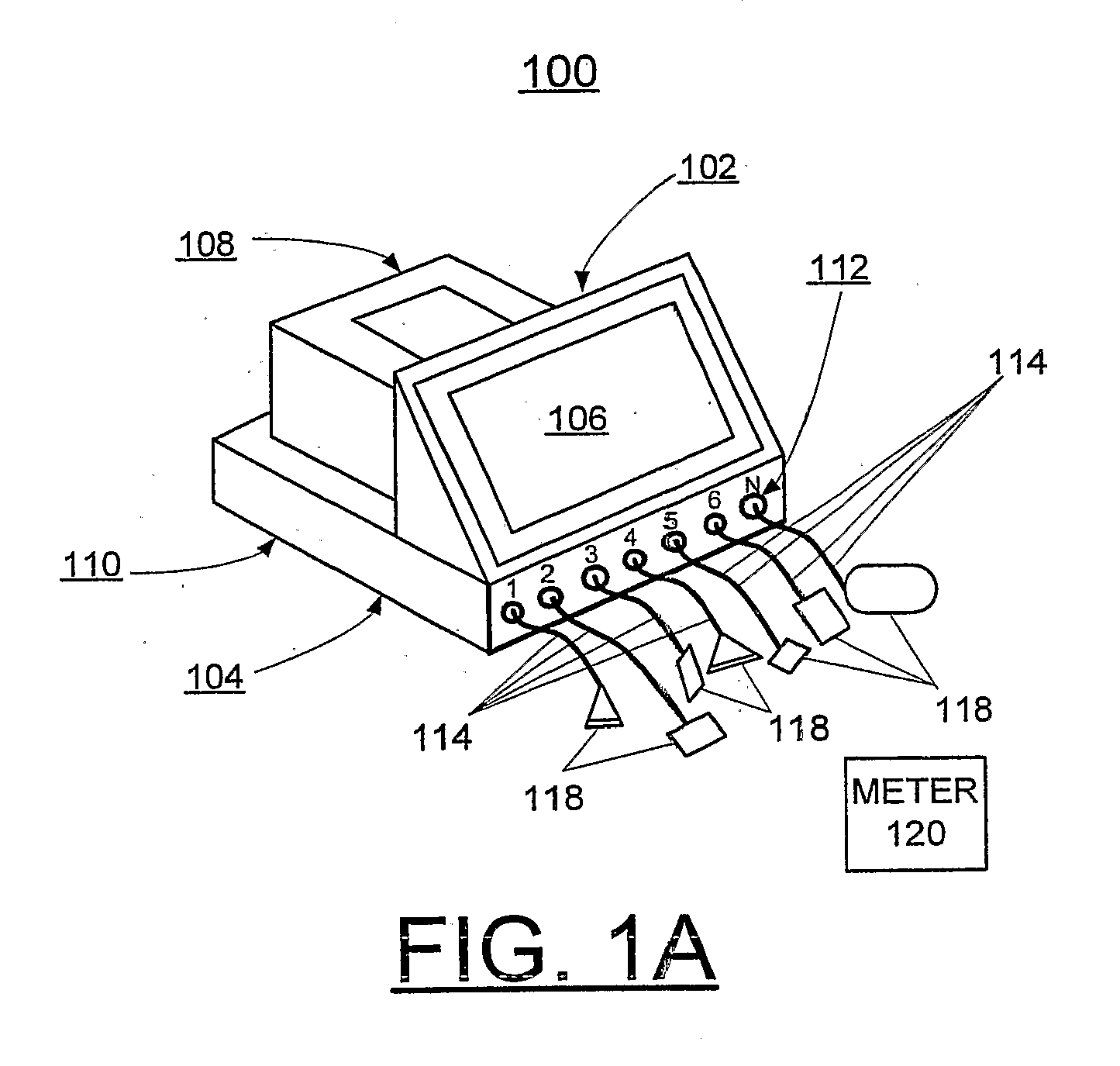

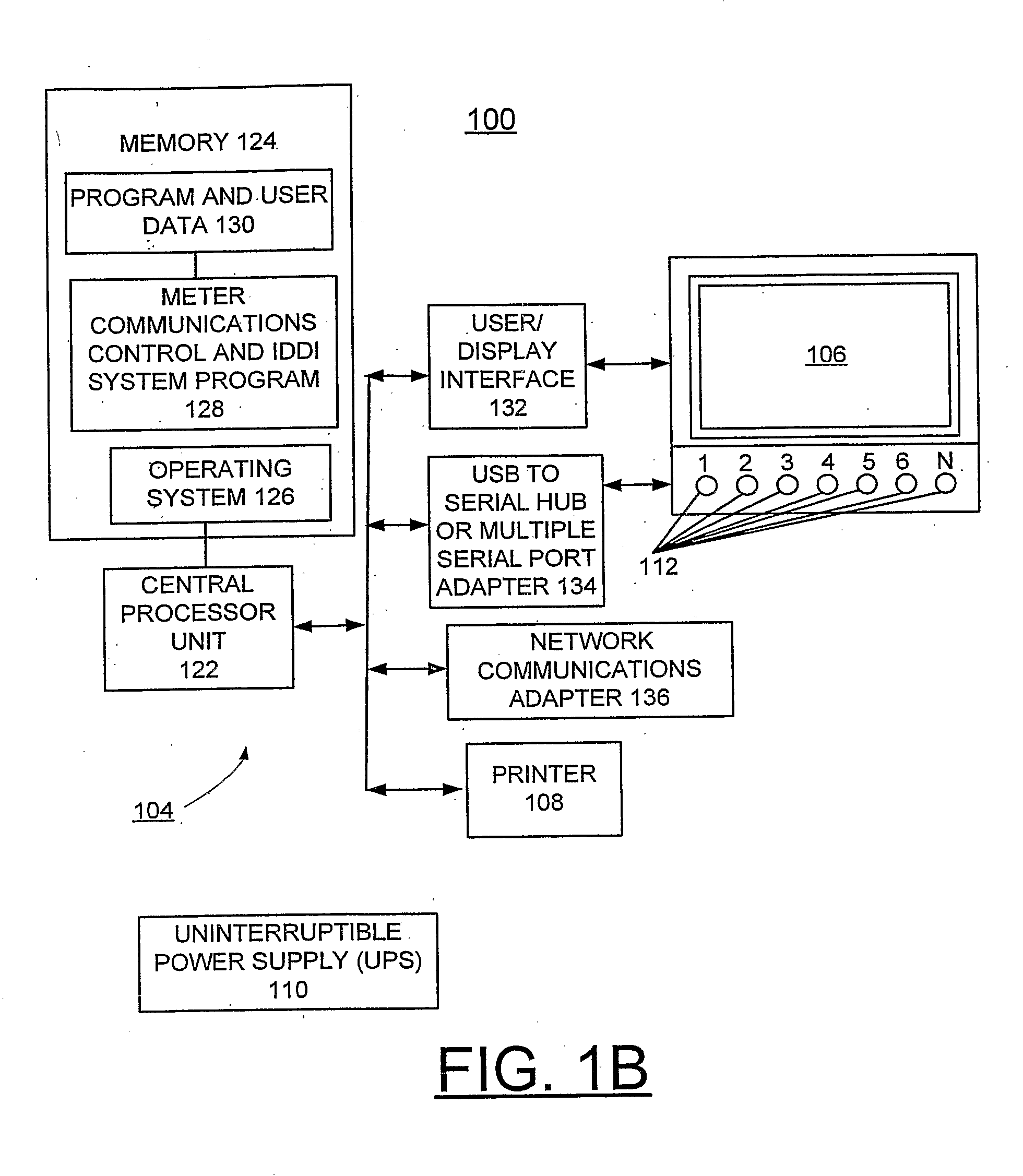

Method and Apparatus for Automatic Detection of Meter Connection and Transfer of Data

InactiveUS20070219432A1Minimize and eliminate needLocal control/monitoringMedical report generationData transmissionCollections data

A method and apparatus are provided for implementing data management with a data collection computer system to aid analysis and treatment. A serial port is monitored to detect the connection of a meter. When a meter connection is identified, patient data is automatically downloaded from the meter to the data collection computer system. Then the patient data or one or more selected reports generated from the patient data are printed. The patient data is downloaded from the meter and printed, with no user intervention required. Reports to be generated and printed are selected in a setup mode and stored. After the patient data is downloaded from the meter, communication with the meter is continued until either the meter is turned off, the cable is disconnected, or the meter automatically shuts itself off after a specific amount of inactivity.

Owner:THOMPSON BRIAN C

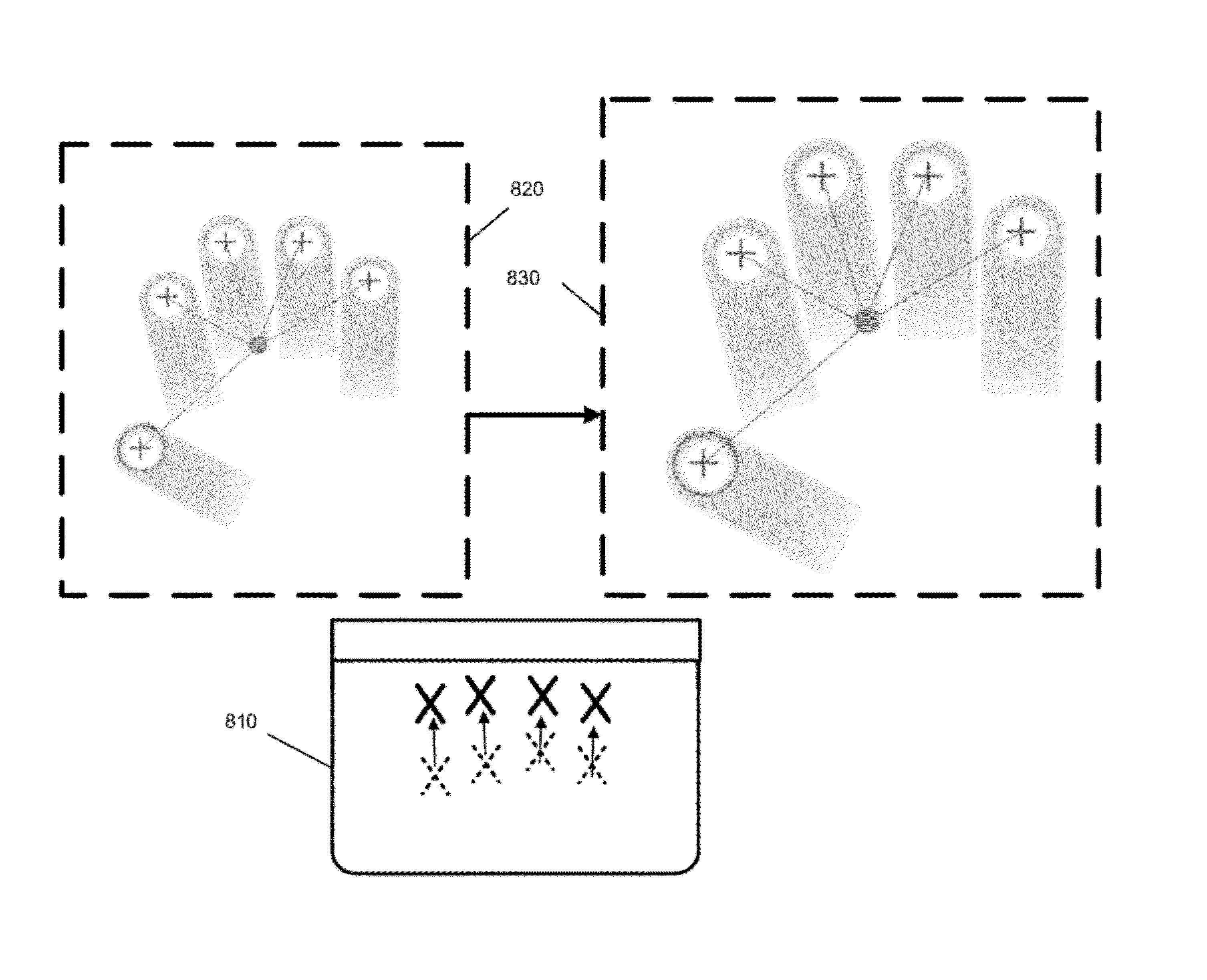

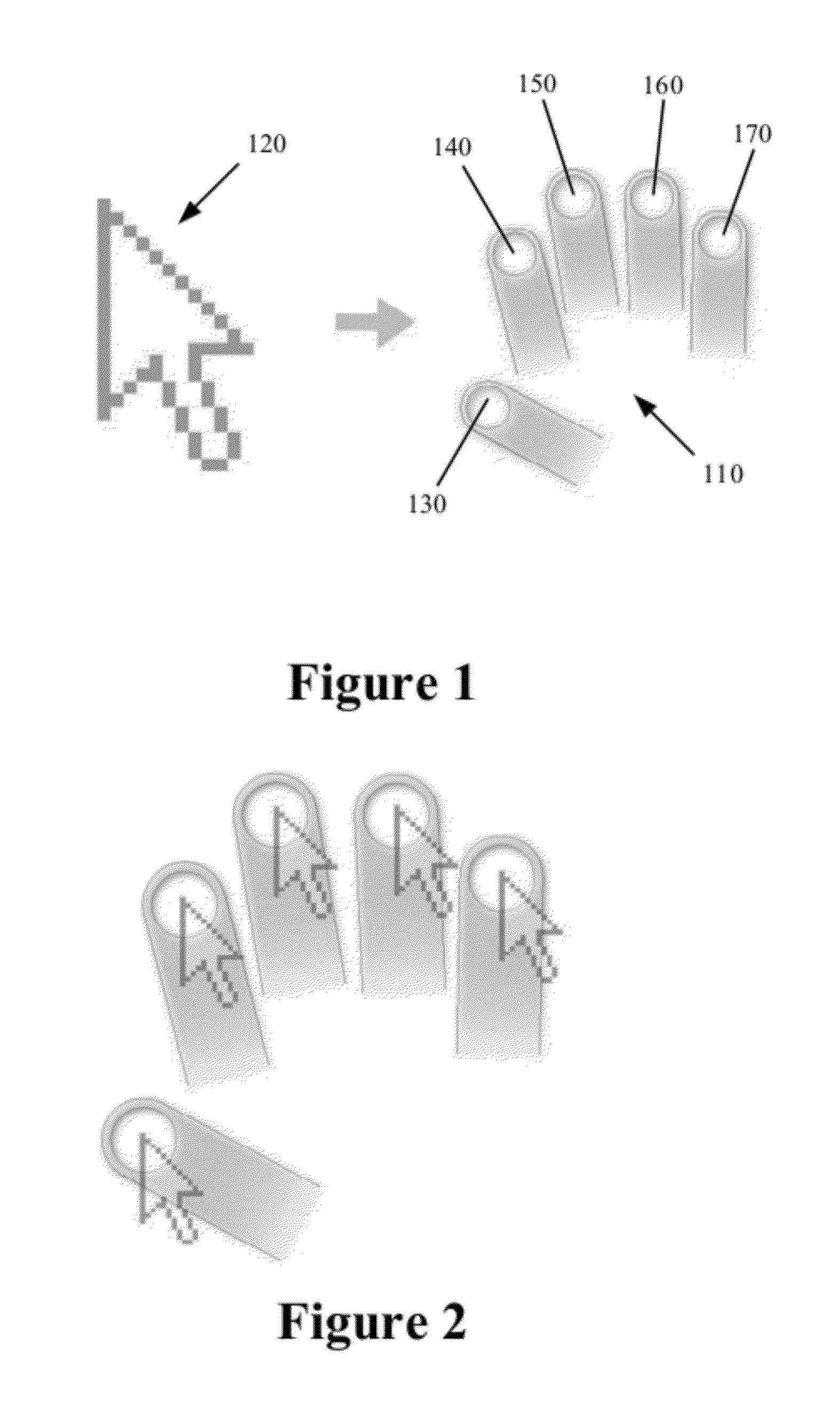

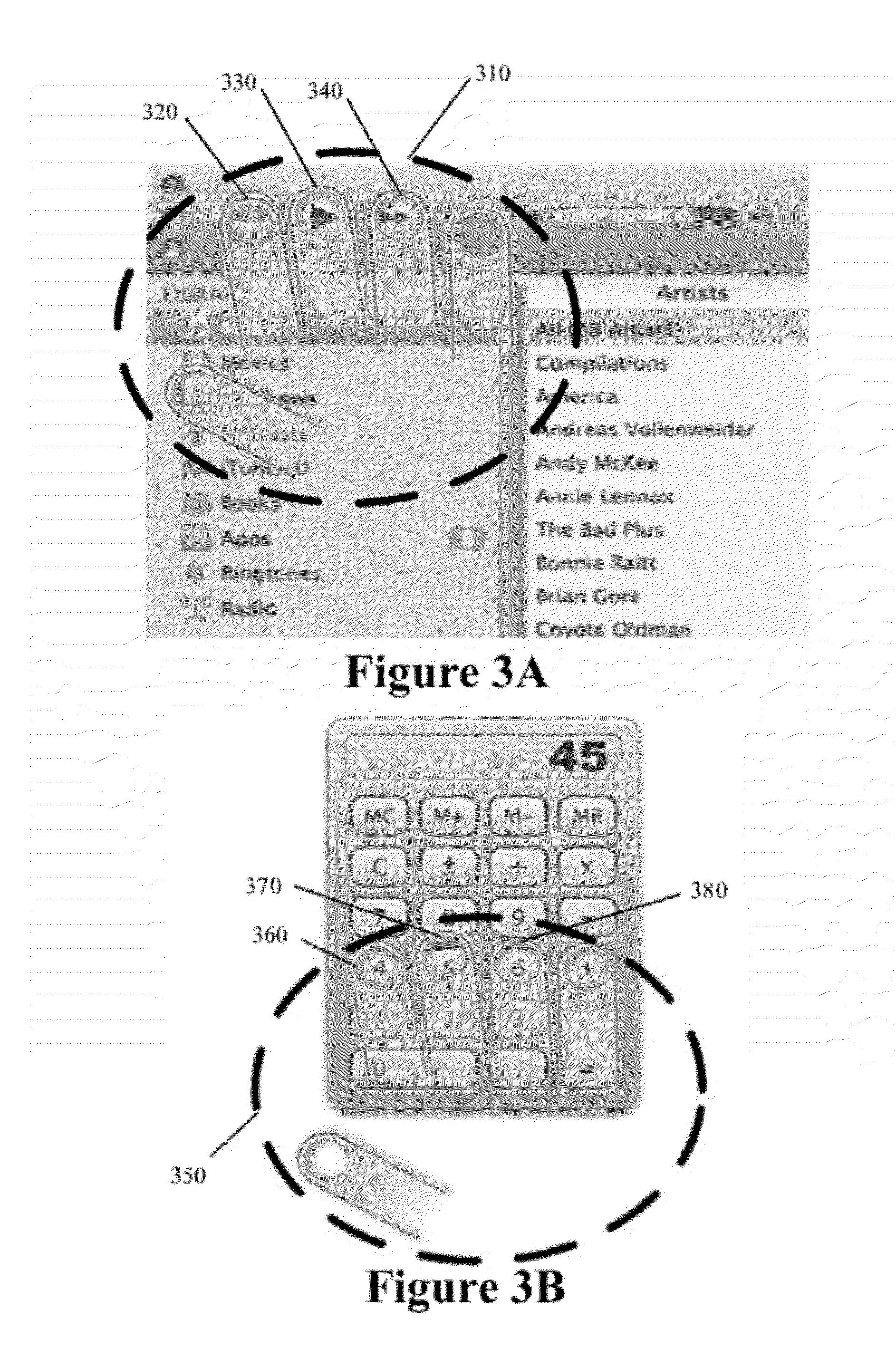

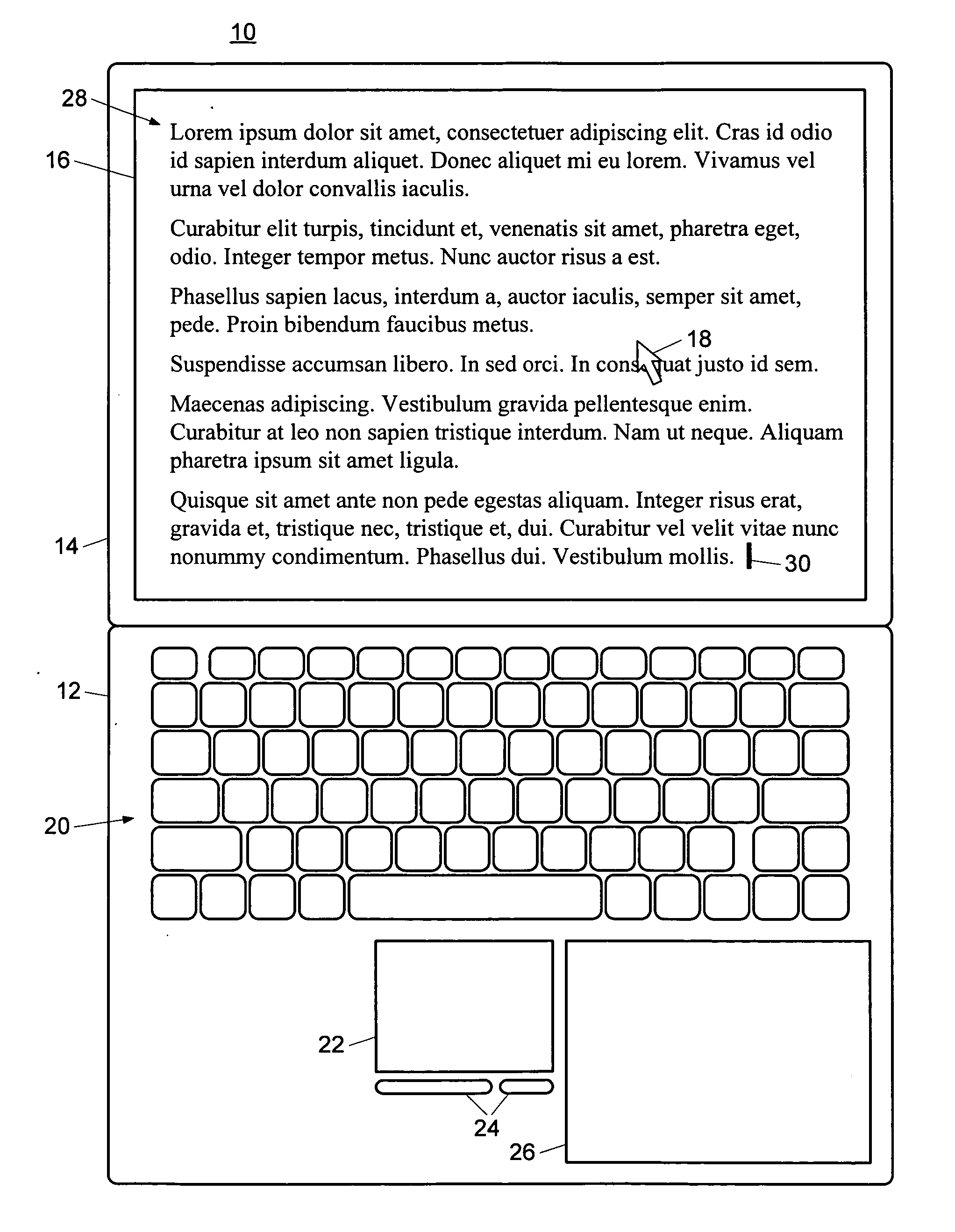

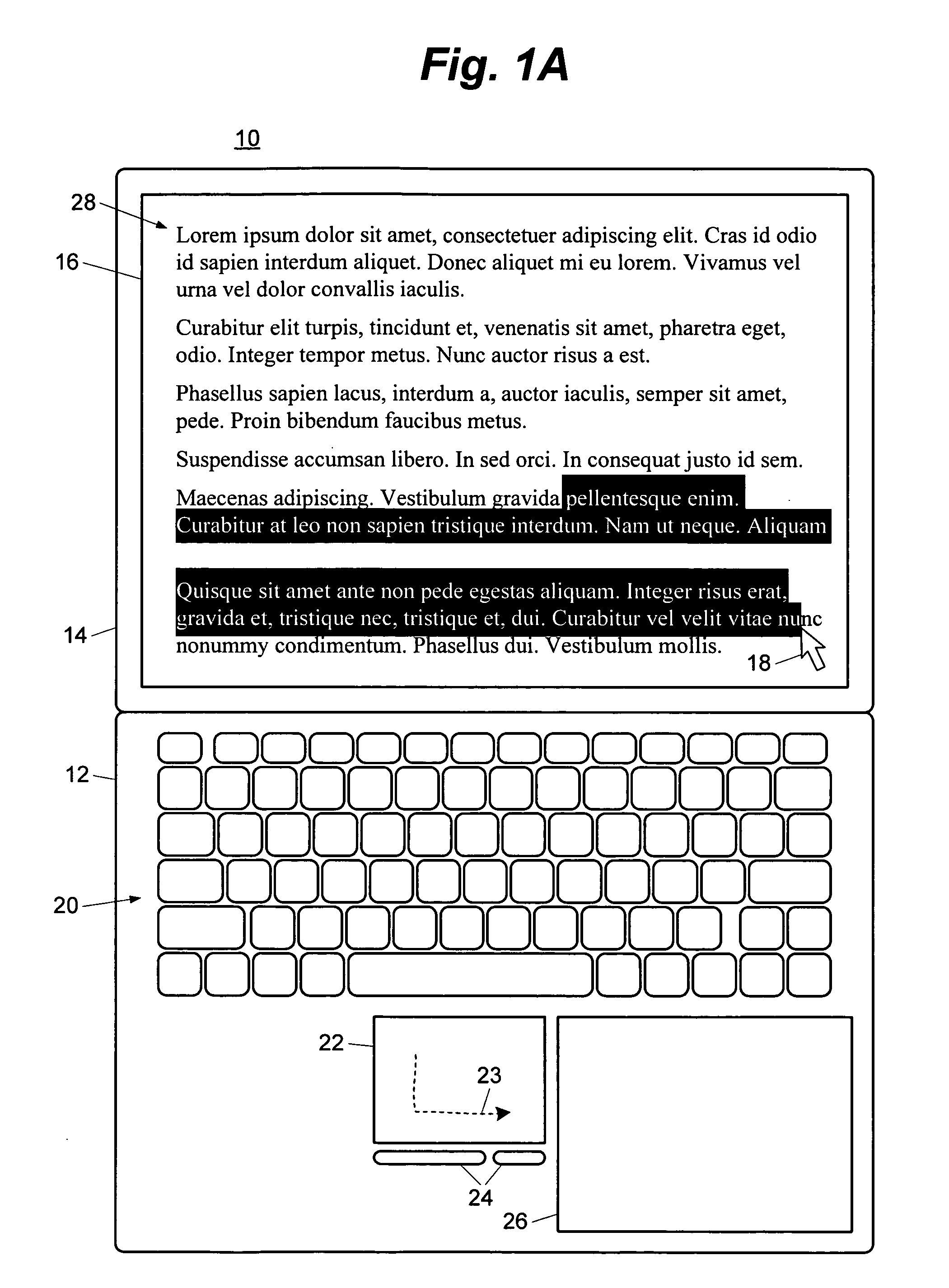

Relative Touch User Interface Enhancements

ActiveUS20120242581A1Minimize and eliminateStrong correspondenceInput/output for user-computer interactionCathode-ray tube indicatorsVertical planeTouchpad

Some embodiments provide a meta touch interface (MTI) with multiple position indicators with each position indicator operating as a separate pointing tool that can be activated (i) using taps on a touchpad or other touch sensitive surface or (ii) by pressing certain keyboard keys. The MT pointer allows for adjacent UI elements to be selected without having to reposition the MT pointer for each selection or activation. Some embodiments provide a multi-device UI that comprises at least two UIs, wherein the first UI is presented on an essentially horizontal plane that is aligned with operational focus and the second UI that is presented on an essentially vertical plane that is aligned with visual focus of the user. Some embodiments provide a precision pointer that includes an adjustable magnified region to better present underlying on-screen content, thereby allowing the user to more precisely position the pointer.

Owner:INTELLITACT

Portable computer and method for taking notes with sketches and typed text

InactiveUS20060071915A1Easy to switchWithout riskCathode-ray tube indicatorsNatural language data processingDisplay deviceTouchpad

A notebook computer that has a keyboard, a navigation input device (e.g., a touchpad or mouse) and a sketch input device (usually an integrated sketch pad and stylus). The sketch input device operates in an absolute coordinate mapping mode and can be tracked on the display when hovering or touching. It draws digital ink when touching. Whenever the digital ink runs into existing text notes the text is reflowed around the sketch. A movement on an input device can either select text or draw digital ink depending on which input device was used. The computer can have sketch tool buttons operable with a stylus. The navigation and sketch input devices can be disjoint or overlapping. Variations of the sketch input device include a second touch pad that works with a finger and a stylus that works without a sketch pad.

Owner:REHM PETER H

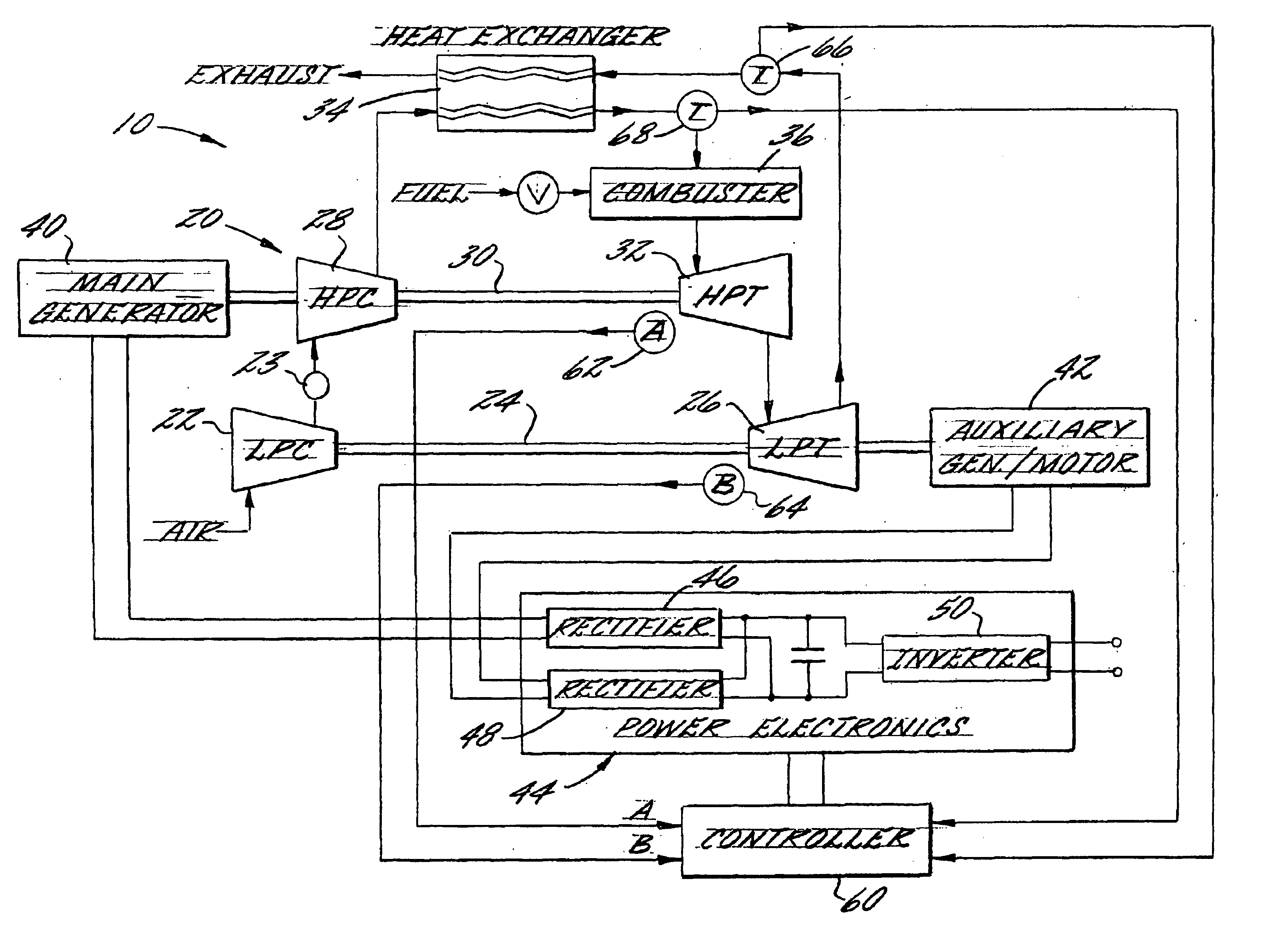

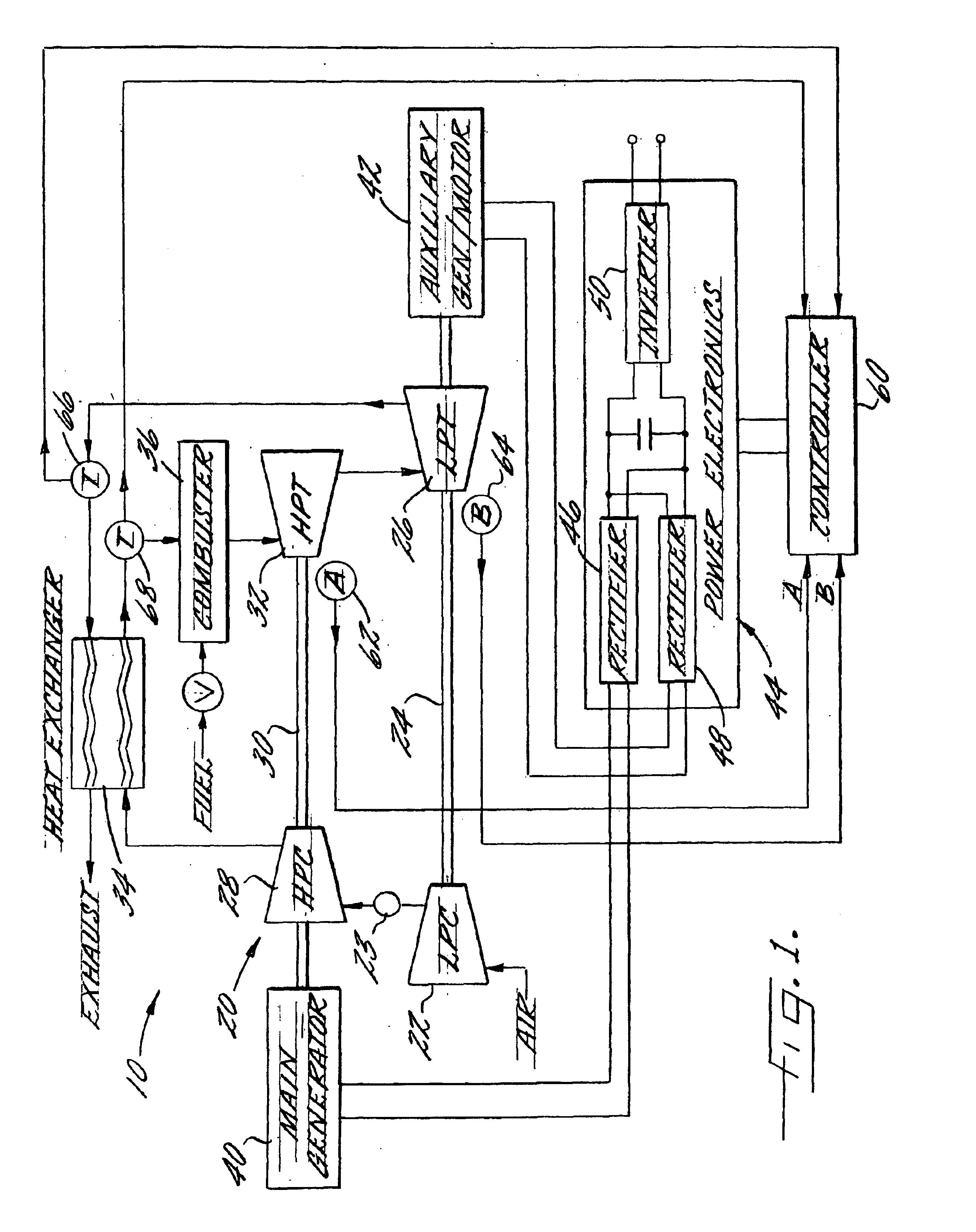

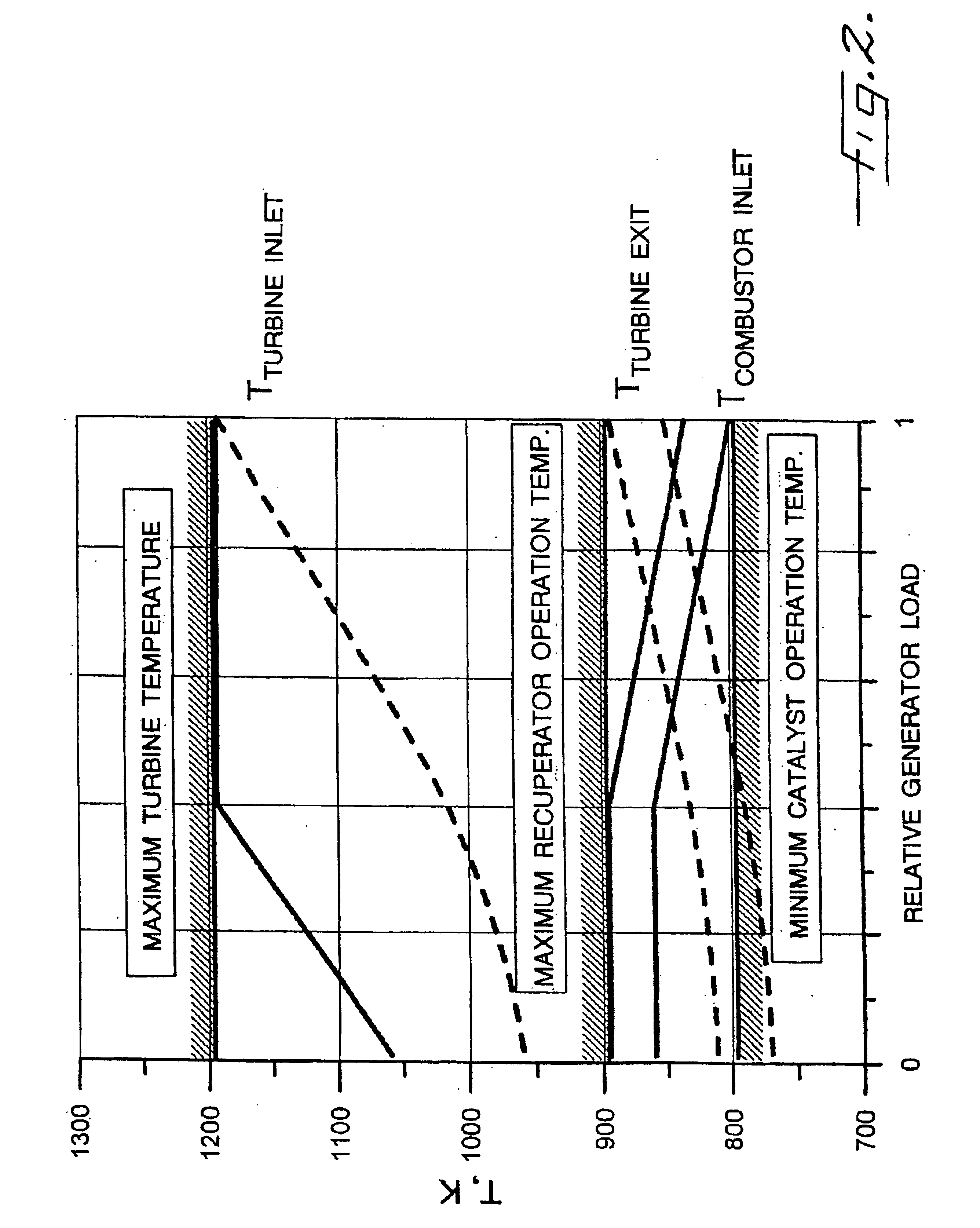

Multi-spool turbogenerator system and control method

InactiveUS6931856B2Eliminate needMinimize and eliminate needTurbine/propulsion engine ignitionTurbine/propulsion engine startersEngineeringTurbine

An electrical power generating system is driven by a multi-spool gas turbine engine including at least first and second spools. The first spool comprises a turbine and a compressor mounted on a first shaft; the second spool has at least a turbine mounted on a second shaft that is not mechanically coupled to the first shaft. A main generator is coupled with one of the spools, and an auxiliary generator / motor is also coupled with one of the spools. Speed control of each of the generators is employed for controlling operation of the engine. The auxiliary generator / motor can operate in either a generation mode to extract power from its spool or a motor mode to inject power into its spool.

