Method and apparatus for installing a helical pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention may be embodied in a number of different forms. However, the specification and drawings that follow describe and disclose only some of the specific forms of the invention and are not intended to limit the scope of the invention as defined in the claims that follow herein.

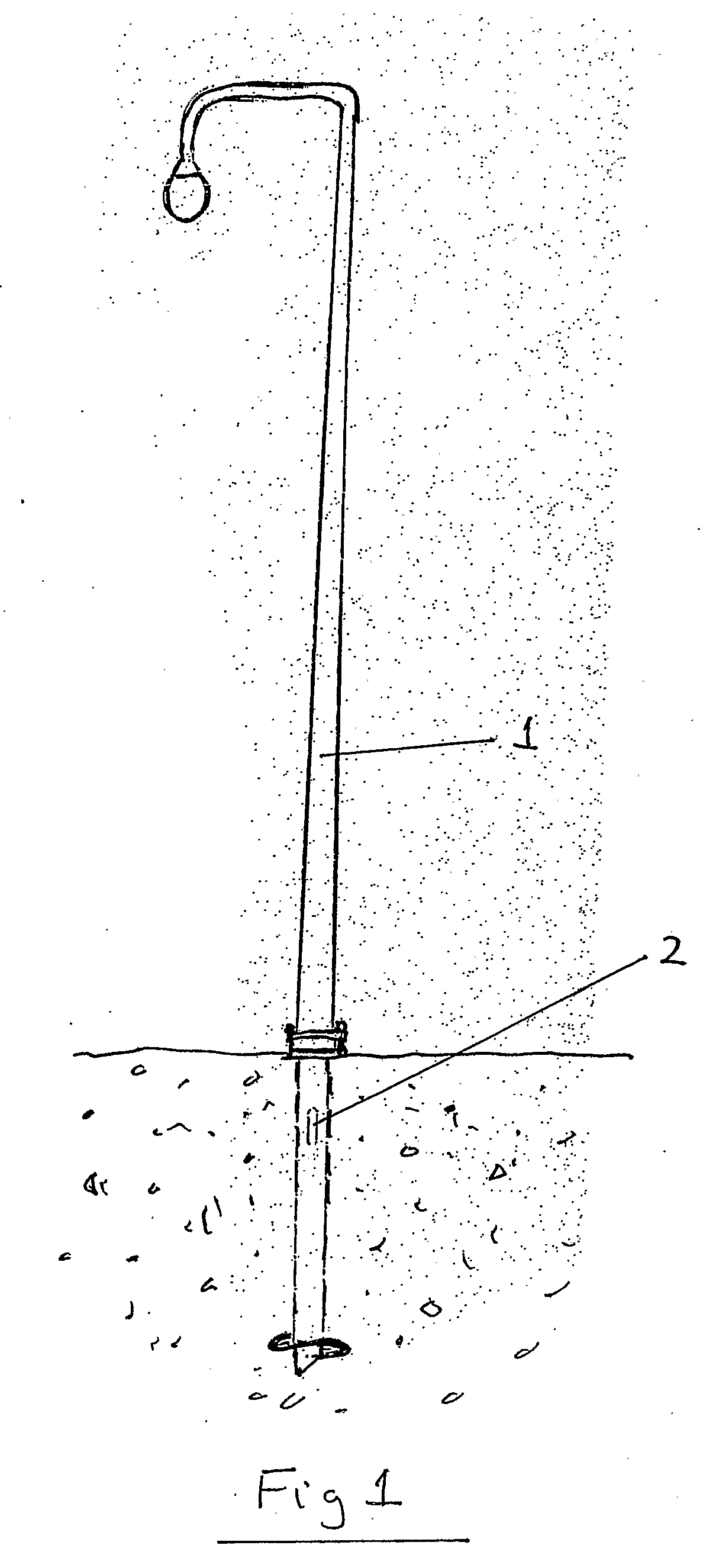

[0035] By way of introduction, FIG. 1 shows a typical street light standard 1 that is anchored to the ground through the use of a helical or screw pile 2. Most commonly helical pile 2 will be comprised of an elongate, generally hollow, cylindrical body or pipe having at its lower end a helical thread attached thereto such that rotation of the pipe causes the pile to be screwed or augered into the ground.

