Production equipment for glue indentation reinforced panel

A technology for production equipment and reinforcing sheets, applied in mechanical/acoustic circuit processing, electrical components, printed circuit manufacturing, etc., can solve the problem of low production efficiency of rubber shrinkage reinforcing sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

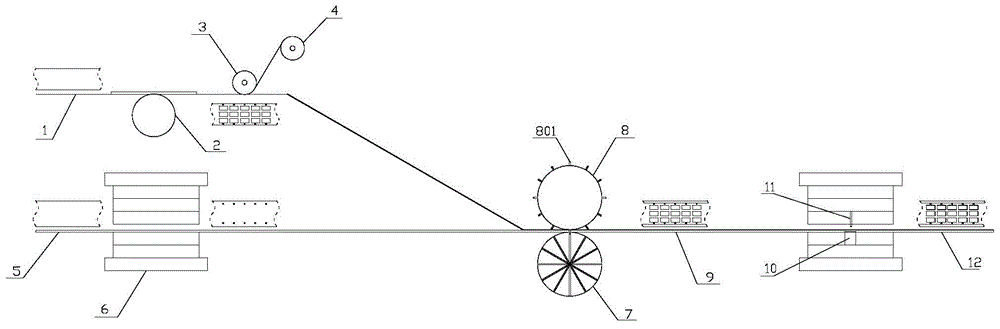

[0012] Such as figure 1 The production equipment for the rubber shrinkage reinforcing sheet shown includes: a die-cut rubber punching unit, a steel strip punching unit, a bonding unit and a product punching unit.

[0013] The die-cutting rubber punching unit is provided with a first cutter 2 for hole forming and glue forming of the adhesive tape 1, and a receiving mechanism for removing waste. The first cutter 2 is specifically a hob, and the adhesive tape 1 passes through the first cutter 2 continuously, and the rubber block and the positioning hole of the required shape are stamped and formed by the first cutter 2 . The rewinding mechanism includes a nip roller 3 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com