Owner:MES INT INC

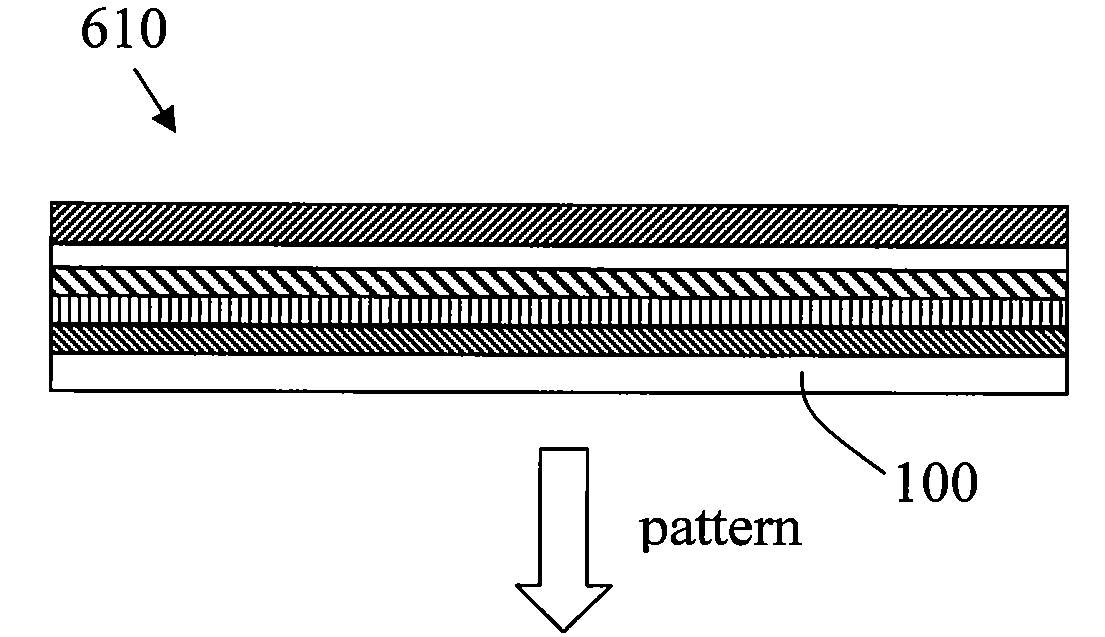

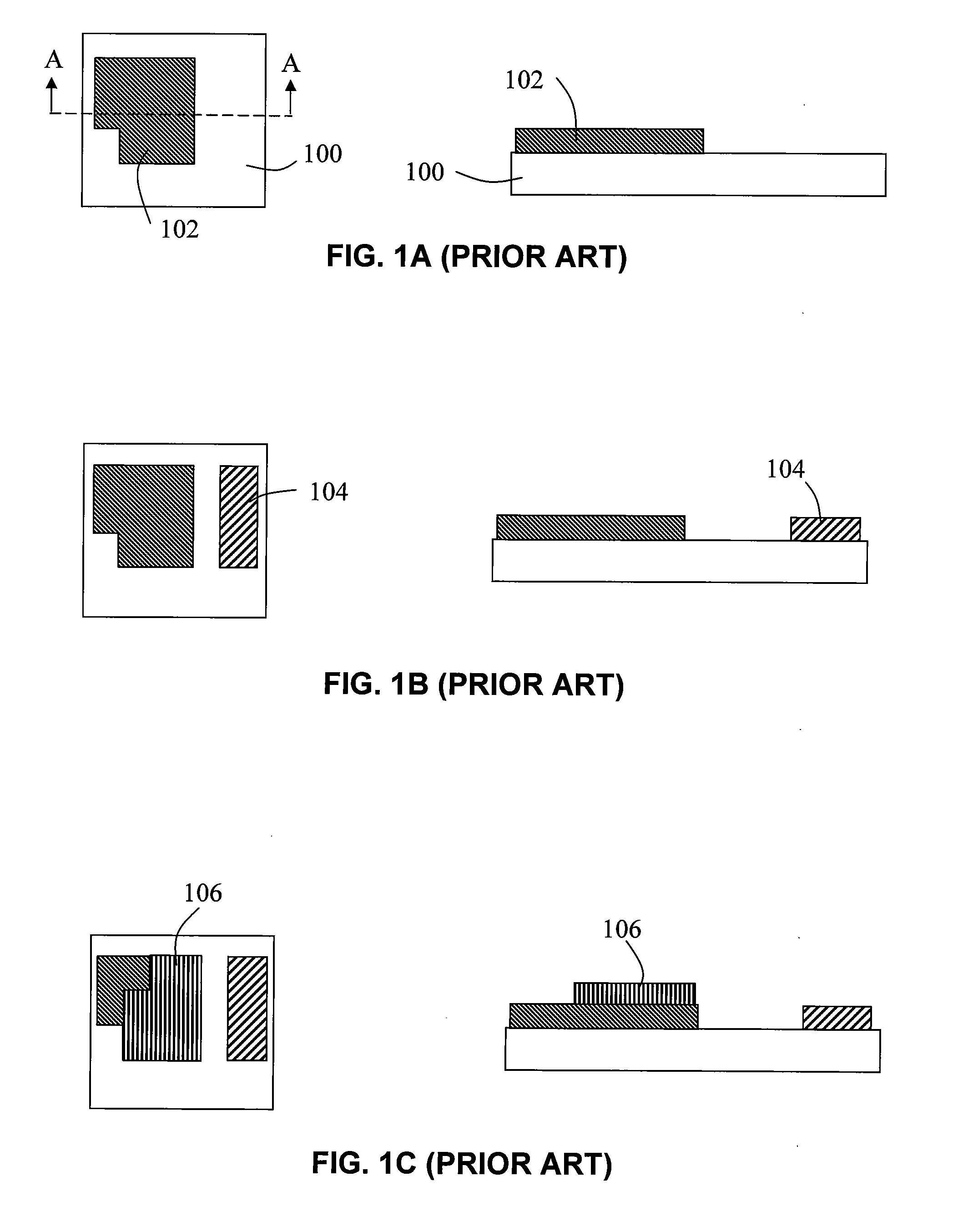

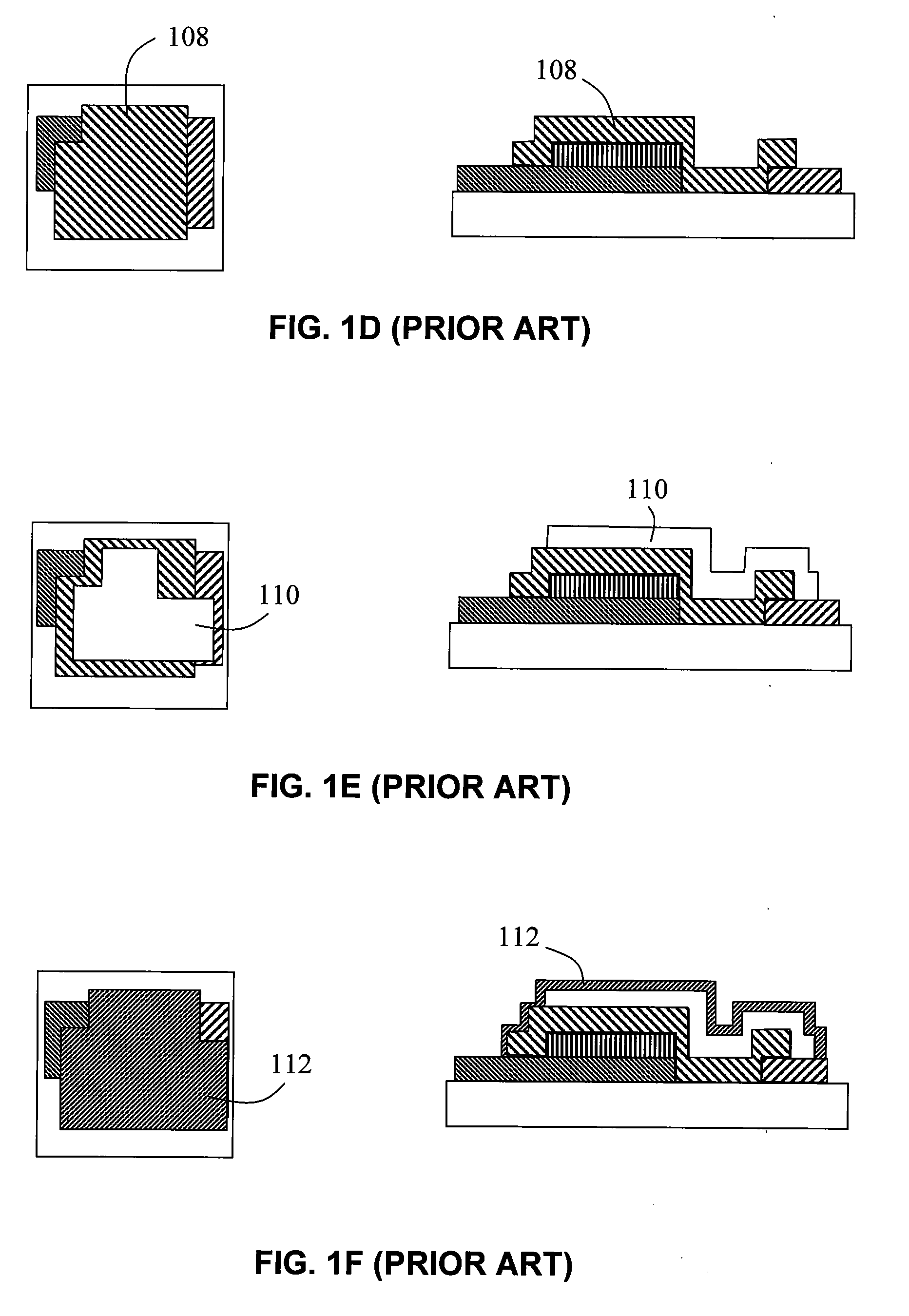

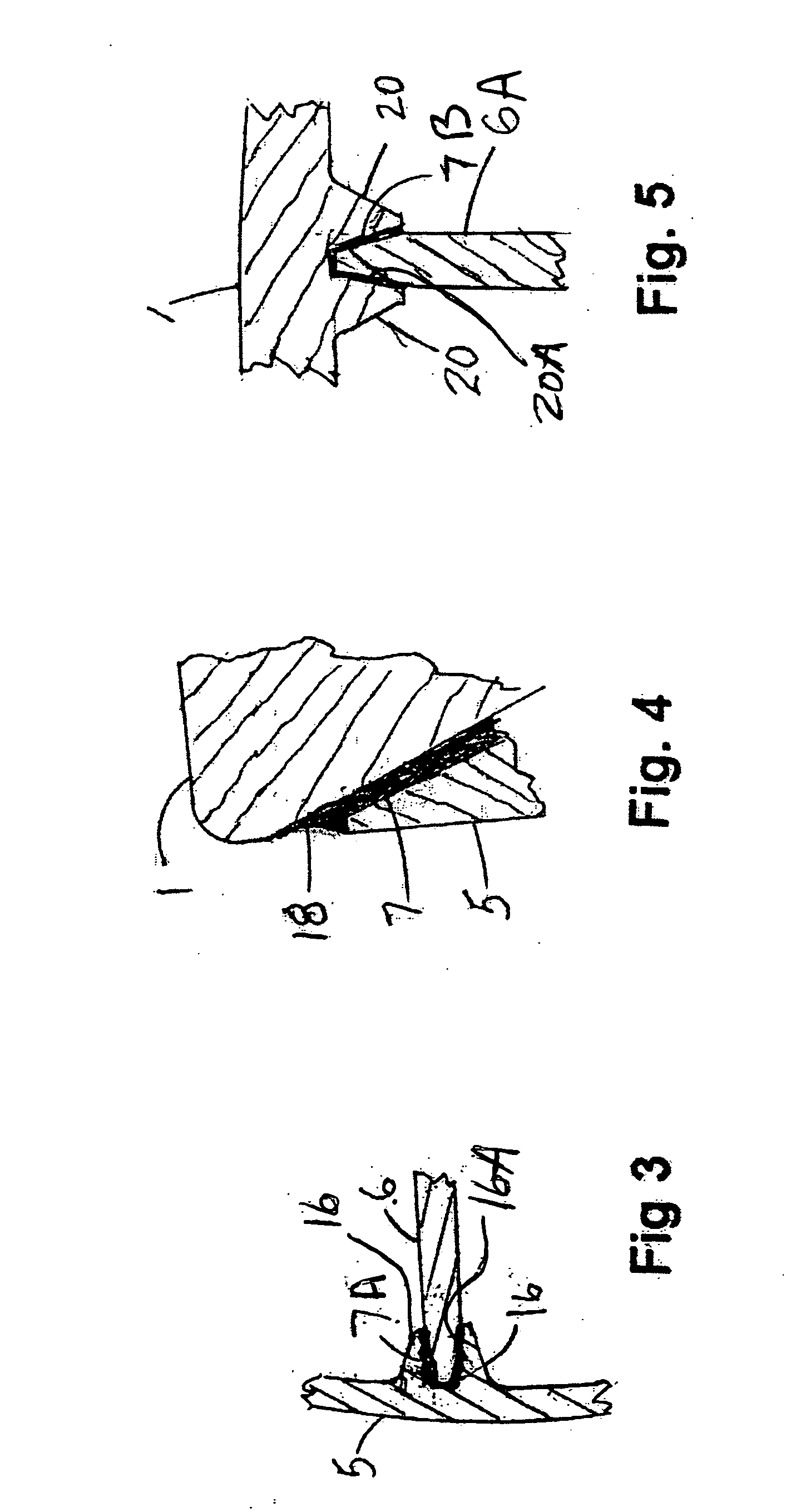

Method for high volume manufacturing of thin film batteries

ActiveUS20090148764A1Improve manufacturabilityLow costFinal product manufacturePrinted batteriesHigh volume manufacturingEngineering

Concepts and methods are provided to reduce the cost and complexity of thin film battery (TFB) high volume manufacturing by eliminating and / or minimizing the use of conventional physical (shadow) masks. Laser scribing and other alternative physical maskless patterning techniques meet certain or all of the patterning requirements. In one embodiment, a method of manufacturing thin film batteries comprises providing a substrate, depositing layers corresponding to a thin film battery structure on the substrate, the layers including, in order of deposition, a cathode, an electrolyte and an anode, wherein at least one of the deposited layers is unpatterned by a physical mask during deposition, depositing a protective coating, and scribing the layers and the protective coating. Further, the edges of the layers may be covered by an encapsulation layer. Furthermore, the layers may be deposited on two substrates and then laminated to form the thin film battery.

Owner:APPLIED MATERIALS INC +1

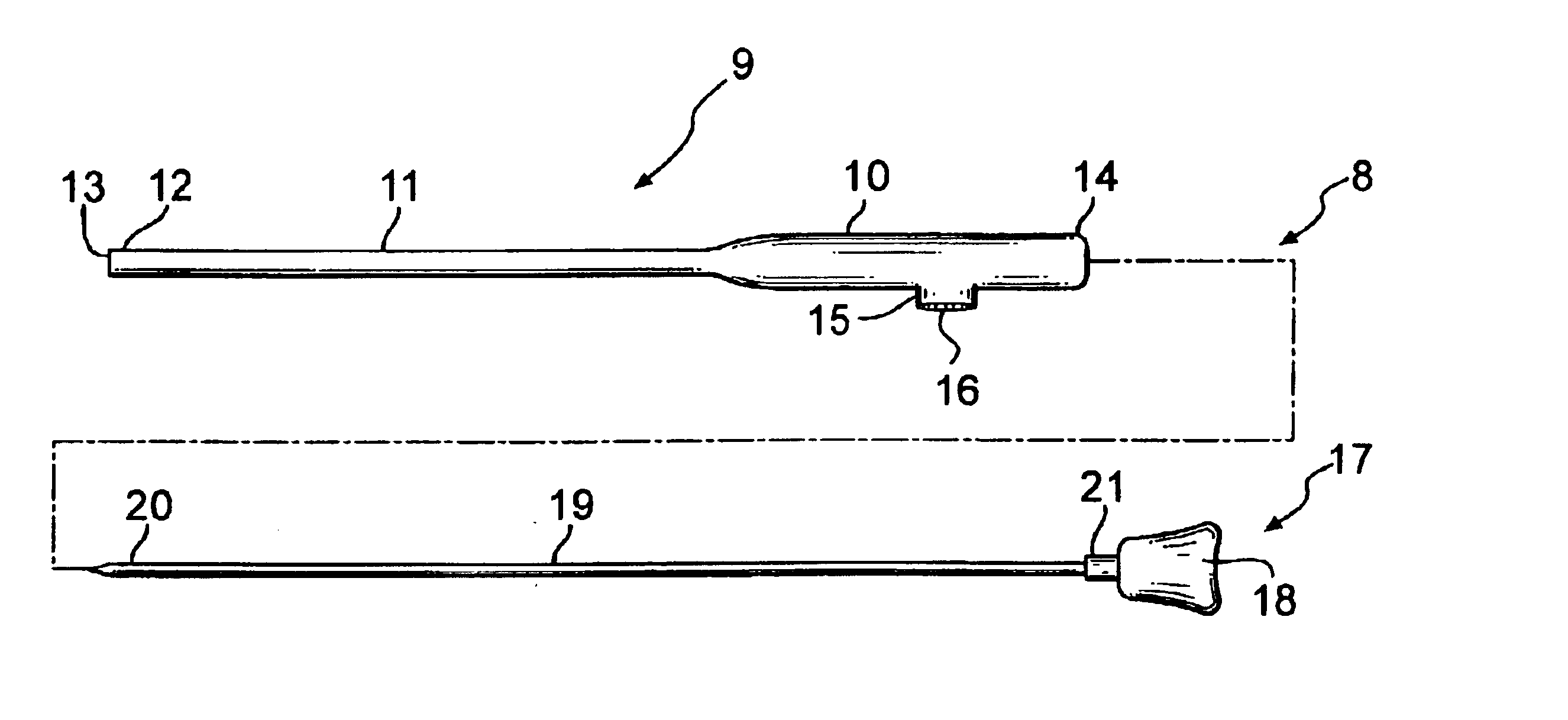

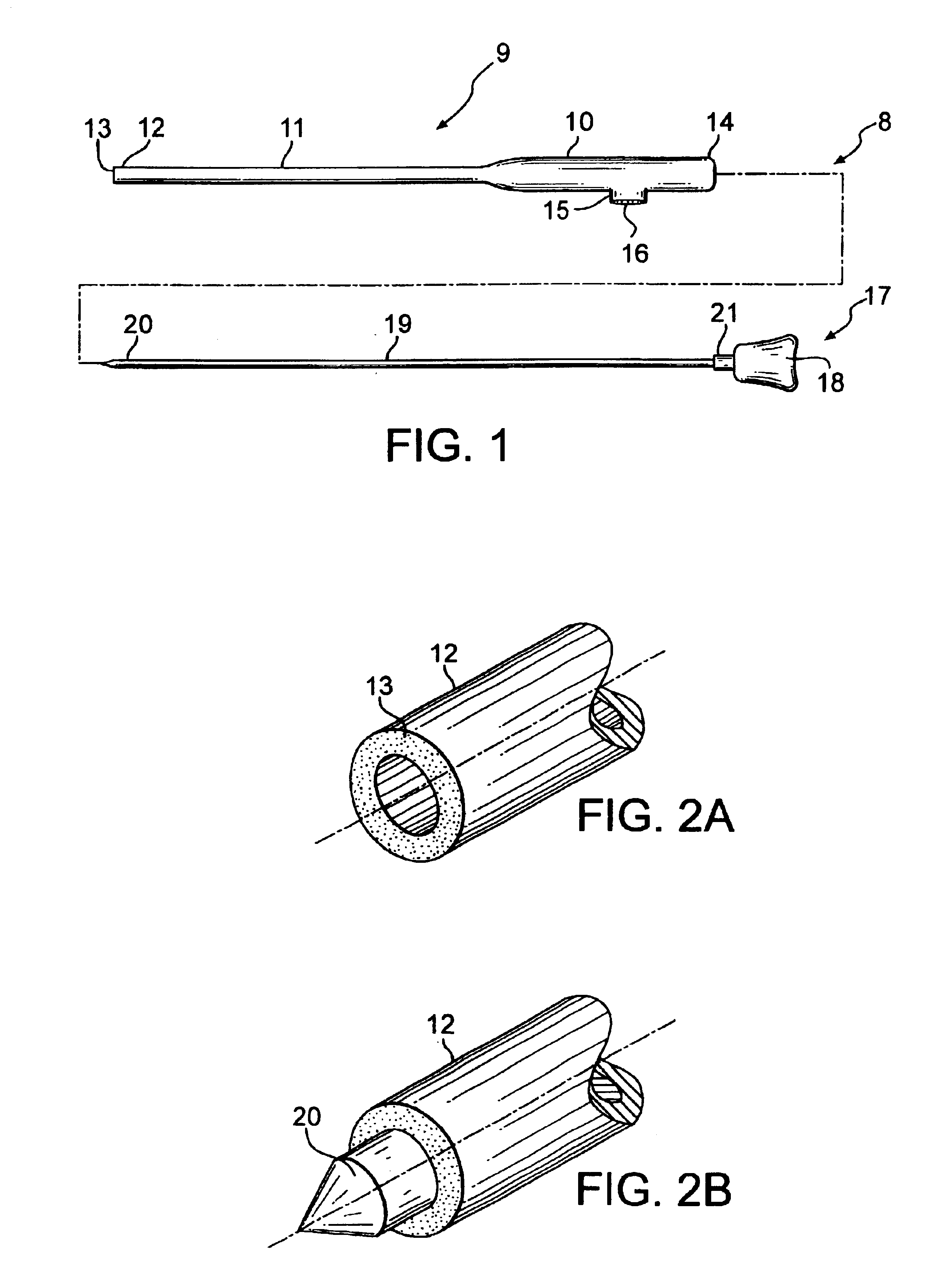

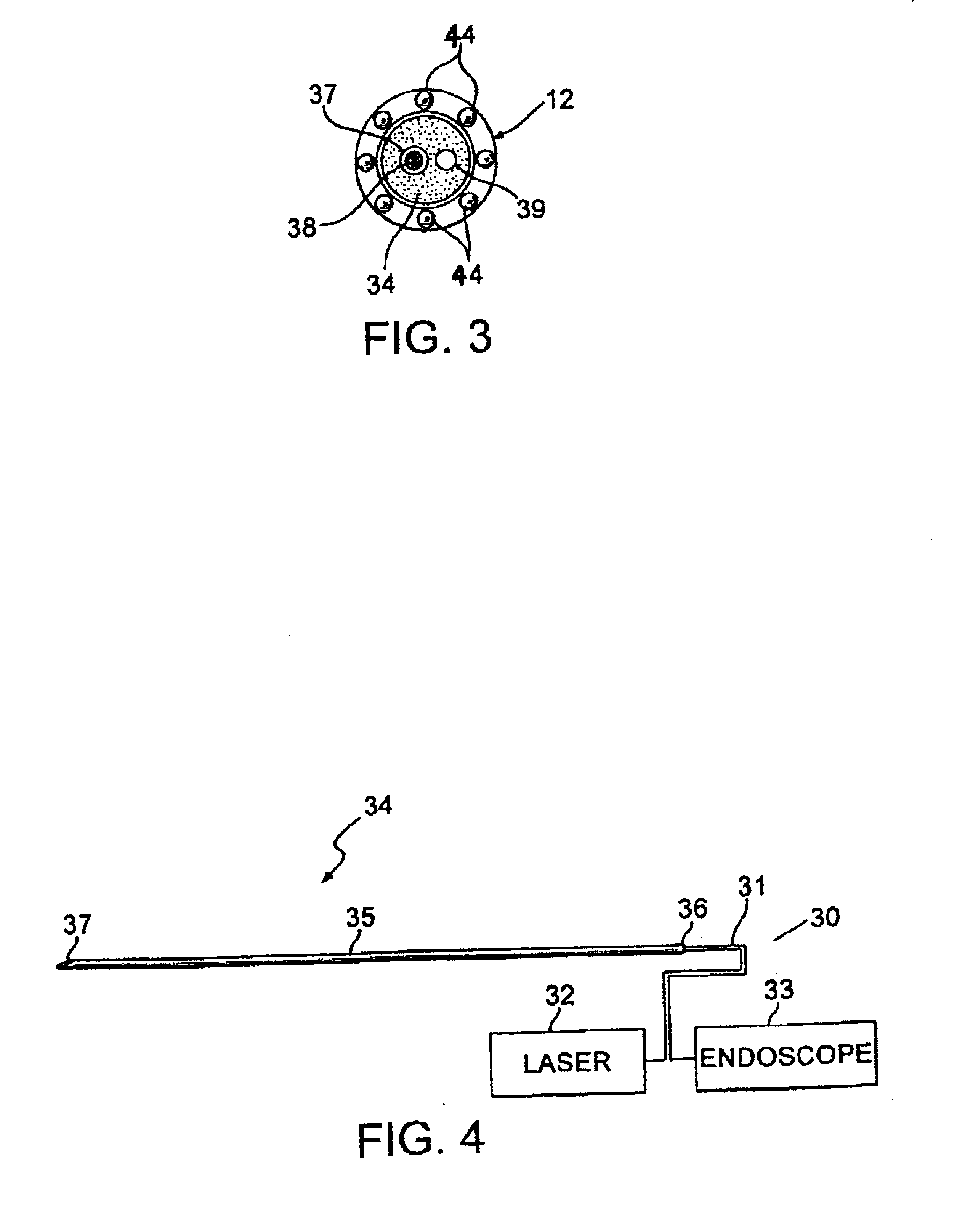

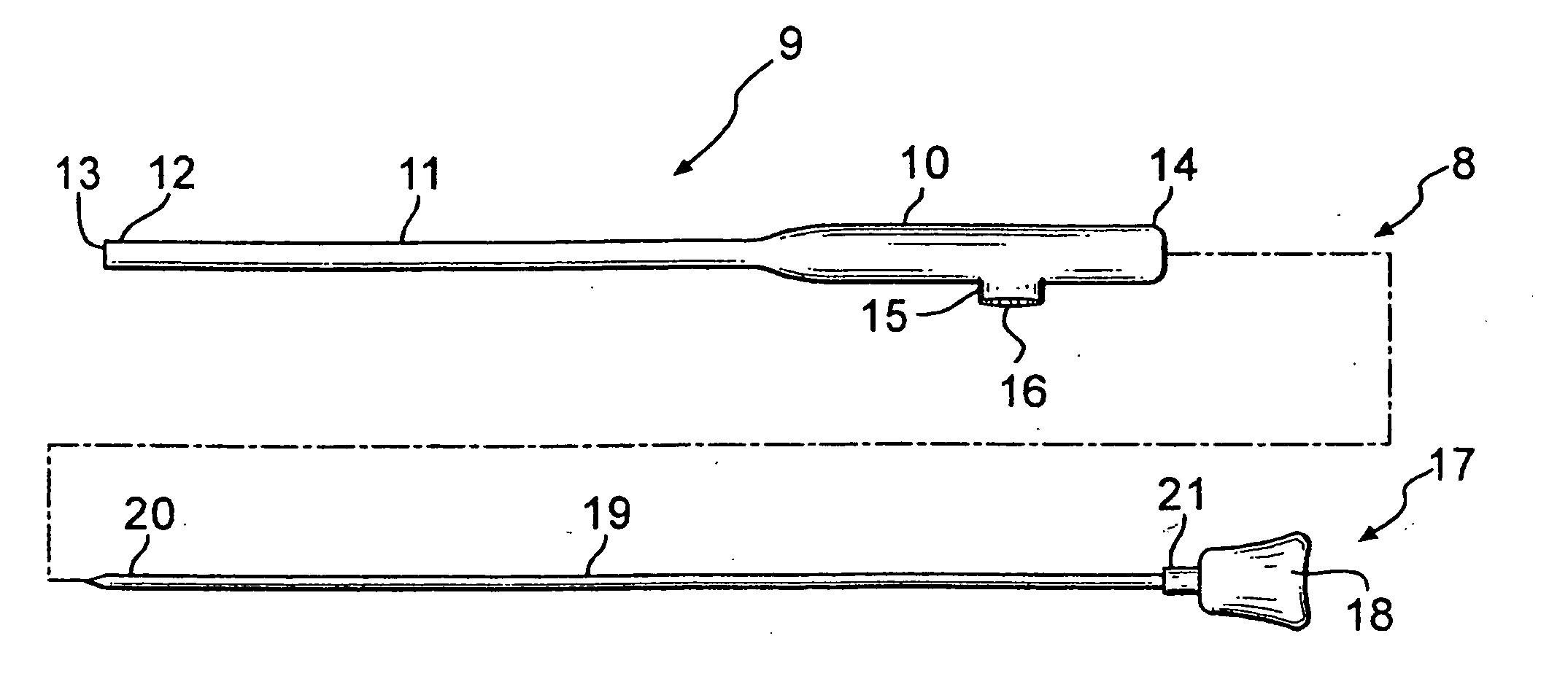

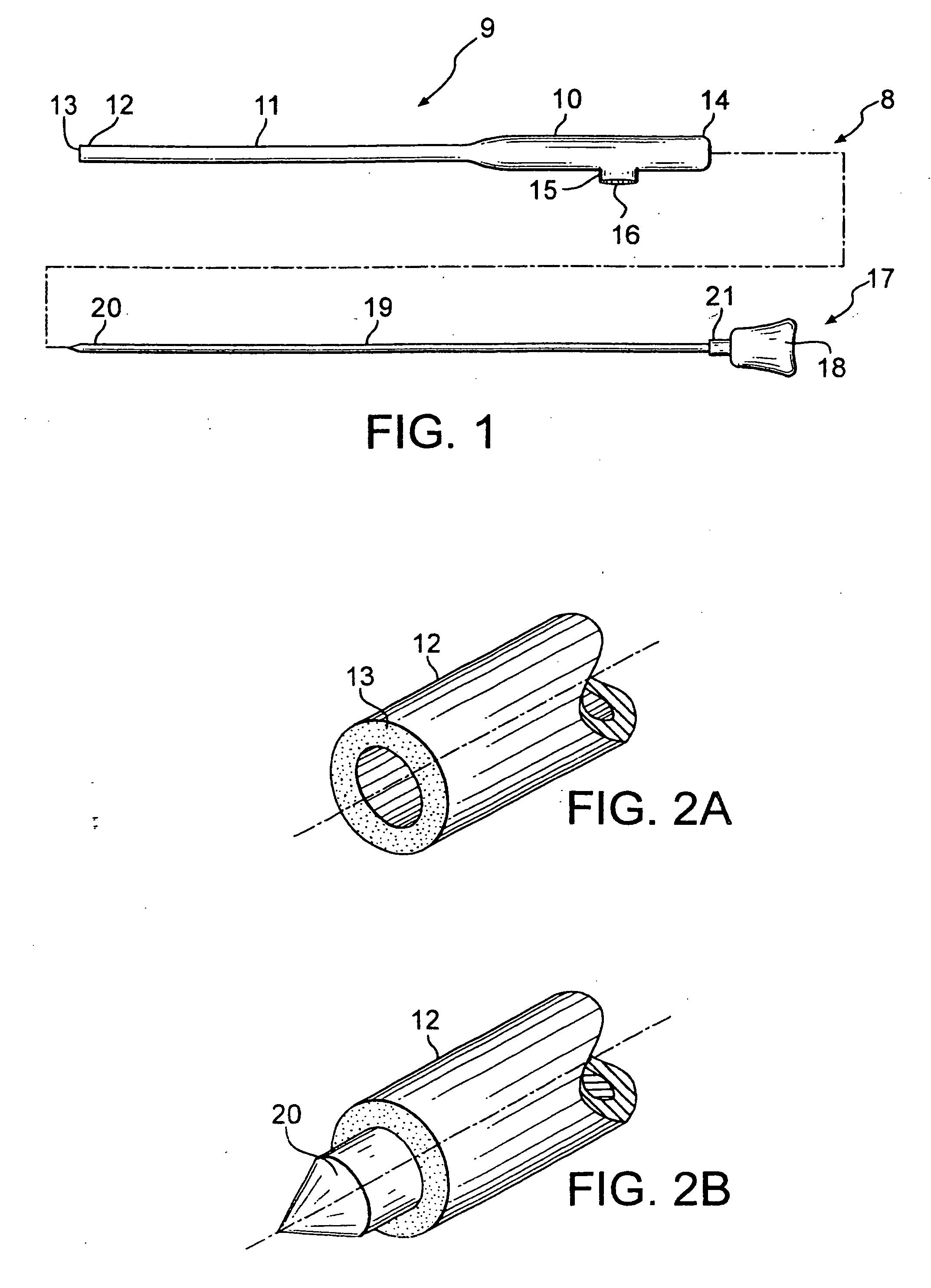

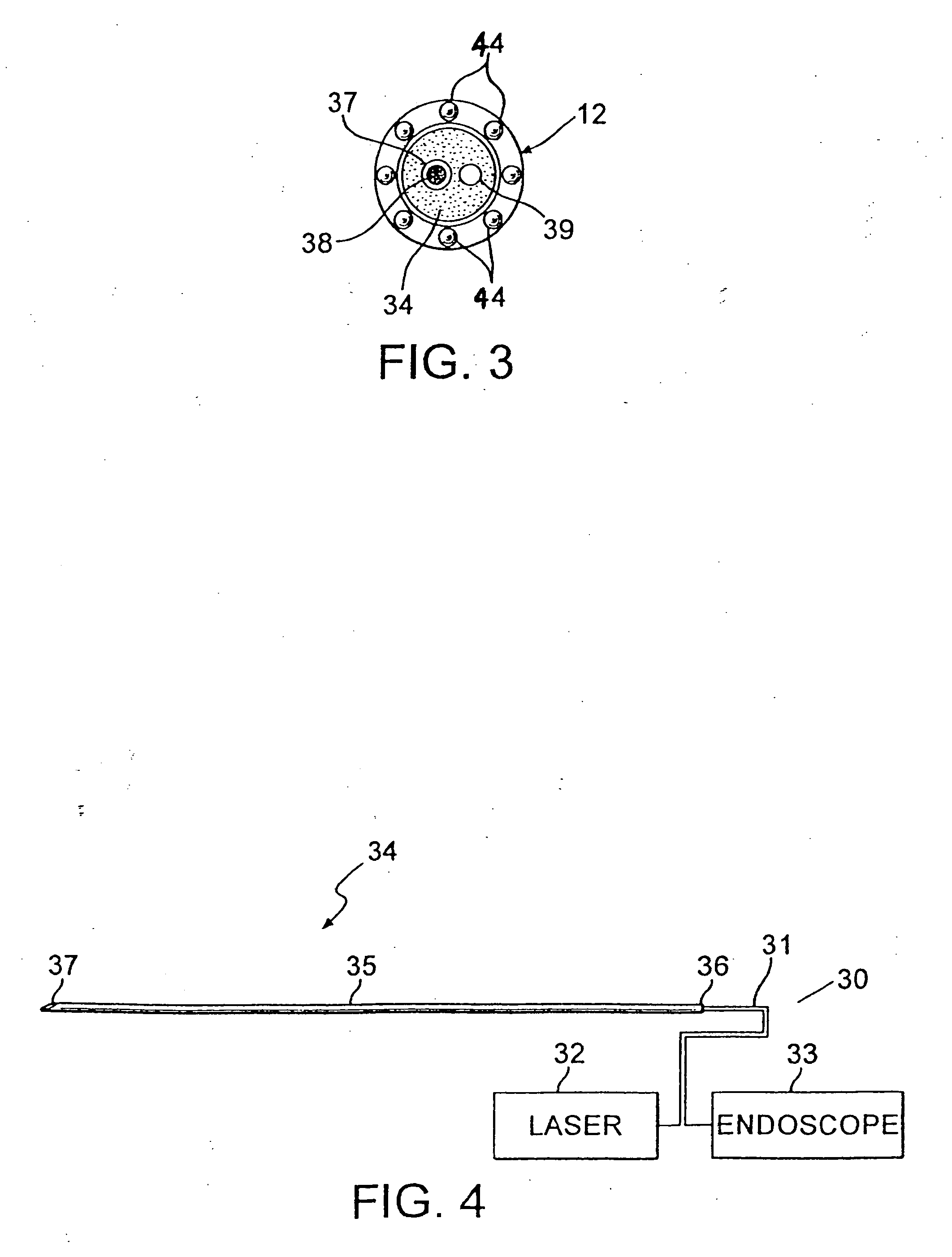

Visualizing ablation device and procedure

InactiveUS6902526B2Eliminates and minimizesPrevent slippingElectrotherapyEar treatmentSacroiliac jointAbdominal trocar

A medical needle set for visualized tissue ablation within a subject's body includes a cannula and components configured for inclusion in the cannula, including a trocar for occlusion of the cannula lumen during needle placement, and a visualizing ablation probe used for simultaneous endoscopic viewing and ablation of tissue sites with a laser beam. The cannula can include a tissue-gripping surface for stabilization of the needle set on the target tissue. A surgical system for tissue ablation includes a visualizing ablation needle set operably connected to an endoscope and a laser. A surgical procedure using this system permits simultaneous visualization and ablation of tissues, including those of the facet joints of the spine.

