Patents

Literature

53results about How to "Reduce the chance of warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

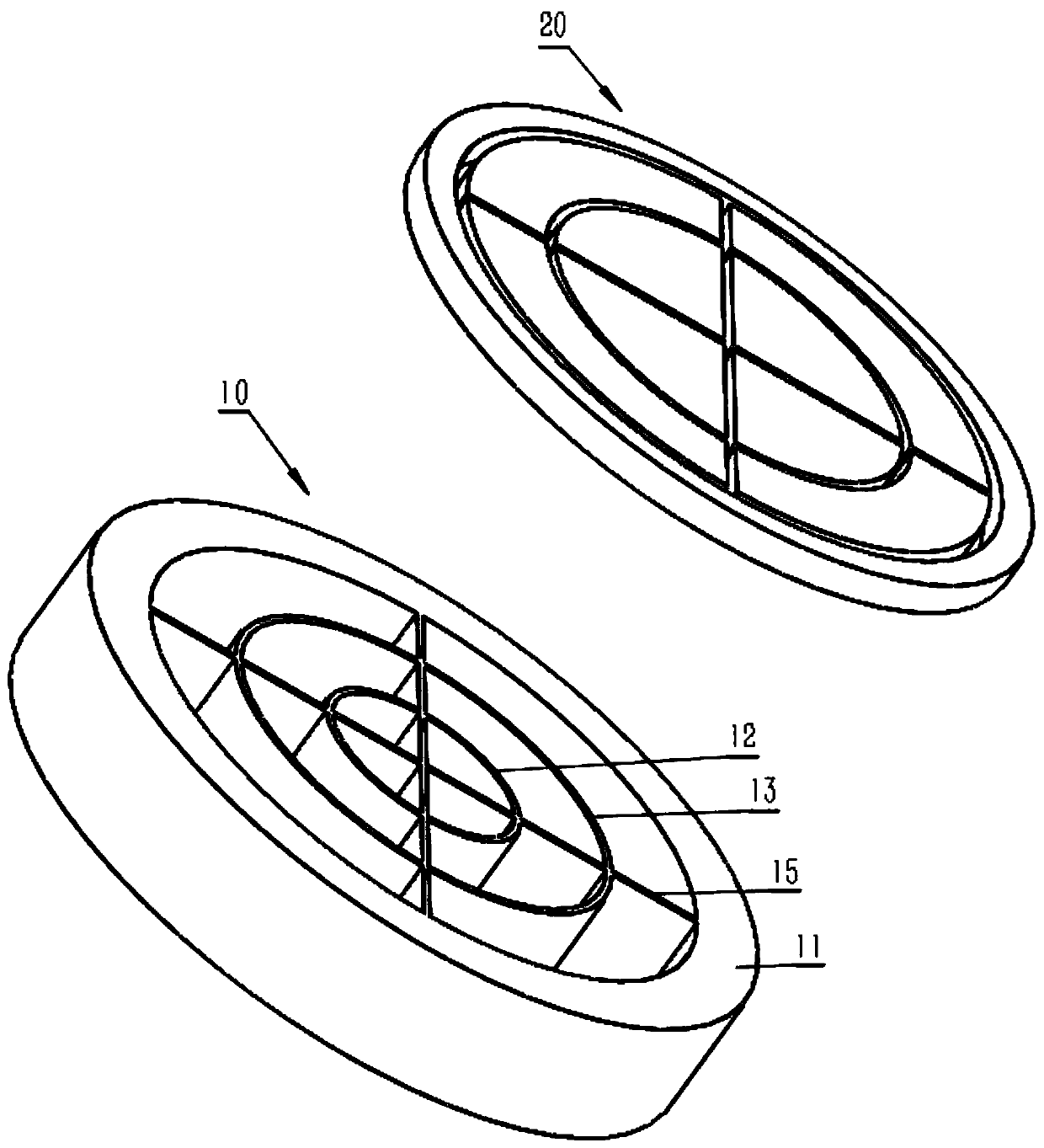

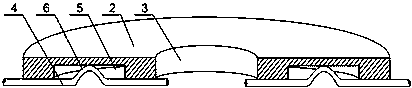

Semiconductor packaging structure for stacking and manufacturing method thereof

ActiveCN102738094ASolve warpingSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

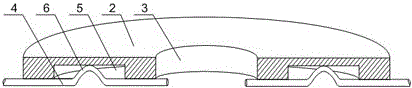

The invention discloses a semiconductor packaging structure for stacking and a manufacturing method thereof. The semiconductor packaging structure comprises a bottom substrate, a chip, an annular switchover substrate and packaging colloid. The bottom substrate is provided with a plurality of welding pads and a chip bearing area; the chip is fixedly arranged on the chip bearing area of the bottom substrate; a plurality of switchover assemblies and an opening are arranged on the annular switchover substrate; the switchover assemblies surround the opening and are electrically connected with the welding pads of the bottom substrate; the packaging colloid is filled in a gap between the bottom substrate and the annular switchover substrate, and is filled in the opening of the annular switchover substrate; and the packaging colloid in the opening is exposed to one top surface of the chip. With the adoption of the annular switchover substrate, the upper side and the lower side of a packaged body are slightly different in coefficient of thermal expansion, so that the warping rate is relatively lowered.

