PCB splitting jig

A jig and split technology, applied in the processing of insulating substrates/layers, mechanical/acoustic circuit processing, electrical components, etc., can solve the problems of many board edges and low efficiency, reduce board edge burrs, improve The effect of shard efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

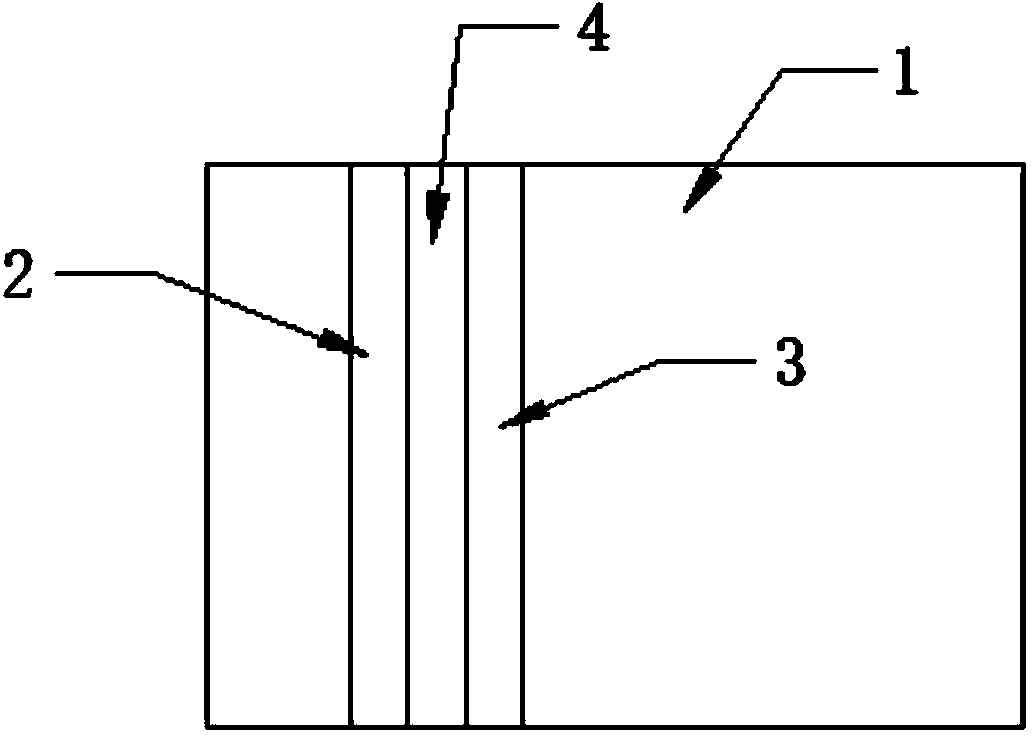

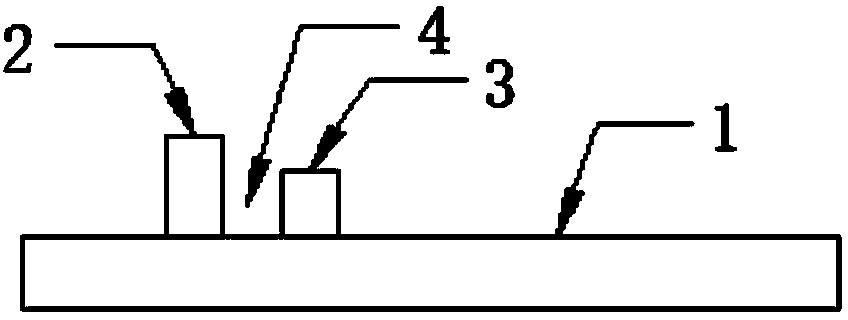

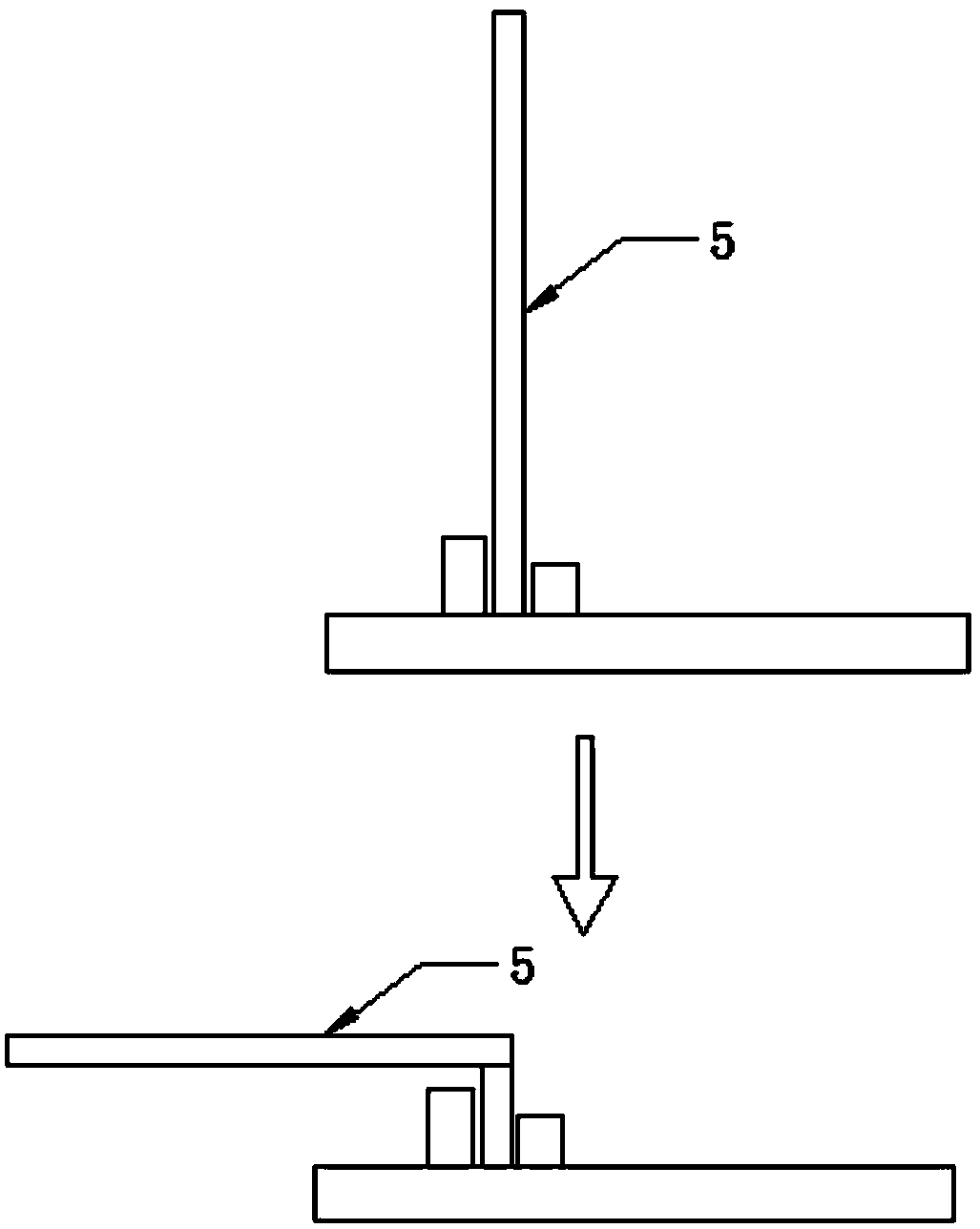

[0020] Embodiment: a kind of PCB splinter fixture, such as figure 1 and figure 2 As shown, it is composed of a working panel 1, a left side panel 2 and a right side panel 3. The working panel is a flat plate arranged horizontally, and the left side panel and the right side panel are all fixed on the upper surface of the working panel. The left side plate and the right side plate are parallel to each other, and there is a gap between the left side plate and the right side to form a slit 4, the width of the slit is greater than the thickness of the joint printed circuit board, and the left side plate The upper surface of the upper surface is higher than the upper surface of the right side board and the height difference is 3 millimeters, and the thickness of the left side board is less than the length and width of the single PCB.

[0021] The specific size of this PCB split fixture is that the thickness of the working panel is 10 millimeters, the thickness of the left side pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com