Owner:ARDENT MEDICAL CORP

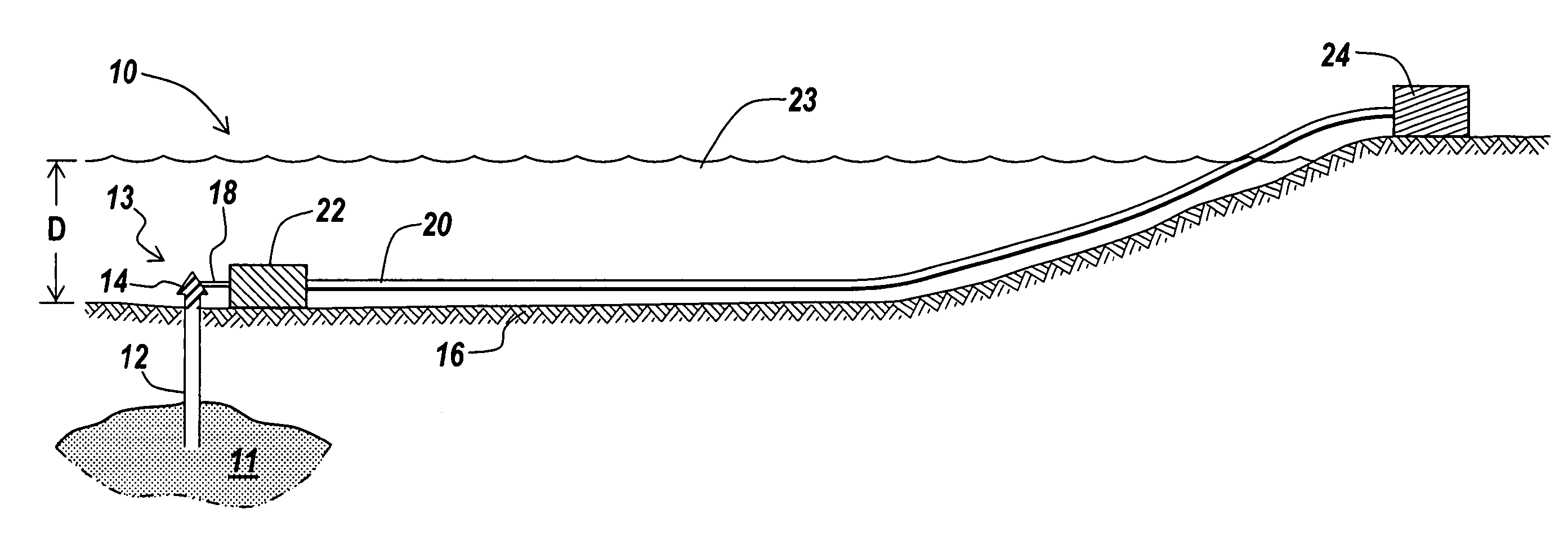

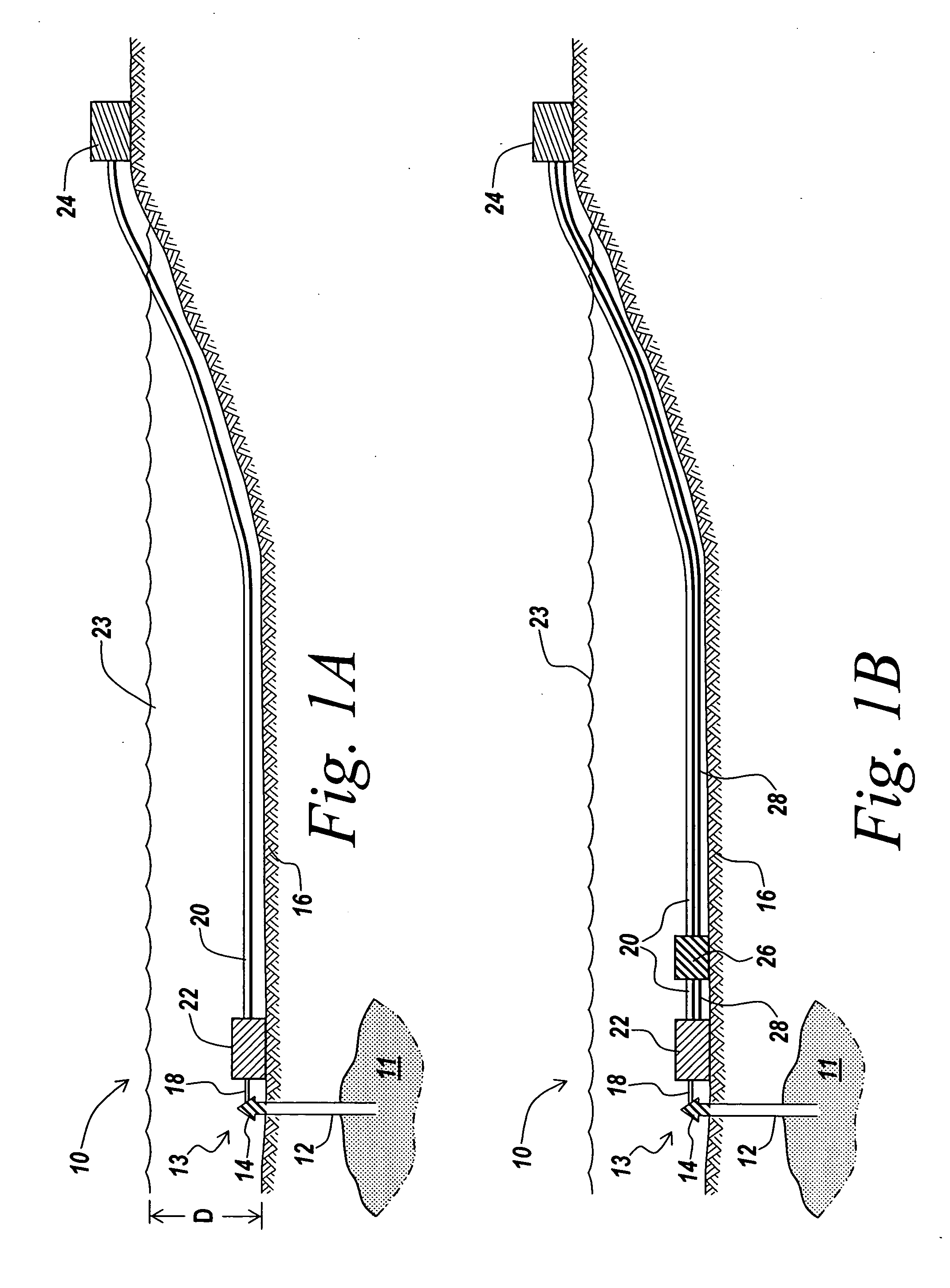

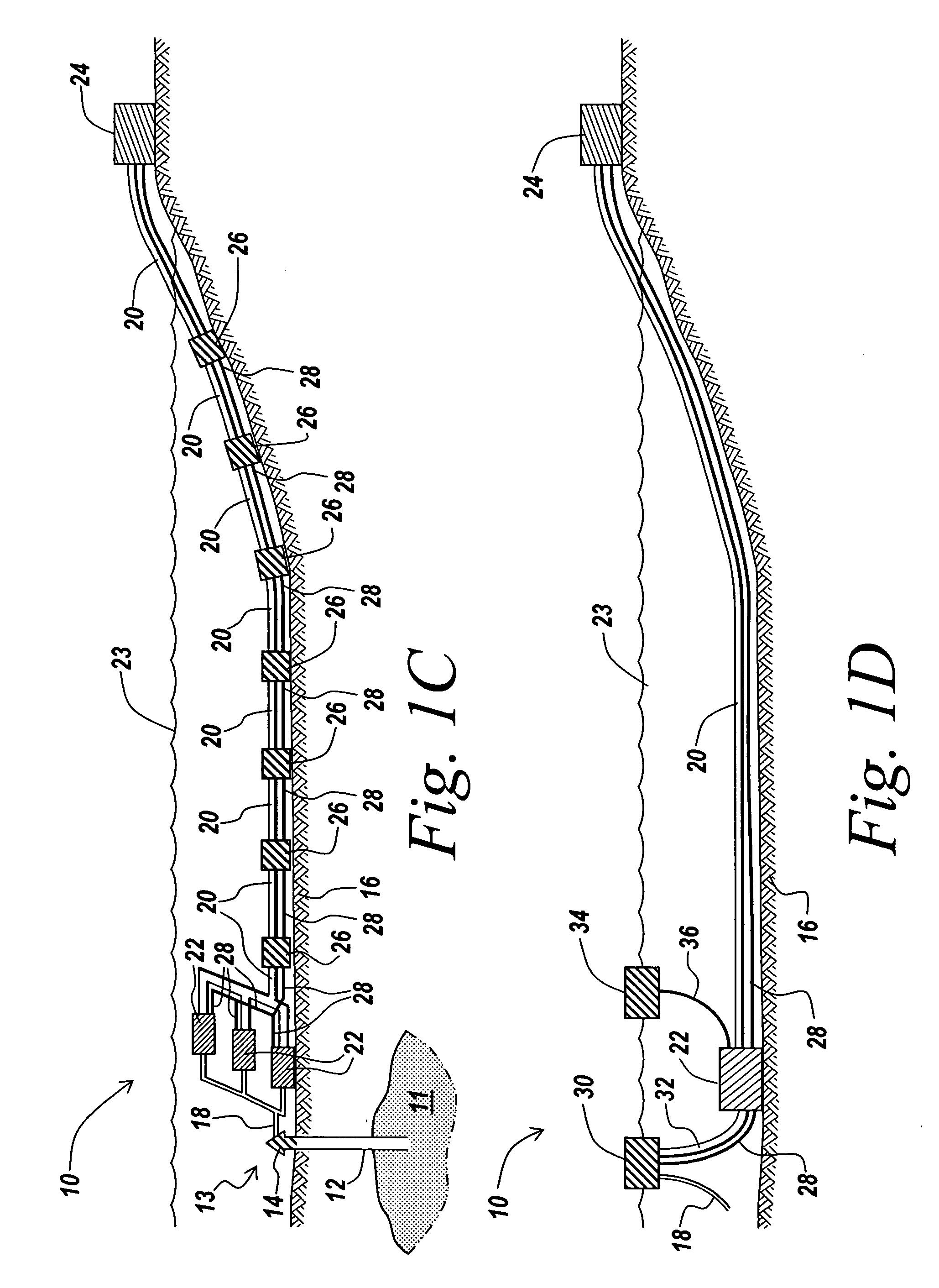

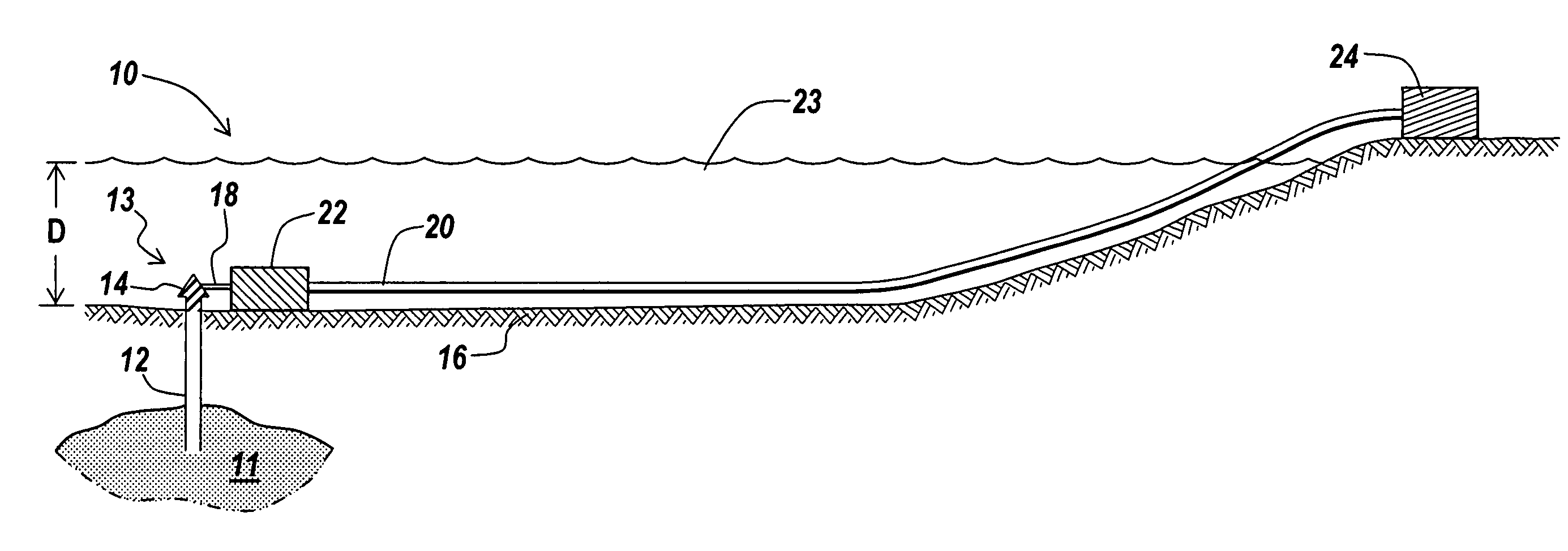

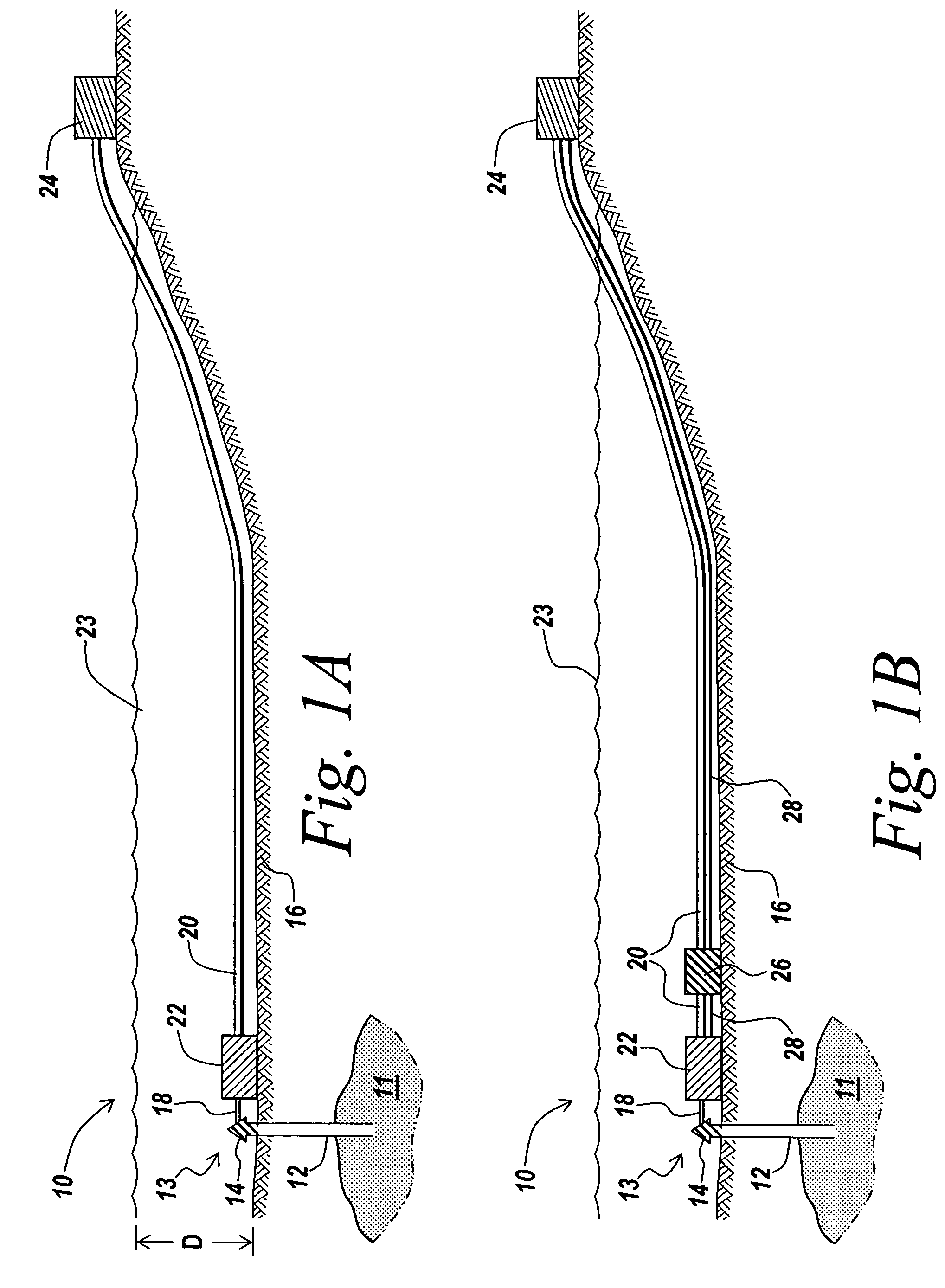

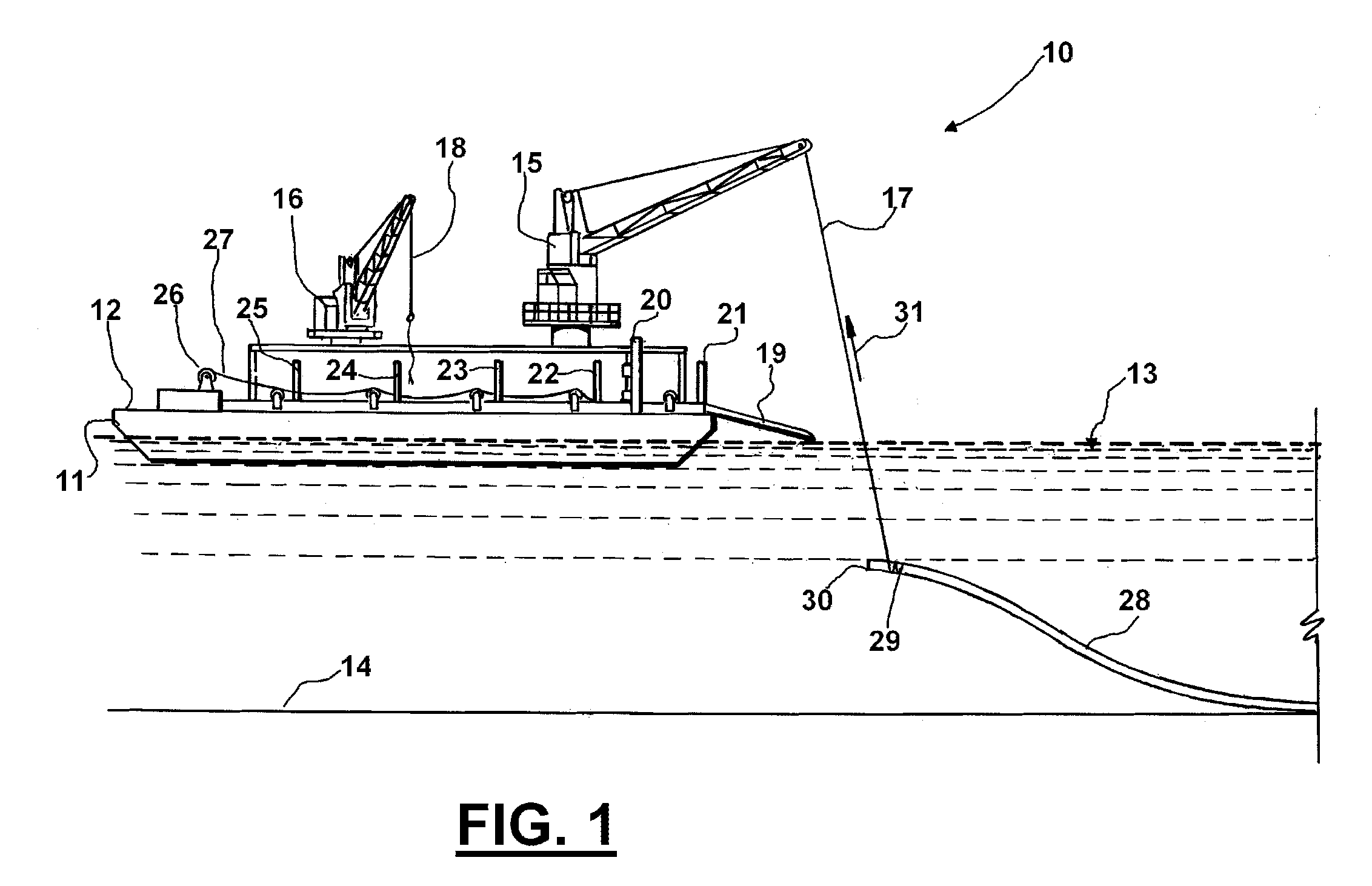

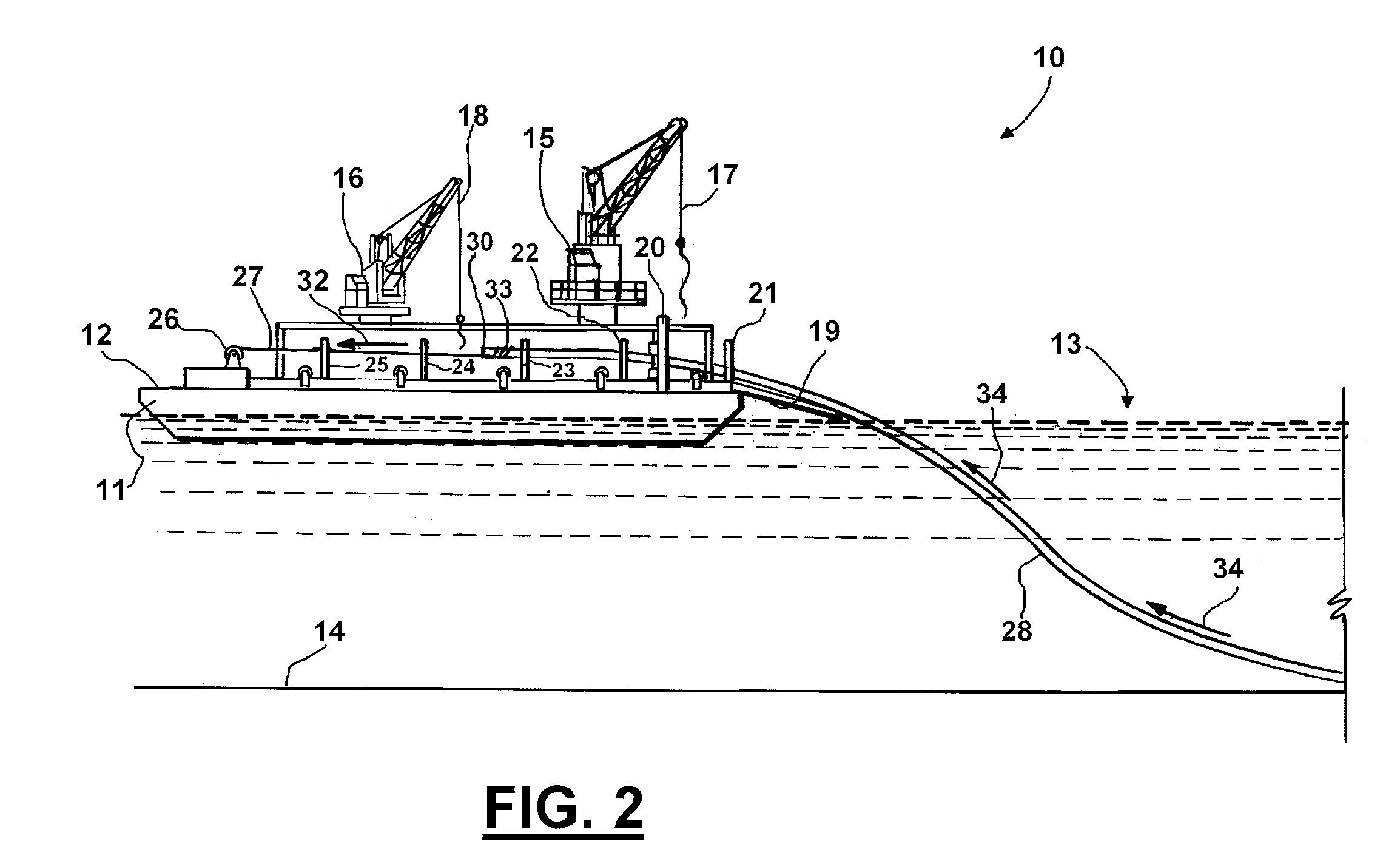

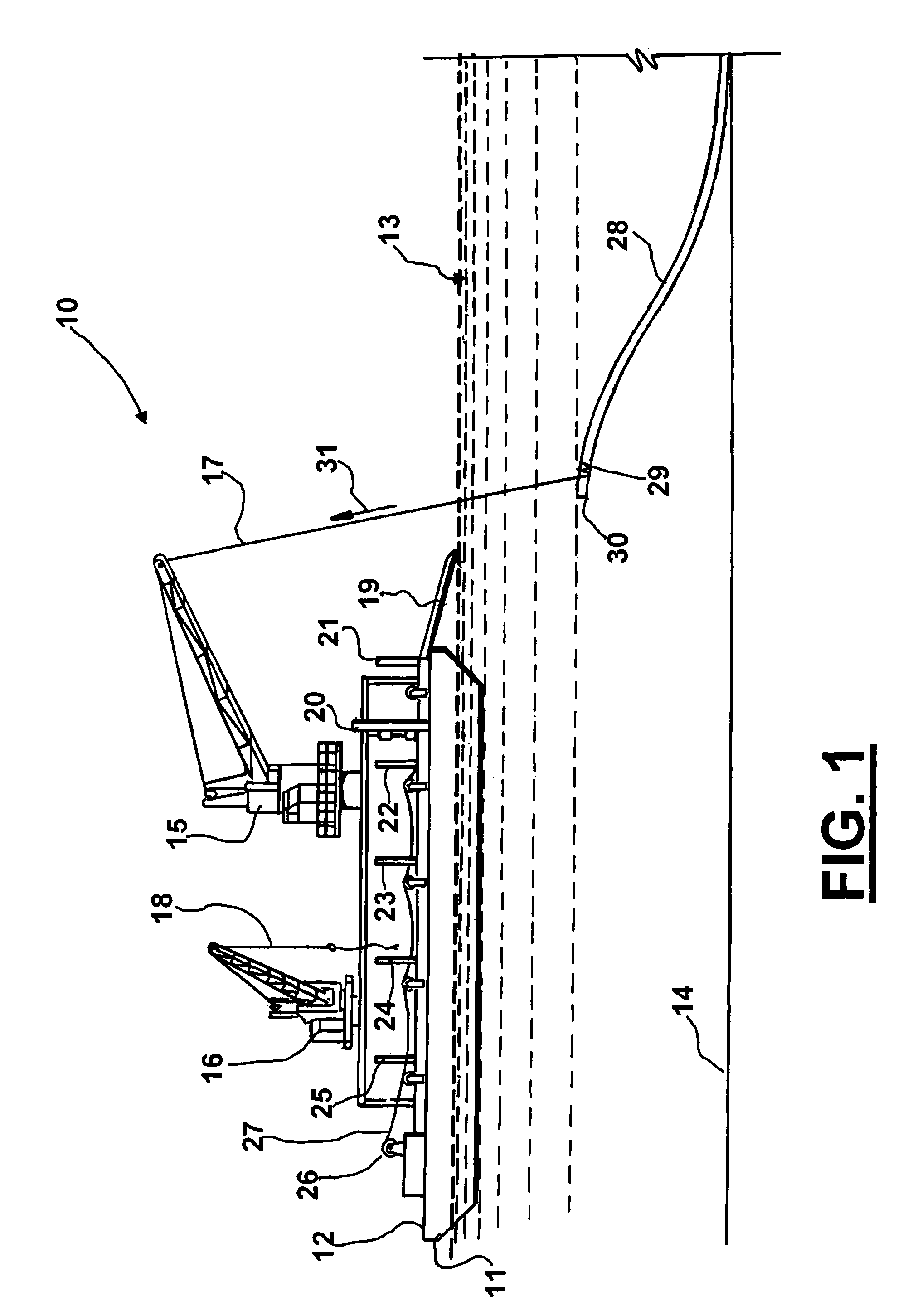

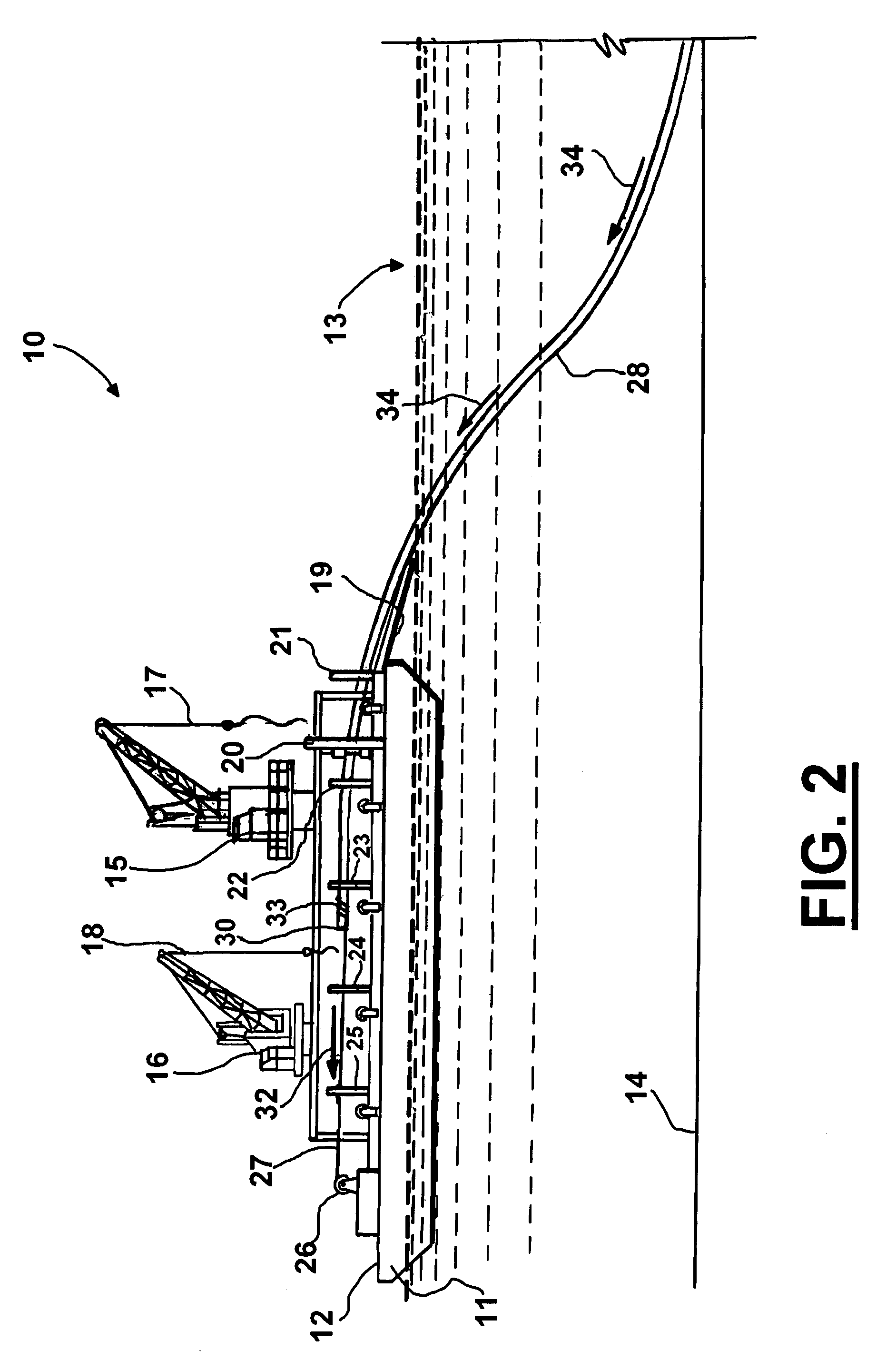

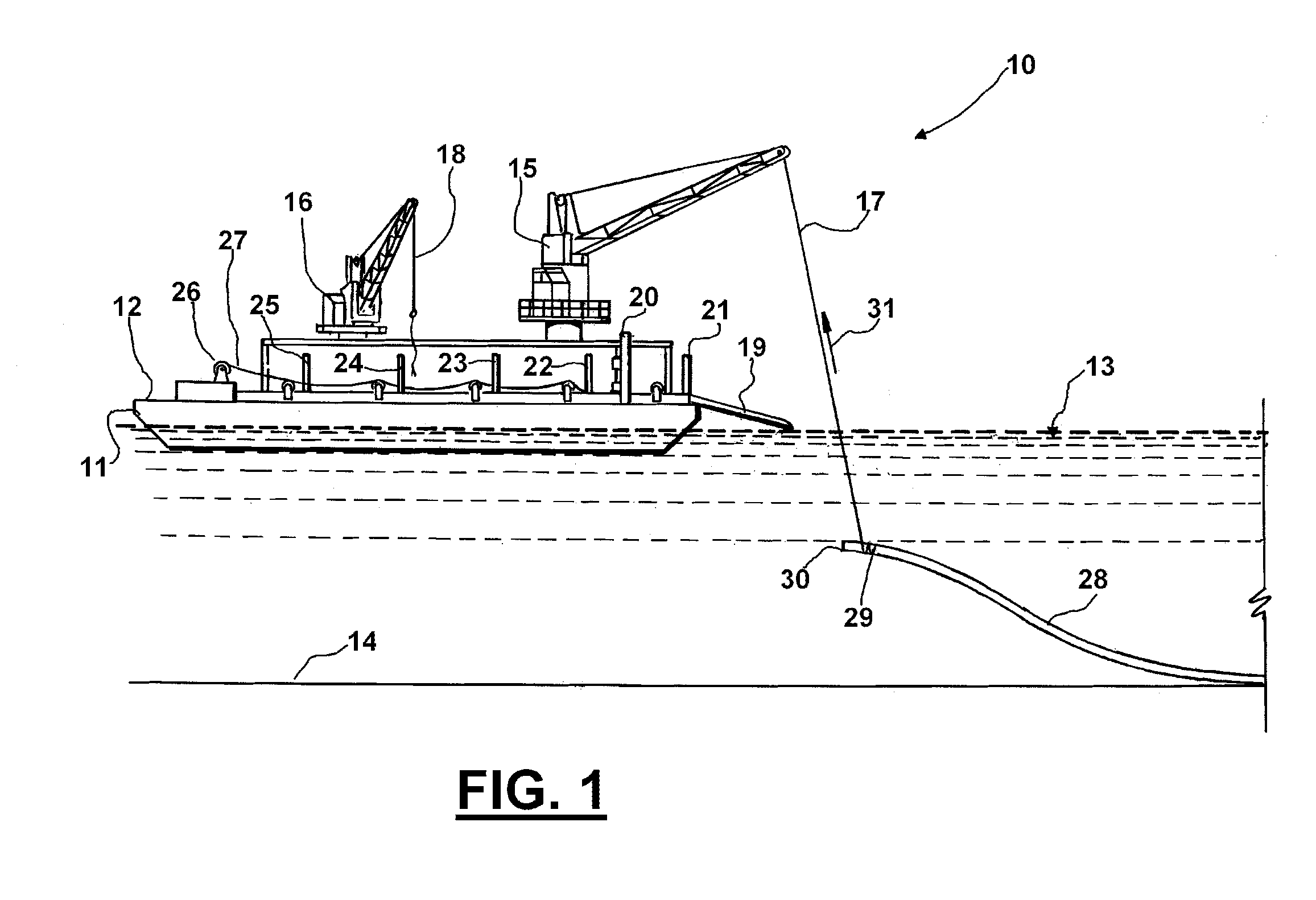

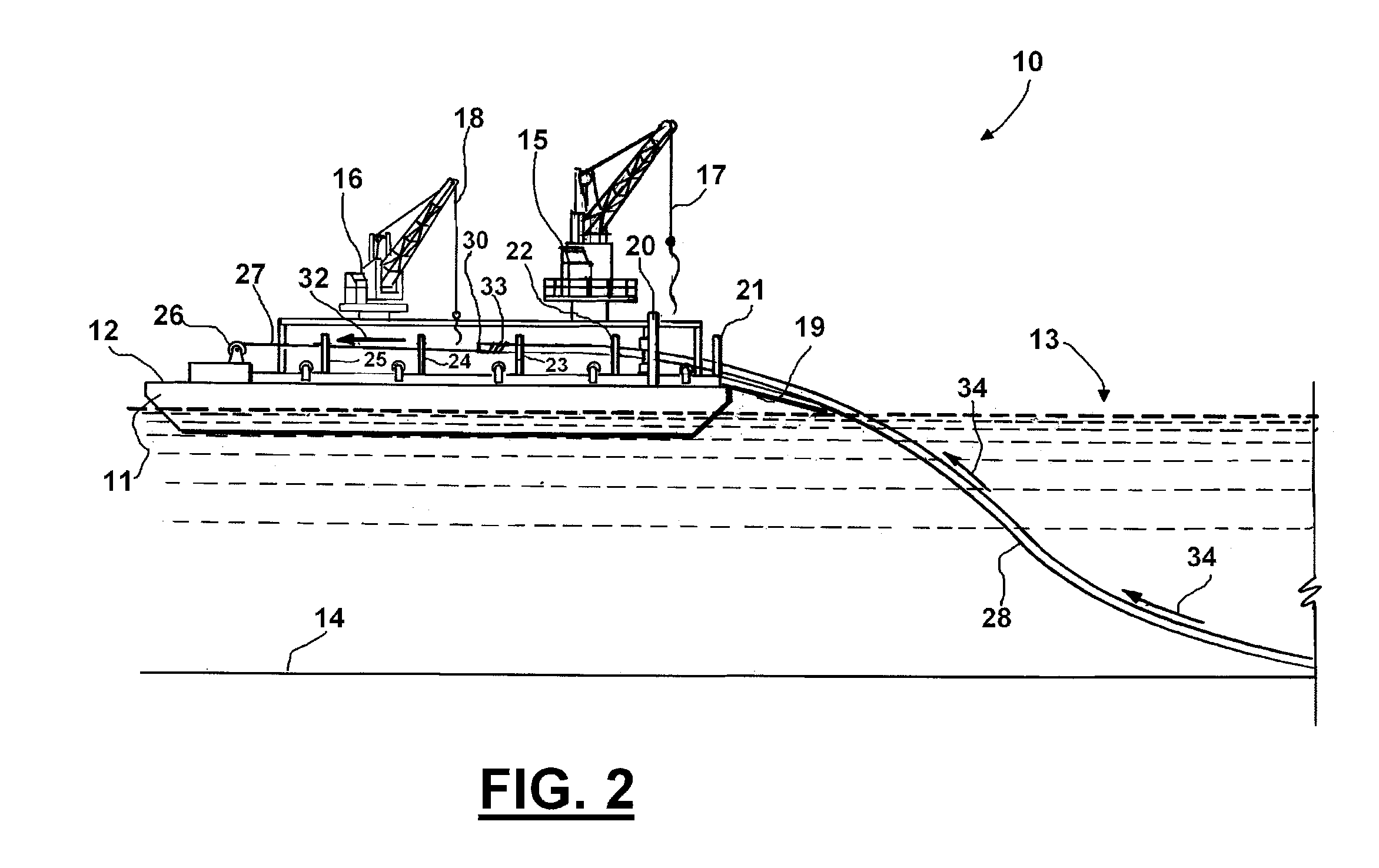

Undersea well product transport

InactiveUS20060175062A1Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationHydrocotyle bowlesioidesShore