Owner:ADVANCED SEMICON ENG INC

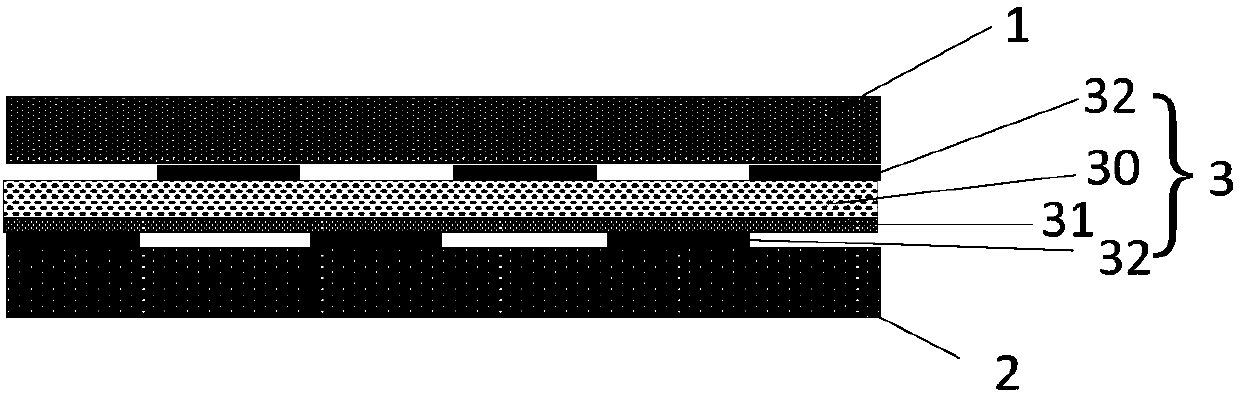

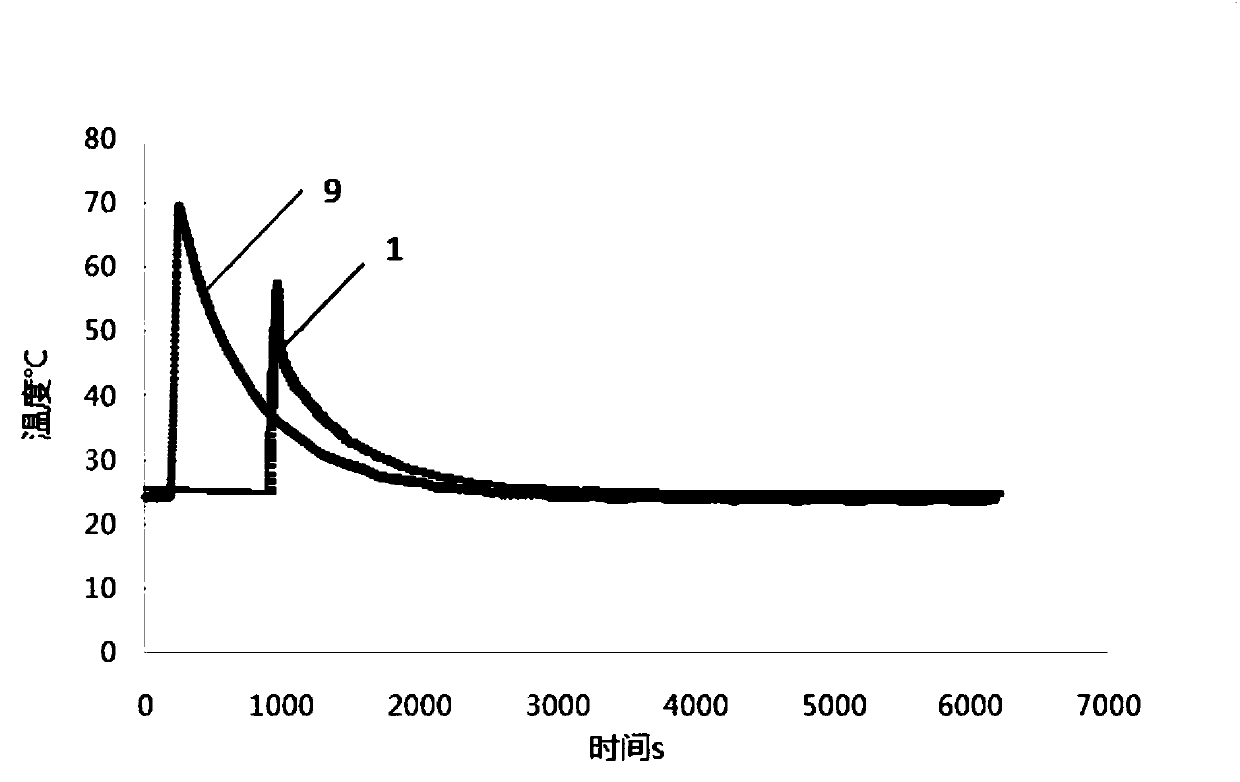

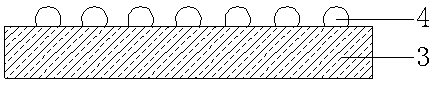

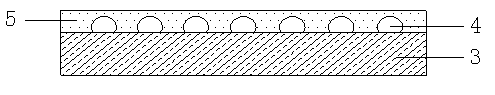

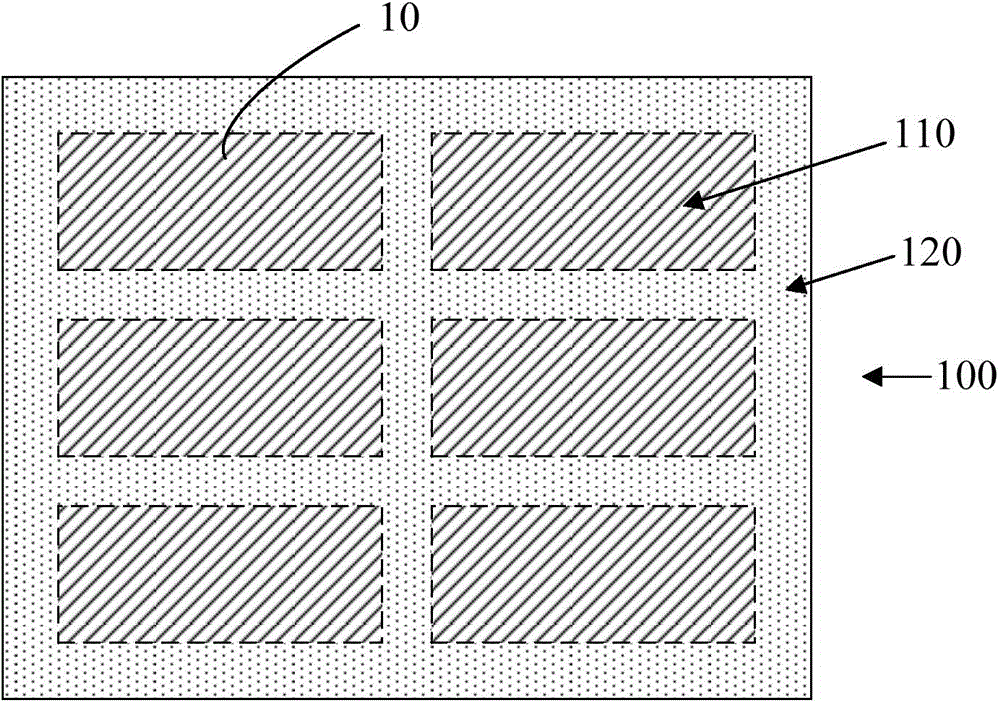

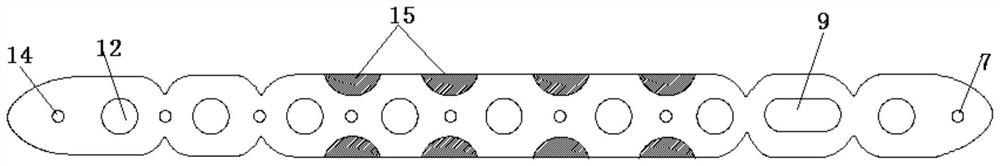

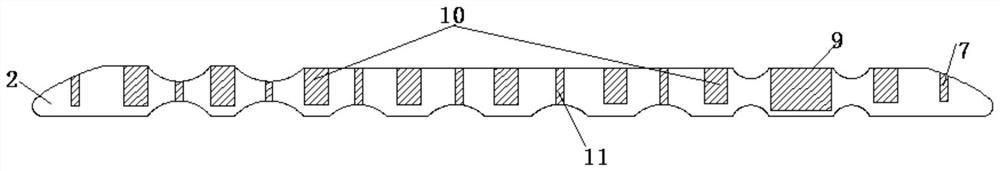

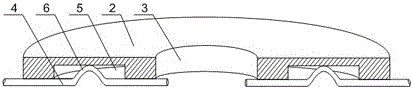

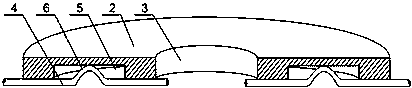

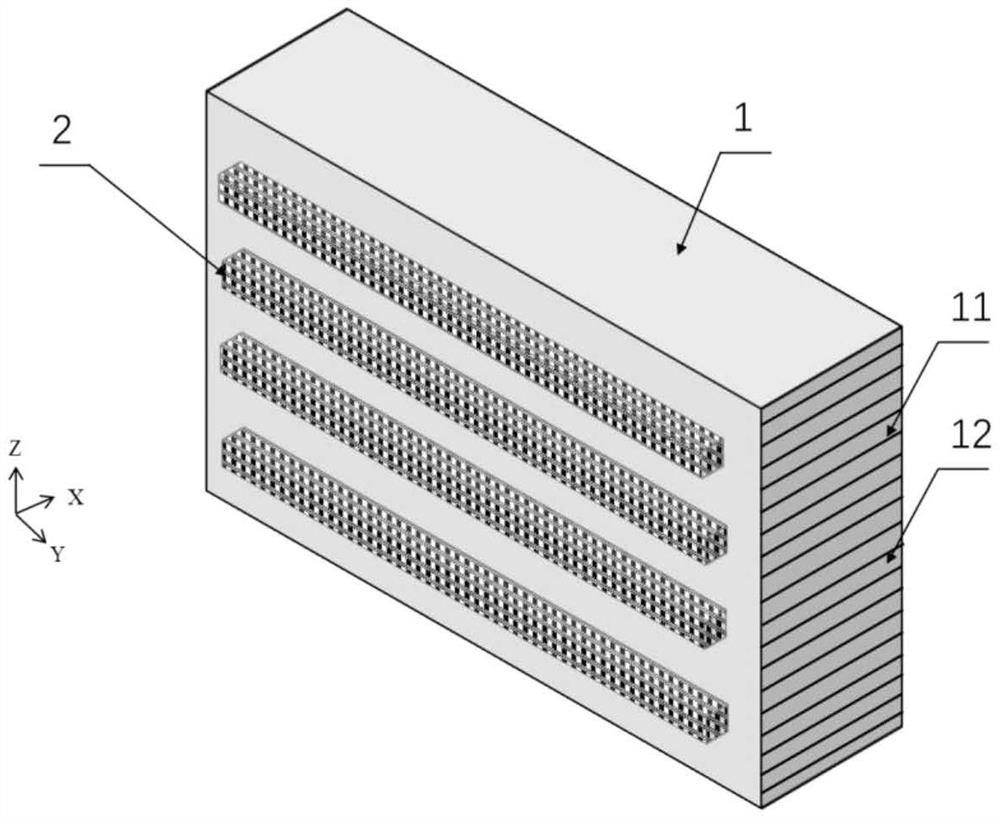

Separator and lithium ion battery

InactiveCN107834007AReduce the chance of warpingImprove cycle lifeCell seperators/membranes/diaphragms/spacersSecondary cellsInternal resistanceElectrical battery

The invention discloses a separator and a lithium ion battery. The separator comprises a separator substrate and an organic coating, wherein the organic coating is formed by distributing a cohesive organic polymer on a single surface or double surfaces of the separator substrate in a form of space dispersed and coated strips with specified thickness. Uniformly distributed concave and convex interval zones are shown on the surface of the separator in a manner of multi-space dispersed and coated strip-shaped organic coatings, a certain buffer space is reserved between a positive pole and a negative pole, stress produced by positive and negative pole pieces because of swelling in the charge-discharge process is released, and the probability of distortion in the cycle process of the lithium ion battery is greatly reduced; the internal resistance of the battery is reduced while the better adhesion effect with the positive and negative poles is guaranteed; besides, a channel is provided forinfiltration and circulation of an electrolyte, and the cycle life of the lithium ion battery is prolonged.

Owner:SUNWODA ELECTRONICS

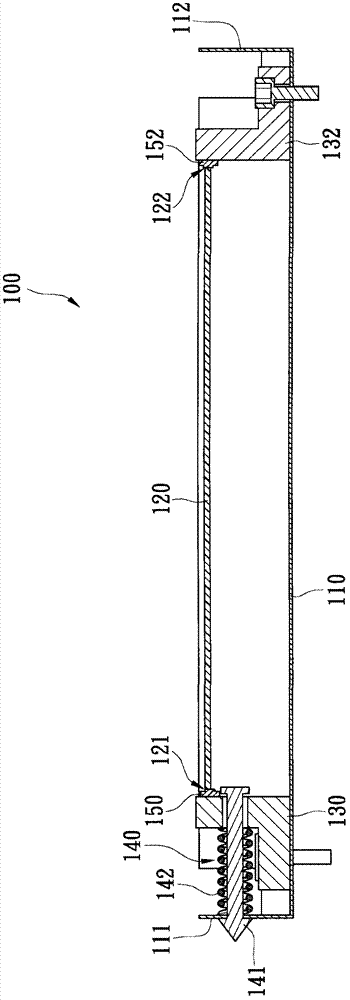

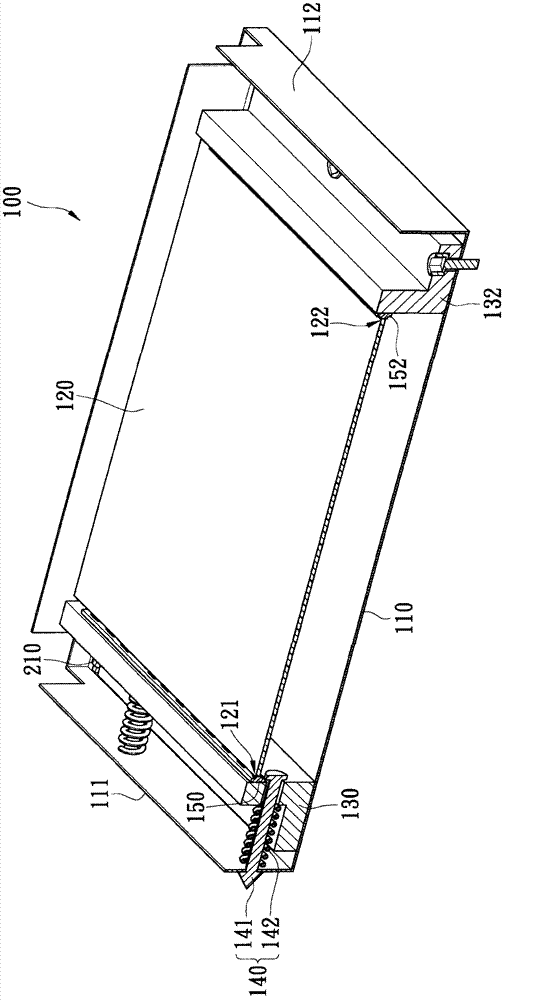

Backlight module

InactiveCN102777812AAvoid spoiling the tasteAvoid affecting brightnessProtective devices for lightingLight fasteningsLight guideEngineering

The invention provides a backlight module, comprising a backplane, a light guide plate, a chatoyancy and a heat dissipation element. The heat dissipation element is arranged on the backplane movably, and the chatoyancy is abutted against the light guide plate tightly via an elastic element abutted between the side wall of the backplane and the heat dissipation element to form a gapless light source structure, thereby improving the outgoing light efficiency. The chatoyancy abutted against the light guide plate can move along with the heat dissipation element, so that the space needed by the light guide plate heated deformation can be supplied to reduce the deformation probability of the light guide plate.

