Method for improving wire dropping of punching dielectric layer of light bar plate

A technology of light strips and dielectric layers, which is applied in the processing of insulating substrates/layers, mechanical/acoustic circuit processing, electrical components, etc., can solve the problems of light strips that are easy to lose wires, and reduce the risk of crushing and scrapping. , The problem of wire loss is improved, and the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a method for improving the thread loss of the medium layer of the punching plate of the lamp strip. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

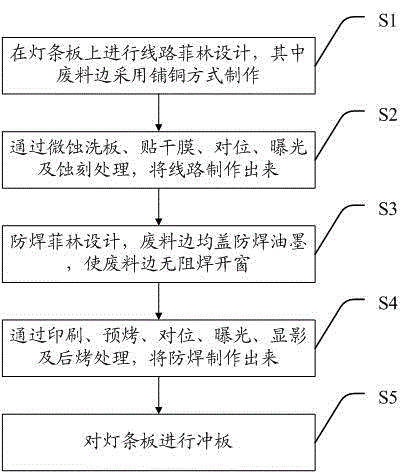

[0022] see figure 1 , figure 1 It is a flow chart of a preferred embodiment of a method for improving the wire drop of the medium layer of the light bar plate punching plate provided by the present invention, which includes steps:

[0023] S1. Carry out circuit film design on the light strip, and the waste side is made by copper laying;

[0024] S2. Make the circuit through micro-etching to wash the board, paste dry film, alignment, exposure and etching;

[0025] S3, Solder-proof film design, the waste material is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com