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

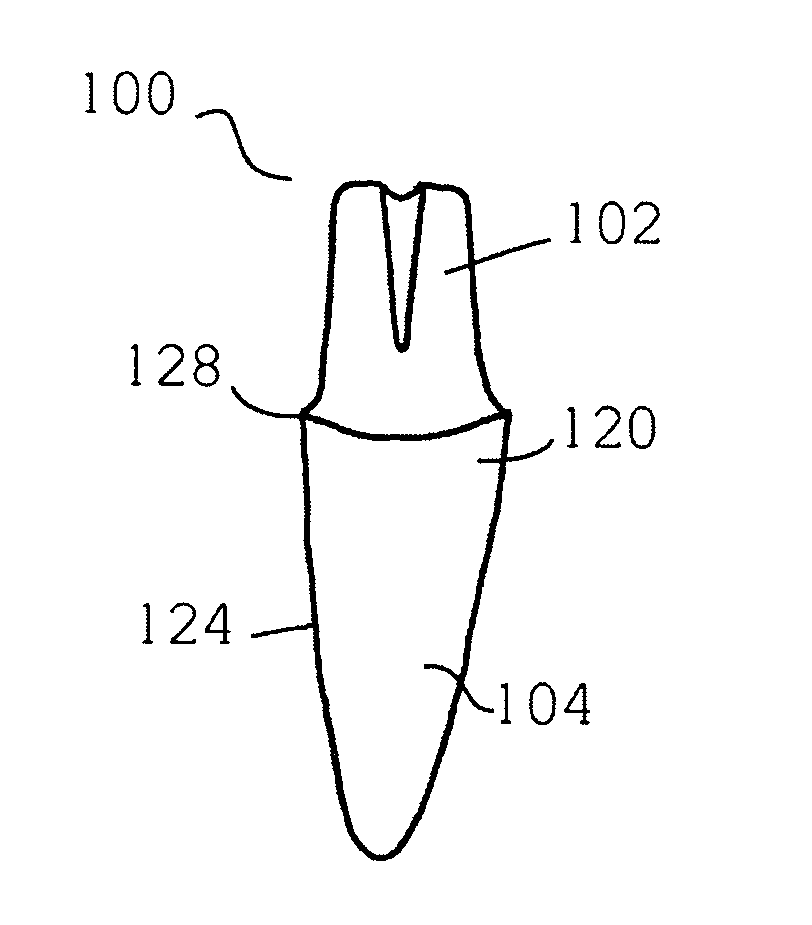

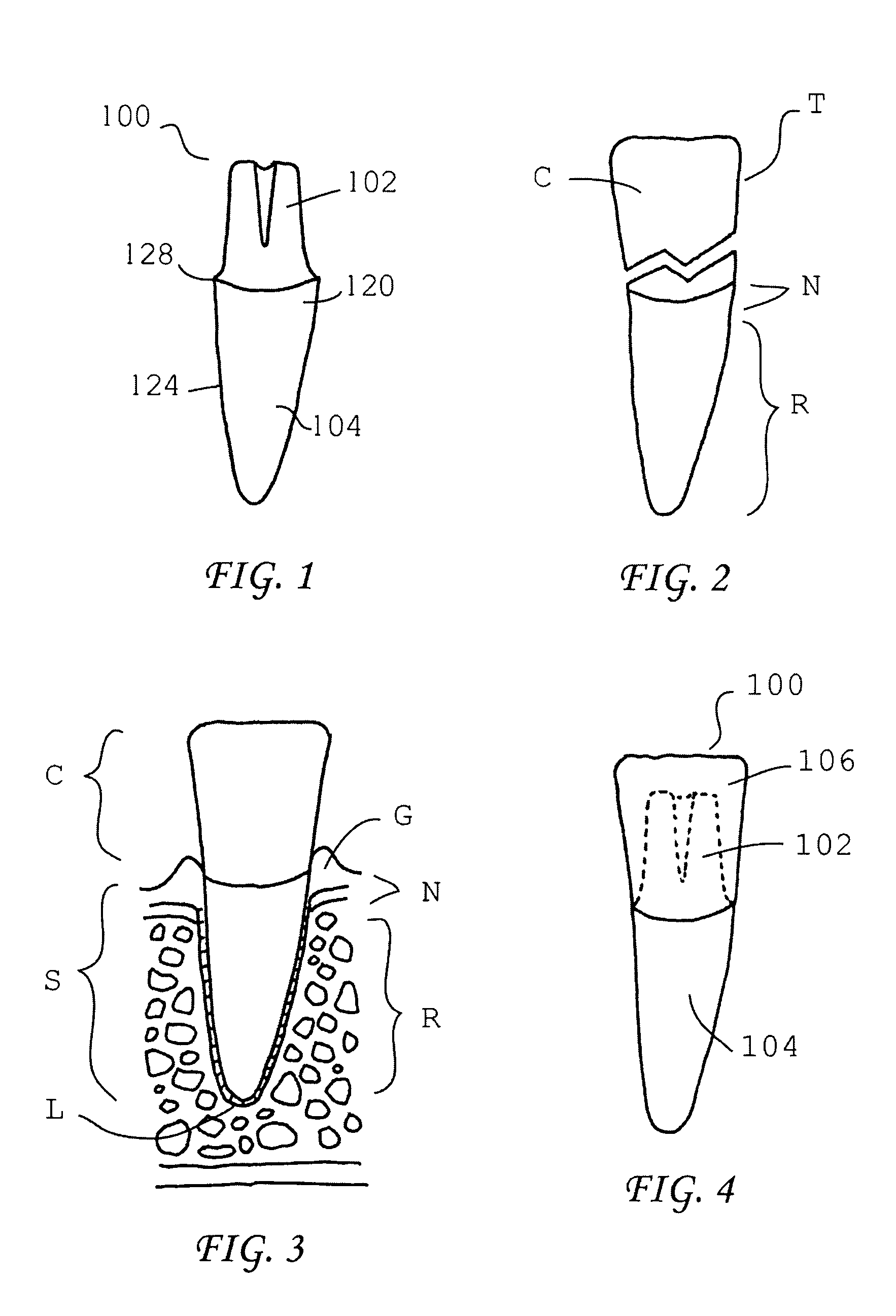

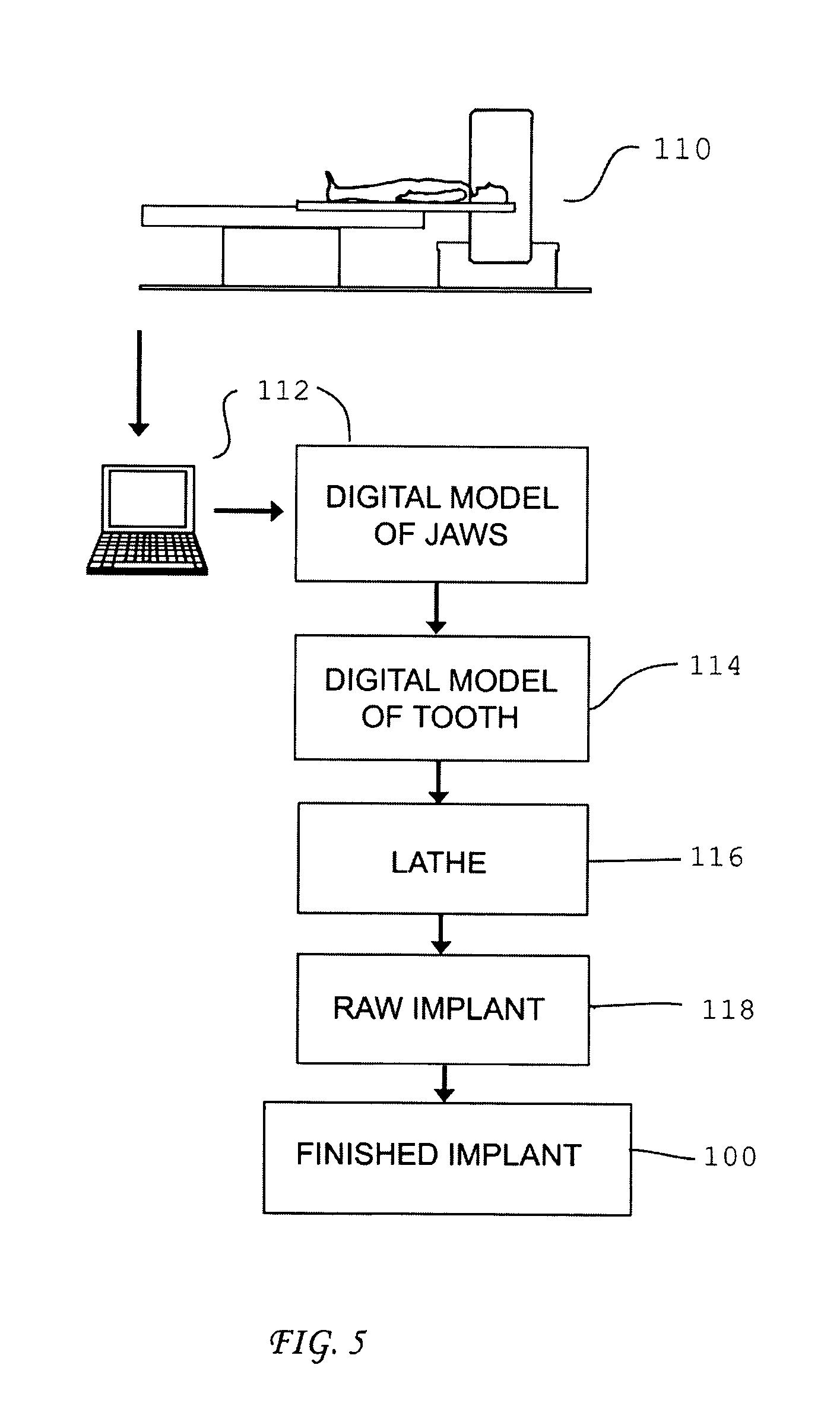

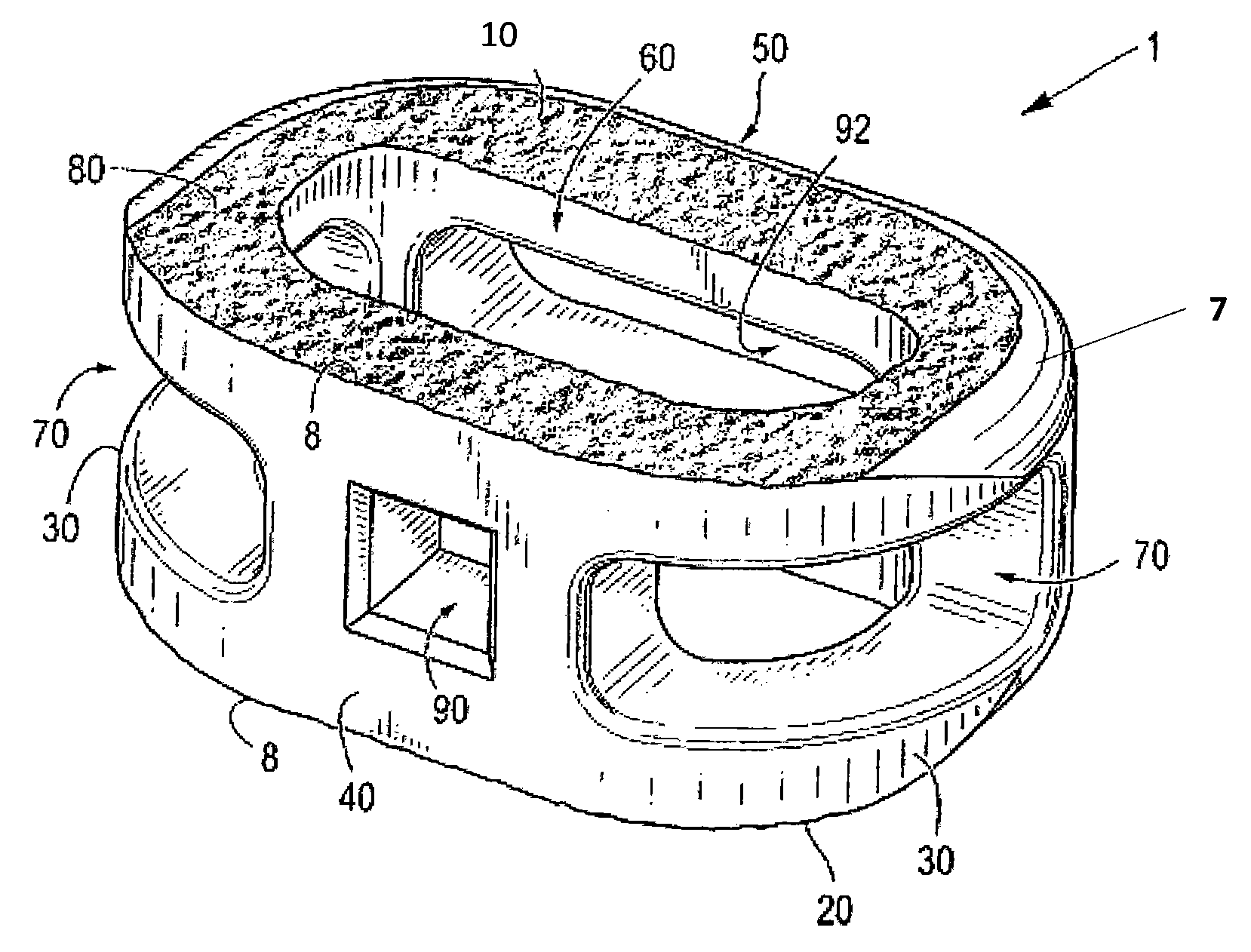

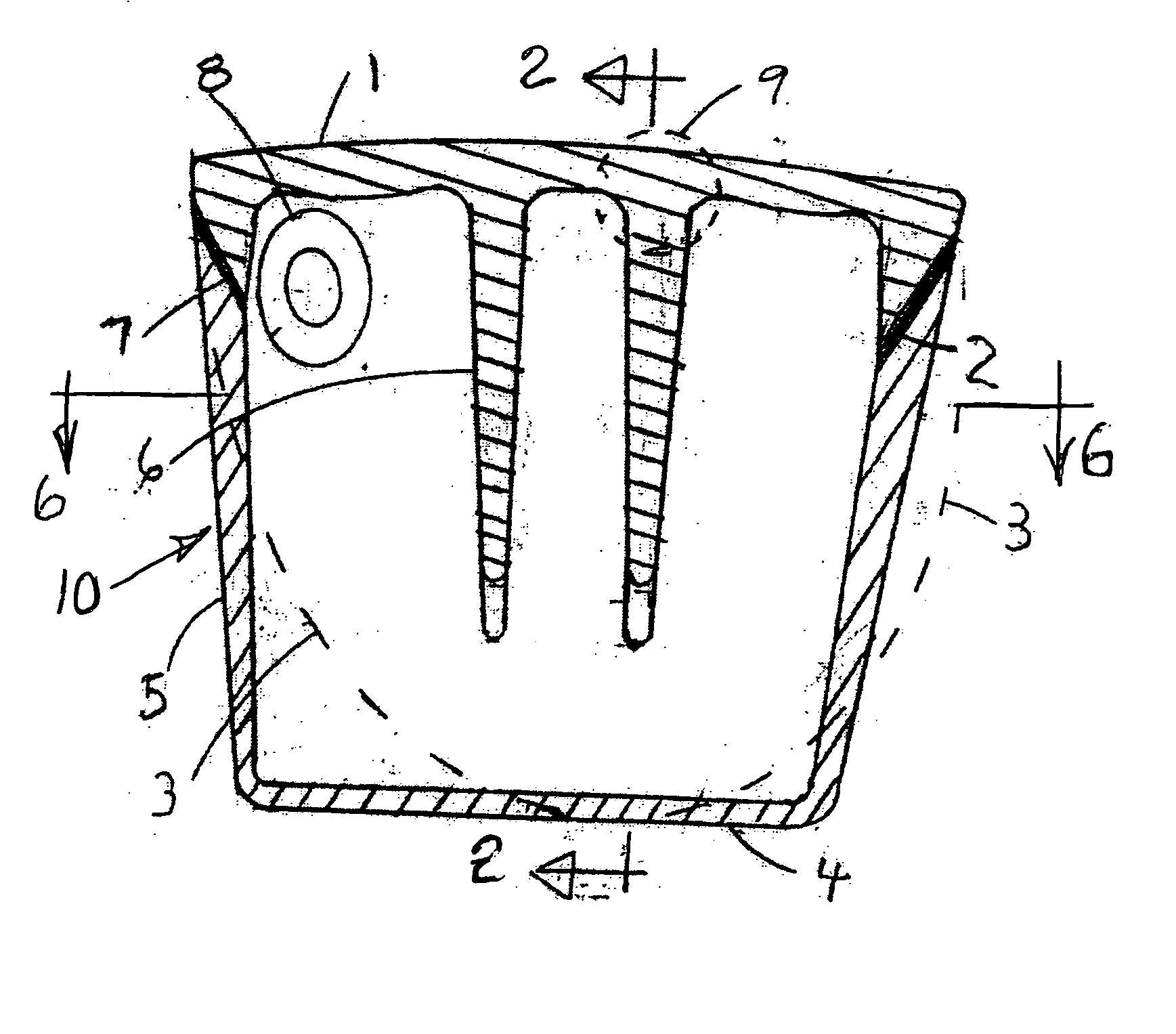

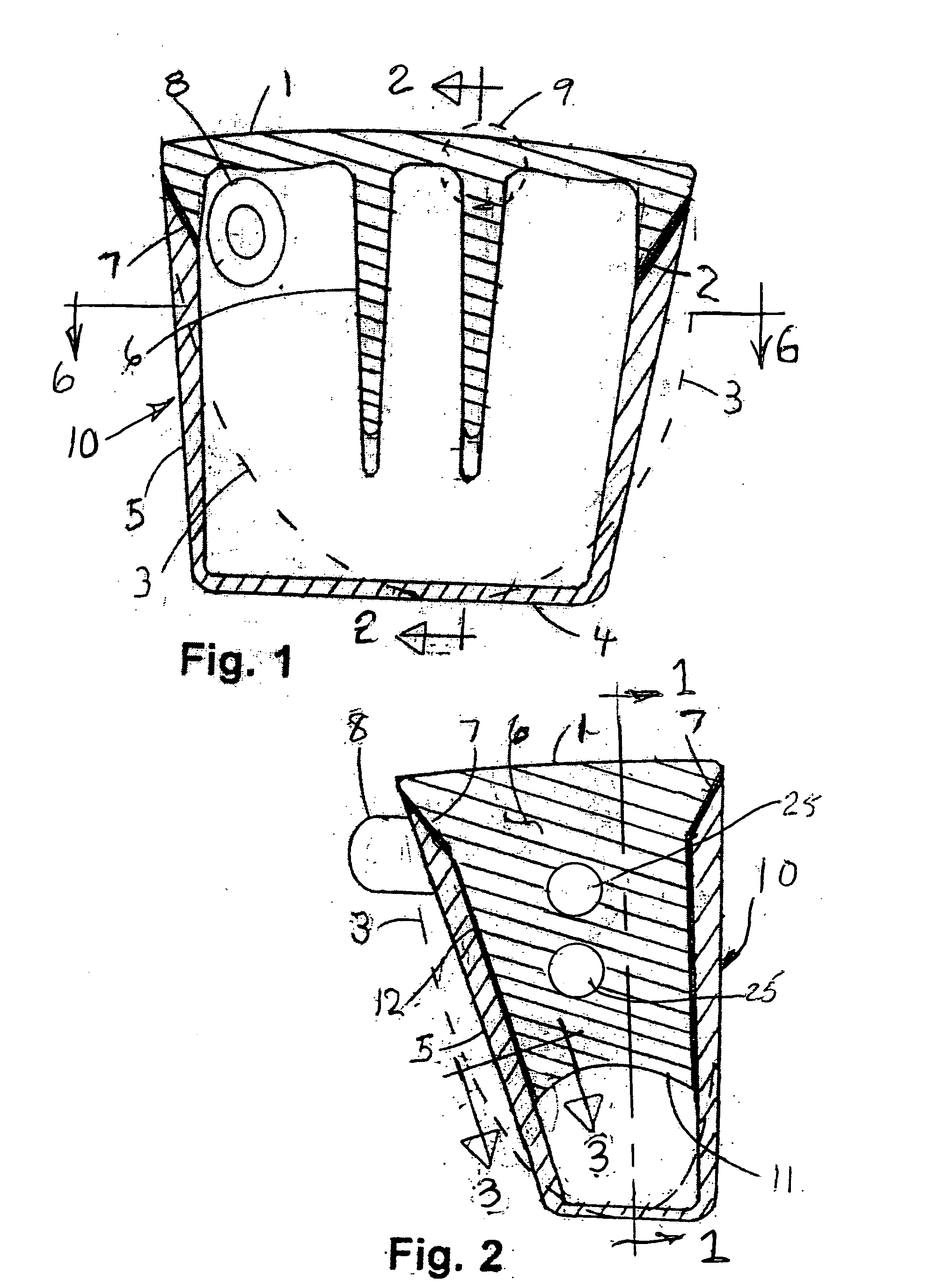

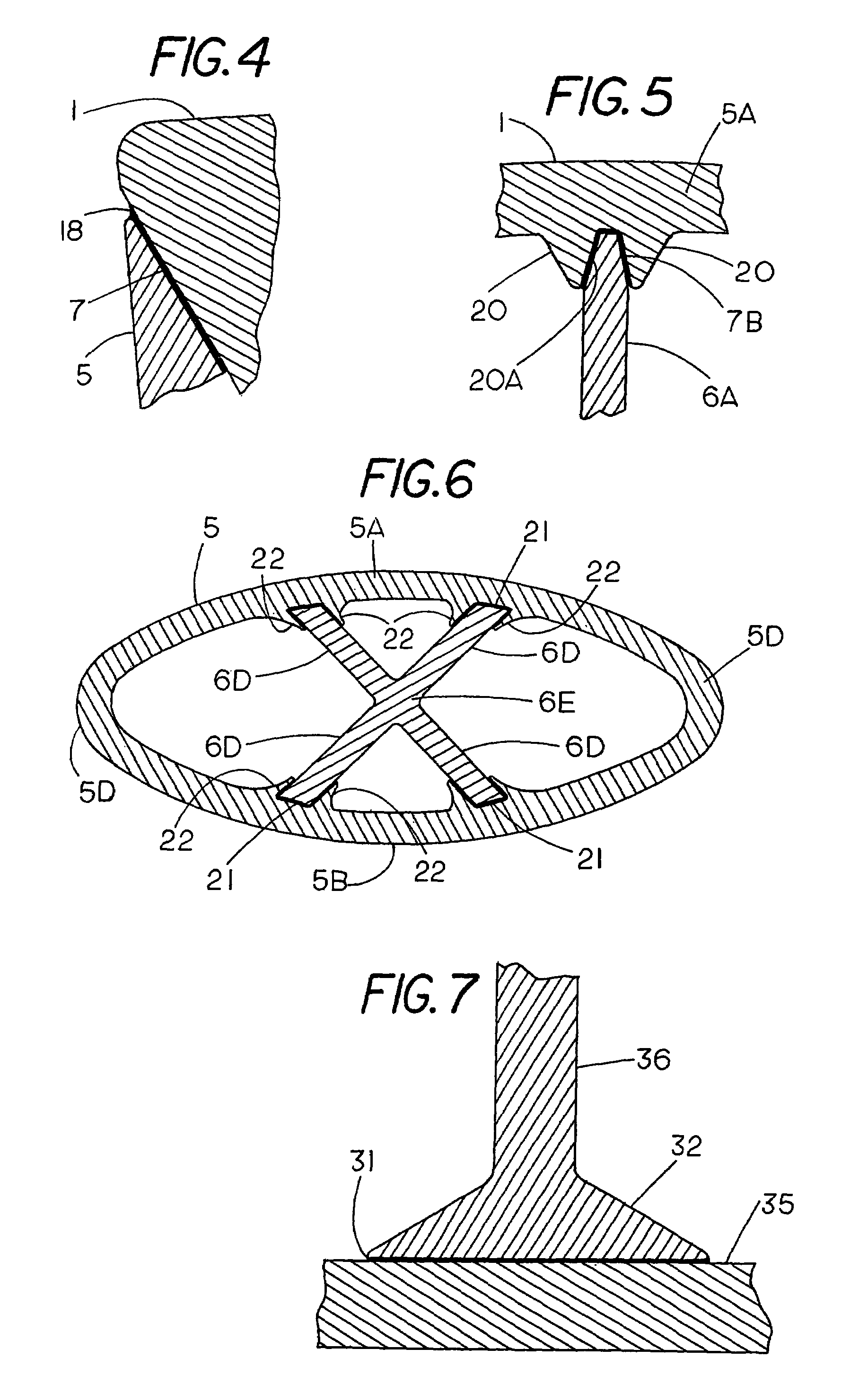

Dental implants and methods for their fabrication and use

InactiveUS20050048440A1Enhance post-implant boneEnhance ligament growthDental implantsTeeth fillingAbutmentDental implant

A dental implant for use in replacing a nonfunctional tooth includes an abutment and a base. The base of the implant has a topography this is substantially identical to the topography of the root of the nonfunctional tooth. Accordingly, the use of the implants eliminates the need for conventionally used bone drills and other traumatic preparing procedures for implant. The implant may be fabricated from a single piece of material so that the abutment and the base are unitary. In addition, the surface of the base may be treated to enhance post-implant bone growth to the base.

Owner:FENG JAMES C

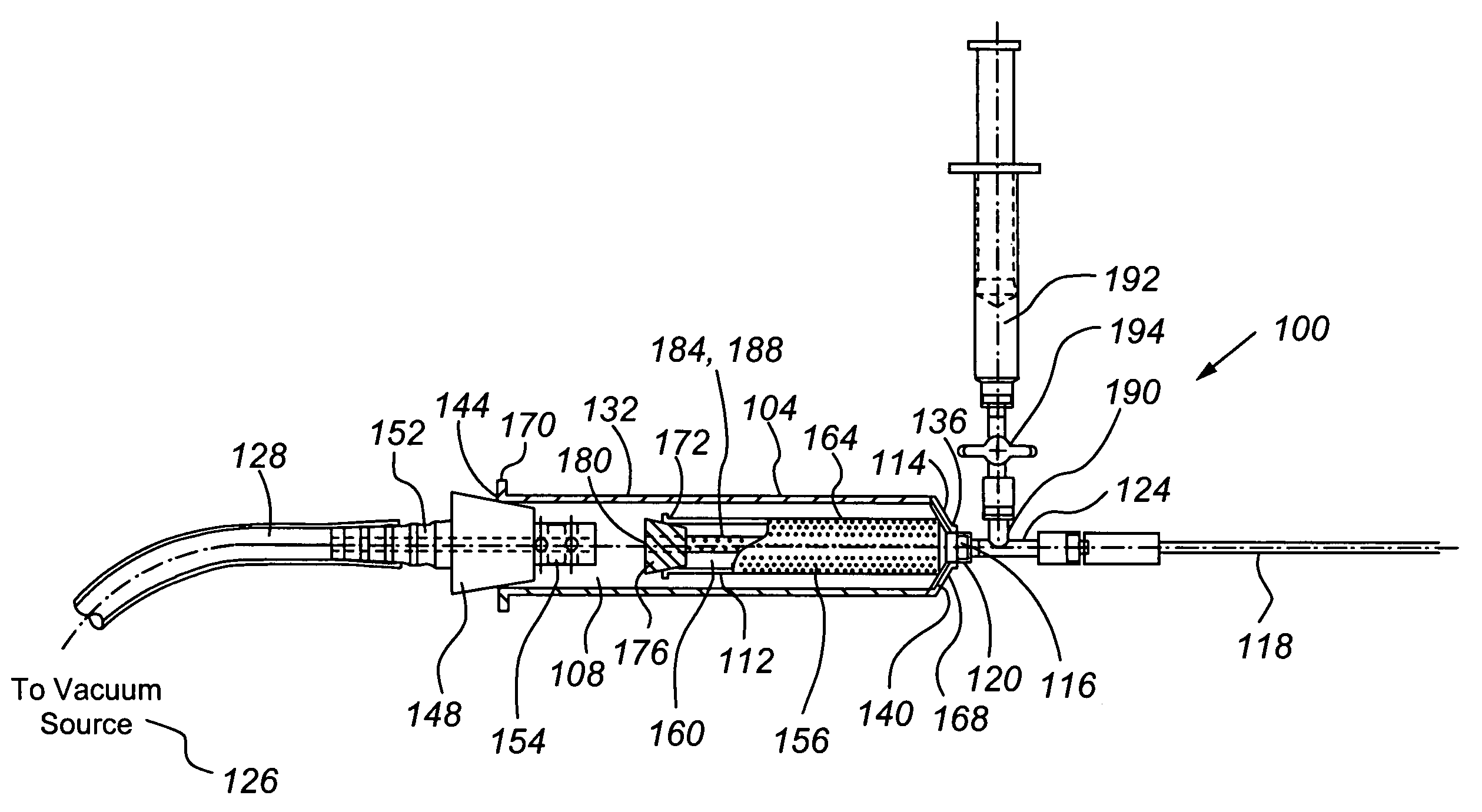

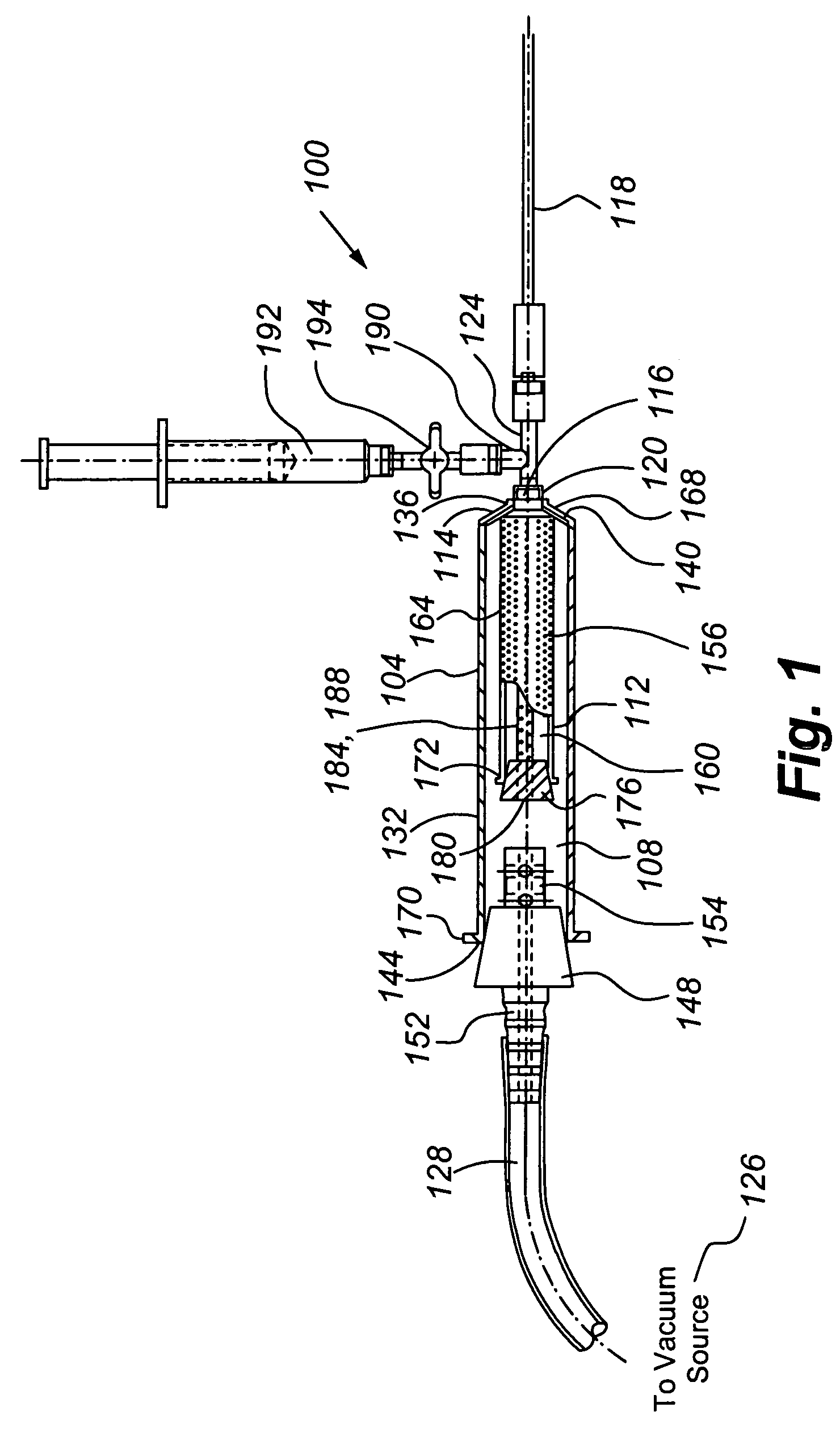

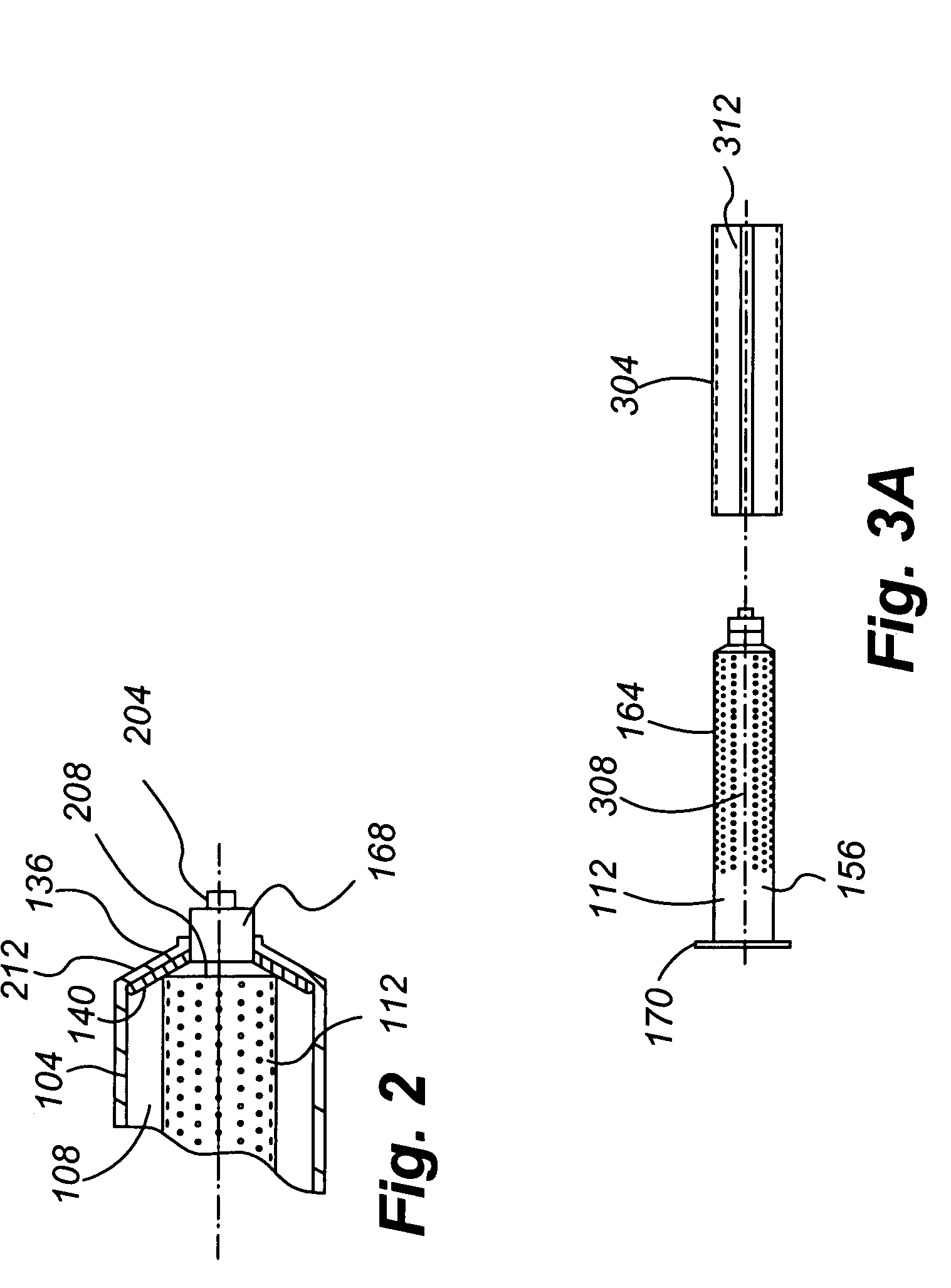

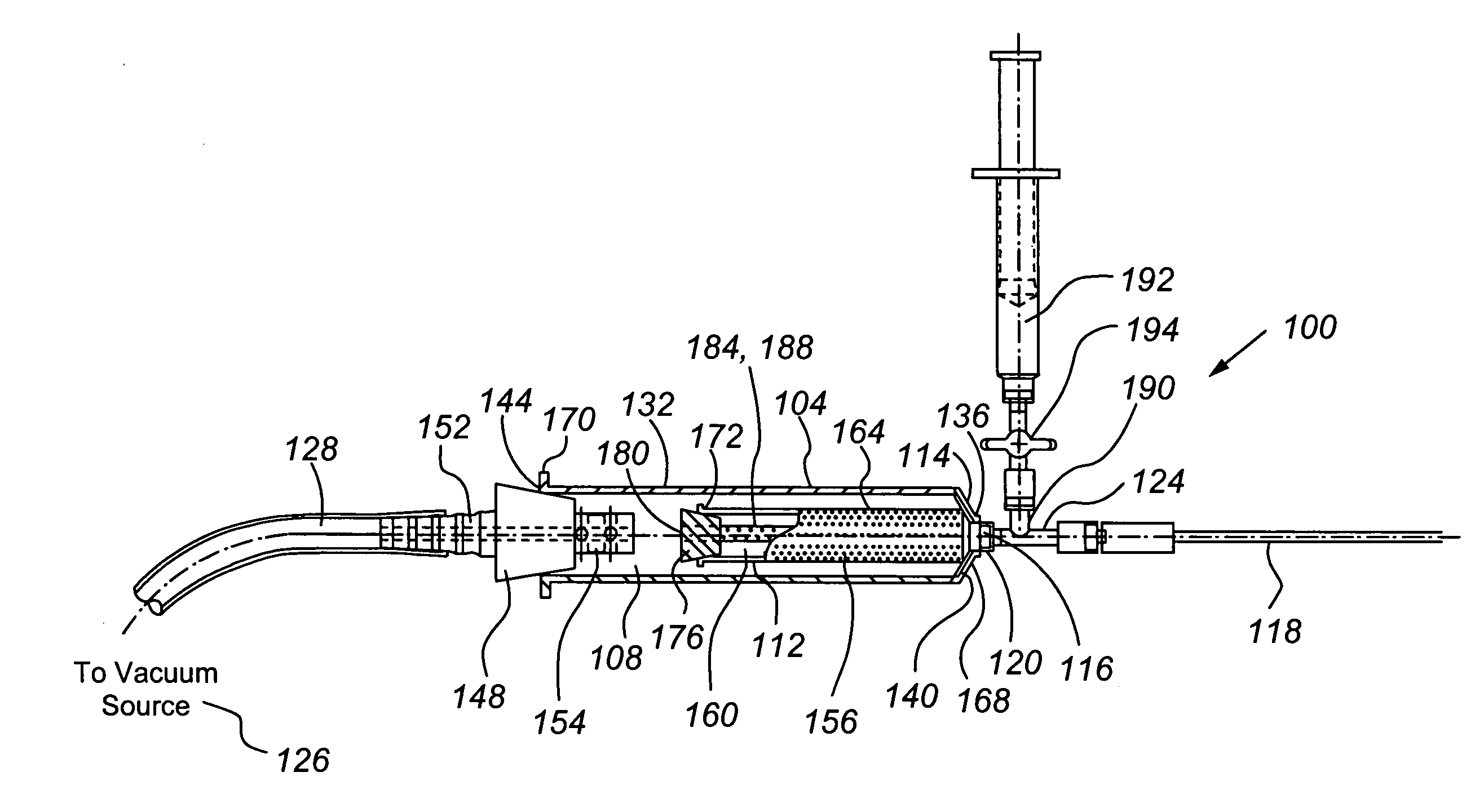

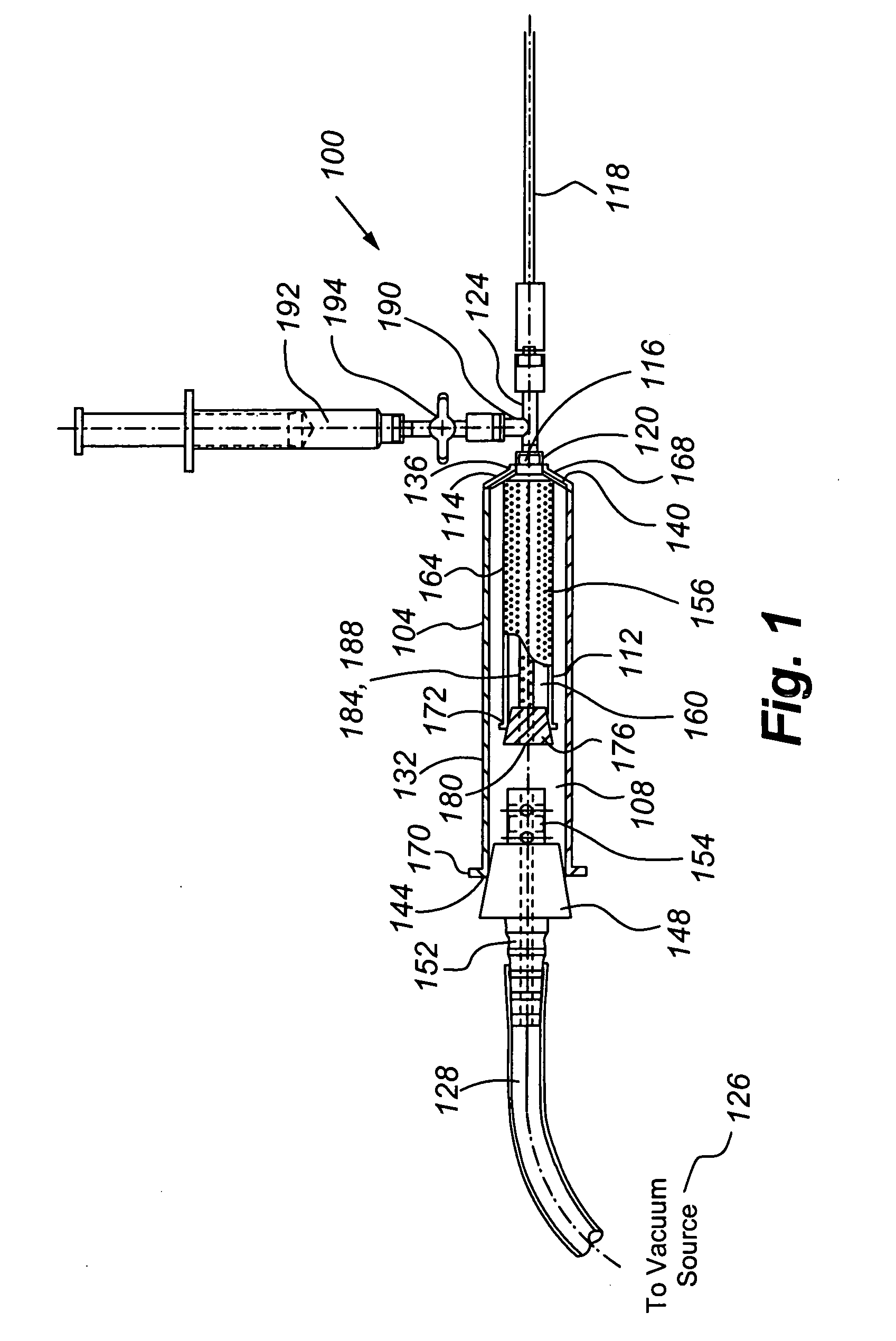

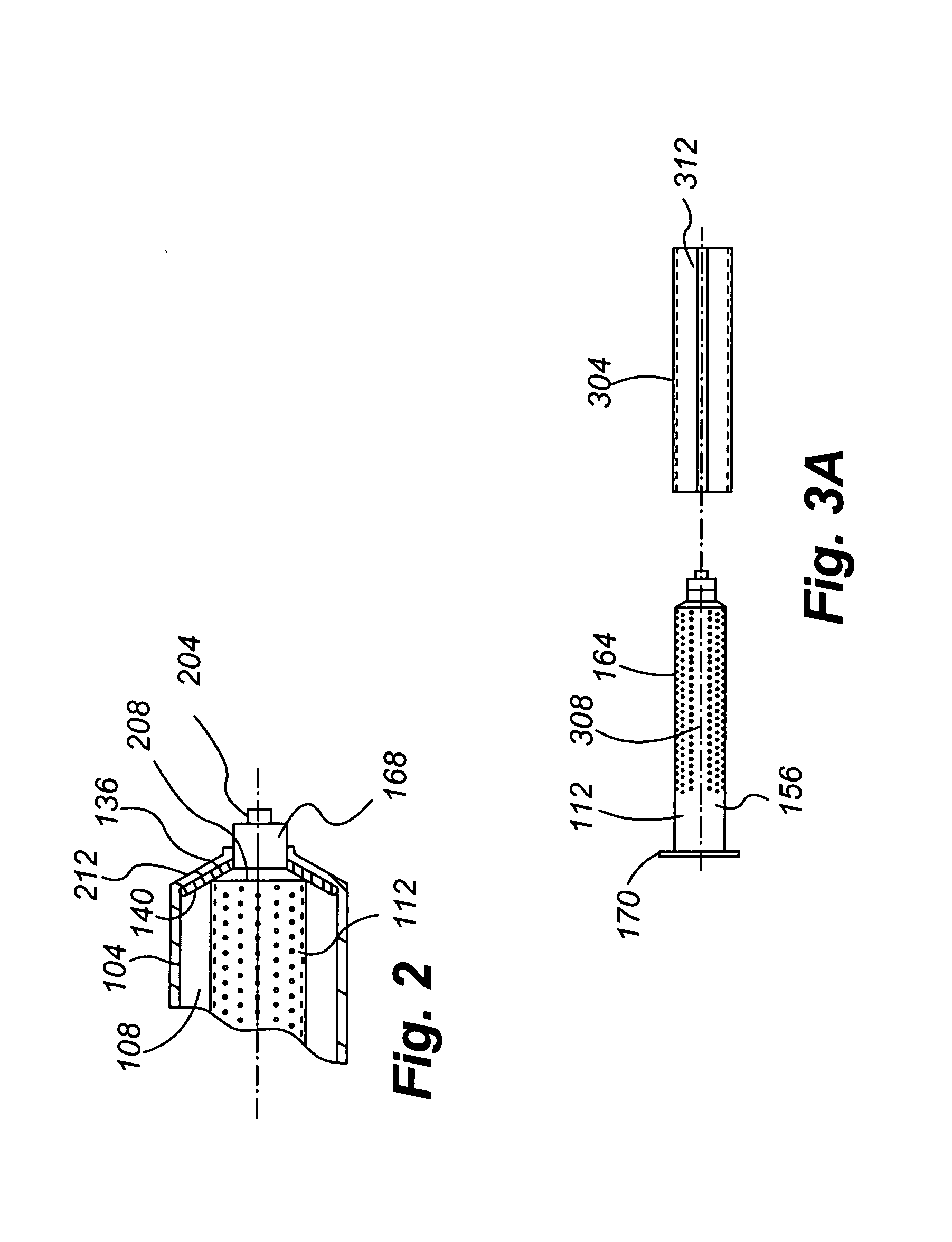

Tissue transplantation method and apparatus

ActiveUS7794449B2Minimize and eliminate needEliminate needInfusion syringesWound drainsTissue GraftMaterial Perforation

The present invention provides for the transplantation of tissue from a donor site in a body to a recipient site. The device includes an outer chamber having an interior volume in which a perforated inner chamber can be placed. During the aspiration of tissue, a vacuum is formed in the interior volume of the outer chamber, to draw tissue from a cannula into the perforated inner chamber. The perforations are sized such that fat is collected within the inner chamber, while fluids and other materials are drawn through the perforations, away from the collected fat. For reinjection, the inner chamber can be removed from the outer chamber, and a sleeve positioned to cover the perforations and thereby form a syringe body that can be interconnected to a needle and plunger for reinjection of the collected fat.

Owner:SHIPPERT ENTERPRISES

Tissue transplantation method and apparatus

ActiveUS20060213374A1Minimize and eliminate needEliminate needInfusion syringesSurgeryTissue transplantationMaterial Perforation

The present invention provides for the transplantation of tissue from a donor site in a body to a recipient site. The device includes an outer chamber having an interior volume in which a perforated inner chamber can be placed. During the aspiration of tissue, a vacuum is formed in the interior volume of the outer chamber, to draw tissue from a cannula into the perforated inner chamber. The perforations are sized such that fat is collected within the inner chamber, while fluids and other materials are drawn through the perforations, away from the collected fat. For reinjection, the inner chamber can be removed from the outer chamber, and a sleeve positioned to cover the perforations and thereby form a syringe body that can be interconnected to a needle and plunger for reinjection of the collected fat.