Owner:LEXTAR ELECTRONICS CORP

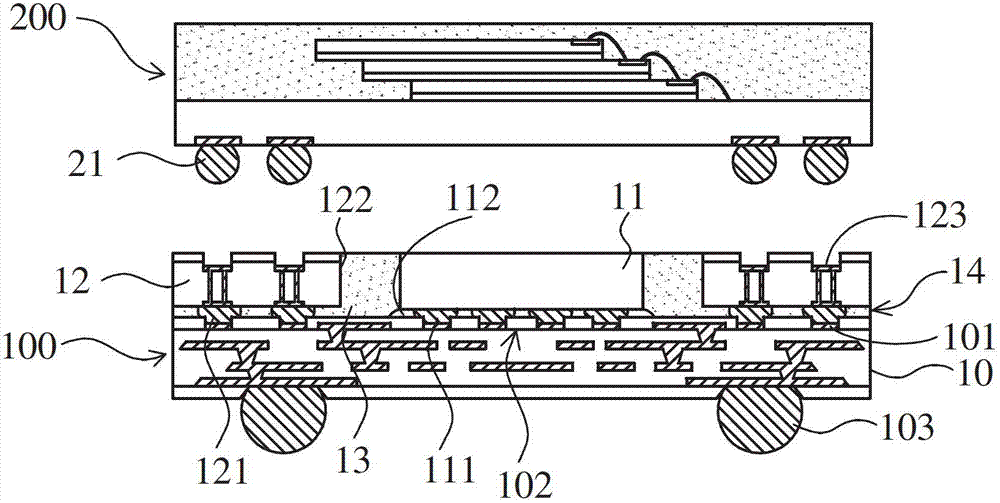

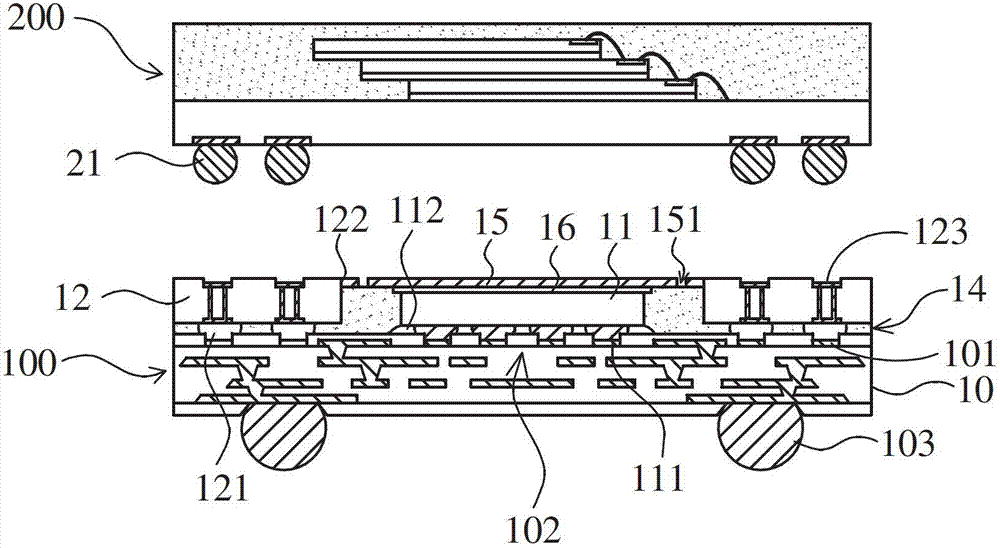

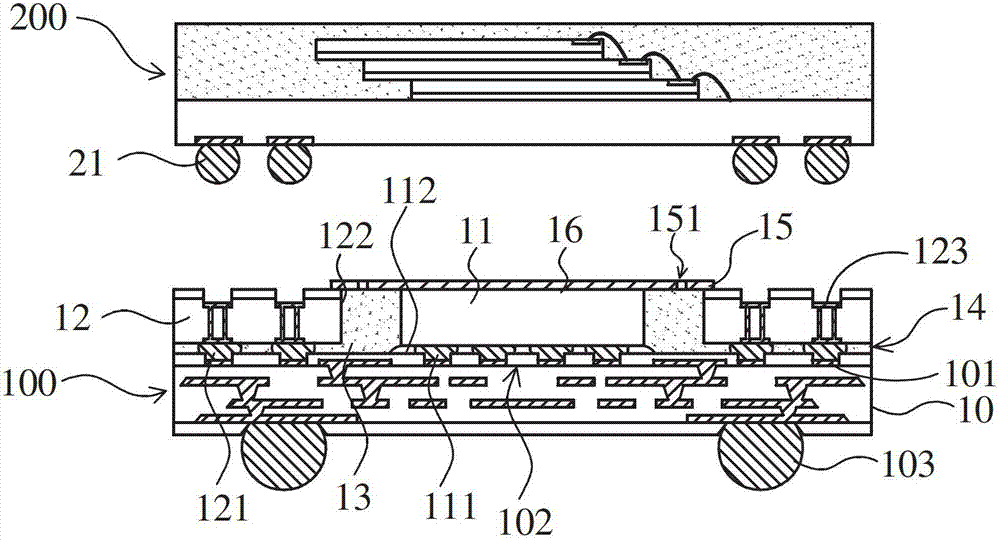

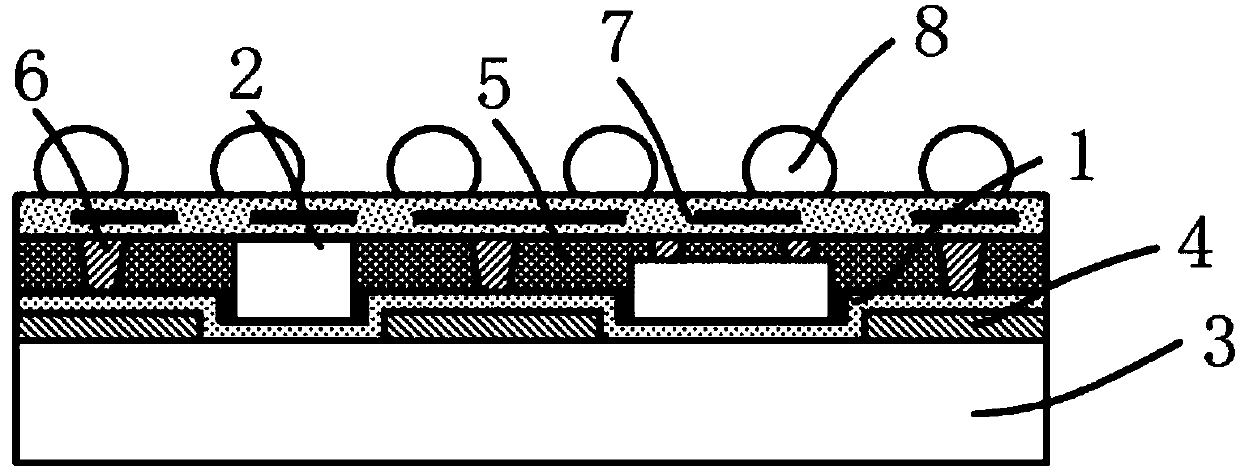

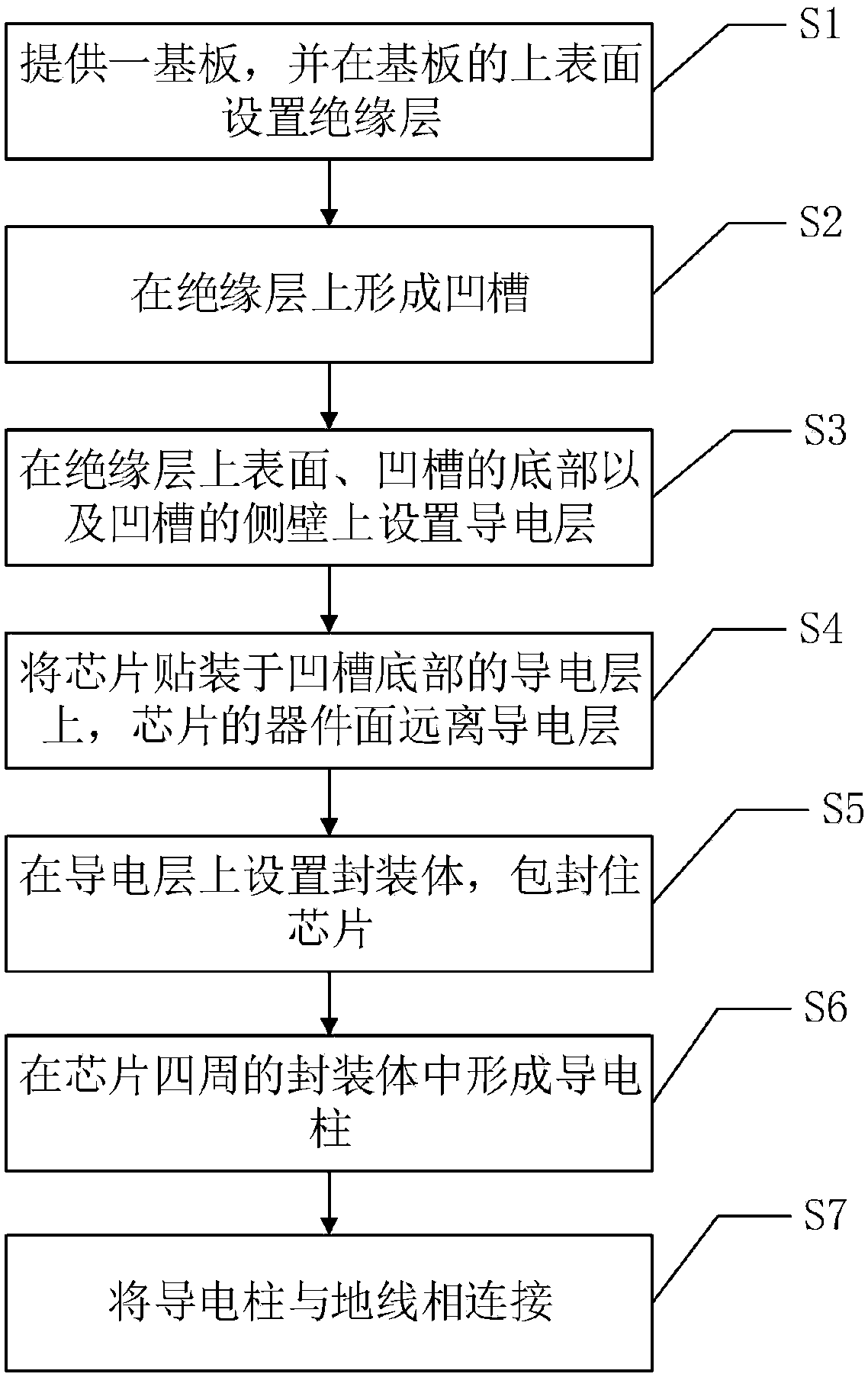

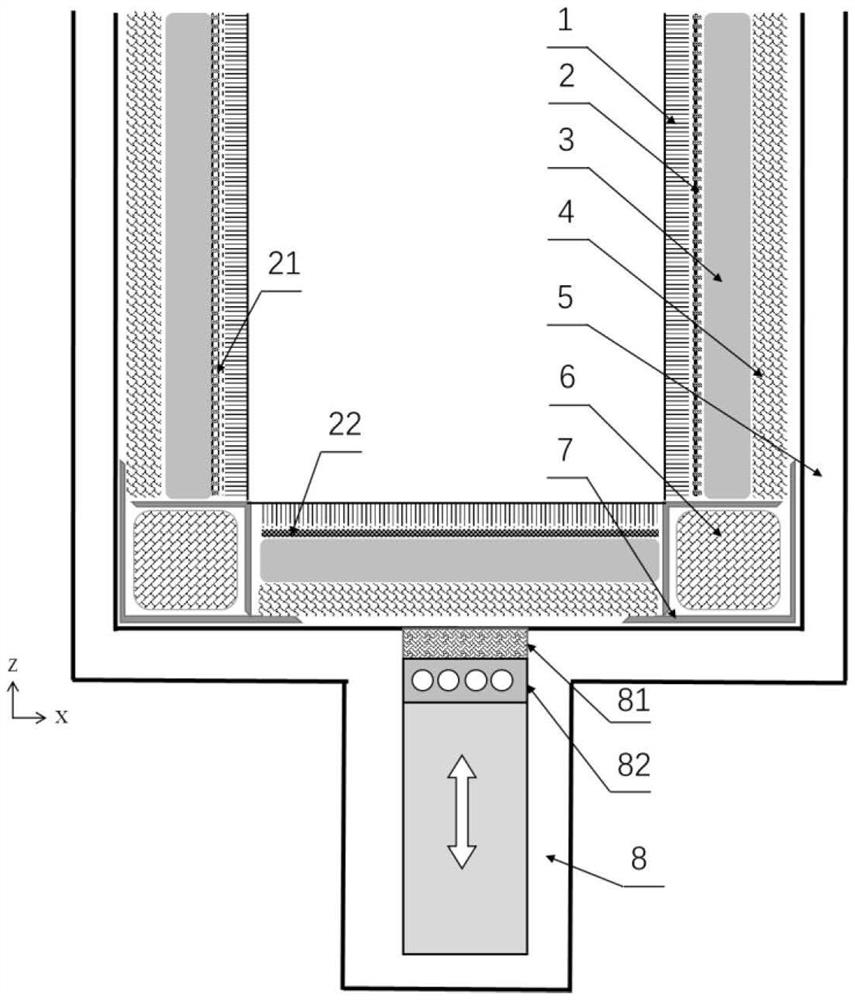

