Making method of substrate with support

A manufacturing method and technology for supporting boards, which are applied in printed circuit manufacturing, cooling/ventilating/heating transformation, mechanical/acoustic circuit processing, etc. Reduces damage and strengthens the edge area of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The existing substrate is prone to warping and deformation, so in the prior art, a whole board is installed on the back of the substrate. However, this kind of whole board does not protect the substrate enough, and it will easily cause the substrate to warp and deform because this kind of whole board is likely to cause uneven heating of the substrate and aggravate the deformation of the substrate, and the whole board needs to be removed after use, and the removal process is easy cause damage to the substrate.

[0038] Therefore, the present invention provides a method for manufacturing a substrate with a bracket, so as to minimize the occurrence of warpage and damage of the substrate.

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

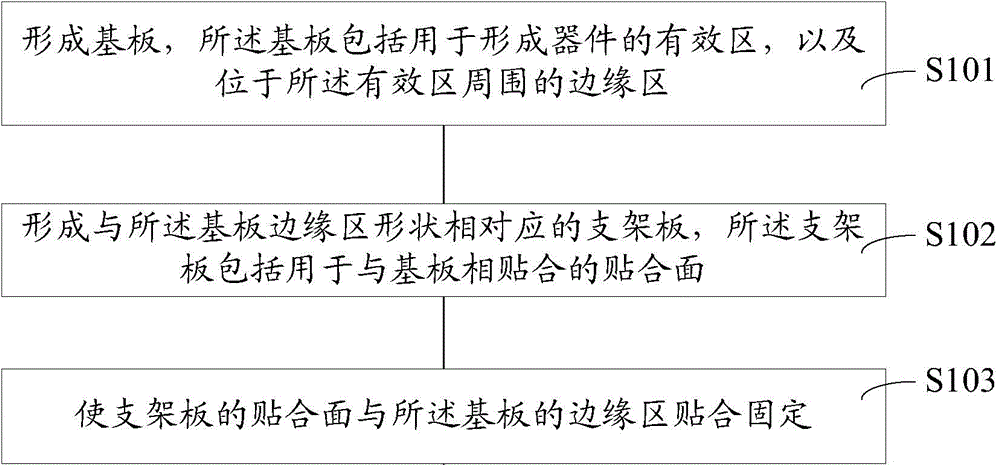

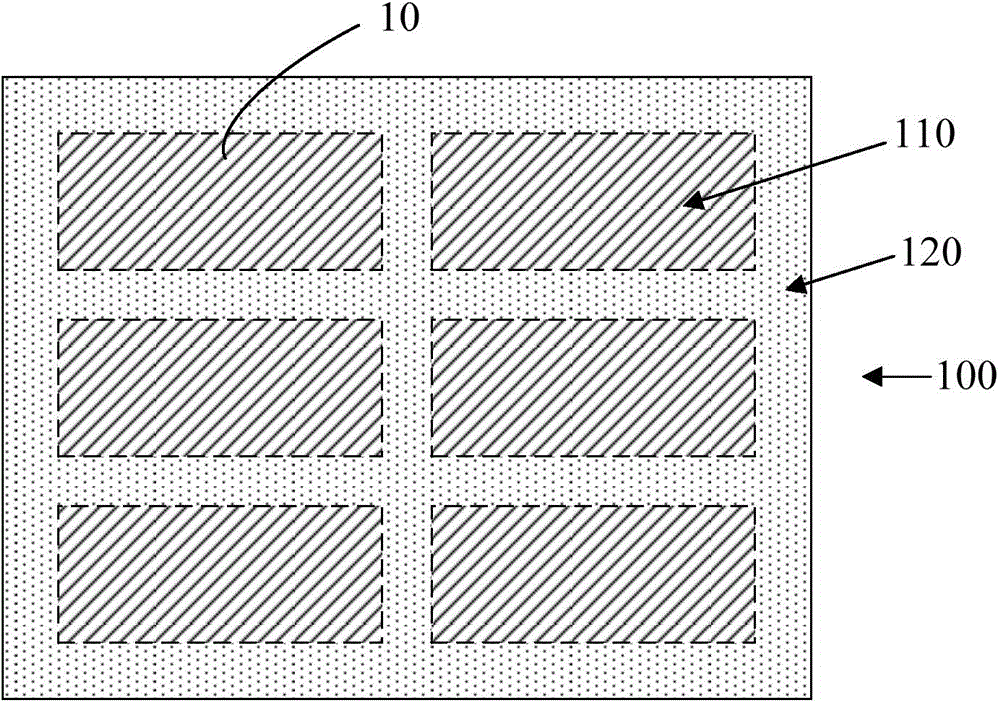

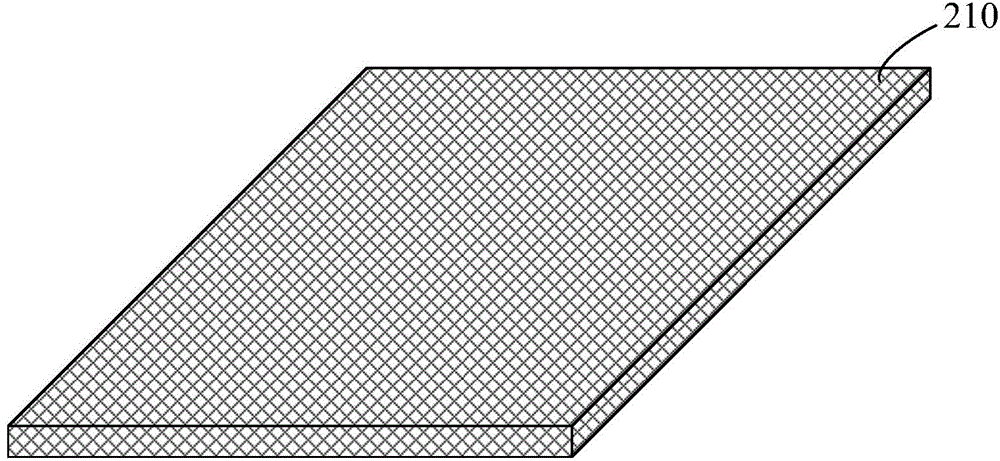

[0040] refer to figure 1 , is a schematic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com