Owner:SHIPPERT ENTERPRISES

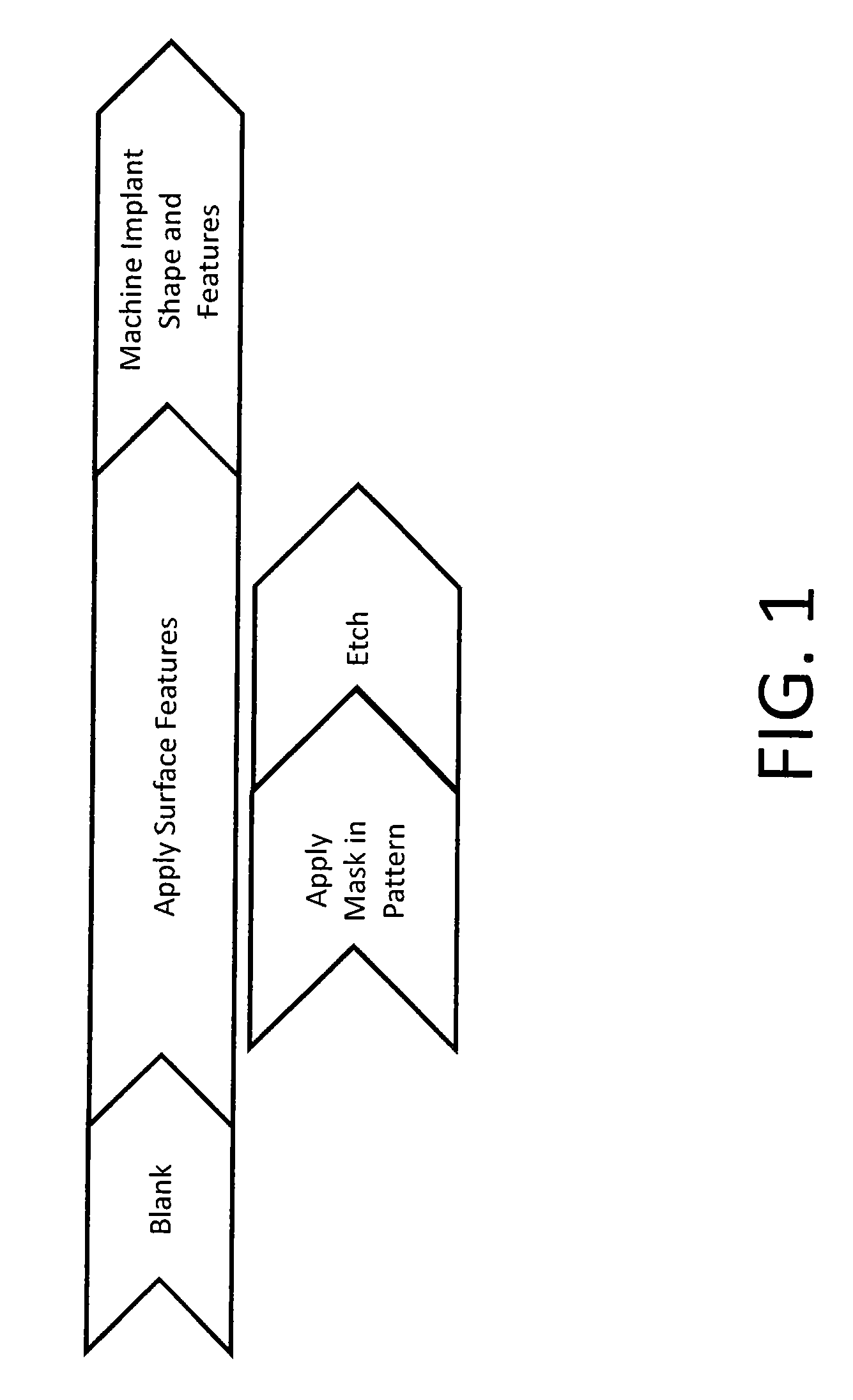

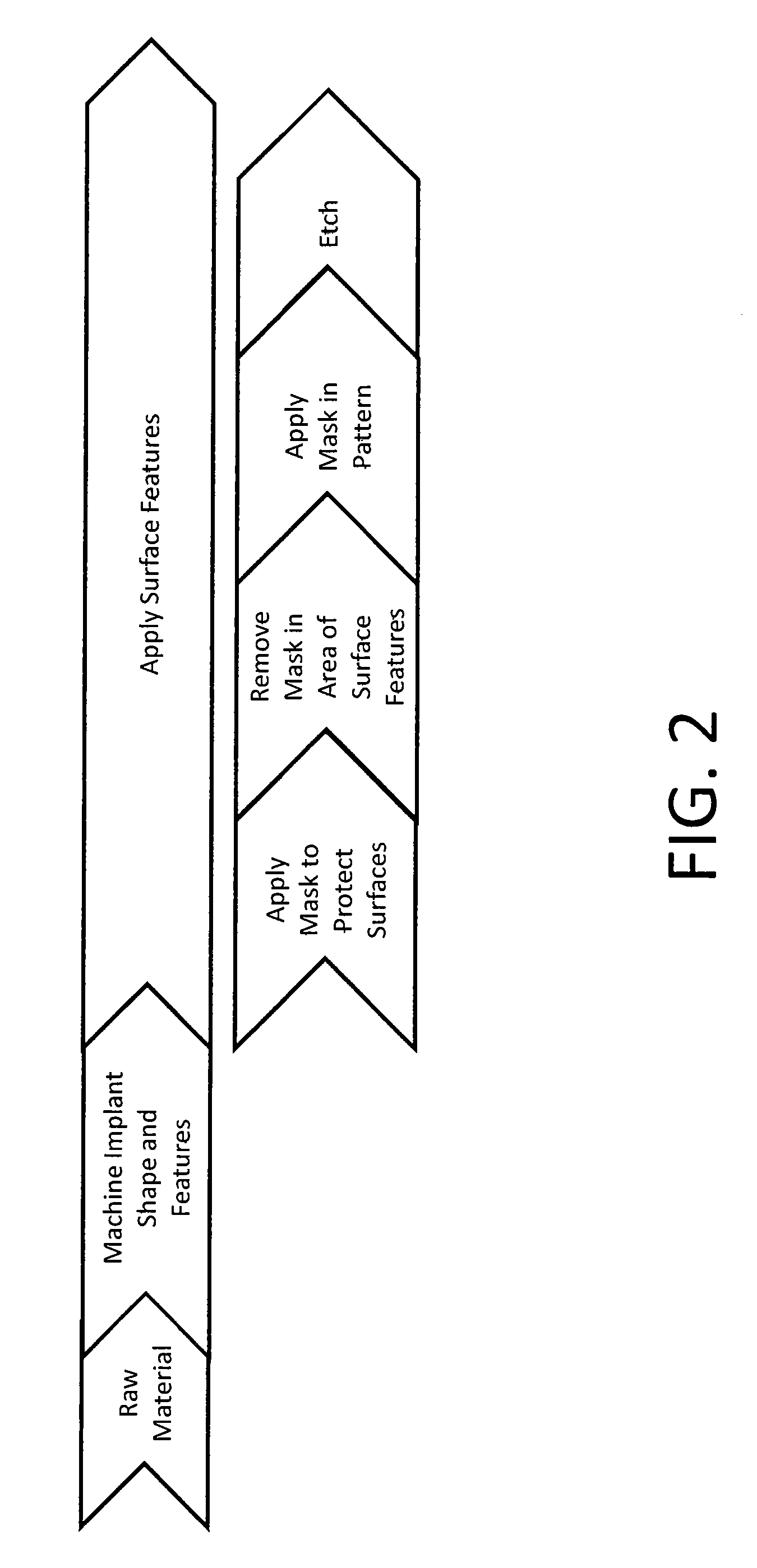

Methods for manufacturing implants having integration surfaces

InactiveUS20120312779A1Quality improvementImprove reliabilityTurning machine accessoriesDecorative surface effectsSpinal implantRough surface

A method of producing an interbody spinal implant. The method includes the steps of obtaining a blank having a top surface, bottom surface, opposing lateral sides, and opposing anterior and posterior portions, and applying a subtractive process (e.g., masked acid etching) to the top surface, the bottom surface, or both surfaces of the blank to form a roughened surface topography. Subsequently, the blank is machined to form the interbody spinal implant, which includes a body having a top surface, a bottom surface, opposing lateral sides, opposing anterior and posterior portions, a substantially hollow center, and a single vertical aperture where the top surface, the bottom surface, or both surfaces of the interbody spinal implant have the roughened surface topography produced by the subtractive process. This simplified method produces more accurate and repeatable implants with fewer process steps and defects, reducing process time and costs.

Owner:TITAN SPINE

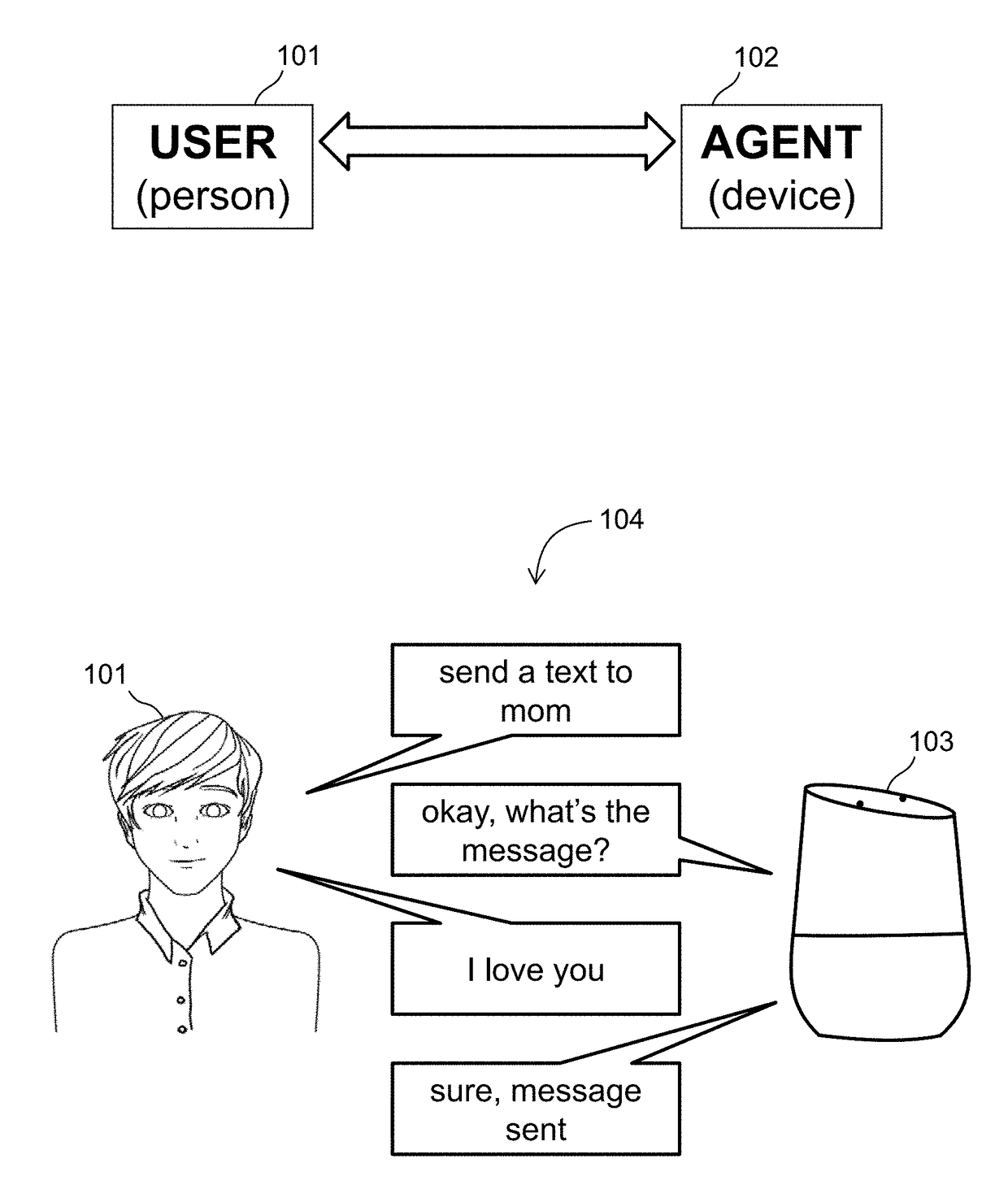

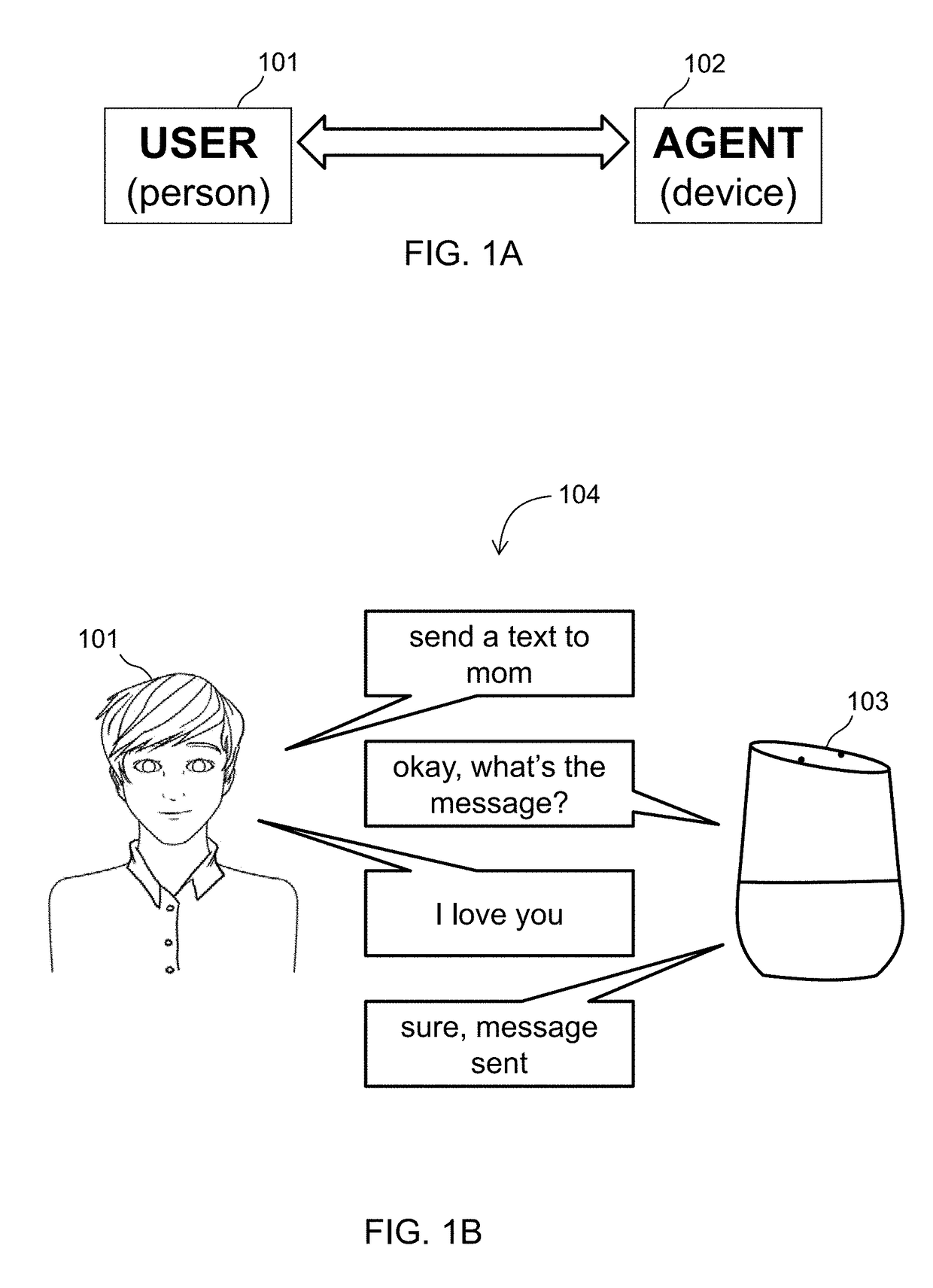

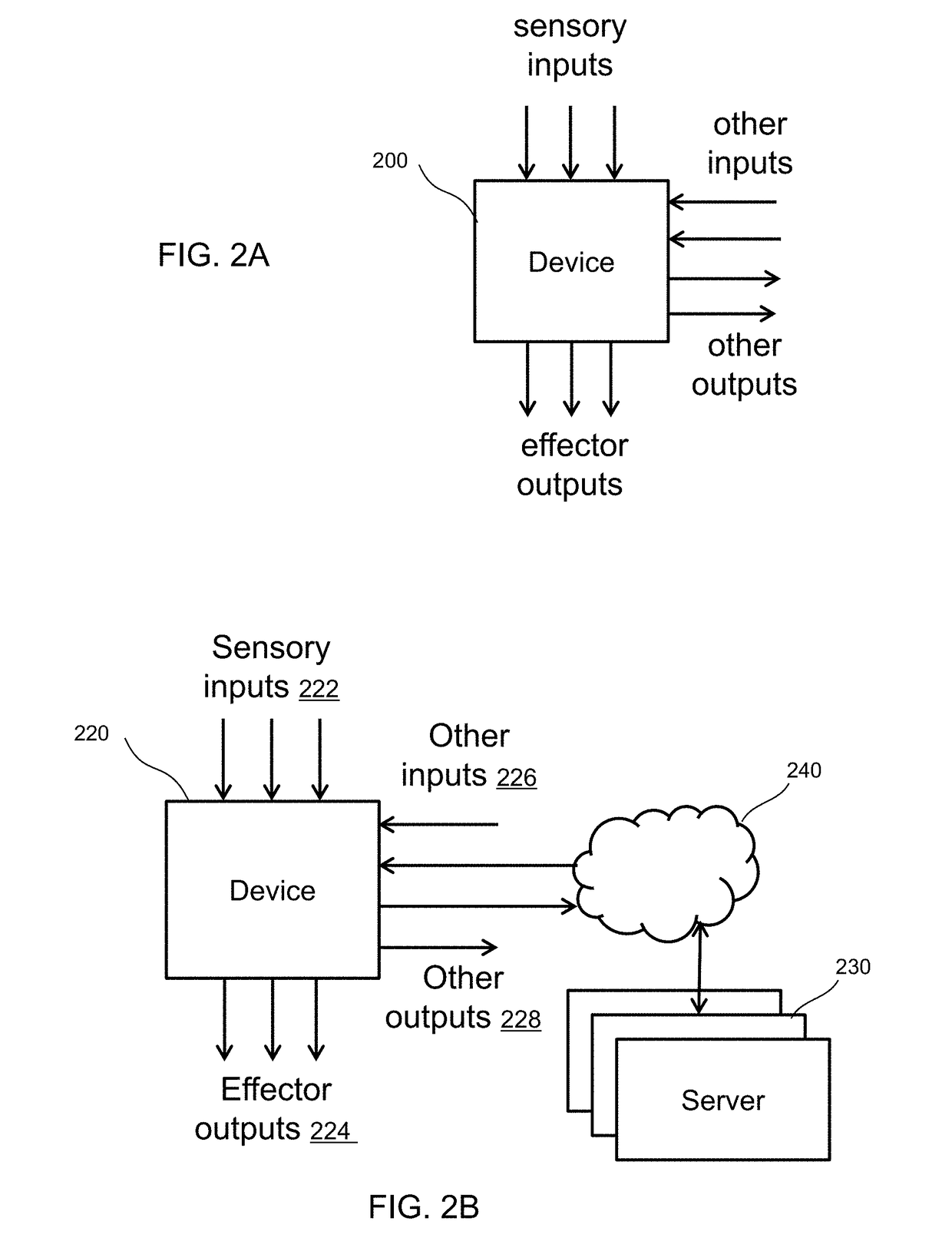

Managing agent engagement in a man-machine dialog

ActiveUS20180301151A1Improve fluidityMinimize or eliminate needCharacter and pattern recognitionDigital data authenticationManagement agentMan machine

Agents engage and disengage with users intelligently. Users can tell agents to remain engaged without requiring a wakeword. Engaged states can support modal dialogs and barge-in. Users can cause disengagement explicitly. Disengagement can be conditional based on timeout, change of user, or environmental conditions. Engagement can be one-time or recurrent. Recurrent states can be attentive or locked. Locked states can be unconditional or conditional, including being reserved to support user continuity. User continuity can be tested by matching parameters or tracking user by many modalities including microphone arrays, cameras, and other sensors.

Owner:SOUNDHOUND

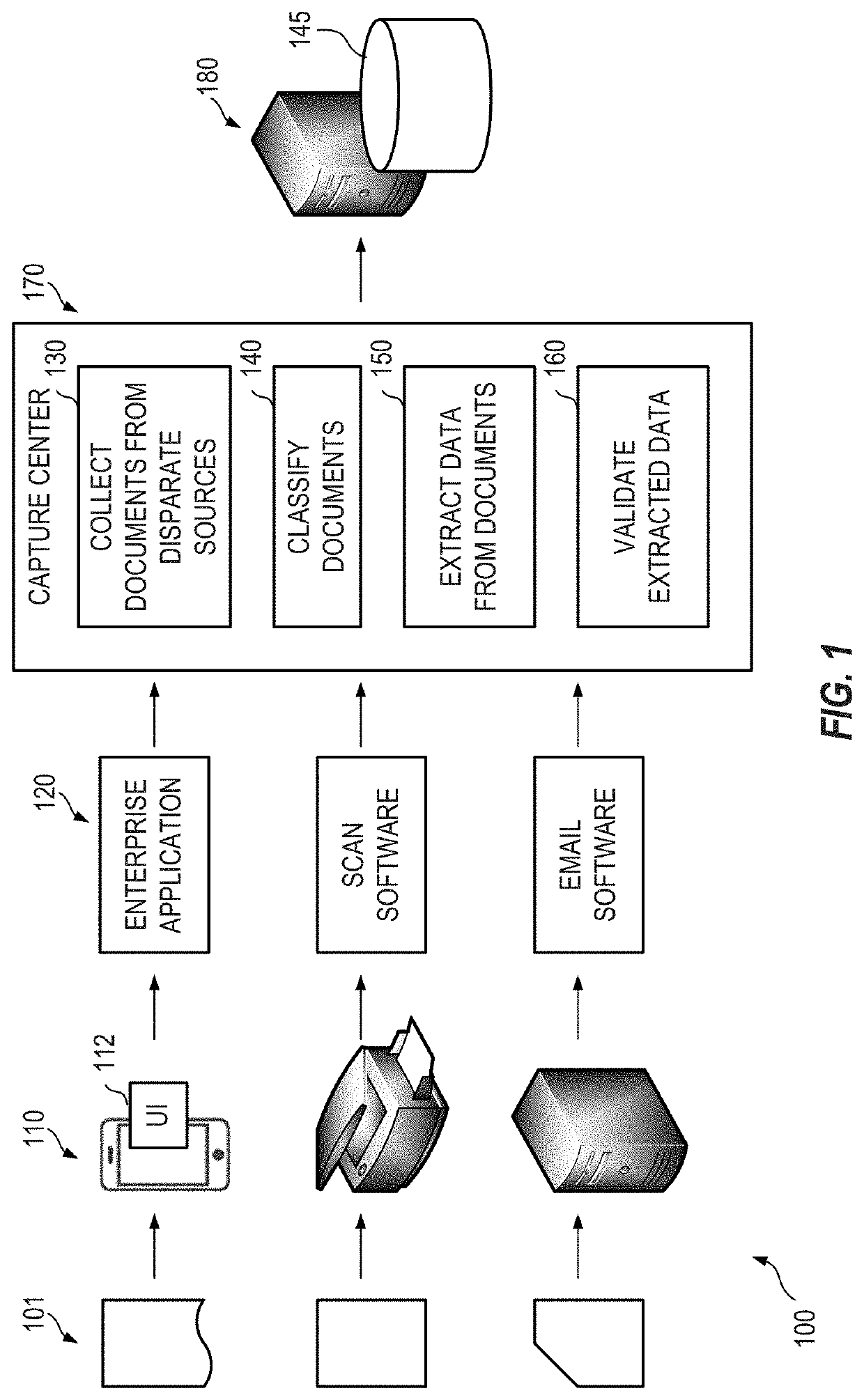

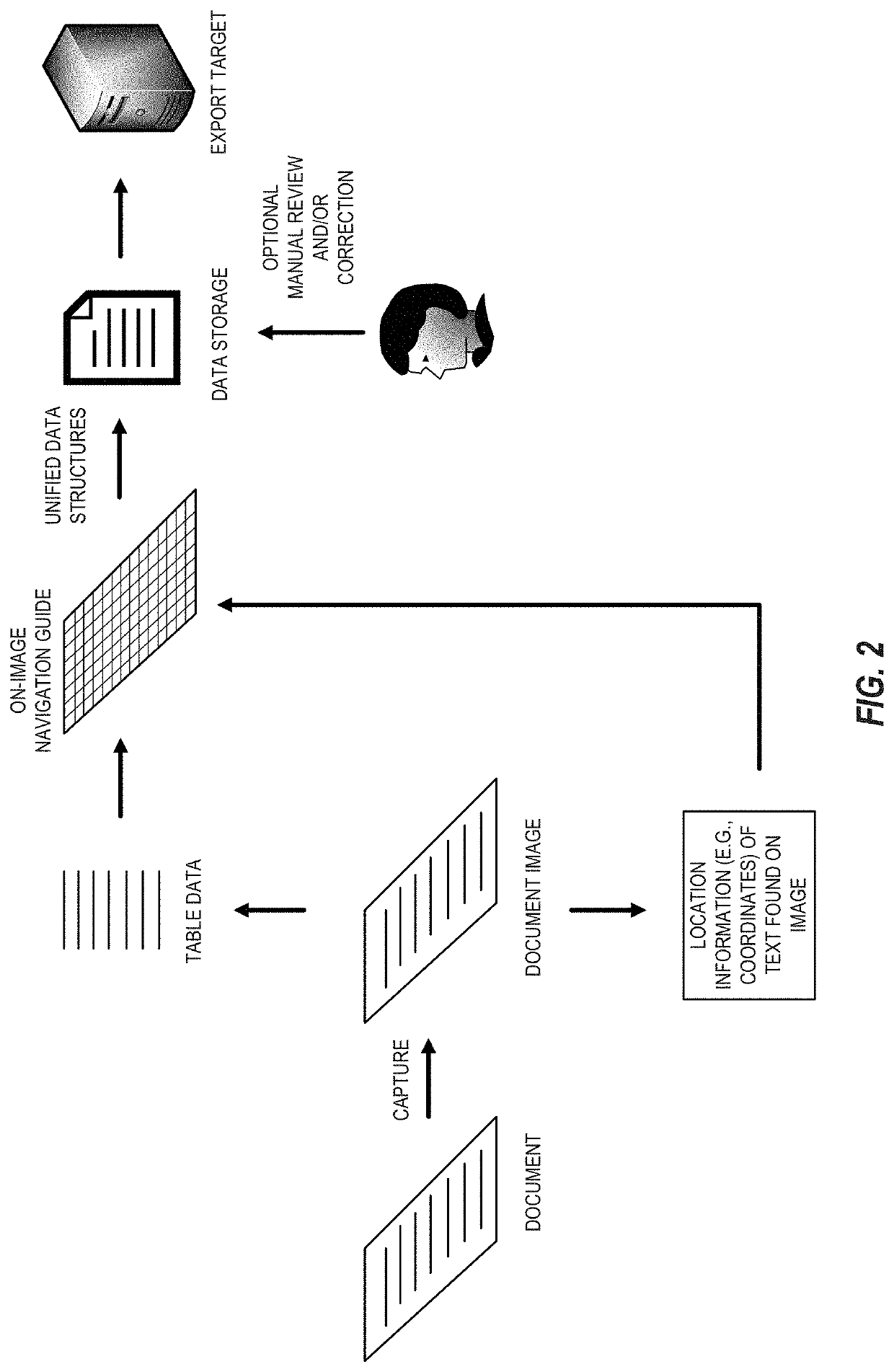

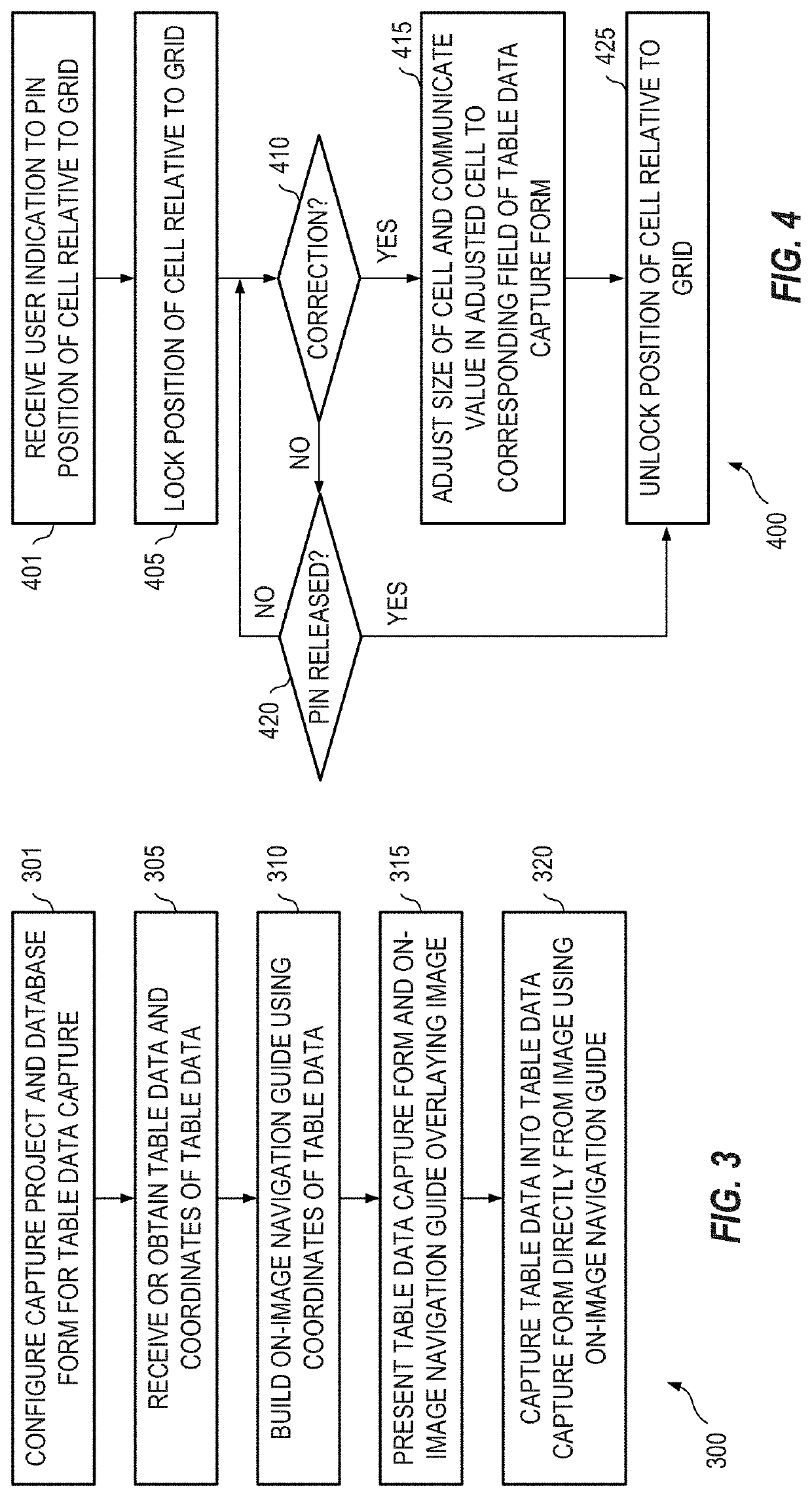

Systems and methods for on-image navigation and direct image-to-data storage table data capture

ActiveUS20200348809A1Minimize and eliminate needNatural language data processingSpecial data processing applicationsComputer graphics (images)Radiology

An on-image navigation guide can be generated utilizing coordinates of table data of a table in a document image. The on-image navigation guide enables a user to populate a data entry form with the table data by interacting directly with the document image. The data entry form is configured with the same number of columns as the table and the document image and the data entry form share the same data structure. The on-image navigation guide is presented on top of the document image. As a user navigates the document image, a focus point of the on-image navigation guide moves from table cell to table cell, providing an immediate visual feedback on what is captured in a corresponding data entry field. The on-image navigation guide includes an on-image context menu and a pin through which the user can make adjustments and / or corrections without leaving the document image.

Owner:OPEN TEXT SA ULC

Undersea well product transport

InactiveUS7703535B2Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationShoreSeawater

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

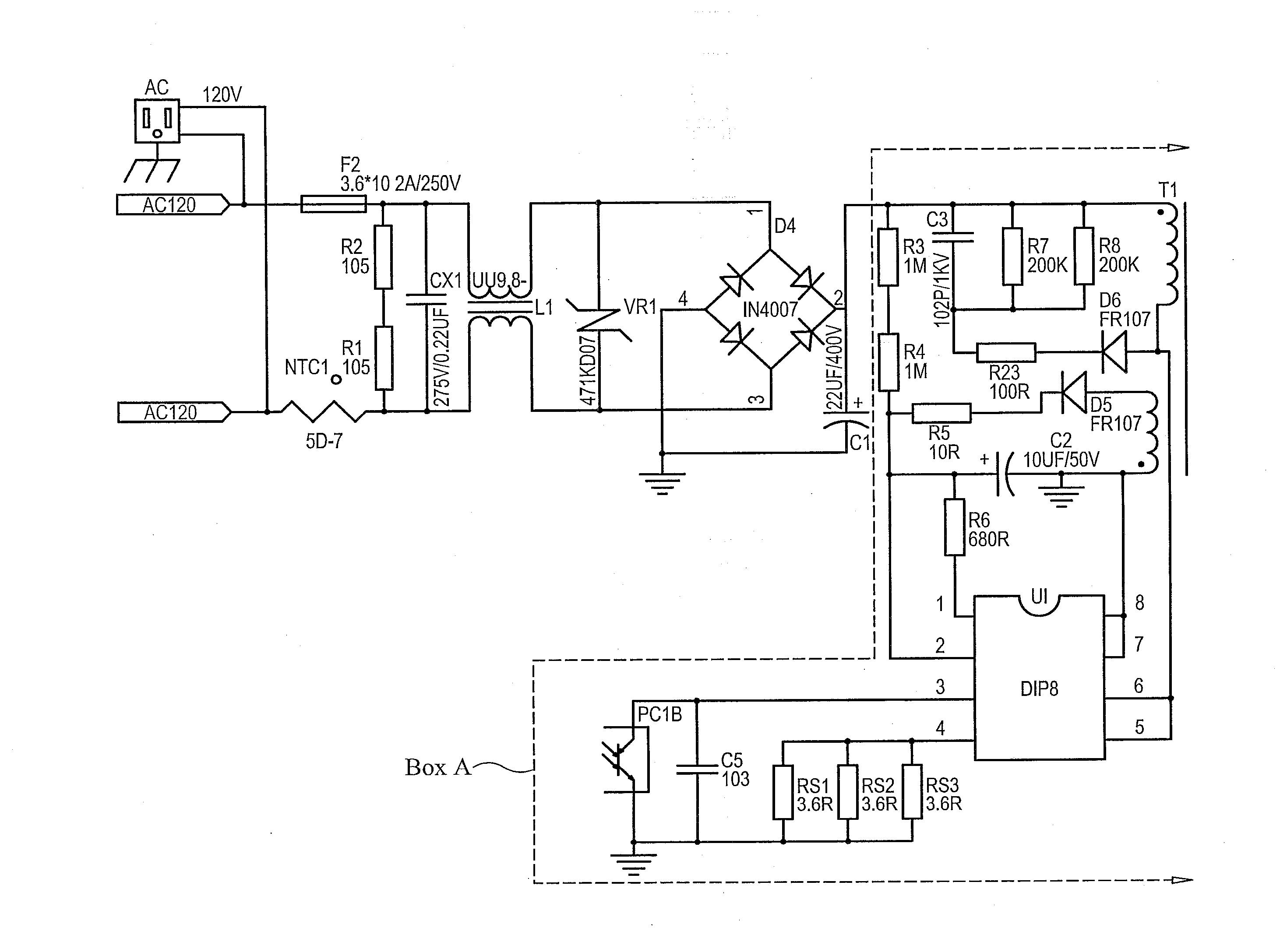

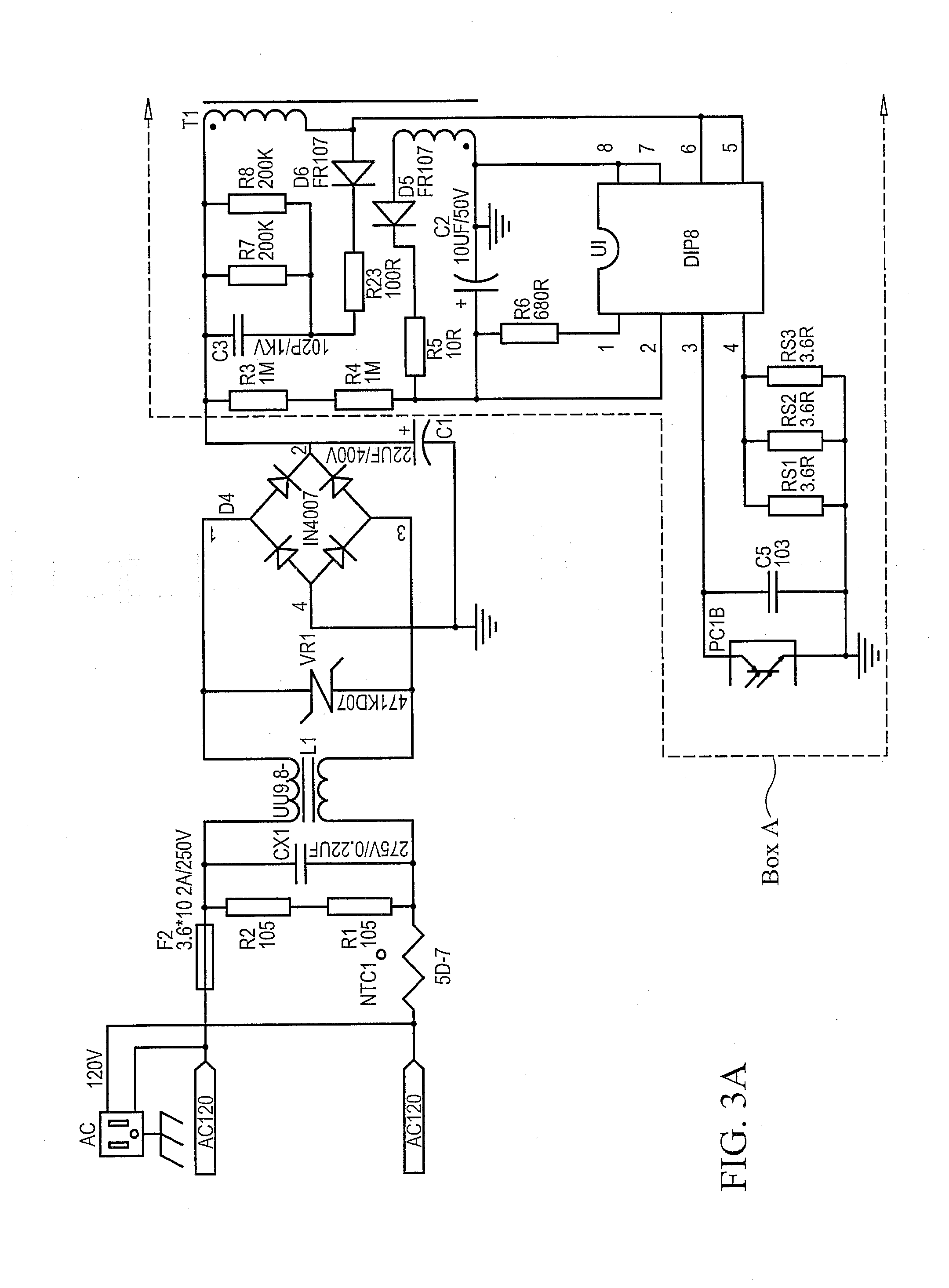

USB wall plate charger

ActiveUS20130175992A1Minimize and eliminate needCoupling device detailsTwo-part coupling devicesEngineeringUSB

A USB wall plate charger for charging an external electronic device is mountable to a common 120 volt AC wall outlet, and includes a power supply to convert the 120 volts AC to +5 volts DC, and a charging profile configuration circuit. A charging profile selection switch is provided for the user to select a desired charging profile that is compatible with the electronic device to be charged.