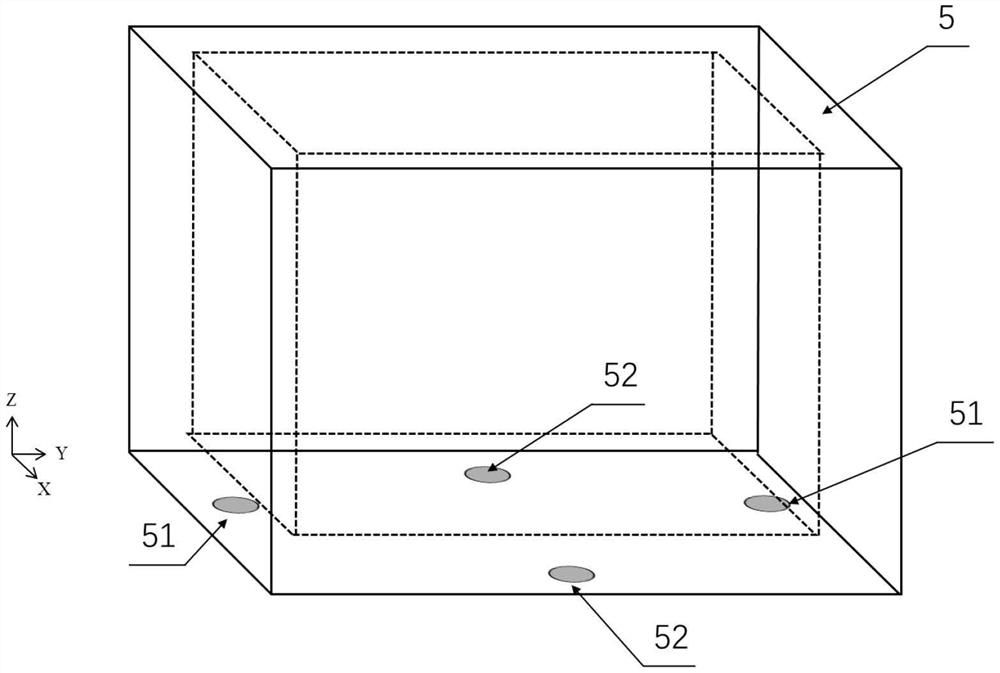

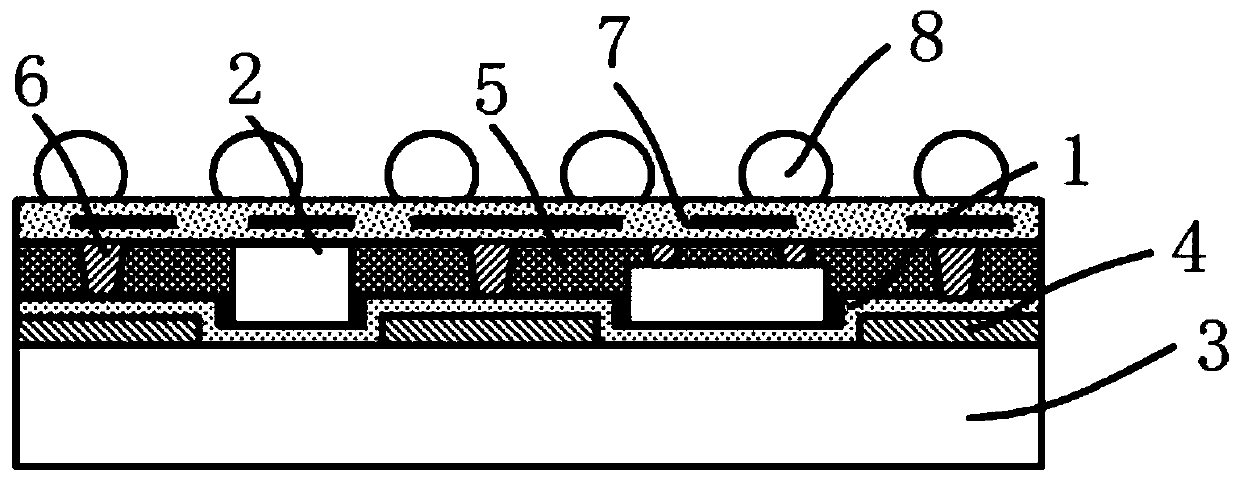

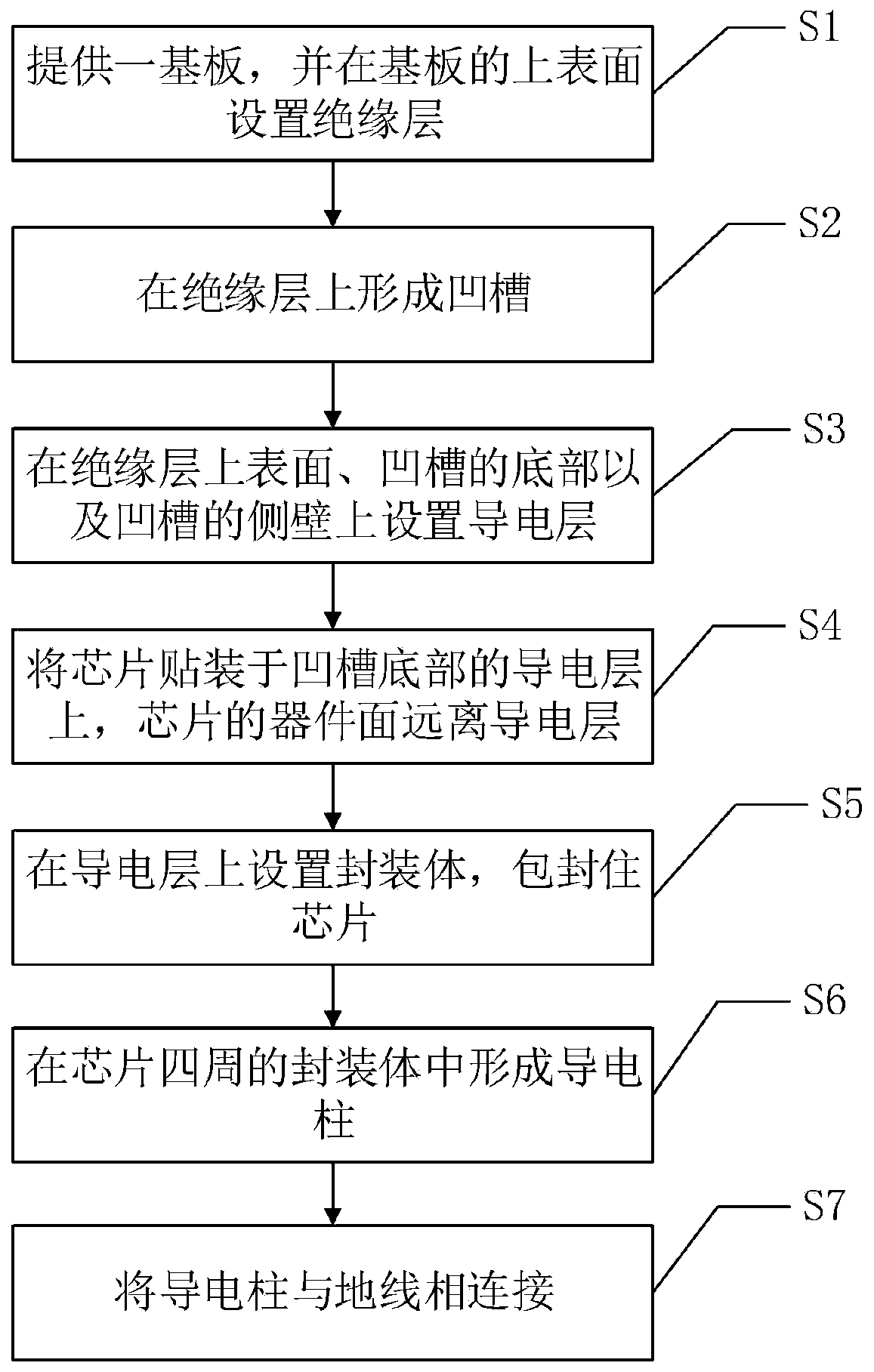

Fan-out wafer-level chip packaging structure and method

ActiveCN107946249AFast heat conductionImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