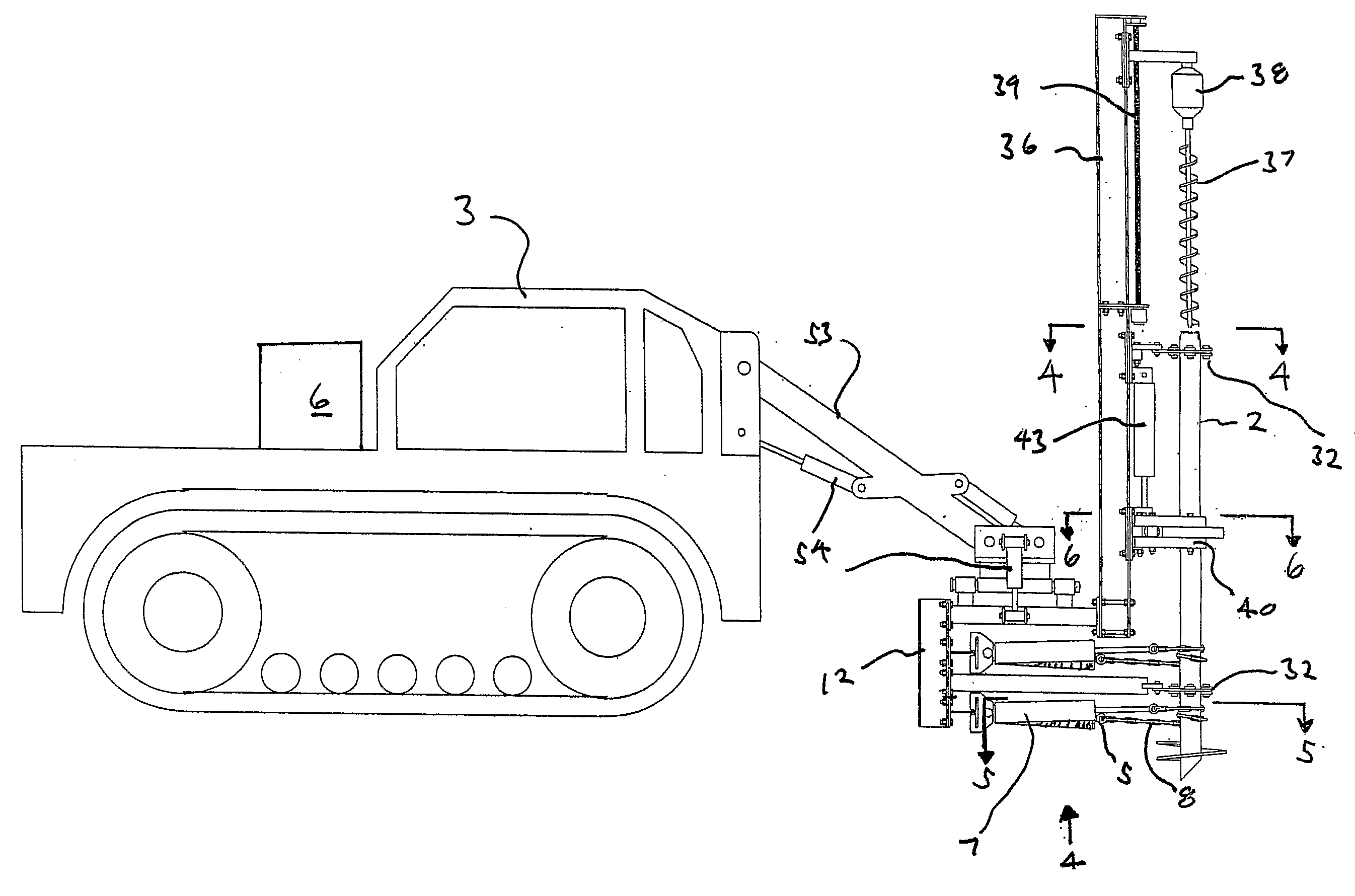

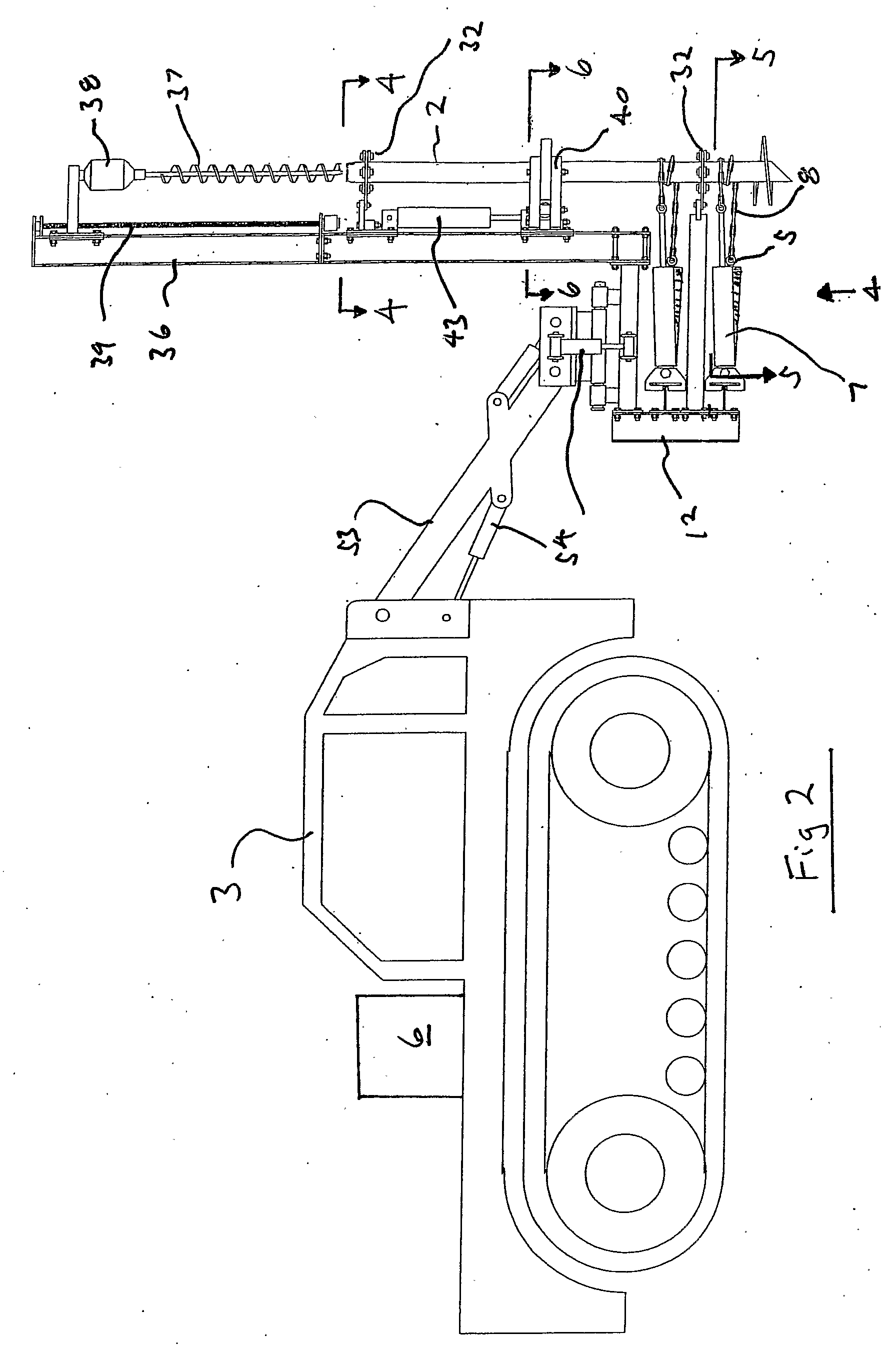

[0036]FIGS. 2 and 3 show a preferred embodiment of the present invention as it would typically be connected to a boom truck or vehicle 3. From a thorough understanding of the invention it will be understood that the apparatus constructed in accordance with the invention described herein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com