Owner:VOXX INT CORP

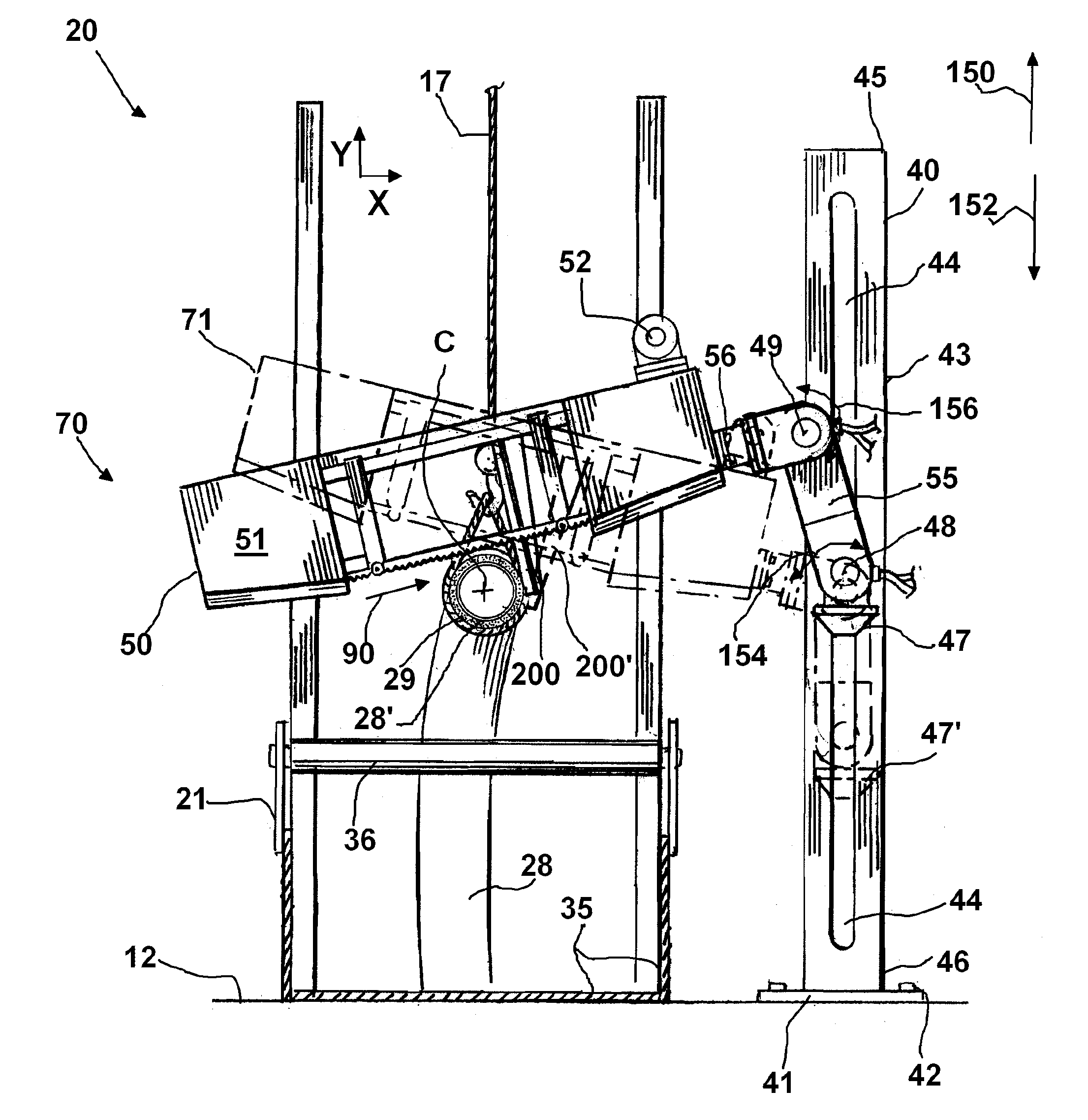

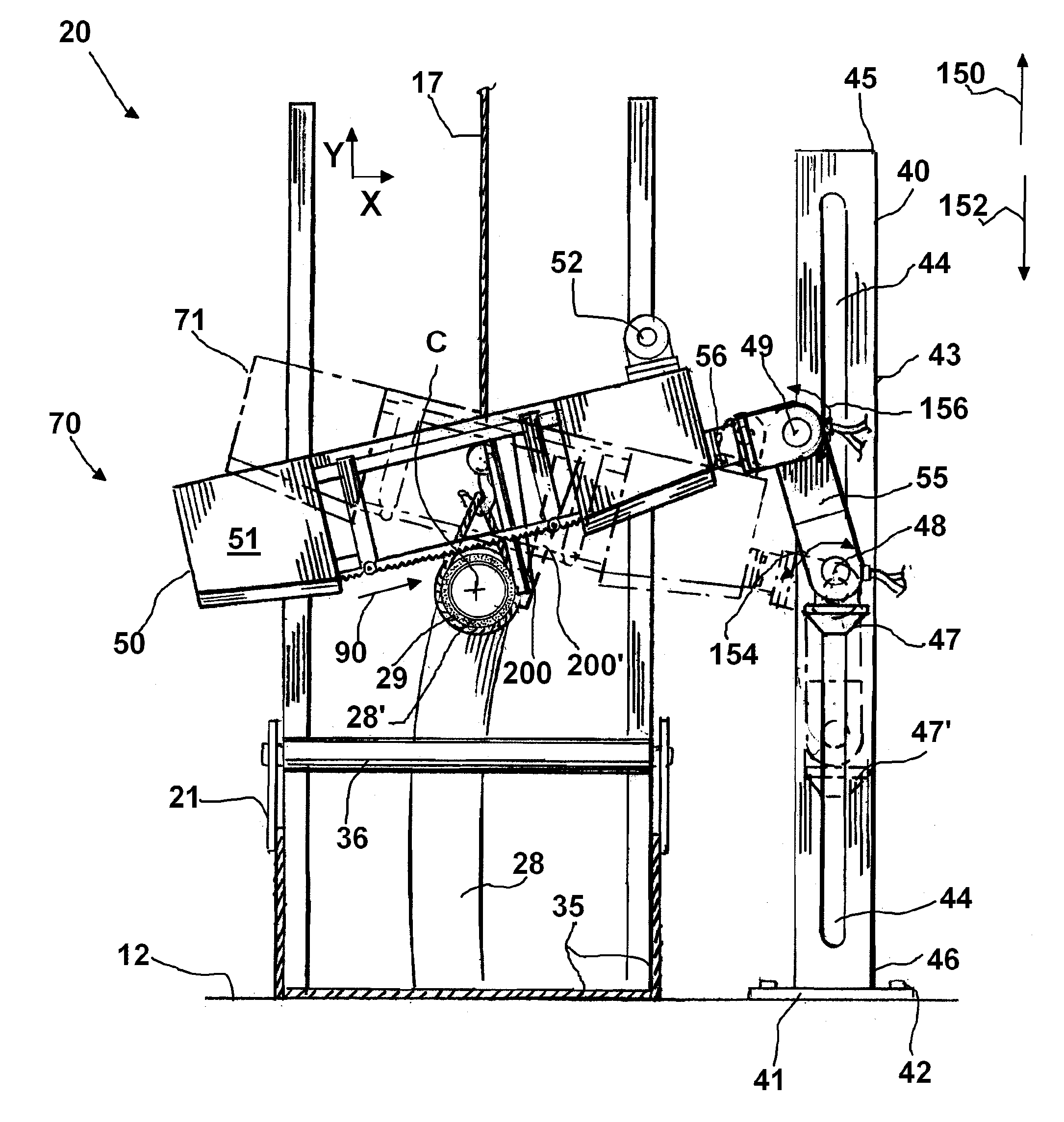

Articulating band saw and method

ActiveUS8475081B2Eliminate needImprove securityMetal sawing devicesPipe laying and repairDiamond wire sawActuator

An articulating band saw apparatus provides a frame that includes a vertically extending section having upper and lower end portions. An elevator moves between the upper and lower end portions of the frame. A first hydraulic actuator is supported on the elevator for movement therewith. A first arm provides arm end portions, the first arm supported by the first hydraulic actuator. An end of the first arm supporting a second hydraulic actuator that is spaced away from the first hydraulic actuator. The second hydraulic actuator supports a second arm. An endless band type saw is mounted on the free end of the second arm generally opposite the second actuator. The band saw is movable by articulation of the first and second actuators and resulting movement of the first and second arms. In one embodiment, the band saw is a diamond wire saw.

Owner:AES EOT EQUIP HLDG LLC

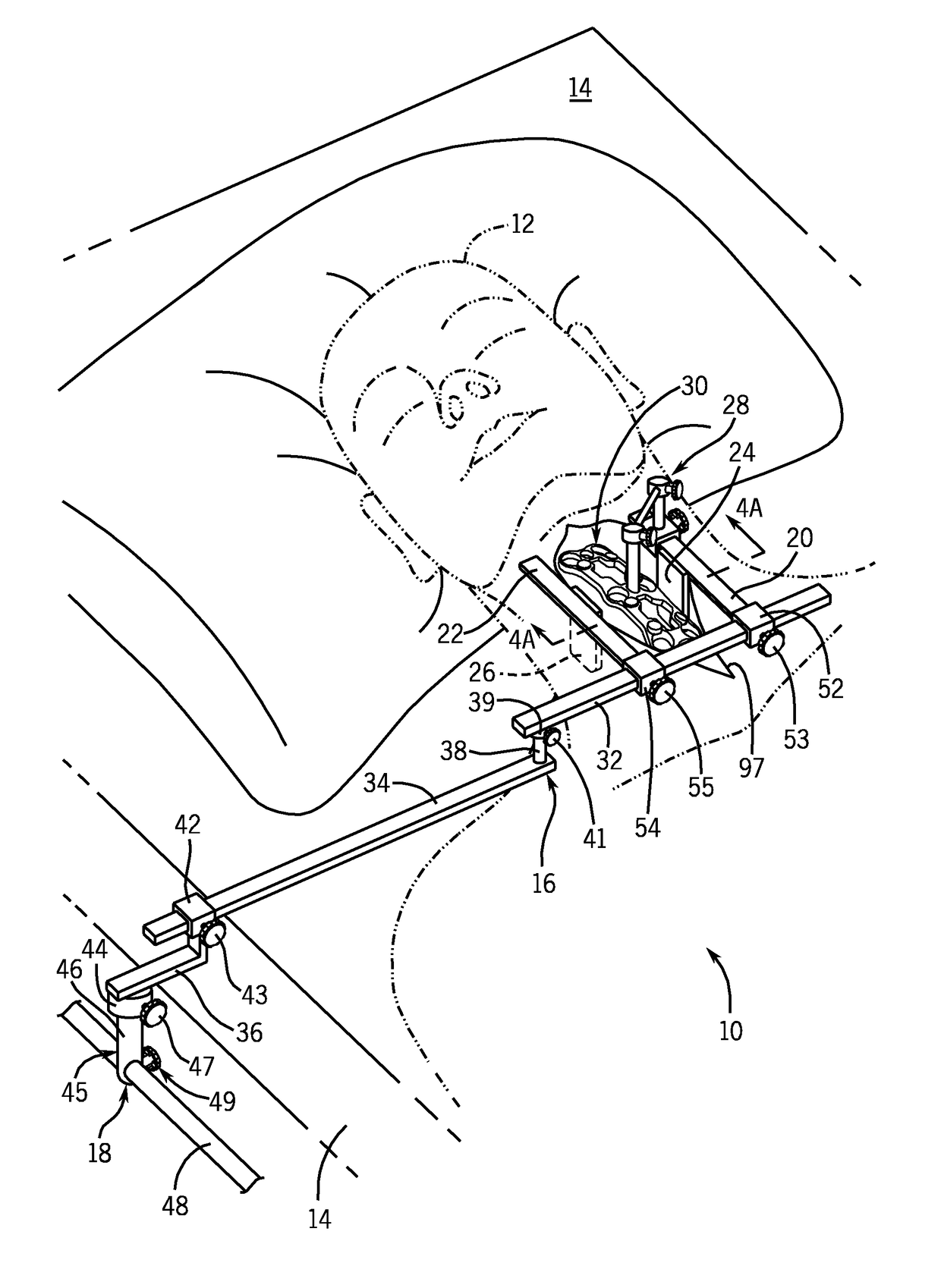

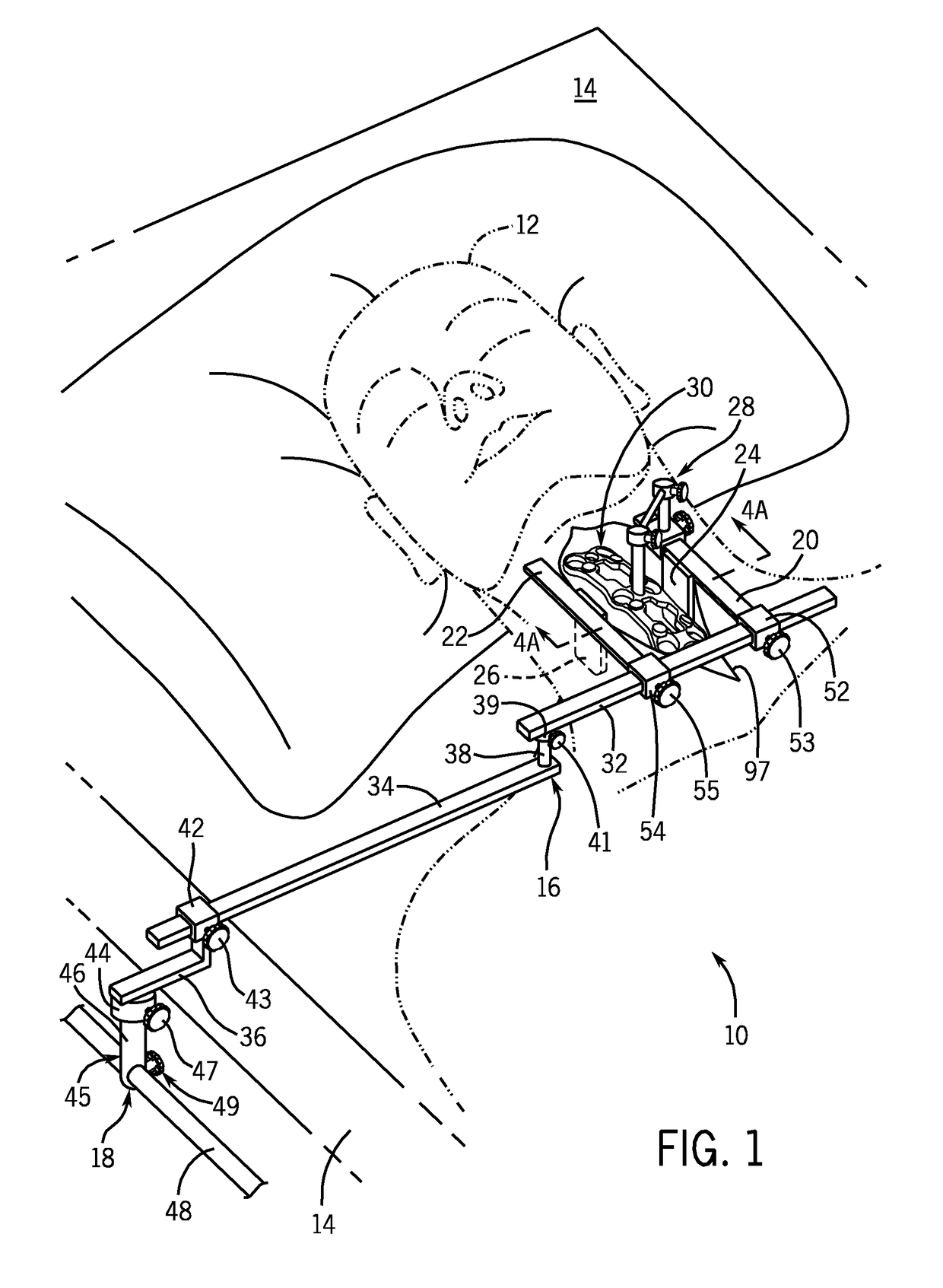

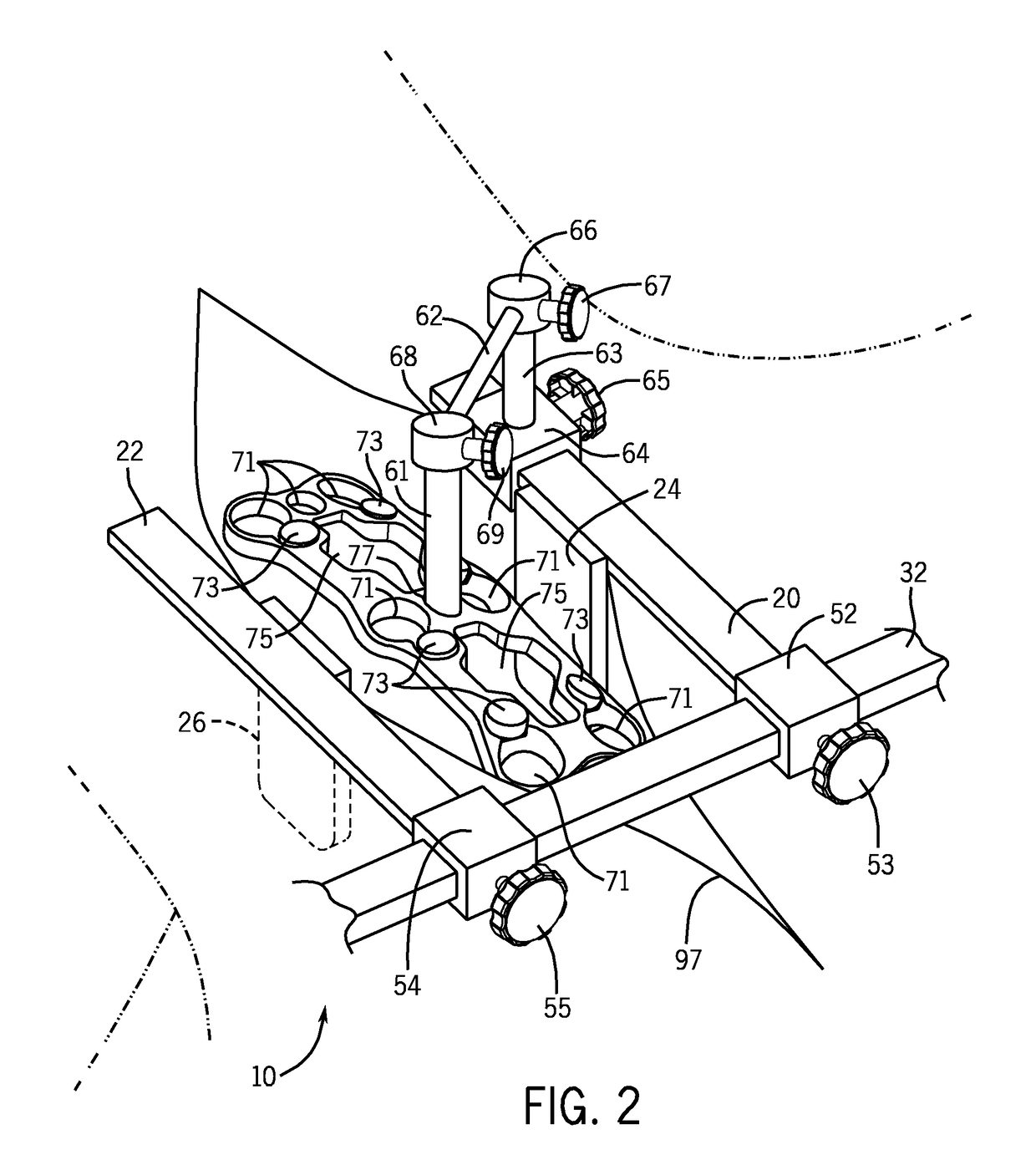

Anterior cervical retractor system

ActiveUS9615733B2Eliminates and minimizes displacementEliminates or minimizes tissue creep into the operative fieldInternal osteosythesisLaproscopesCervical spine surgeryEngineering

An orthopedic surgery system includes: a retractor support arm; a table mounting assembly for securing the retractor support arm to the operating table; a first blade mounting arm slidably engaging the retractor support arm; a second blade mounting arm slidably engaging the retractor support arm in spaced relationship with respect to the first blade mounting arm; a first retractor blade connected to the first blade mounting arm; a second retractor blade connected to the second blade mounting arm; and a plate support assembly for releasably engaging an orthopedic plate wherein the plate support assembly slidably engages at least one of the retractor support arm or the first blade mounting arm or the second blade mounting arm. In one version of the invention, the system used in anterior cervical spine surgery and the orthopedic plate is an anterior cervical plate.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

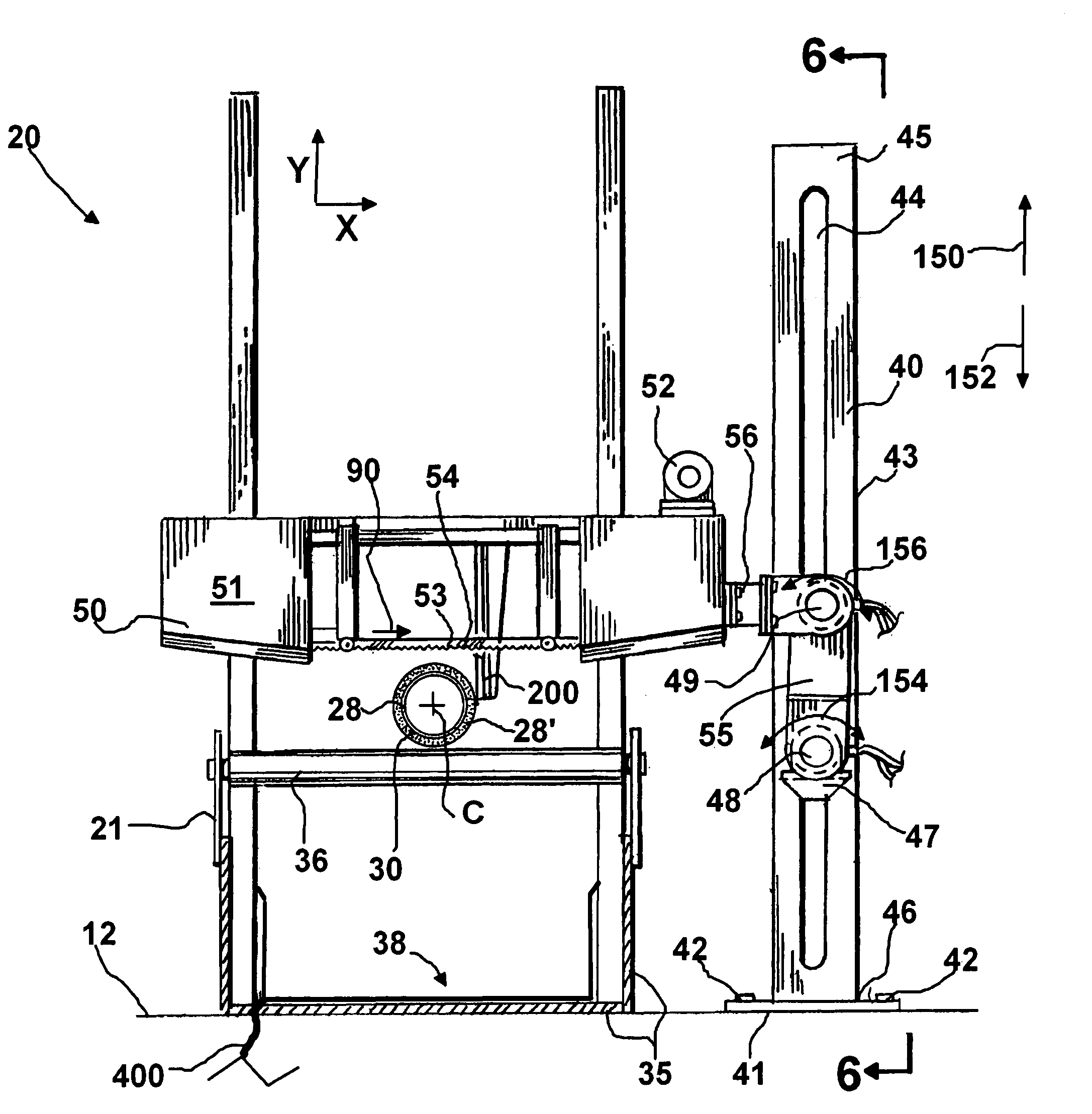

Articulating band saw and method

ActiveUS7645093B1Eliminate needImprove securityMetal sawing devicesPipe laying and repairDiamond wire sawActuator

An articulating band saw apparatus provides a frame that includes a vertically extending section having upper and lower end portions. An elevator moves between the upper and lower end portions of the frame. A first hydraulic actuator is supported on the elevator for movement therewith. A first arm provides arm end portions, the first arm supported by the first hydraulic actuator. An end of the first arm supporting a second hydraulic actuator that is spaced away from the first hydraulic actuator. The second hydraulic actuator supports a second arm. An endless band type saw is mounted on the free end of the second arm generally opposite the second actuator. The band saw is movable by articulation of the first and second actuators and resulting movement of the first and second arms. In one embodiment, the band saw is a diamond wire saw.

Owner:AES EOT EQUIP HLDG LLC +2

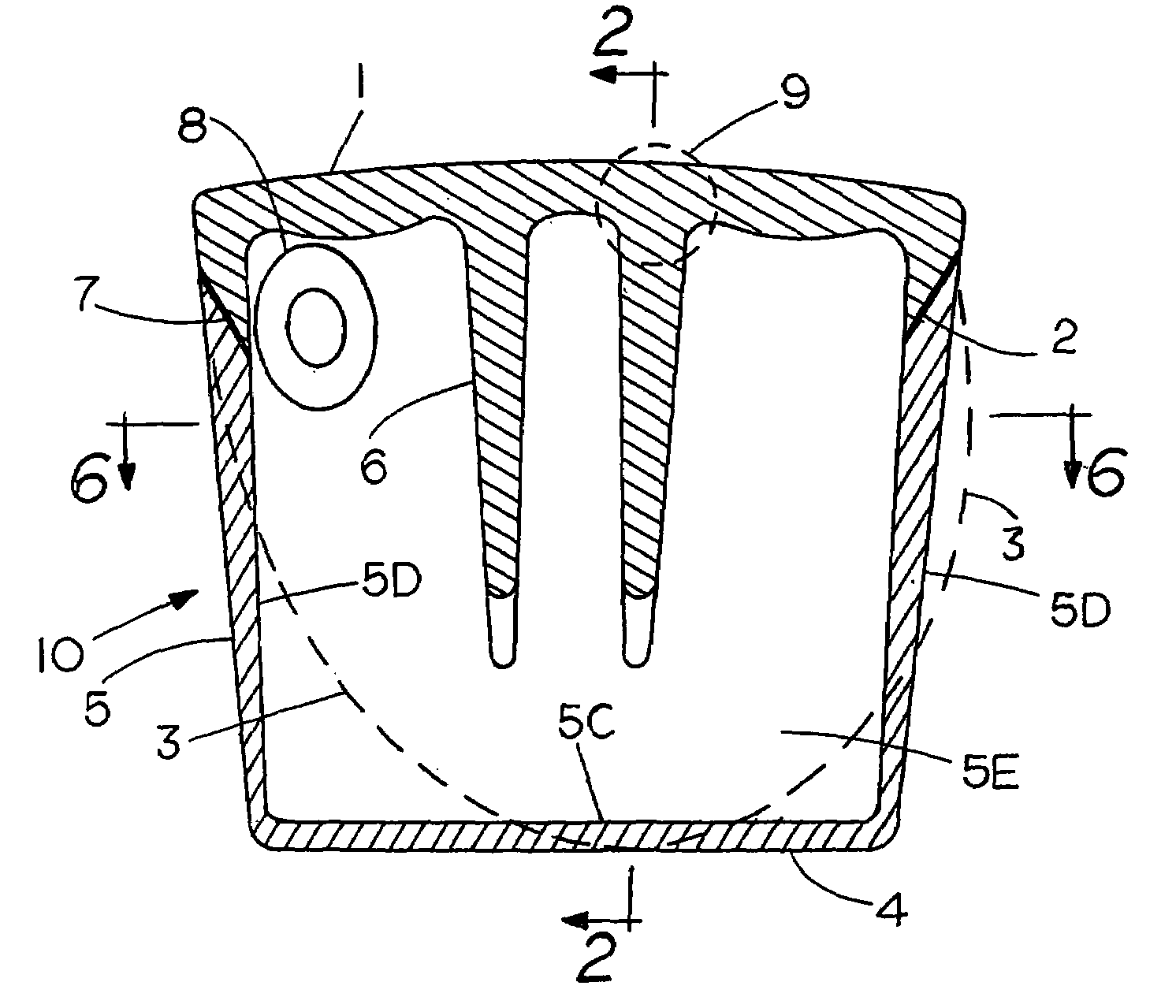

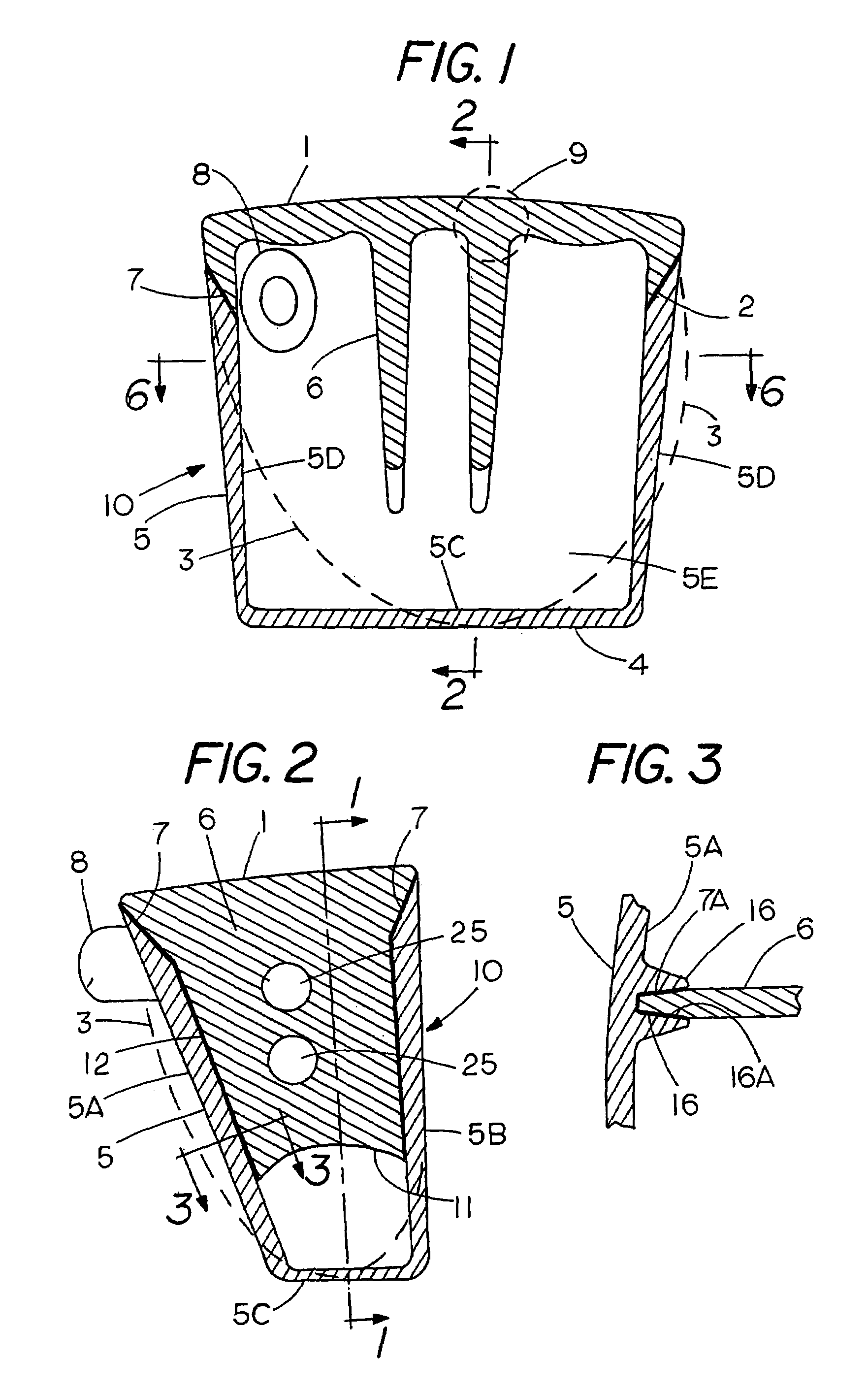

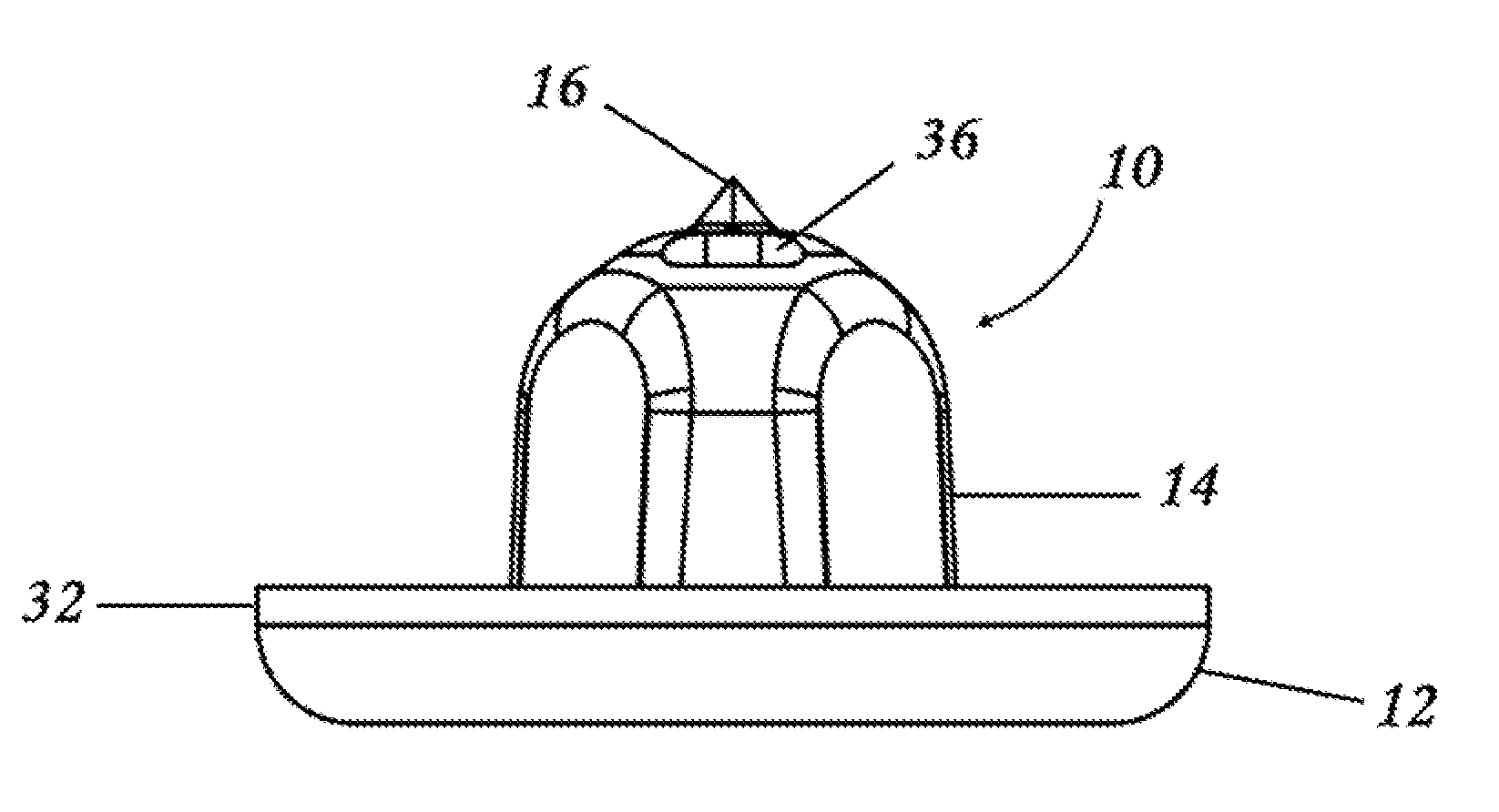

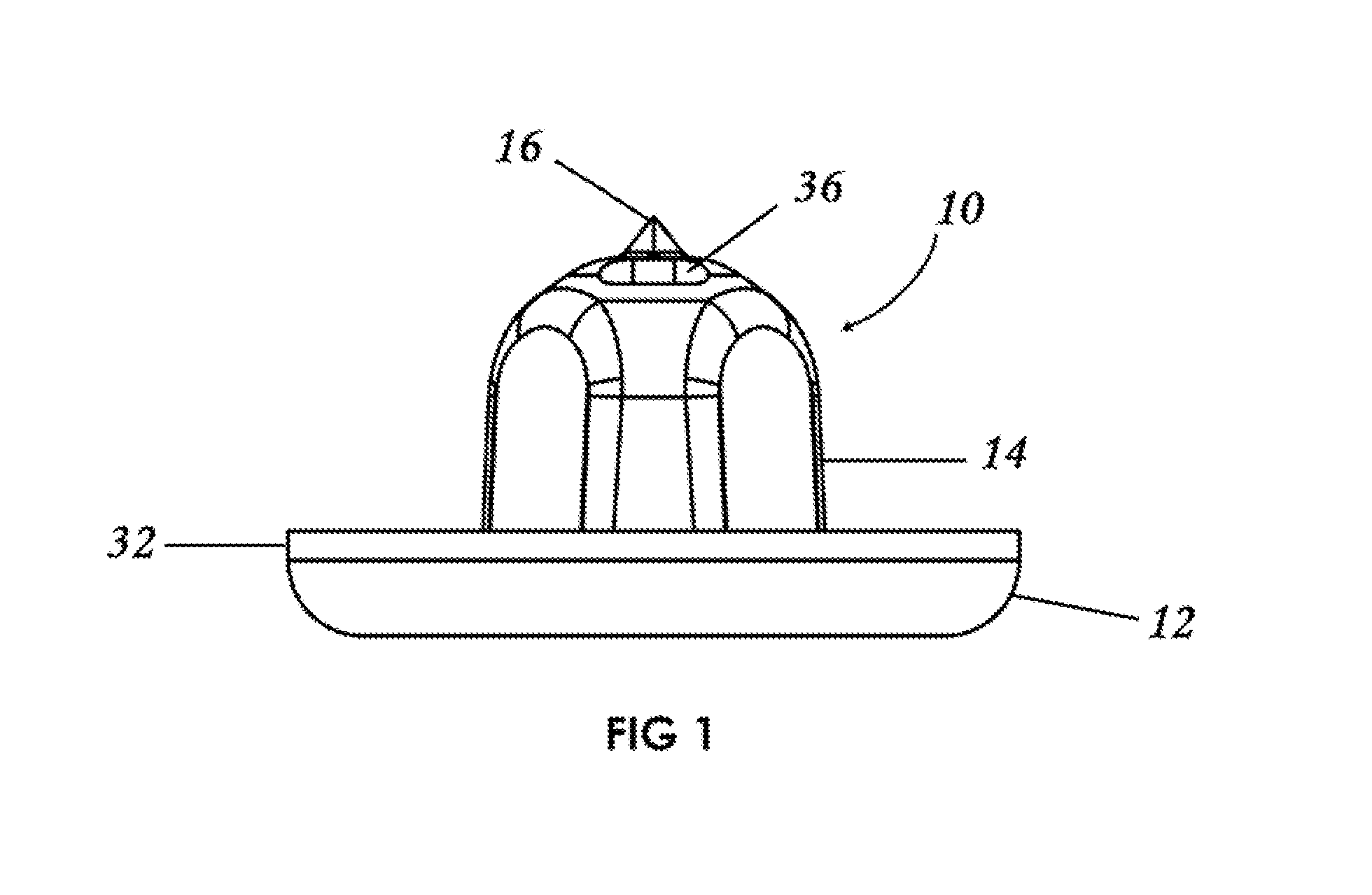

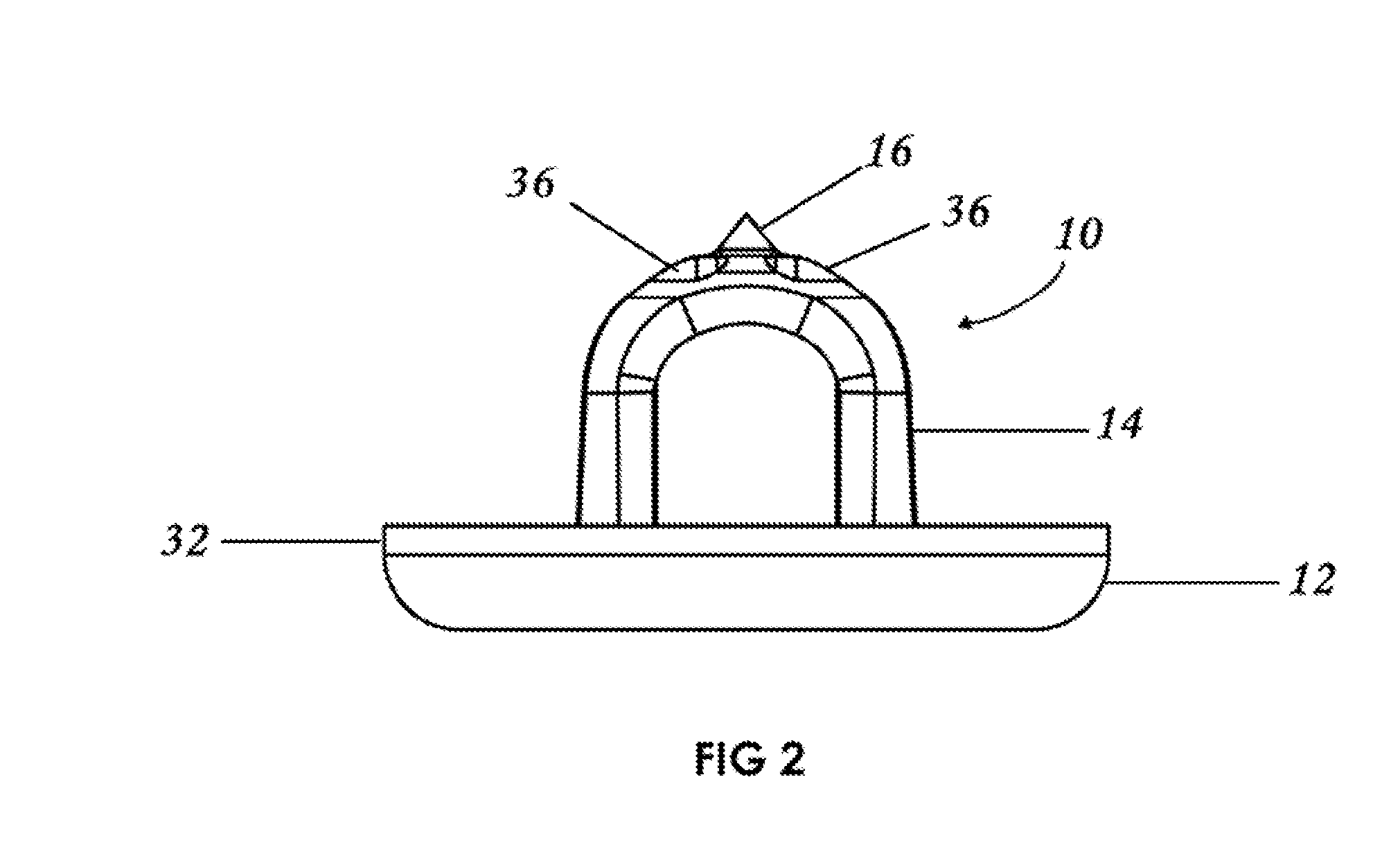

Plastic golf club head

A method of assembly of construction and assembly of golf club head parts used to manufacture golf club heads primarily composed of strong plastic materials that can be formed by injection plastic molding processes in a minimum of two parts. Draft is practical for both molded parts to simplify mold making. A preferred plastic is polycarbonate. Internal reinforcement elements are designed and arranged to provide structural features to facilitate assembly and improve strength of bonds. Internal reinforcement elements may be molded as separate parts to join with the face and shell structure. A hosel, which is not considered part of the shell and which may be made of plastic or metal, is bonded into the golf club head parts described.