The present invention provides a fan-out wafer-level chip packaging structure and method. The fan-out wafer-level chip packaging structure comprises: a conducting layer, wherein one groove configuredto arrange one chip is formed on the conducting layer, and the conducting layer is arranged on a substrate; an insulation layer arranged between the conducting layer and the substrate and configured to fill a gap between the conducting layer and the substrate; a packaging body arranged at the upper surface of the conducting layer, wherein the chip is packaged in the packaging body, one bonding padof each chip is exposed out of the packaging body; a conducting column arranged in the packaging body, wherein one end of the conducting column is coupled to the conducting layer, the other end of the conducting column is exposed out of the packaging body, and the conducting column is connected with a ground wire. The chip is arranged in the groove on the conducting layer, and the conducting layer is connected with the ground wire through the conducting column to form an electromagnetic shielding structure located in the fan-out wafer-level chip packaging structure, and therefore, the possibility can be reduced that the chip is subjected to electromagnetic wave interference by devices in the packaging structure and external devices, the preparation difficulty is small and the production cost is low.

Owner:NAT CENT FOR ADVANCED PACKAGING

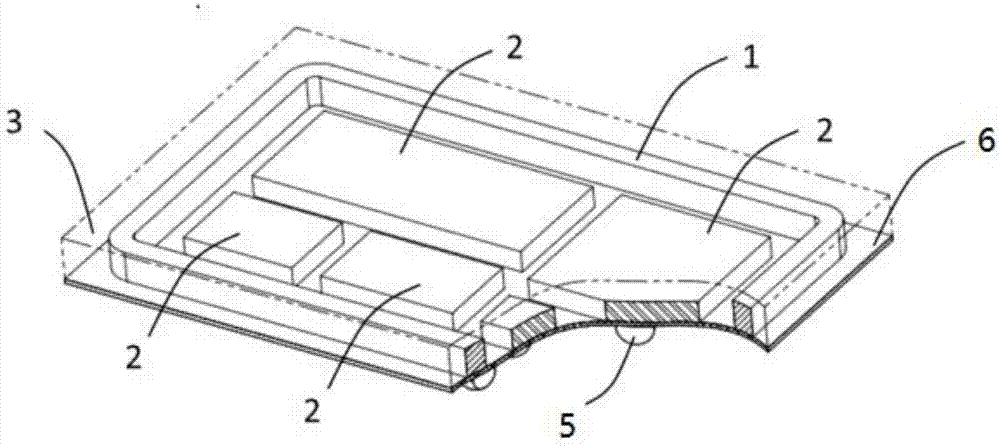

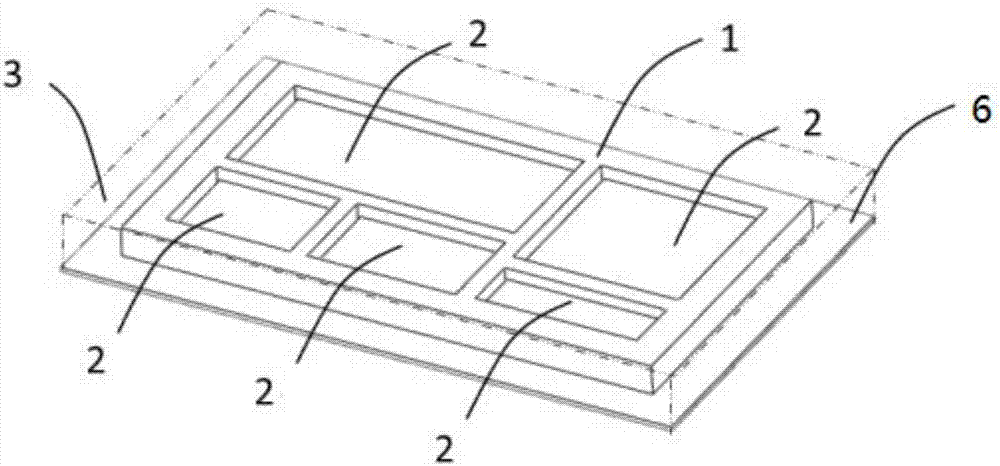

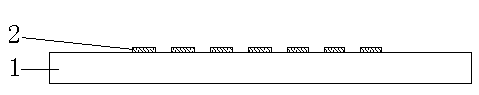

Wafer-grade fan-out packaging structure and method

ActiveCN107481977AImprove electrical performanceReduce electromagnetic interferenceSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

The present invention discloses a structure and method of wafer-grade fan-out packaging with electromagnetic shielding. The structure comprises: a frame which is internally provided with one or more than one chips, wherein the frame is connected with a ground wire; a packaging body, wherein the frame and the one or more than one chips are packaged in the packaging body, and the lower surface of the packaging body, the lower surface of the frame and the devices of the one or more than one chips are located at the same plane. A metal conductor and the frame made of ceramic material and having a surface plated with metal are earthed to allow the packaging body and the frame in the wafer-grade fan-out packaging structure to form a complete loop so as to reduce the possibility of electromagnetic wave interference of the packaging structure itself and the external portion of the packaging structure on the wafer-grade packaging and the one or more than one chips at the internal portion of the structure and improve the electrical properties of the wafer-grade fan-out packaging structure.

Owner:NAT CENT FOR ADVANCED PACKAGING

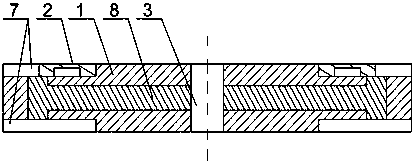

Single-chip packaging piece with adhesive film replacing bottom fillers and manufacture process thereof

InactiveCN103021988AImprove reliabilityReduce the chance of warpingSemiconductor/solid-state device detailsSolid-state devicesSolder ballComposite material

The invention discloses a single-chip packaging piece with an adhesive film replacing bottom fillers and manufacture process thereof. The packaging piece is mainly composed of a substrate, a nickel pad, a chip, a solder silver bump, the adhesive film and a solder ball. The nickel pad is fixedly connected onto the substrate, and the solder silver bump is fixedly connected onto the chip; the solder silver bump is coincided with a central line of the nickel pad and connected with the central line of the nickel pad in soldering mode; and the adhesive film fills the gap between the substrate and the chip and surrounds the nickel pad and the solder silver bump. The manufacture process is conducted according to the following steps: pasting the adhesive film; installing the chip and reflow soldering; reducing thickness of the back of a wafer; and placing the ball, inspecting, packaging and putting in storage. By means of the technology, packaging cost is reduced, packaging reliability is improved, and process links are reduced.