Owner:ORIGIN INC

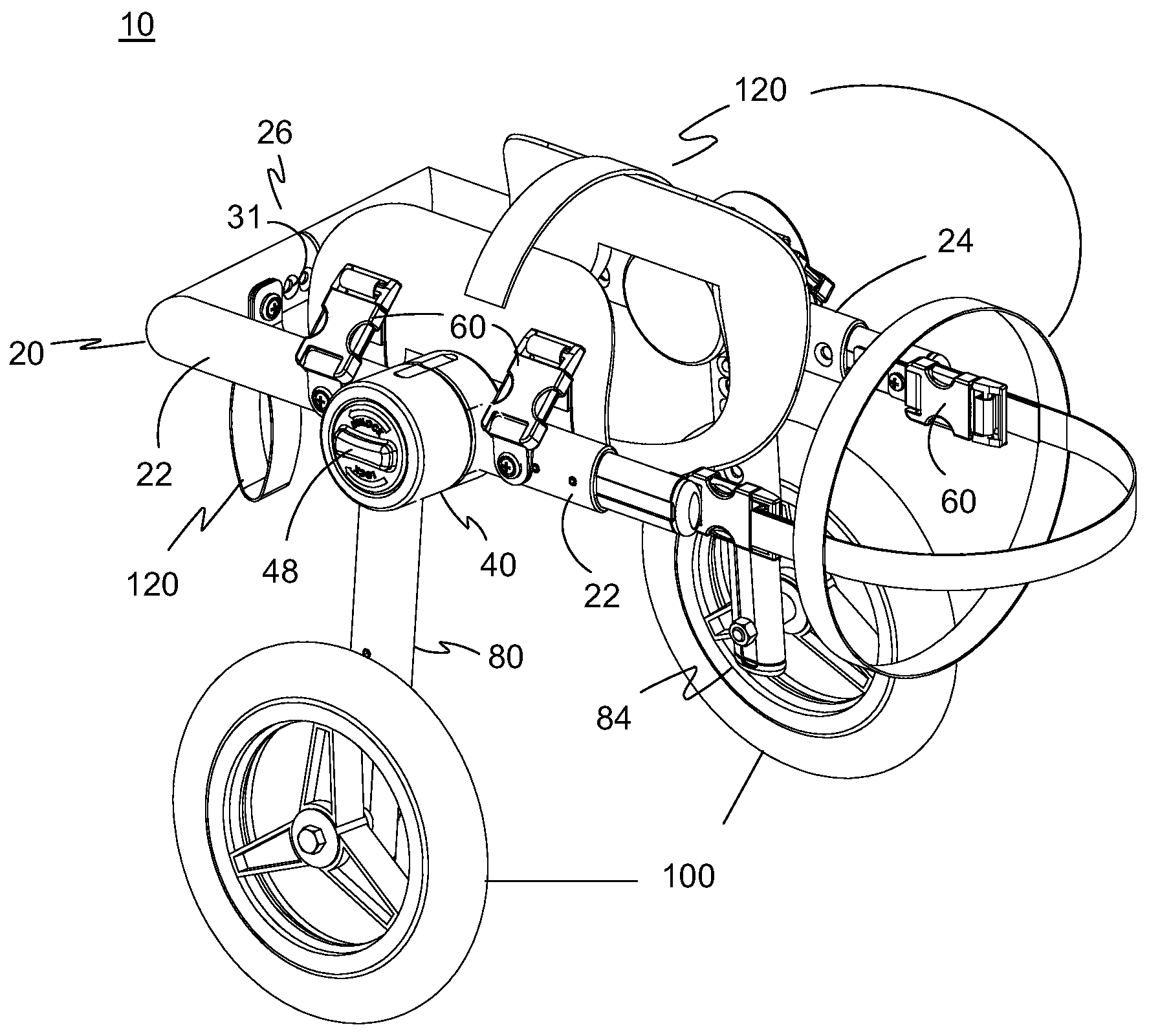

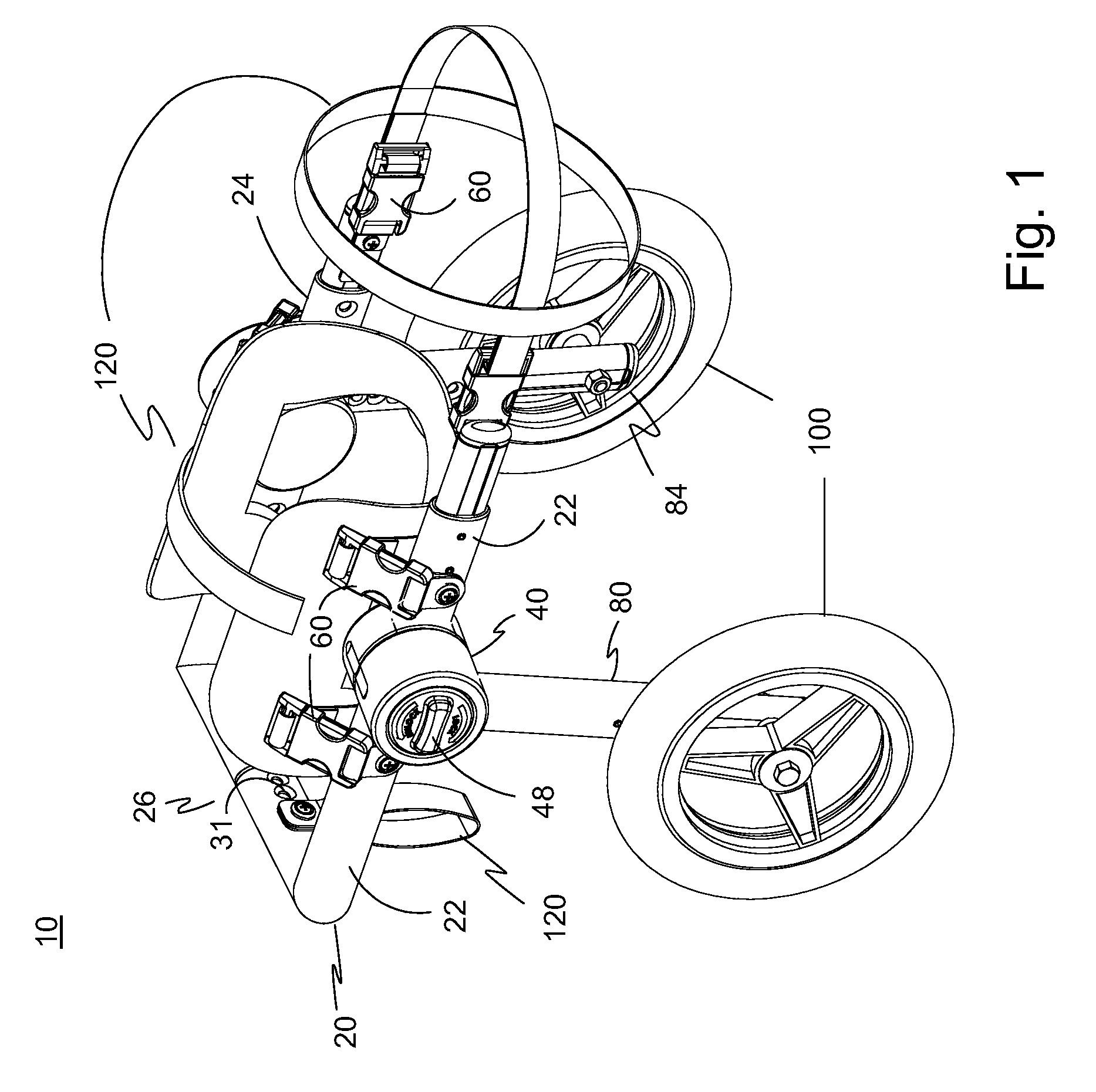

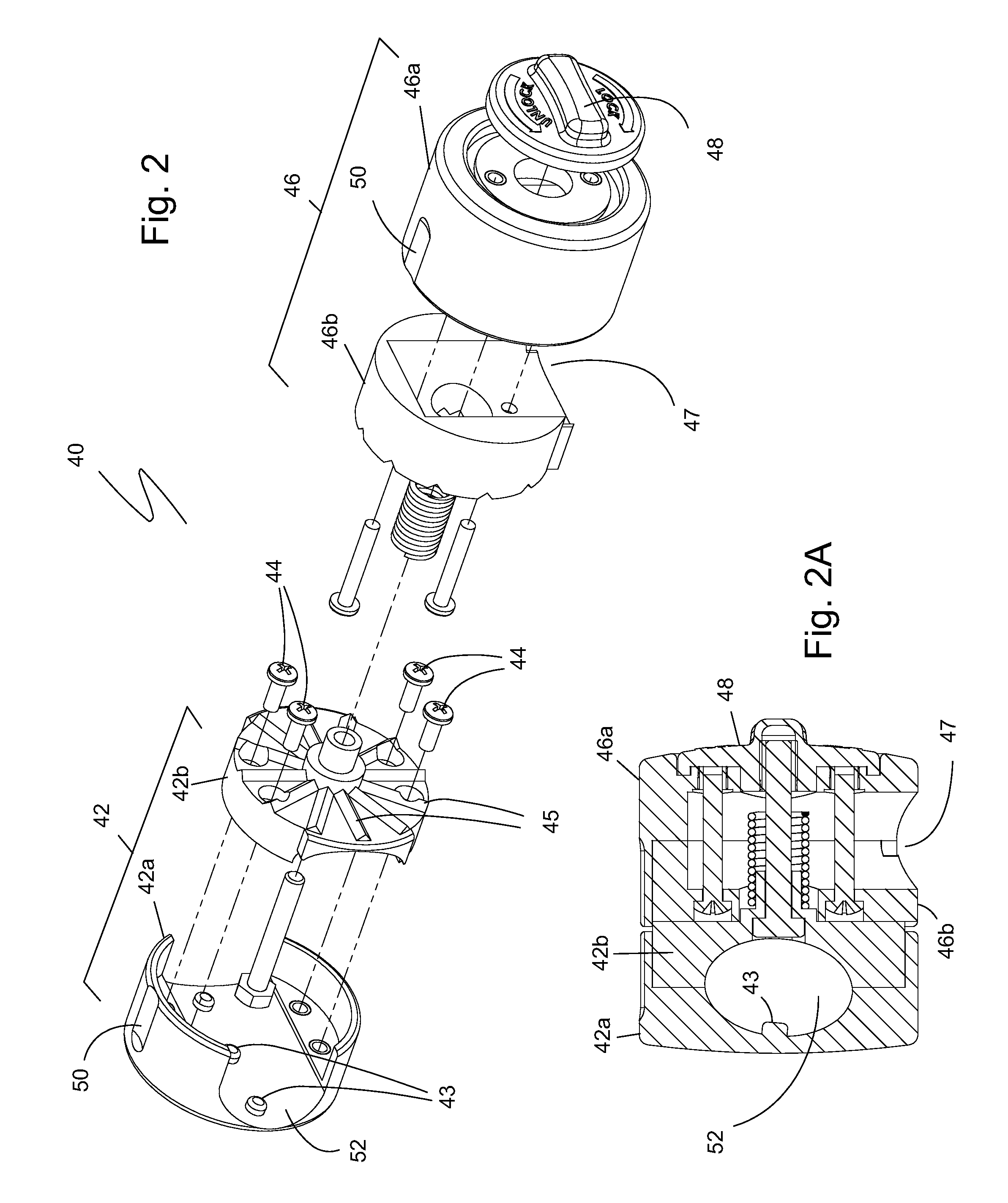

Adjustable wheelchair for pets

ActiveUS7549398B2Small sizeChoose accuratelyAnimal fetteringTaming and training devicesWheelchairEngineering

A wheelchair for animals includes a harness support frame having first and second lateral supports spaced from each other and a width extender adjustably connected between the first and second lateral supports, first and second knuckle clamp assemblies where each one of the first and second knuckle clamp assemblies has a first clamp component and a second clamp component, a plurality of harness connectors attached to the harness support frame, first and second leg assemblies where the second clamp components receives a leg assembly proximal end of one of the first and second leg assemblies, first and second wheels where each one of the first and second wheels is rotatably connected adjacent to a leg assembly distal end of one of the first and second leg assemblies, and a harness assembly detachably connected to the harness support frame. Each first clamp component has a lateral bore for receiving one of the first and second lateral supports therethrough and is positioned between a support frame proximal end and a support frame distal end. Each second clamp component has a clamp recess that receives the leg assembly proximal end and is rotatably and adjustably connected to the corresponding first clamp component.

Owner:WALKIN PETS INC

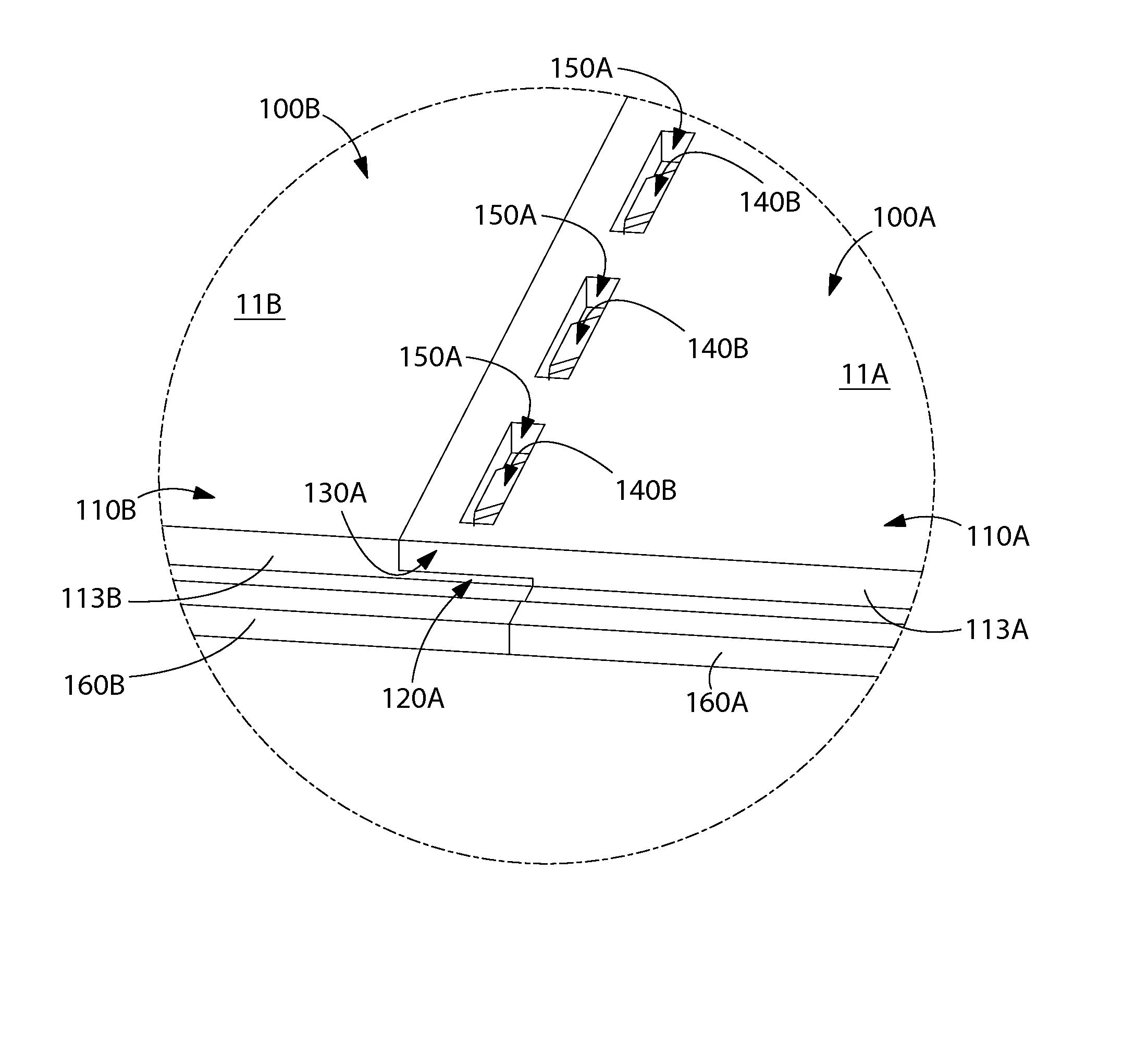

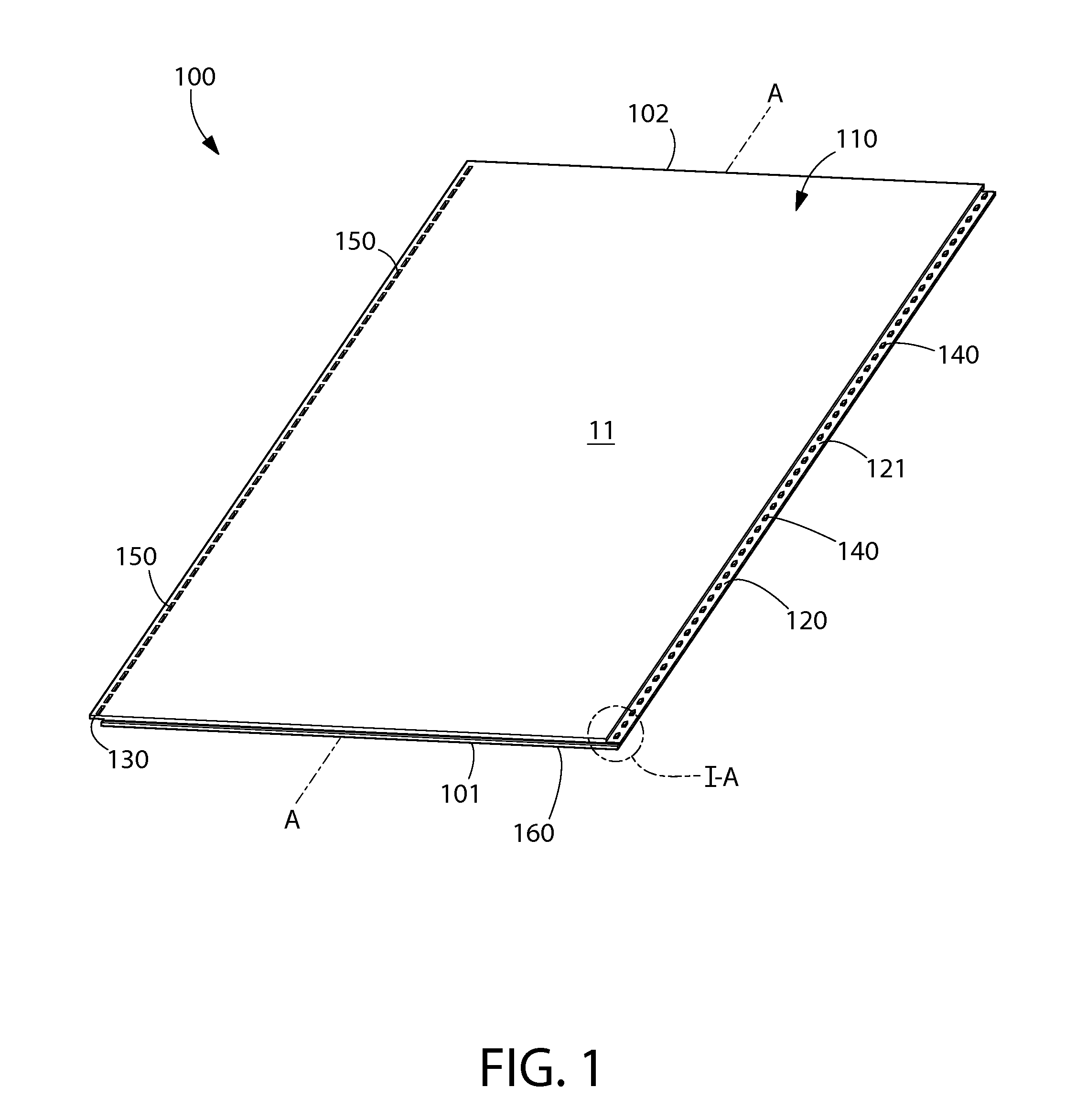

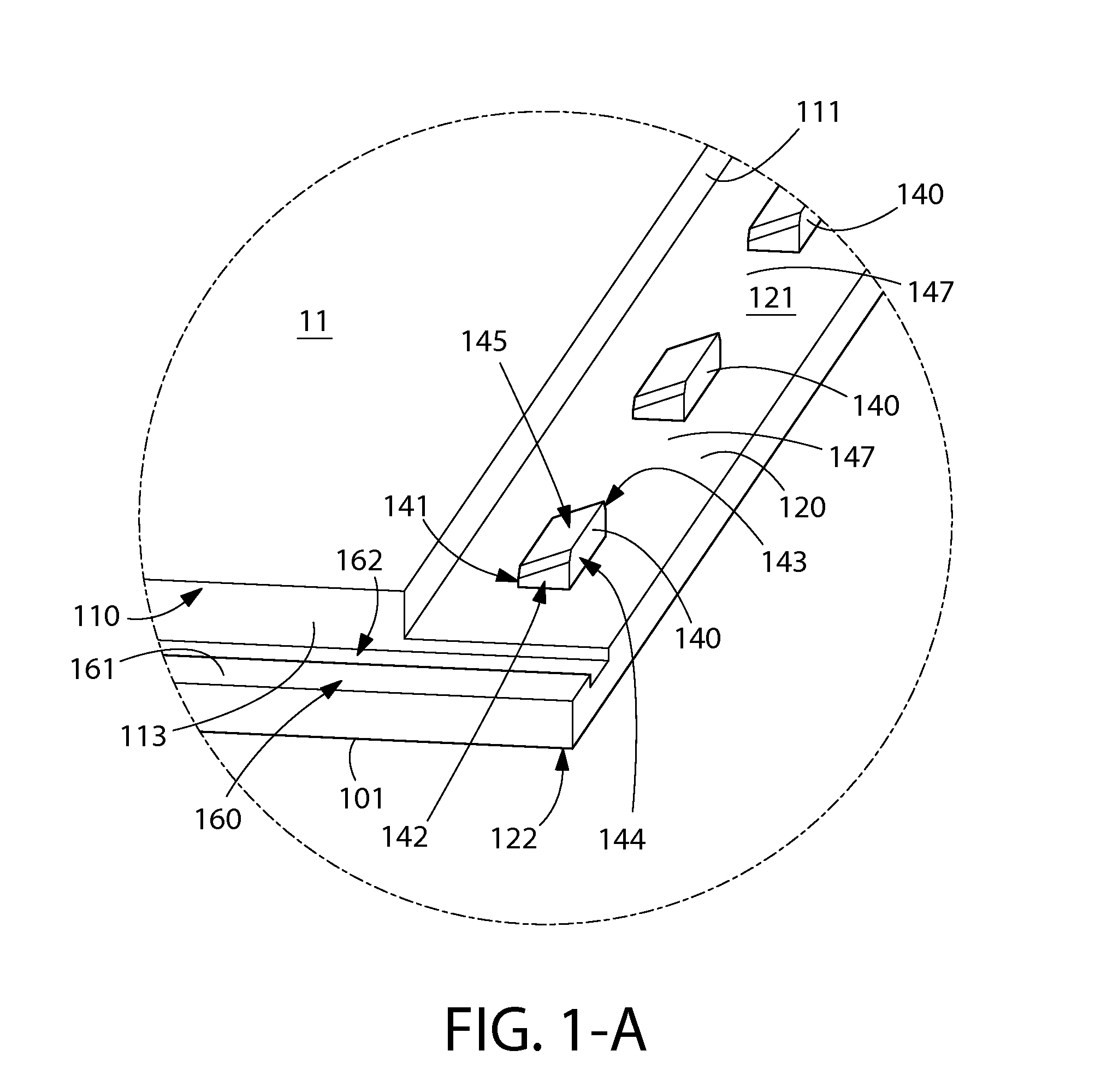

Floating floor system, floor panel, and installation method for the same

InactiveUS9540825B2Minimize and eliminate needSimplify the installation processCovering/liningsFlooringEngineeringUltimate tensile strength

A floating floor system and a floor panel and method for use with the same that includes an improved mechanical interlock system. The mechanical interlock system allows laterally adjacent floor panels that are mechanically interlocked to slide relative to one another a predetermined distance in a longitudinal direction, while prohibiting relative translation in the vertical and transverse directions. In one embodiment, the predetermined distance eliminates the need for precision cuts during installation, thereby making installation fast and easy. In a further embodiment, the invention optimizes the floor panels (and floating floor system.) to balance ease of installation and horizontal locking strength between laterally adjacent floor panels.

Owner:AFI LICENSING

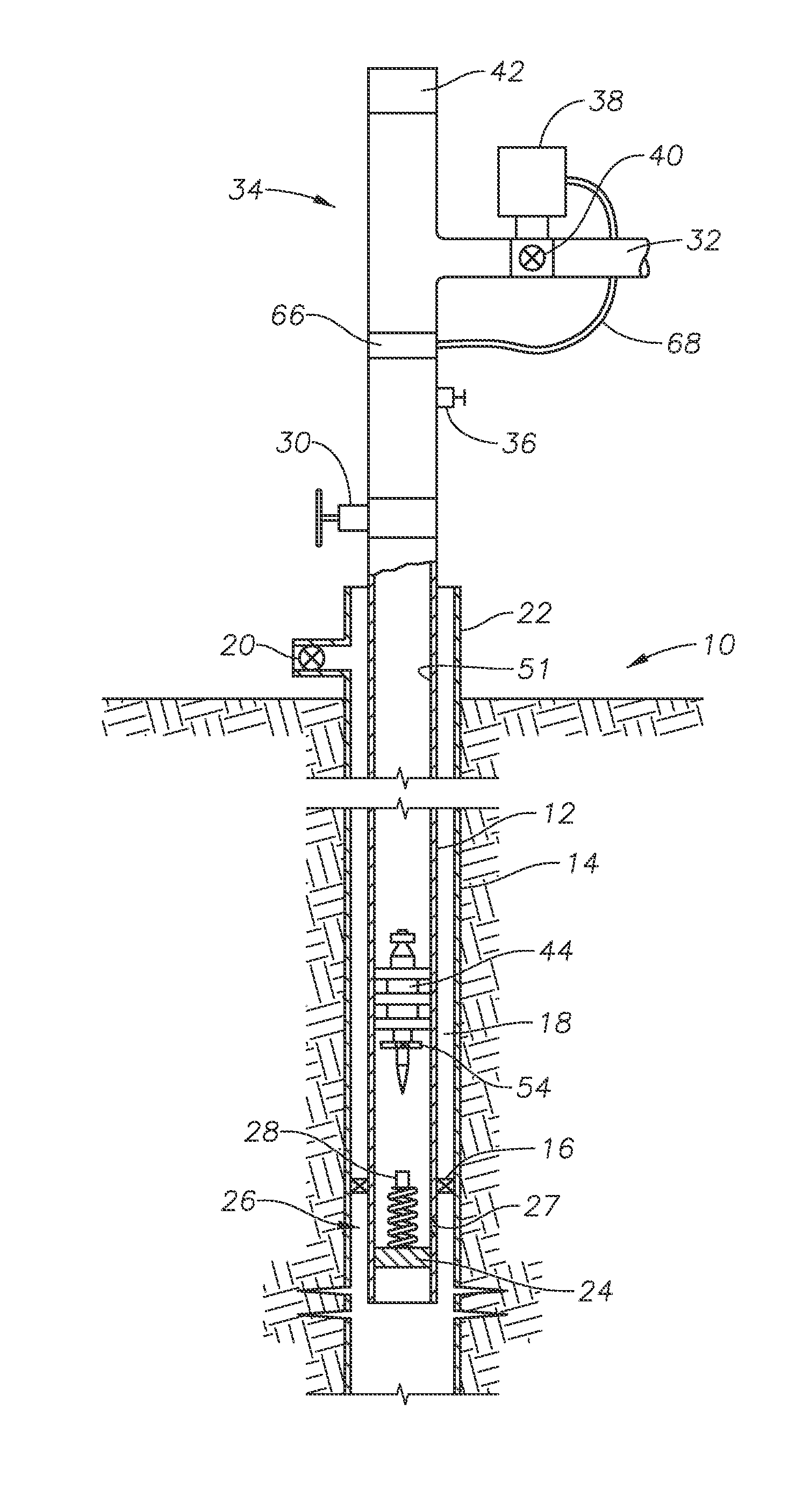

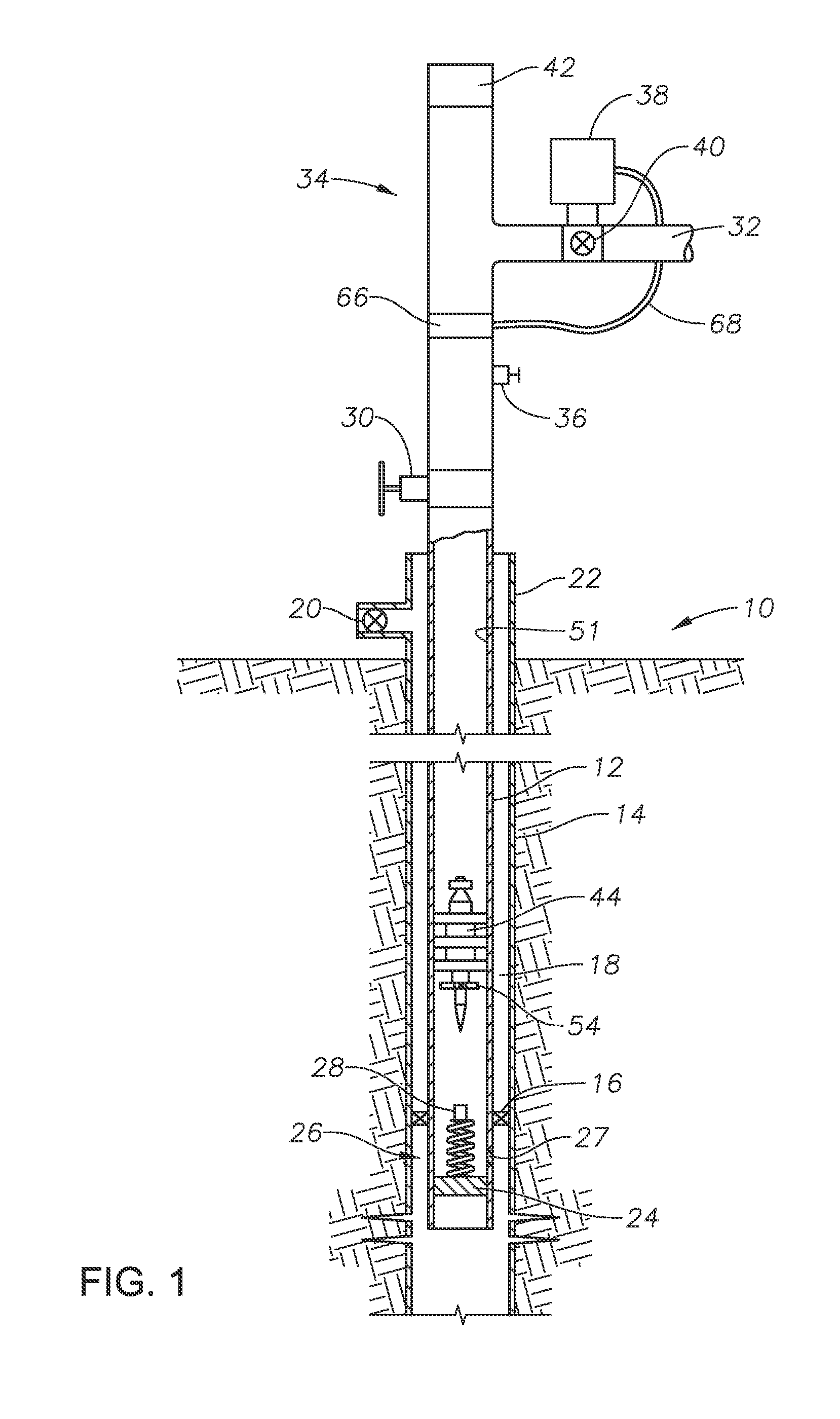

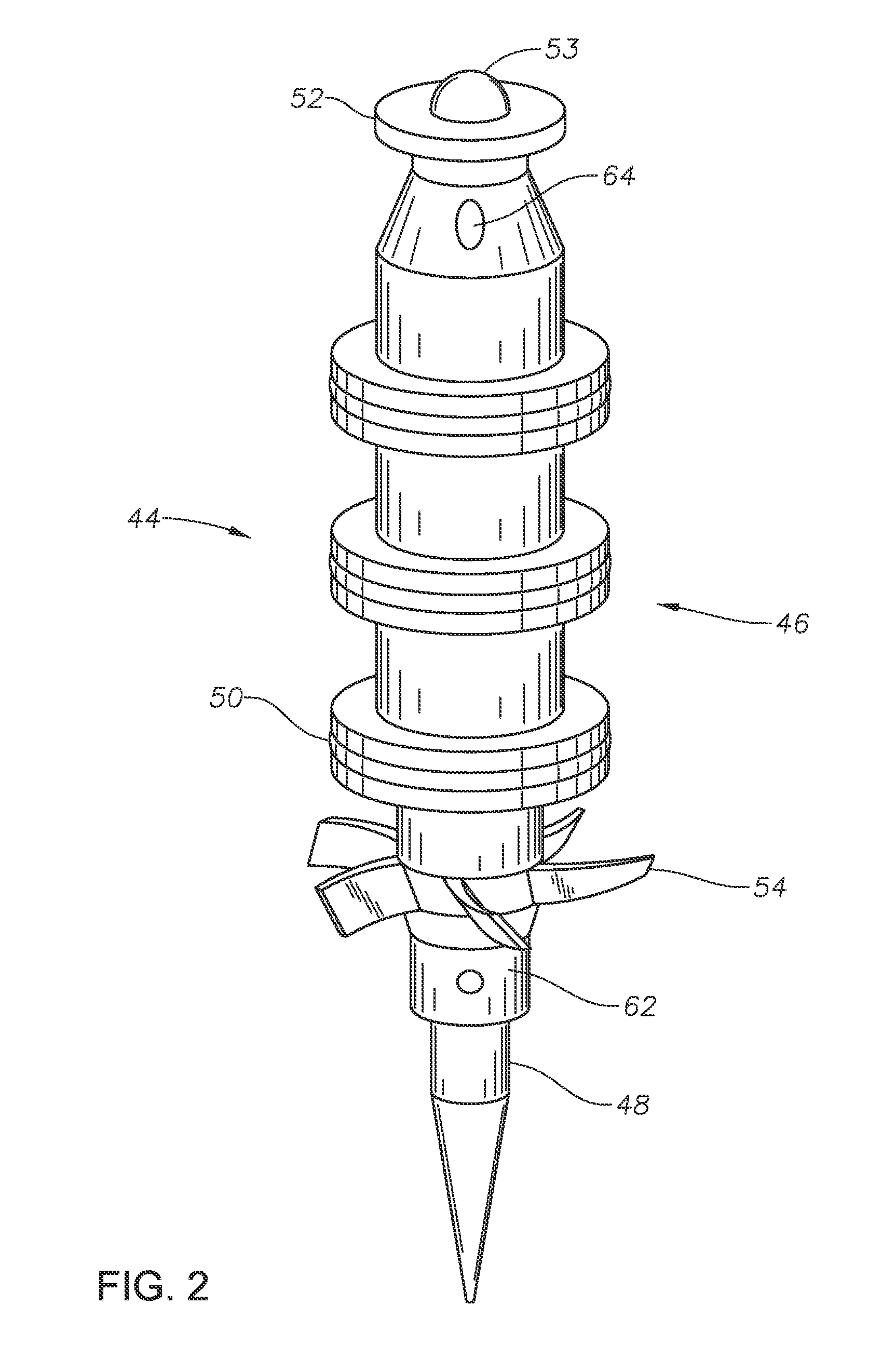

Downhole fluid transport plunger with thruster

A method for lifting fluids within a subterranean well includes lowering an elongated plunger to a lower region of a bore of the subterranean well. The plunger includes a motor assembly operably connected to a propeller. A seal can be created between the plunger and an inner surface of the bore of the subterranean well. A thruster, such as motor assembly connected to a propeller, generates thrust to lift the plunger to a plunger retainer located proximate to a wellhead of the subterranean well.

Owner:SAUDI ARABIAN OIL CO

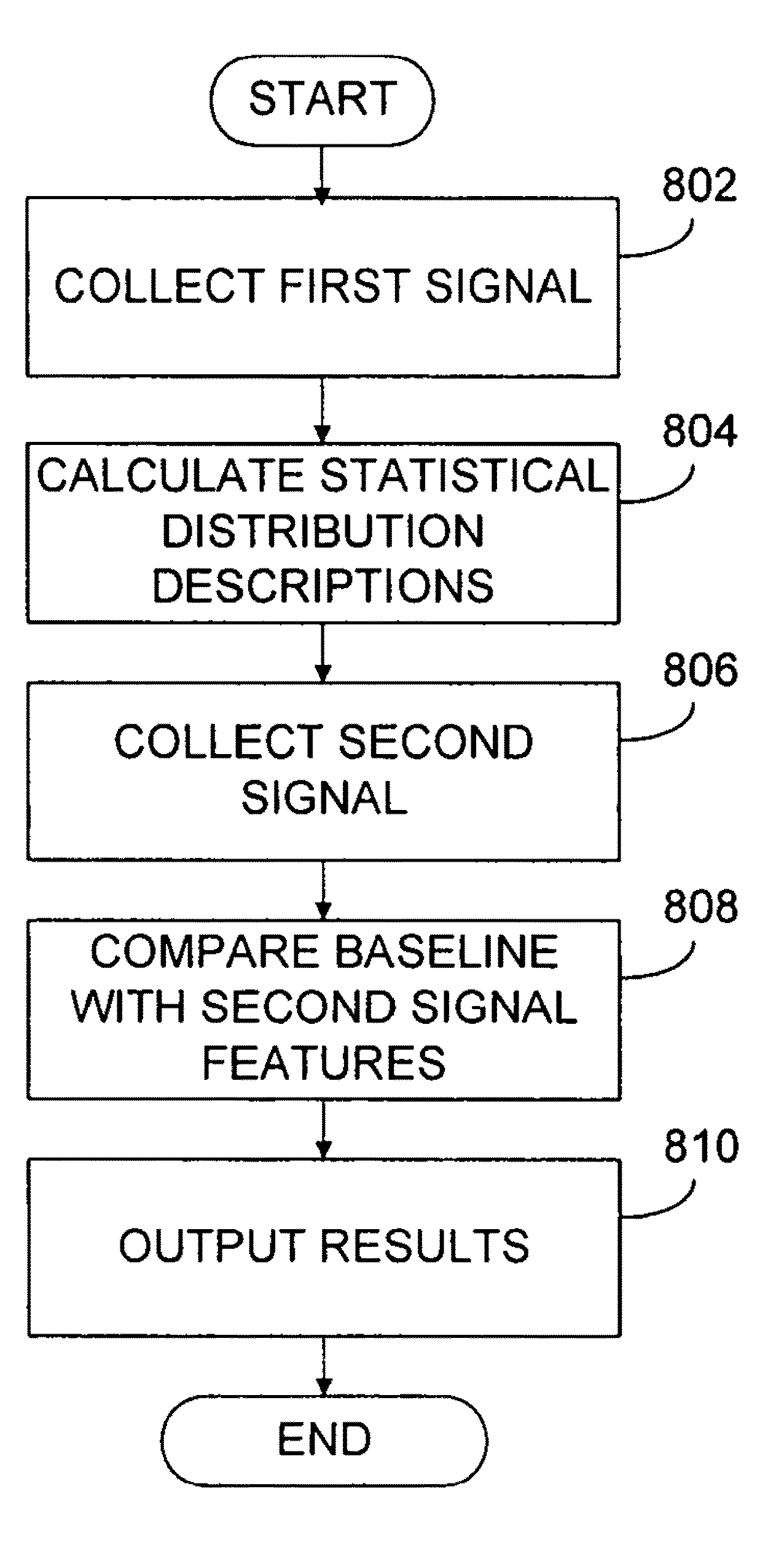

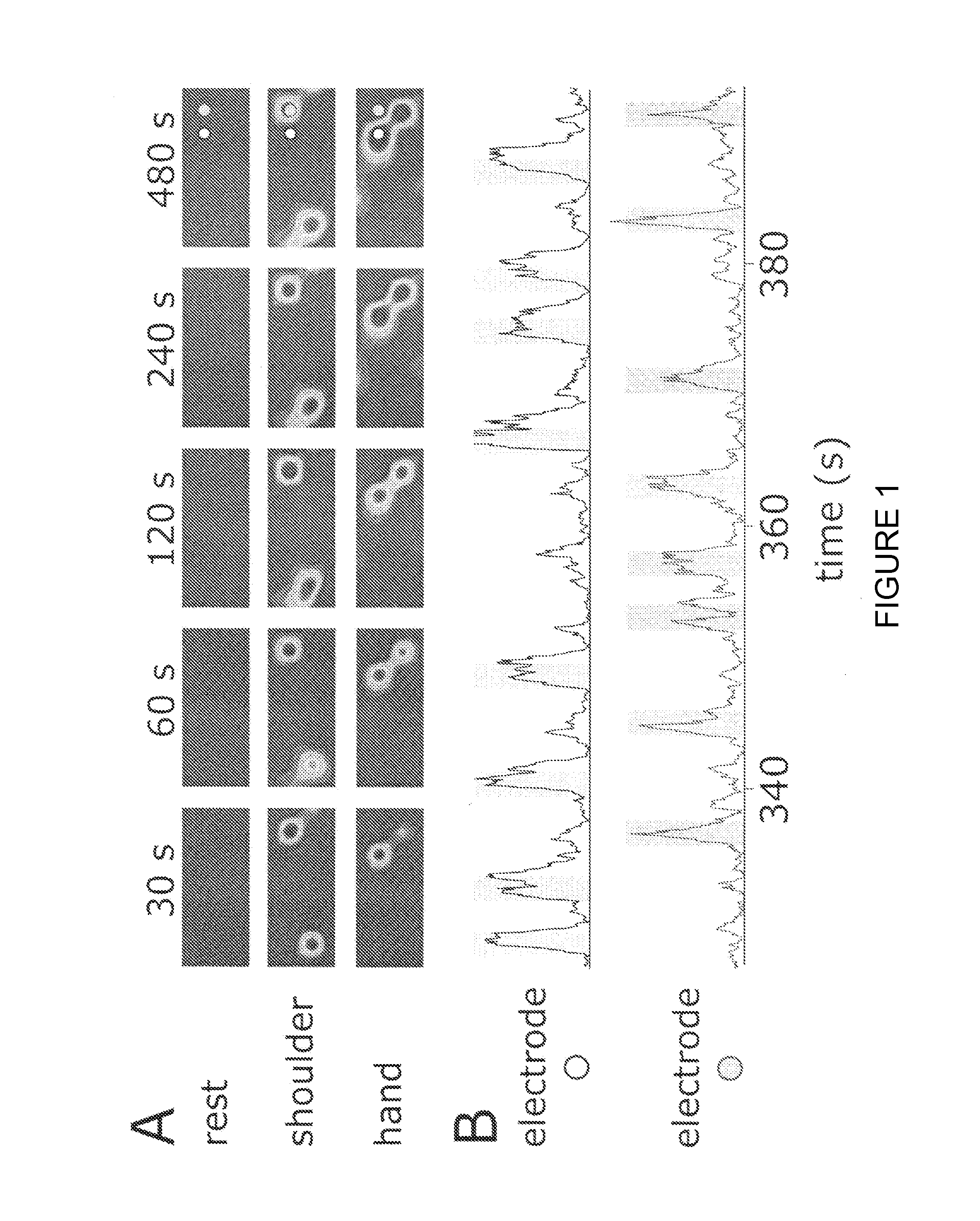

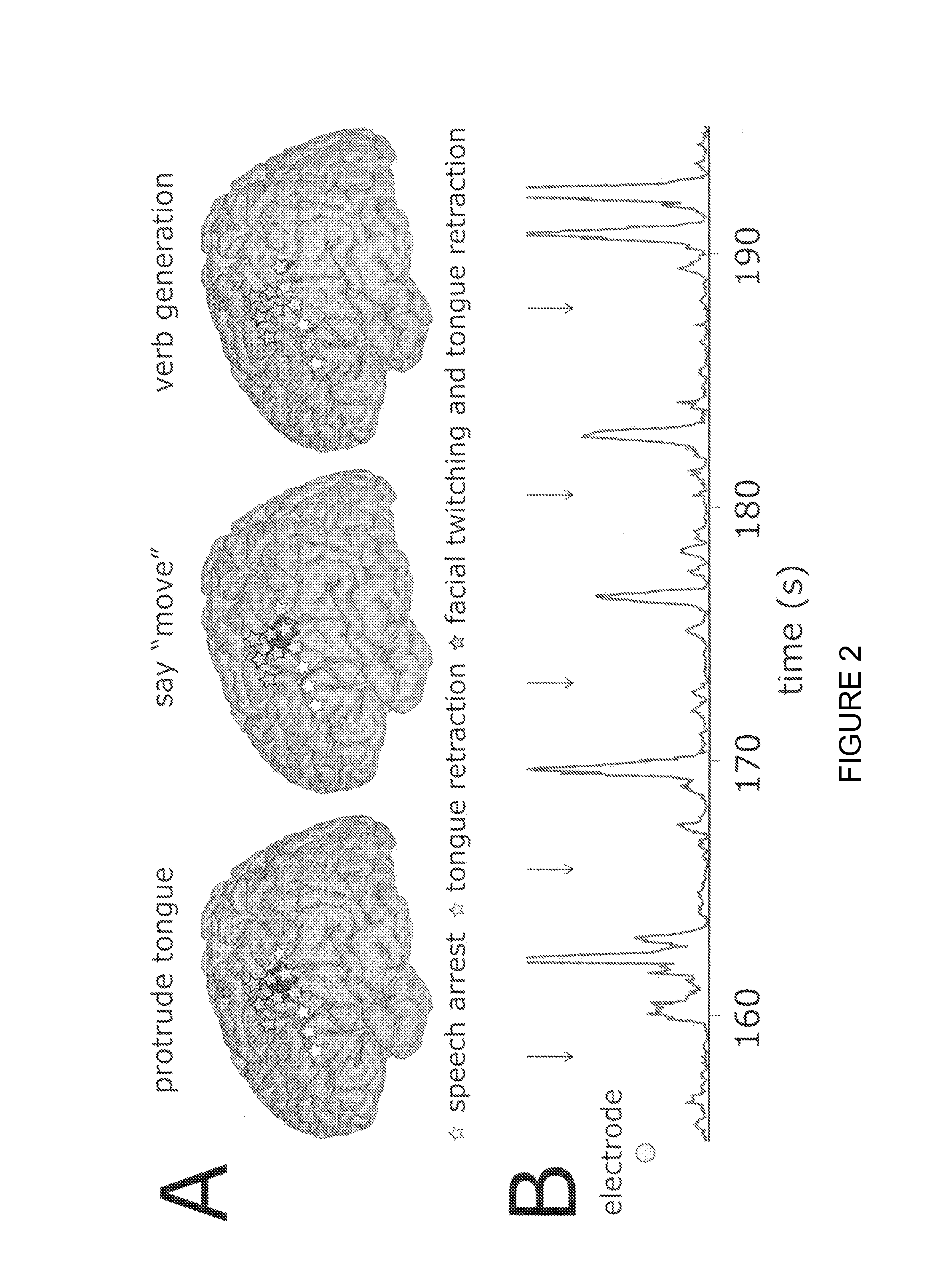

Method for analyzing function of the brain and other complex systems

ActiveUS8532756B2Minimize and eliminate needElectroencephalographyElectro-oculographyEngineeringRetrospective analysis