Owner:HUATIAN TECH XIAN

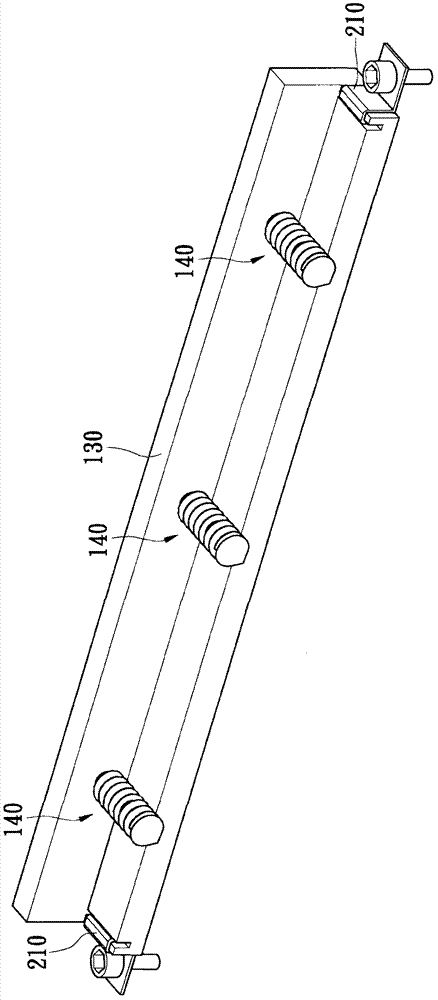

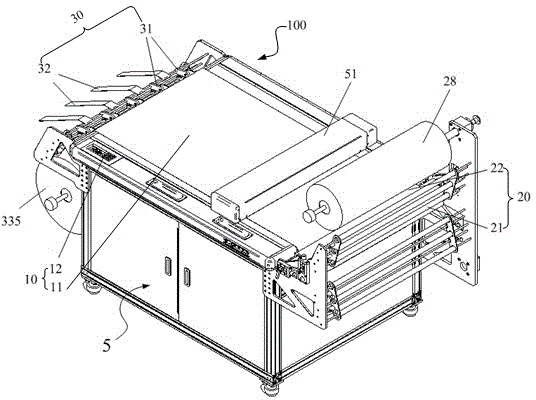

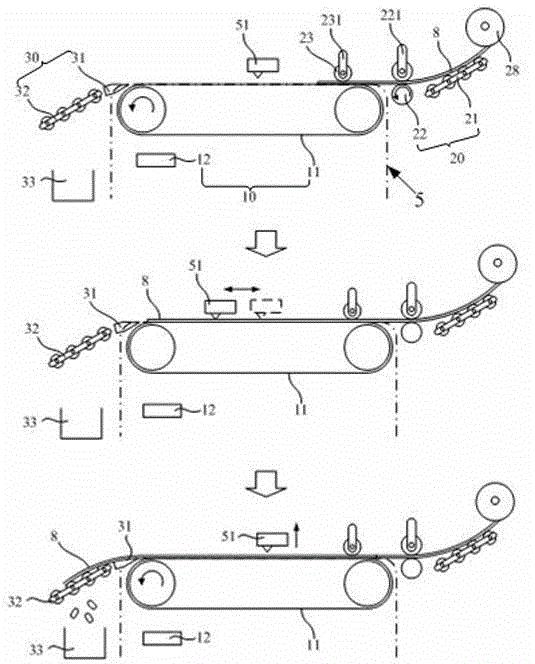

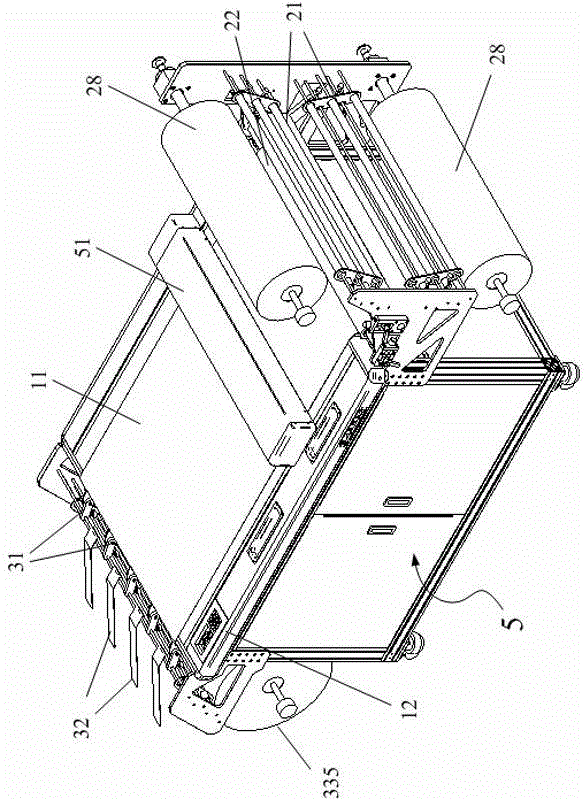

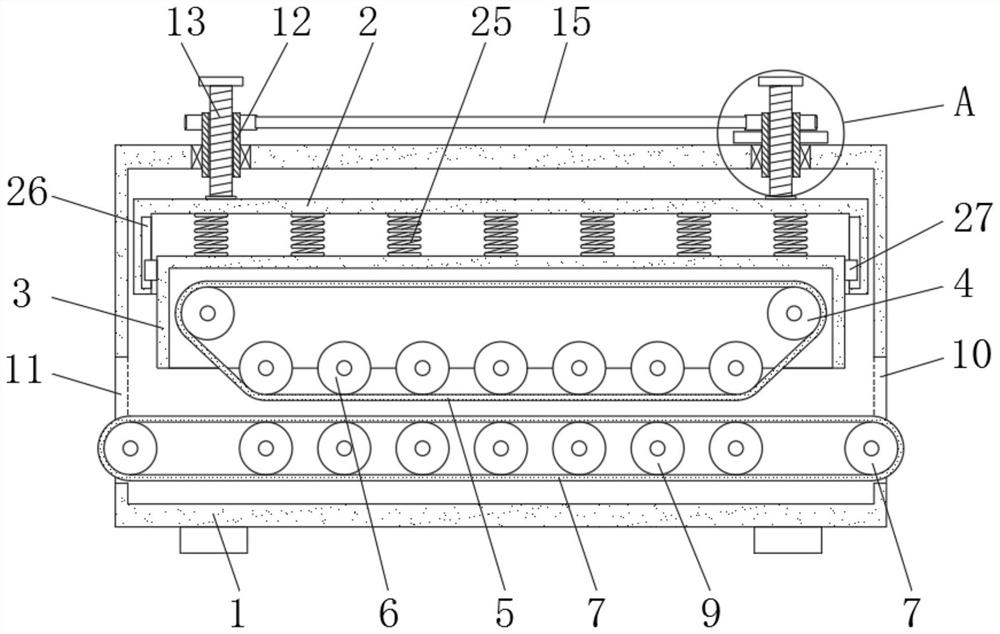

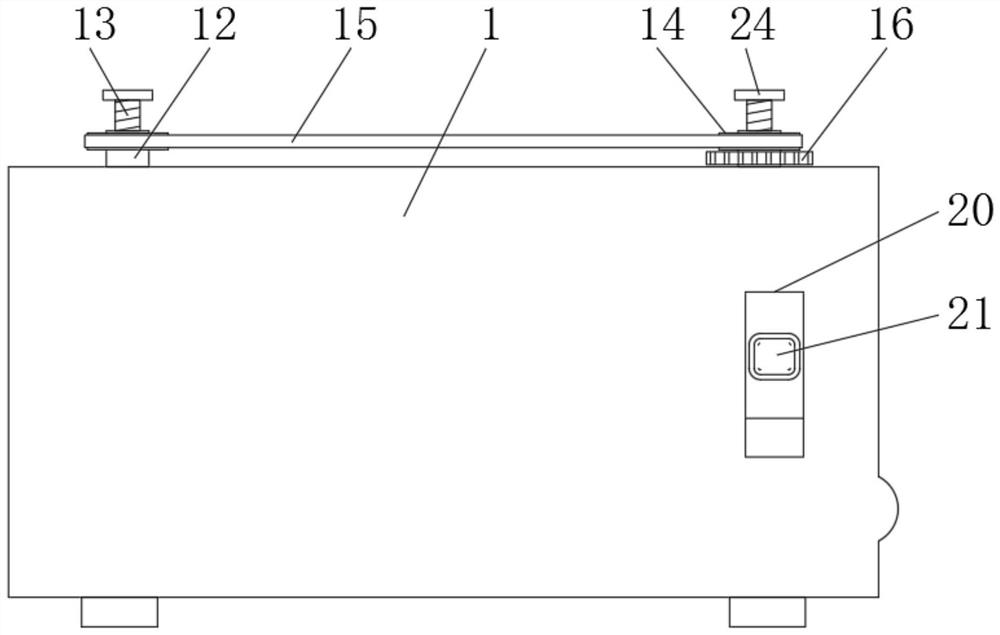

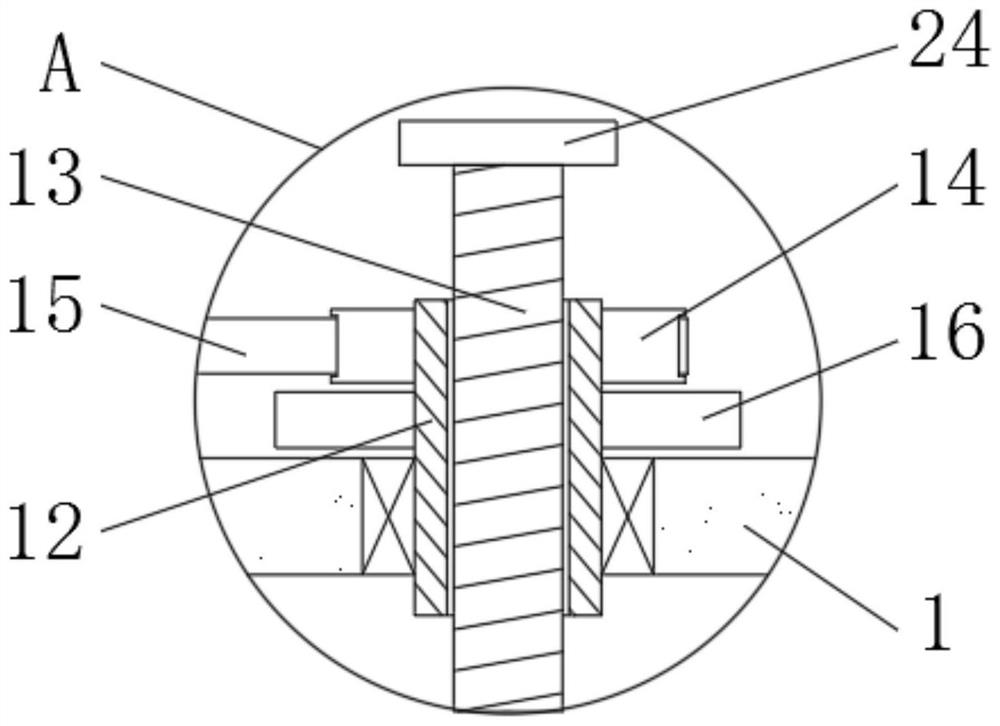

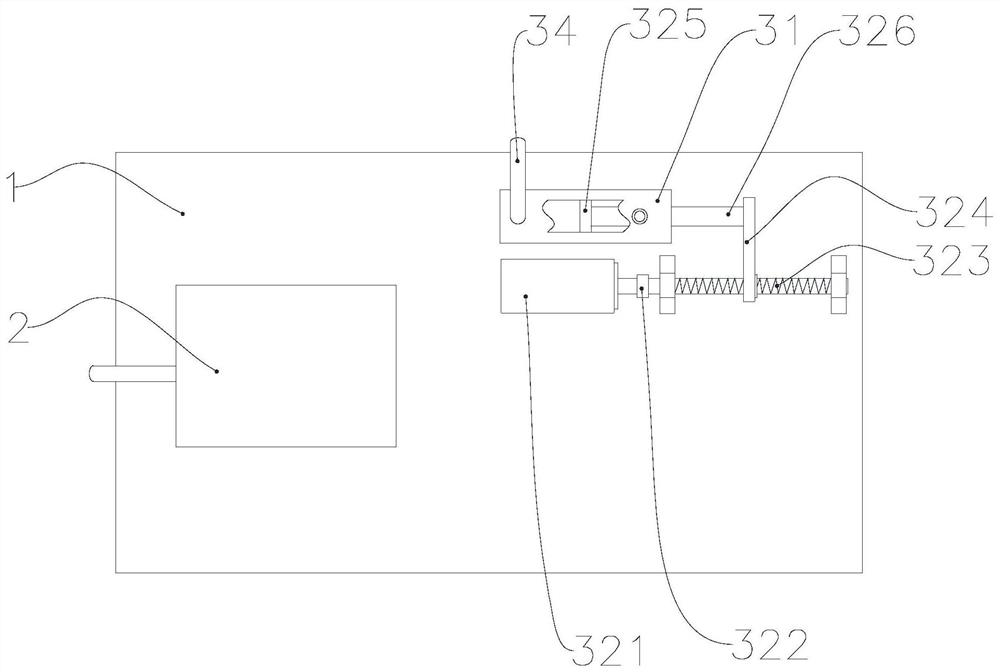

Adhesive film feeding mechanism

InactiveCN106276382AReduce the chance of warpingImprove yieldLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention discloses an adhesive film feeding mechanism. The adhesive film feeding mechanism comprises a conveying module, a feeding module and a receiving module; the conveying module comprises a conveying belt and a control unit; the feeding module comprises an adhesive film support and a guide wheel set; the receiving module comprises an adhesive film separating structure and an adhesive film guide structure; and during feeding, an adhesive film is attached to the conveying belt and is driven through motion of the conveying belt to be fed, and through motion between the modules and design changes of allocation relations, the control complexity of the feeding mechanism is reduced. According to the adhesive film feeding mechanism, a guide wheel set can be used for extruding bubbles generated during adhesive film attaching out, a leveling wheel can be used in a matched manner to flatly attach the adhesive film to the conveying belt, and therefore the cutting quality of the adhesive film is maintained.

Owner:SHIU LI TECH

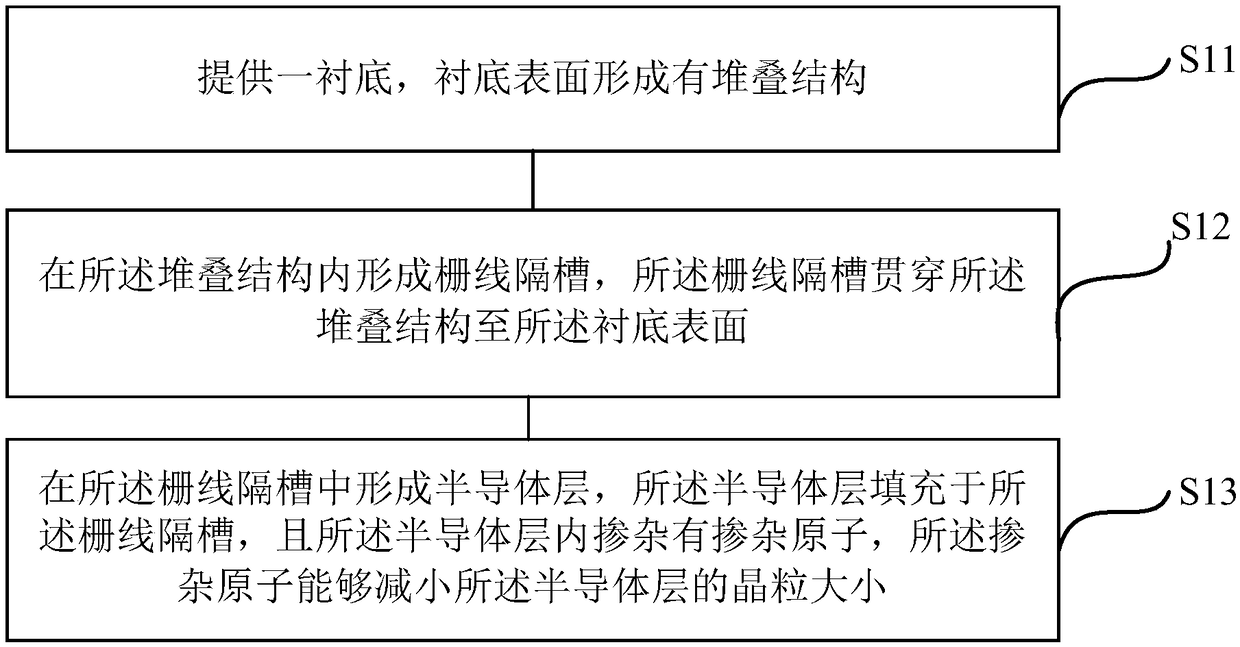

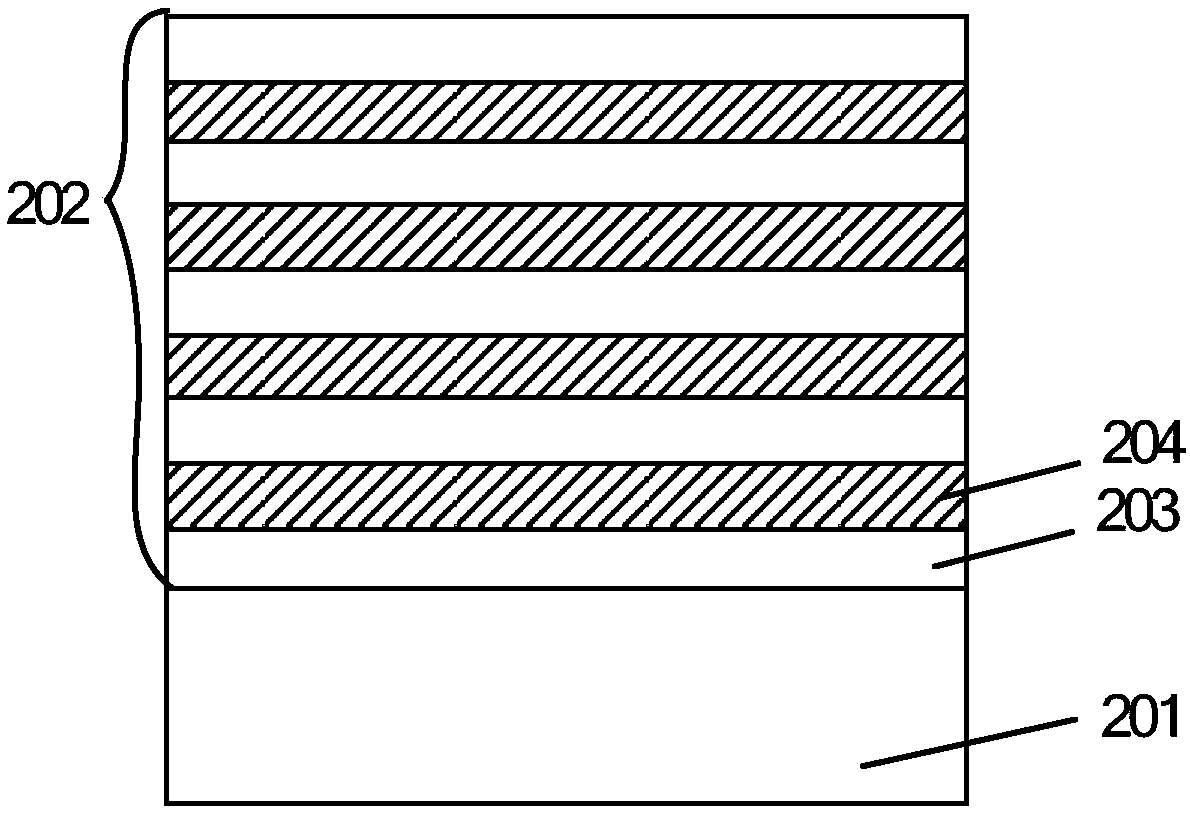

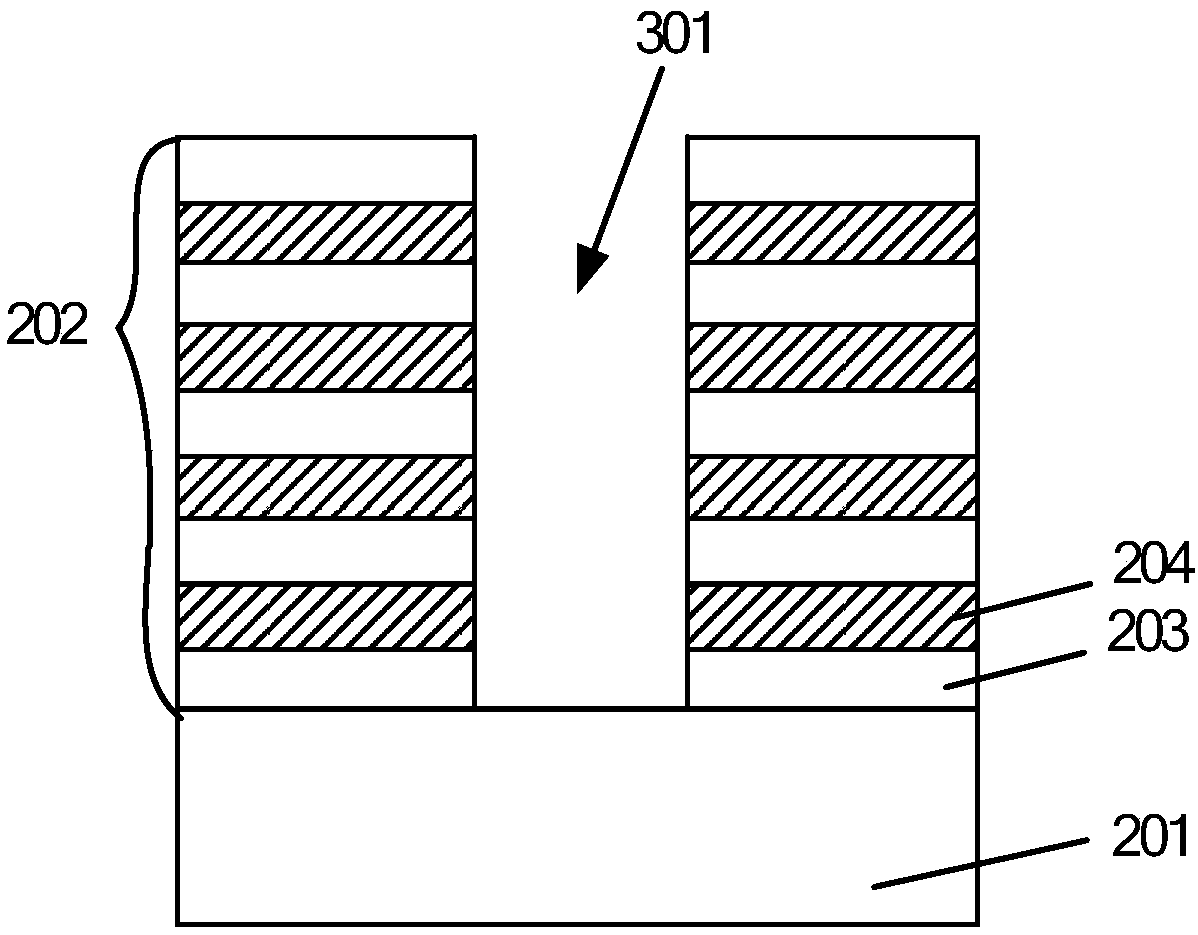

Semiconductor structure

PendingCN108962903AReduce grain sizeUniform grain sizeSolid-state devicesSemiconductor devicesSemiconductor structureSemiconductor package

The invention relates to a semiconductor structure comprising a substrate, a memory stacked structure formed on the surface of the substrate, a grid line spacing slot penetrating the memory stacked structure to the surface of the substrate, and a semiconductor layer filling the grid line spacing slot. The semiconductor layer is doped with doping atoms for reducing the crystal particle size. The semiconductor layer formed based on the semiconductor structure has small crystal particles; and the performance of the semiconductor structure can be improved.