Owner:HEALTH RES INC +1

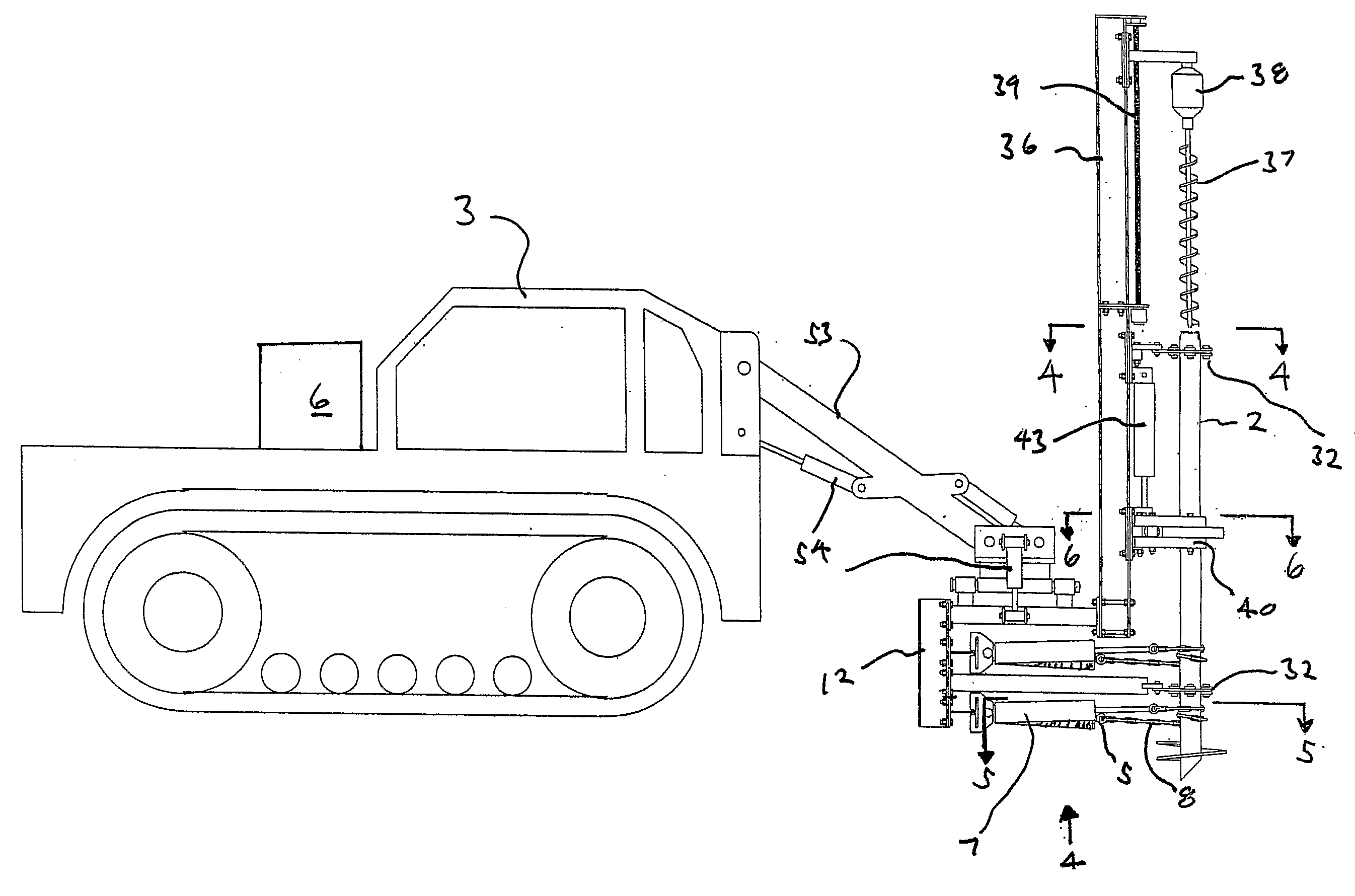

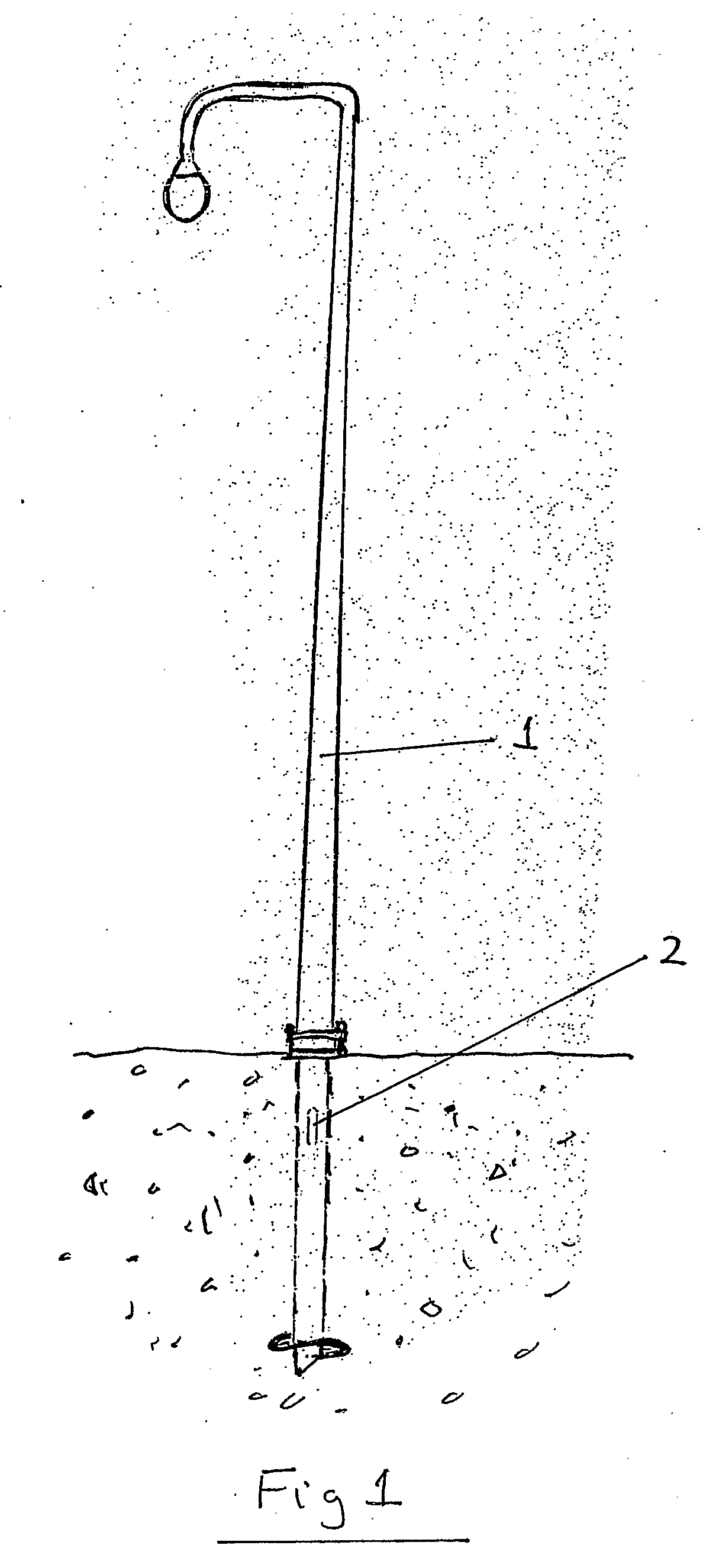

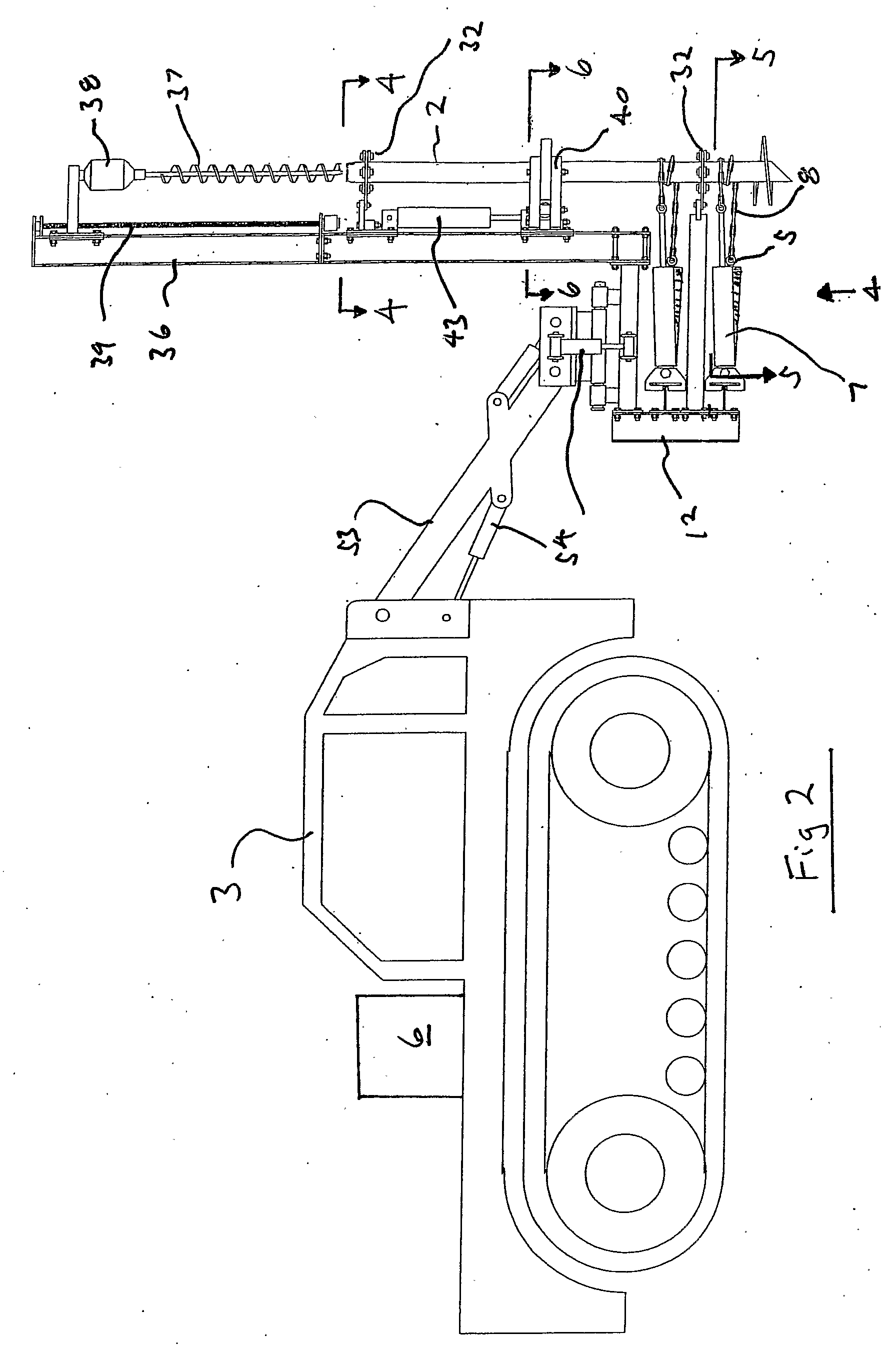

Method and apparatus for installing a helical pile

An apparatus and a method to assist in the installation of a helical pile. The apparatus comprises a drive mechanism having an engaged and a disengaged configuration. When in its engaged configuration the drive mechanism operatively grips the exterior surface of the helical pile. When in its disengaged configuration the drive mechanism operatively releases the exterior surface of the helical pile. Movement of the drive mechanism when in its engaged configuration causes rotational movement of the pile. When in its disengaged configuration the drive mechanism moves without rotation of the pile.

Owner:NIMENS JOSEPH R E

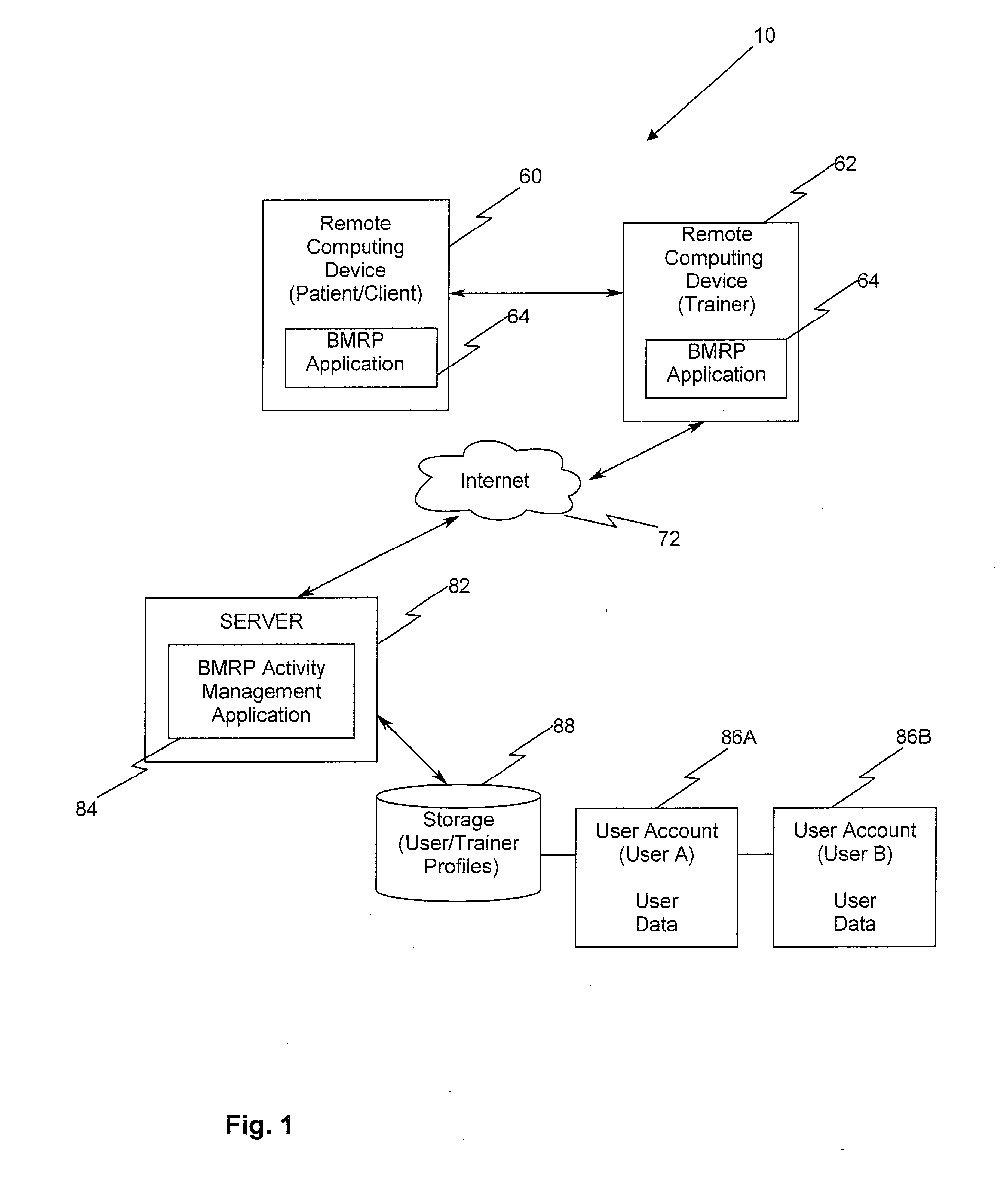

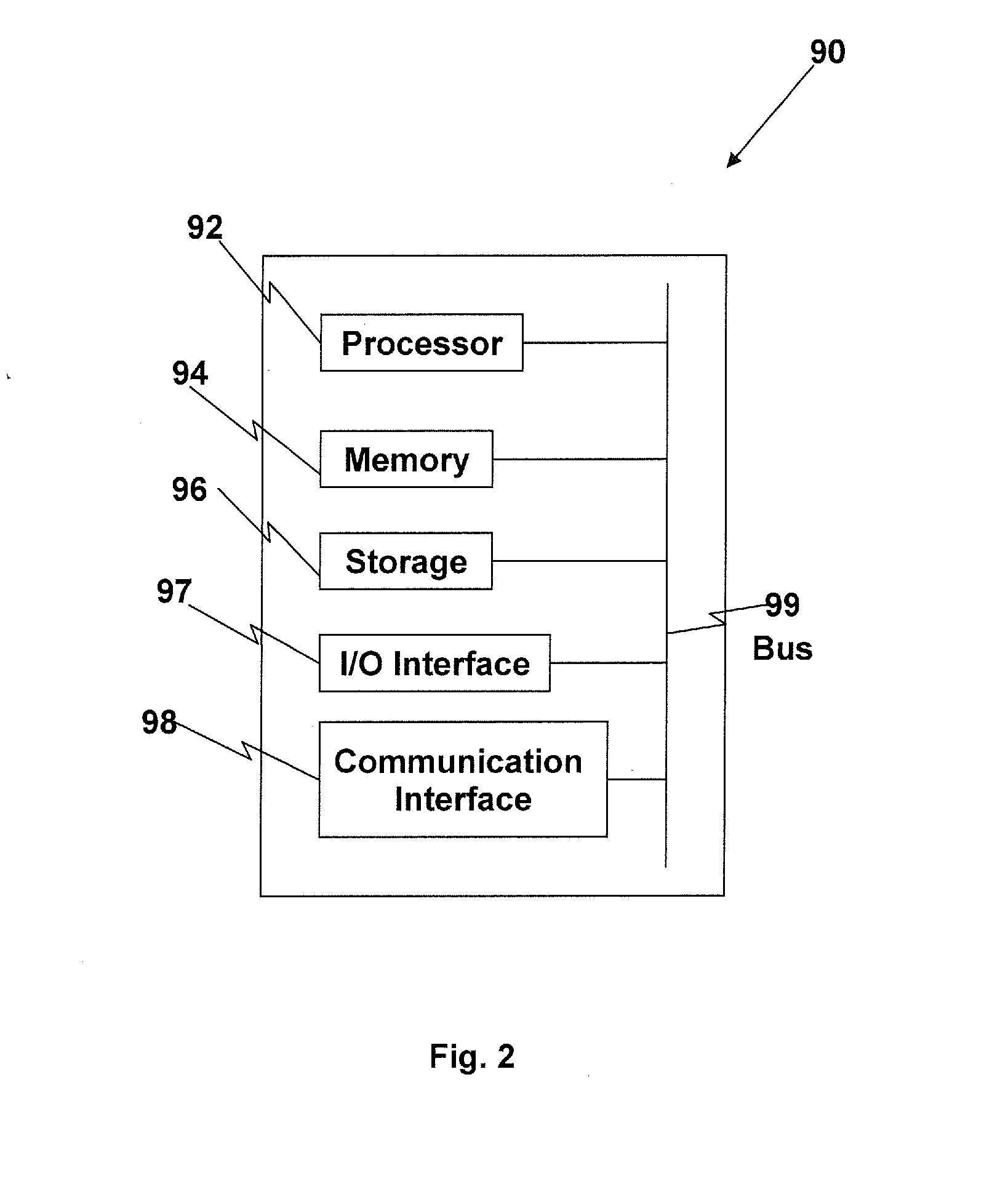

Mobile Platform Designed For Hosting Brain Rehabilitation Therapy And Cognitive Enhancement Sessions

InactiveUS20140330576A1Restore patient learningRestore reasoningData processing applicationsTelemedicineGuidelineInformation resource

A mobile platform allows trainers to host online brain rehabilitation and cognitive enhancement sessions with clients. The sessions can be individually tailored or chosen from a plethora of prepared sessions. The trainer / evaluator uses real time questionnaires to evaluate the status of the patient prior to preparing the training session. They can also view the results and performance of the patient in real time or at any time after the session has been completed. The mobile platform is designed to facilitate the creation and growth of a community of users by facilitating communication and interactivity between the users upon the satisfactory completion of a battery of tests and evaluations. The mobile platform serves as an information resource for trainers and clients by incorporating a set of algorithms, rules, and guidelines regarding the administration of brain rehabilitation and cognitive enhancement sessions. This aids both trainers and clients participating in the sessions.

Owner:BAUER JAMES DEAN

Visualizing ablation cannula

ActiveUS20050182293A1Prevent slippingRelieve low back painEndoscopesLaproscopesSurgical departmentTarget tissue

A medical needle set for visualized tissue ablation within a subject's body includes a cannula and components configured for inclusion in the cannula, including a trocar for occlusion of the cannula lumen during needle placement, and a visualizing ablation probe used for simultaneous endoscopic viewing and ablation of tissue sites with a laser beam. The cannula can include a tissue-gripping surface for stabilization of the needle set on the target tissue. A surgical system for tissue ablation includes a visualizing ablation needle set operably connected to an endoscope and a laser. A surgical procedure using this system permits simultaneous visualization and ablation of tissues, including those of the facet joints of the spine.

Owner:ARDENT MEDICAL CORP

Plastic golf club head

A method of assembly of construction and assembly of golf club head parts used to manufacture golf club heads primarily composed of strong plastic materials that can be formed by injection plastic molding processes in a minimum of two parts. Draft is practical for both molded parts to simplify mold making. A preferred plastic is polycarbonate. Internal reinforcement elements are designed and arranged to provide structural features to facilitate assembly and improve strength of bonds. Internal reinforcement elements may be molded as separate parts to join with the face and shell structure. A hosel, which is not considered part of the shell and which may be made of plastic or metal, is bonded into the golf club head parts described.

Owner:ORIGIN INC

Controllable Rate Turbulating Nozzle

ActiveUS20150101595A1Accurate doseReduce reboundRespiratorsLiquid surface applicatorsInlet channelEngineering

A piercing device for use in internally pierced blister delivery devices include a base, a piercer body and an internal fluid path. The internal fluid path includes one or more inlet channels into a central cavity which is connected to one or more delivery channels and exit ports. The cavity is defined by angular walls and top to create turbulence in the fluid flow and to produce a controllable spray, mist, drops, plume or stream delivery. The piercer body also provides a pointed lancet disposed in the center of the exit ports for piercing the lidstock of a formed blister.

Owner:MYSTIC PHARMA INC

Articulating band saw and method

ActiveUS20110138983A1Minimize useReduce and eliminate heat generateMetal sawing devicesPipe laying and repairDiamond wire sawActuator

An articulating band saw apparatus provides a frame that includes a vertically extending section having upper and lower end portions. An elevator moves between the upper and lower end portions of the frame. A first hydraulic actuator is supported on the elevator for movement therewith. A first arm provides arm end portions, the first arm supported by the first hydraulic actuator. An end of the first arm supporting a second hydraulic actuator that is spaced away from the first hydraulic actuator. The second hydraulic actuator supports a second arm. An endless band type saw is mounted on the free end of the second arm generally opposite the second actuator. The band saw is movable by articulation of the first and second actuators and resulting movement of the first and second arms. In one embodiment, the band saw is a diamond wire saw.

Owner:AES EOT EQUIP HLDG LLC

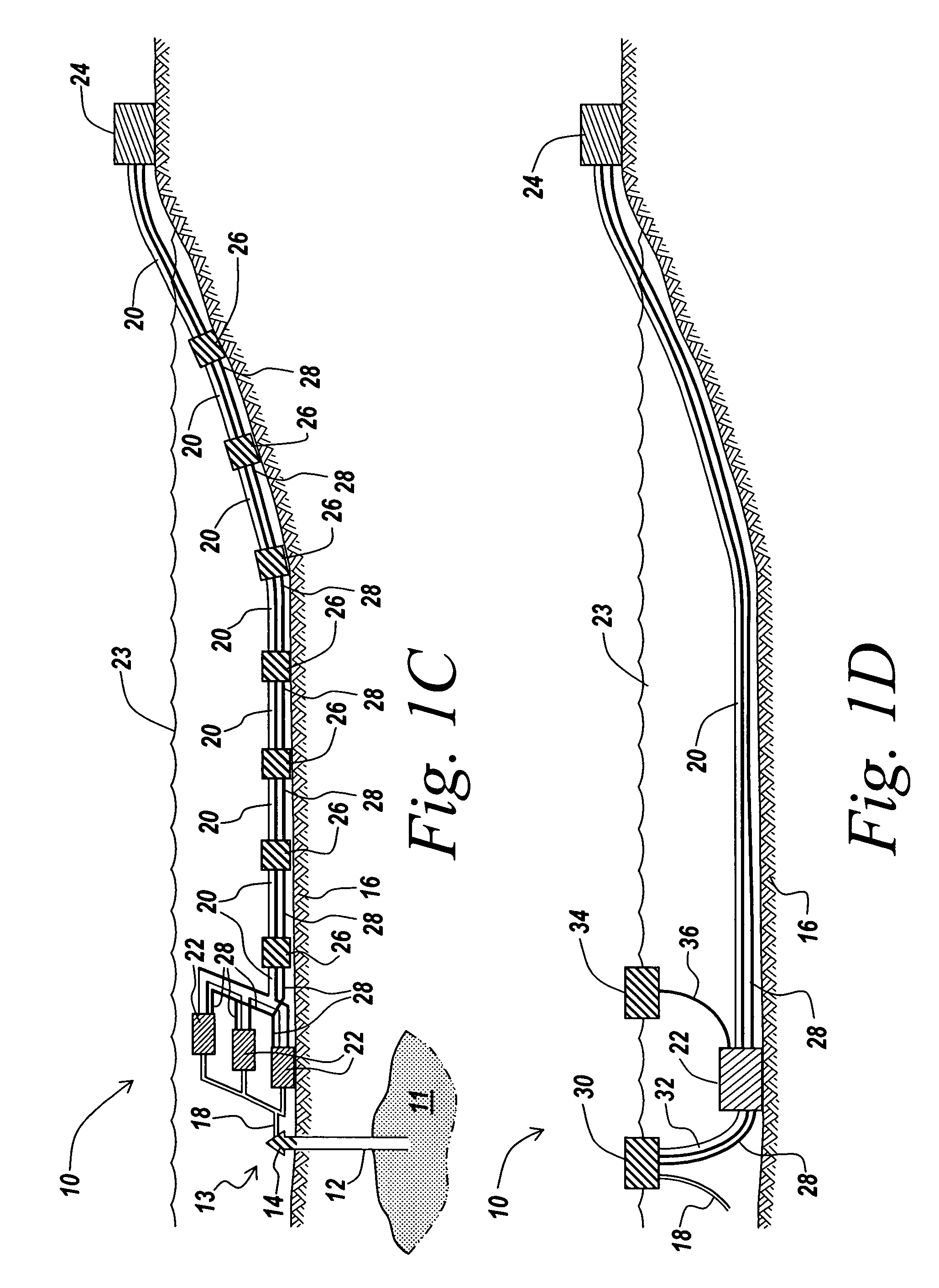

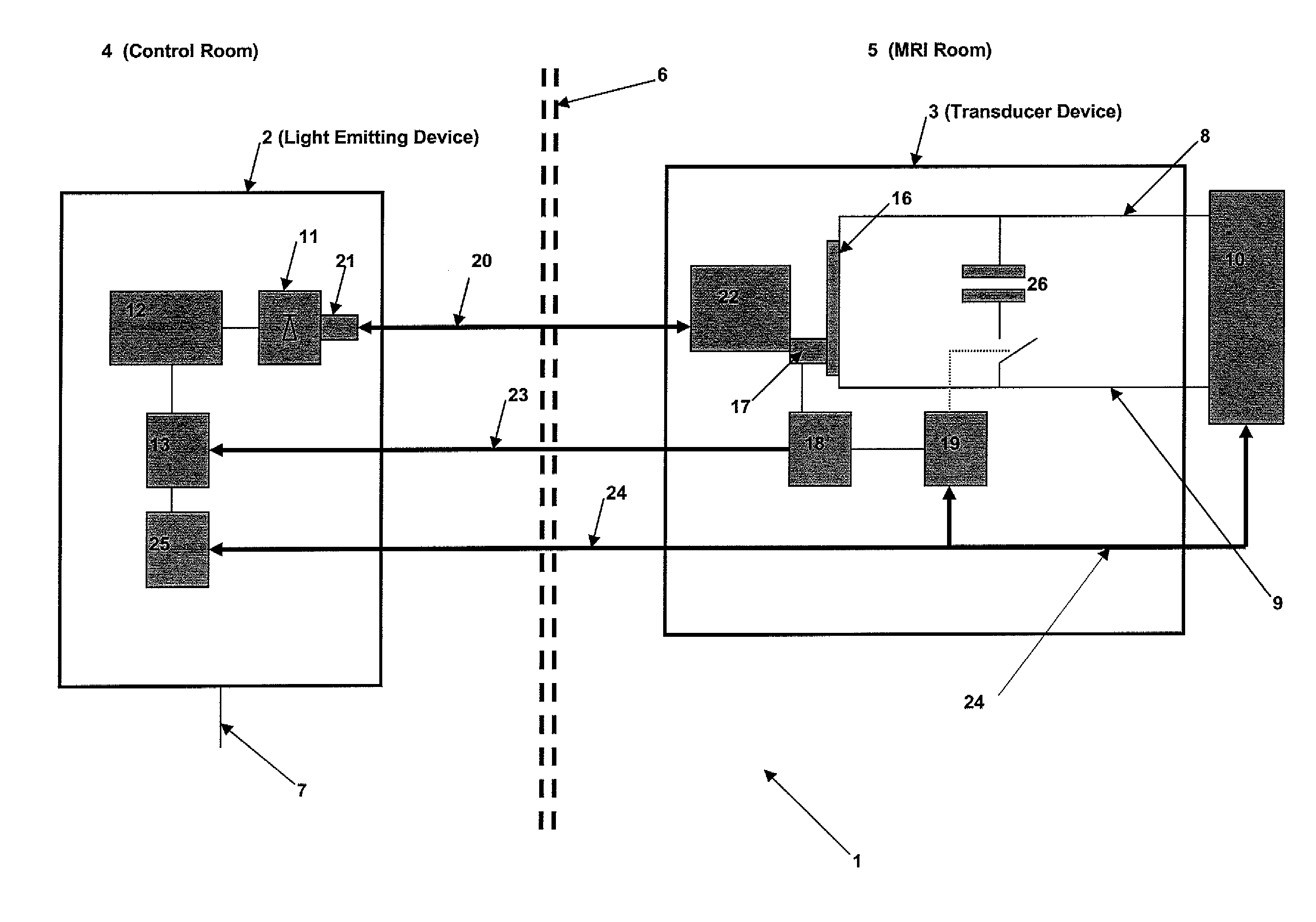

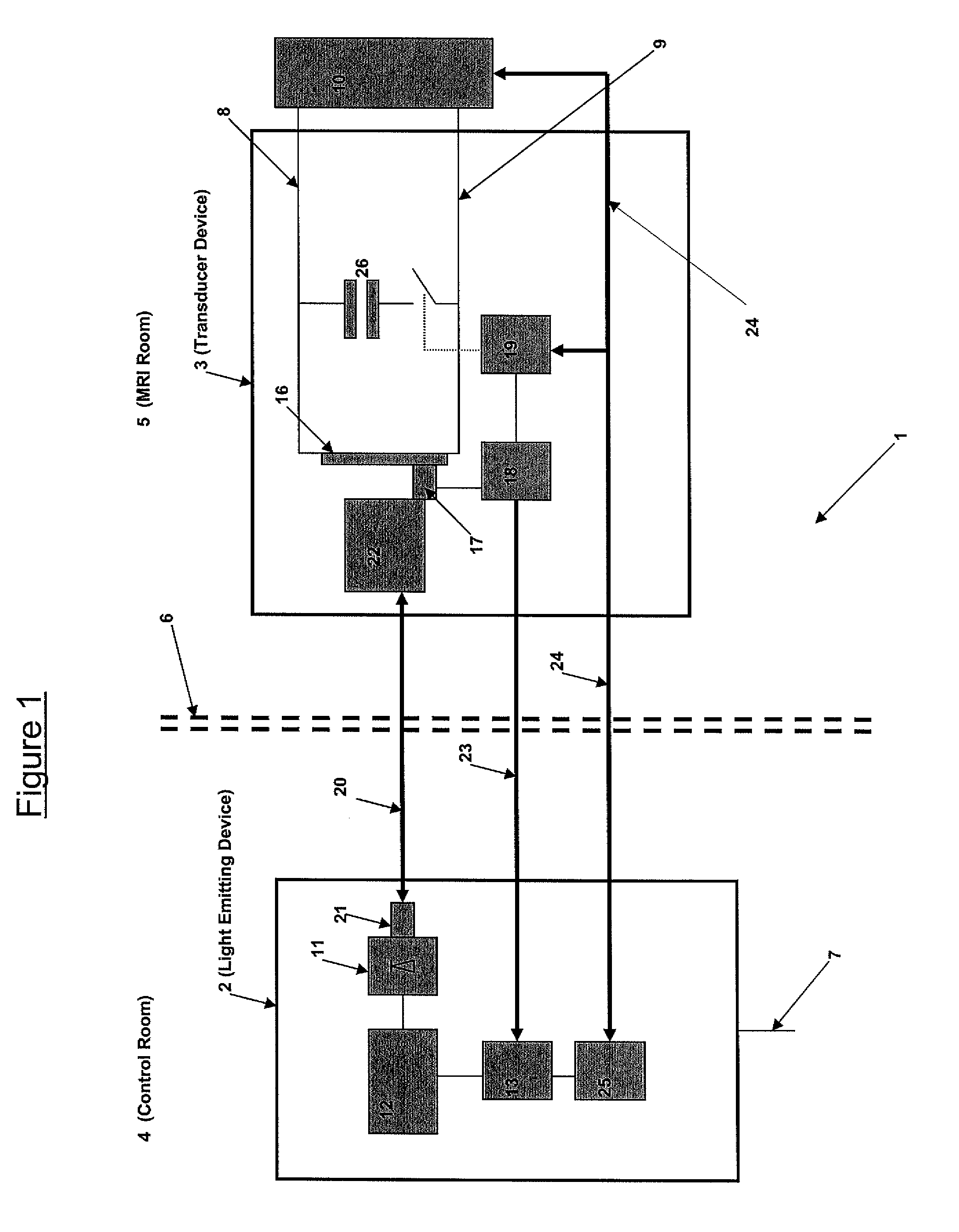

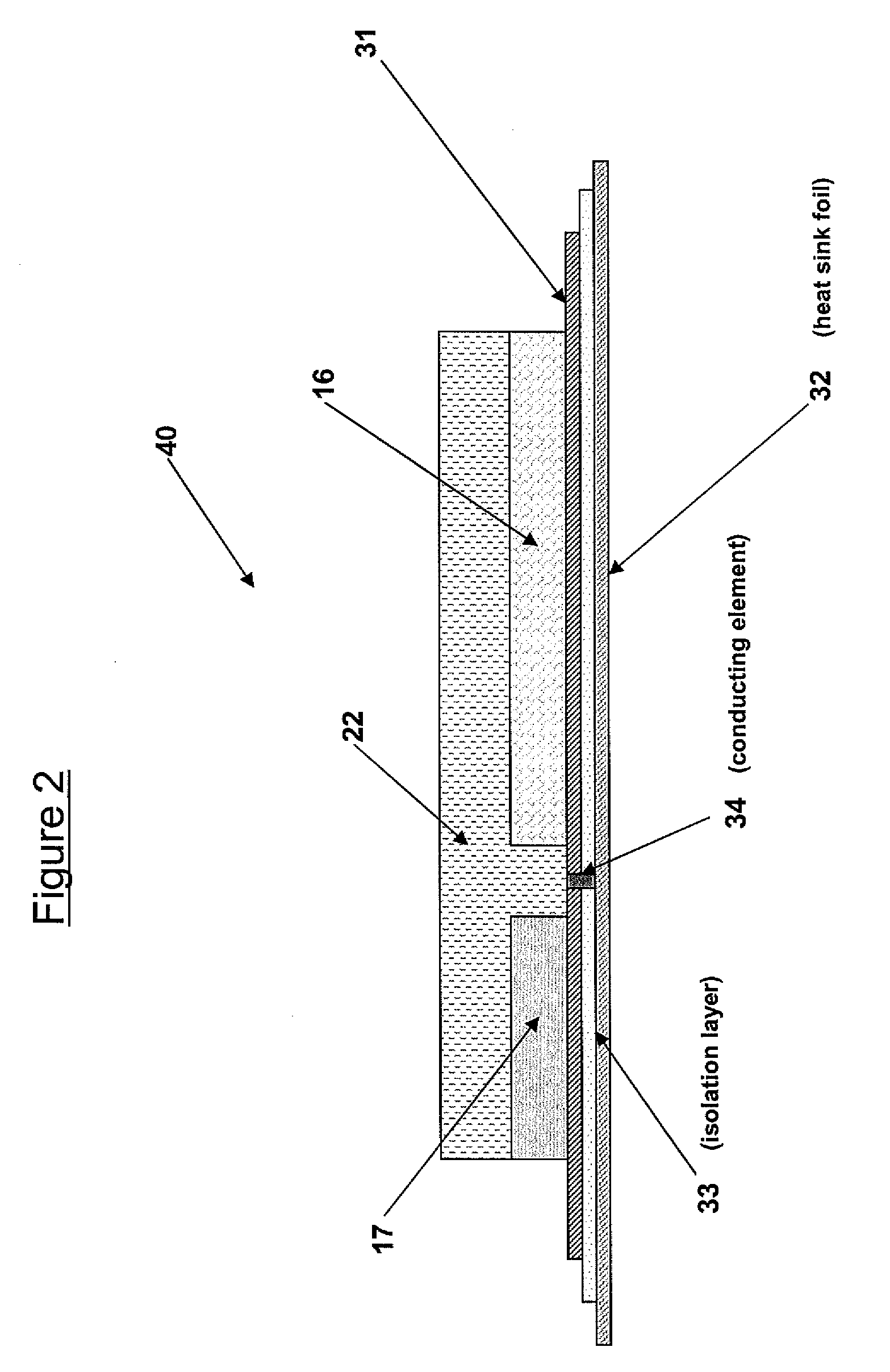

Process and system for providing electrical energy to a shielded medical imaging suite

ActiveUS20070285021A1Room can be minimizedMinimize interfering magnetic fieldElectric discharge tubesVariable inductancesEngineeringLighting spectrum

A process and system are disclosed for supplying electrical energy to a device located in a room housing an imaging system (such as an MRI system, for example), wherein the room is shielded from external electromagnetic fields. Certain embodiments of the present invention provide systems and processes for emitting electromagnetic radiation in the wavelength range of the light spectrum from at least one light emission device. Embodiments of the present invention further provide a process and system for transforming the electromagnetic radiation into electrical energy using at least one transducer device located in the room, and supplying the electrical energy to the device so as to minimize interfering electromagnetic fields within the room.

Owner:ACIST MEDICAL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com