Owner:YANGTZE MEMORY TECH CO LTD

Single-chip package part with wafer thinned after bottom fillers cures and manufacture process thereof

InactiveCN103094236ASmall sizeReduce the chance of warpingSemiconductor/solid-state device detailsSolid-state devicesSolder ballWafer thinning

The invention relates to a single-chip package part with a wafer being thinned after bottom fillers cures and a manufacture process thereof. The package part is mainly composed of a substrate, a nickel gold soldering pad, a chip, a tin-silver salient point, bottom fillers and a solder ball, wherein the nickel gold soldering pad is fixedly connected on the substrate, the tin-silver salient point is fixedly connected on the chip, the tin-silver salient point coincides with the central line of the nickel gold soldering pad and is welded with the nickel gold soldering pad, the bottom fillers are filled in a gap between the substrate and the chip to surround the nickel gold soldering pad and the tin-silver salient point, and the tin-silver salient point and the nickel gold soldering pad are welded through soldering flux. The manufacture process comprises the following steps of bonding the chip, reflow soldering, cleaning with deionized water, filling, curing, thinning the wafer, reballing, checking, packing and storing. The manufacture process enables the package part to be thin in size, high in performance and can obviously reliability of the package part.

Owner:HUATIAN TECH XIAN

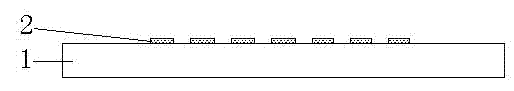

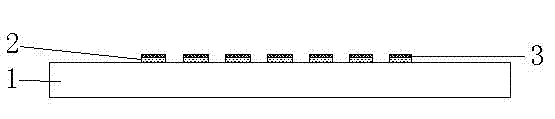

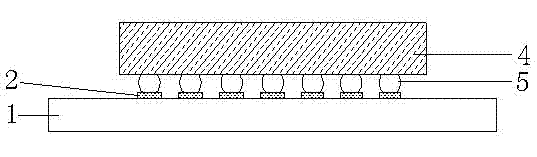

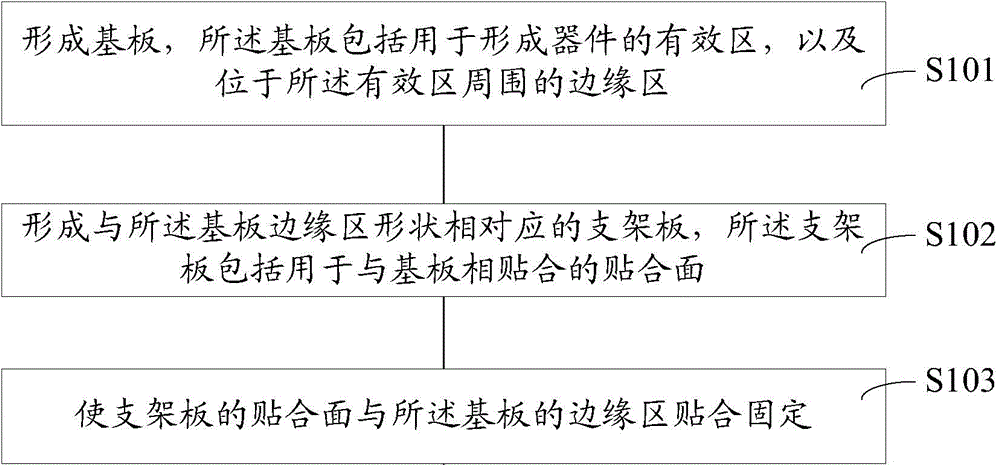

Making method of substrate with support

InactiveCN104411100AAvoid warpingAvoid damageMechanical/acoustic circuit processingCooling/ventilation/heating modificationsState of artEngineering

Owner:NANTONG FUJITSU MICROELECTRONICS

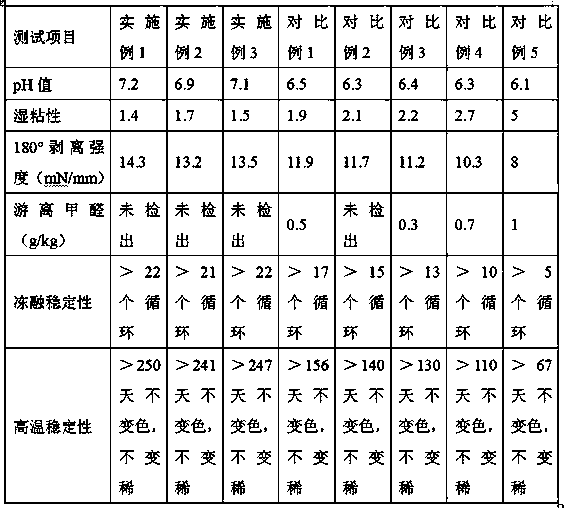

Anti-warping glutinous rice glue and preparation method thereof

InactiveCN110183974AReduce molecular weightReduce viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAmylasePolymer science

The invention discloses anti-warping glutinous rice glue and a preparation method thereof, and belongs to the technical field of building materials. Glutinous rice base glue is prepared by taking glutinous rice as a raw material for gelatinization, alpha-amylase is added to cut off starch molecular main chains, and then a part of alcohol hydroxyl groups on the starch molecular chains are oxidizedby substances such as hydrogen peroxide and the like, so that solubility of the glutinous rice glue is enhanced. According to the invention, palm oil and the like are taken as raw materials, vermiculite and diatomaceous earth are added at the same time, moisture of the glutinous rice glue is kept through water absorption, and bonding performance is improved. An amphiphilic moisturizing active agent is prepared by carrying out a reaction on coconut oil acyl chloride with phospholipid, and glacial acetic acid and the like are added for a reaction to form a stable glutinous rice glue system, so that warping possibility of wallpaper is reduced. The glutinous rice based glue is used for improving permeability of the glutinous rice glue, a grease additive is added for preventing dry shrinkage and cracking, and the amphiphilic moisturizing active agent is added to reduce warping of the wallpaper, so that usability of the glutinous rice rubber is improved. According to the invention, the problem that the wallpaper is warped due to the fact that a hardening phenomenon occurs easily after existing glutinous rice glue is used for construction is solved.

Owner:陈光辉

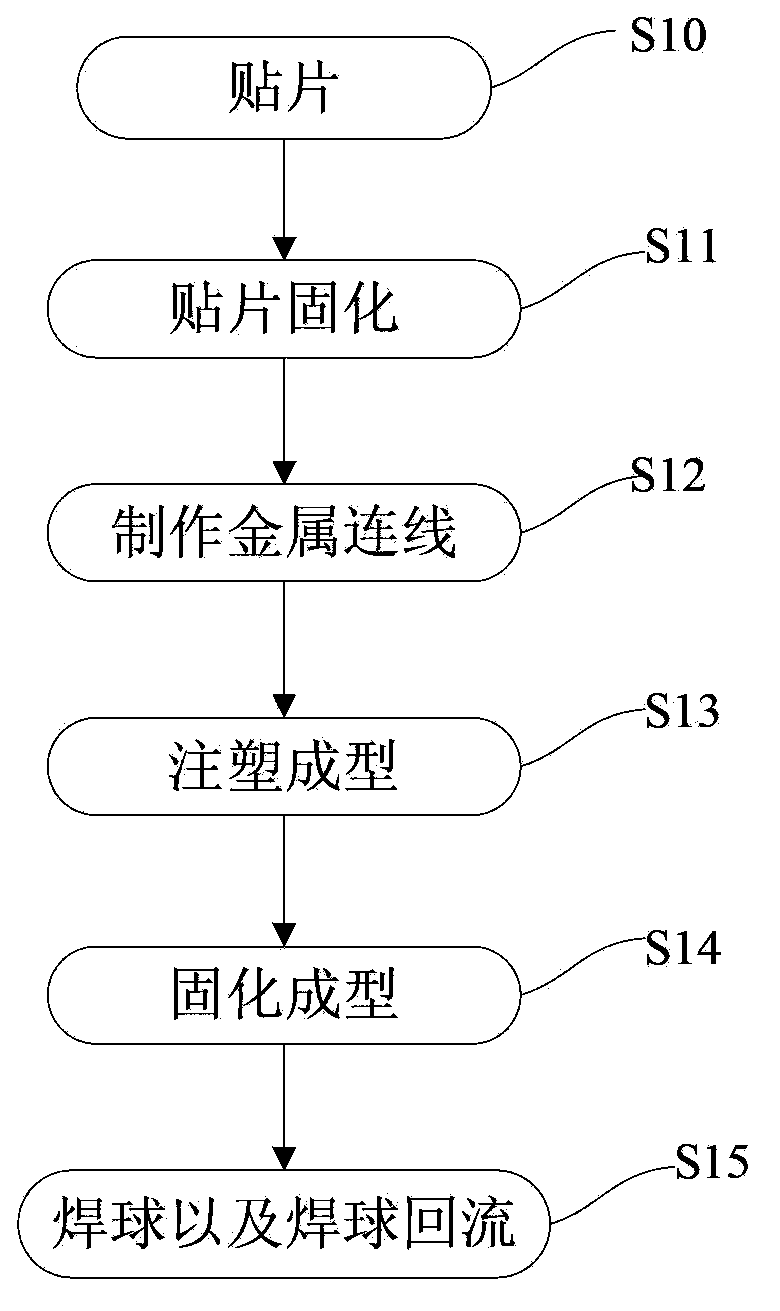

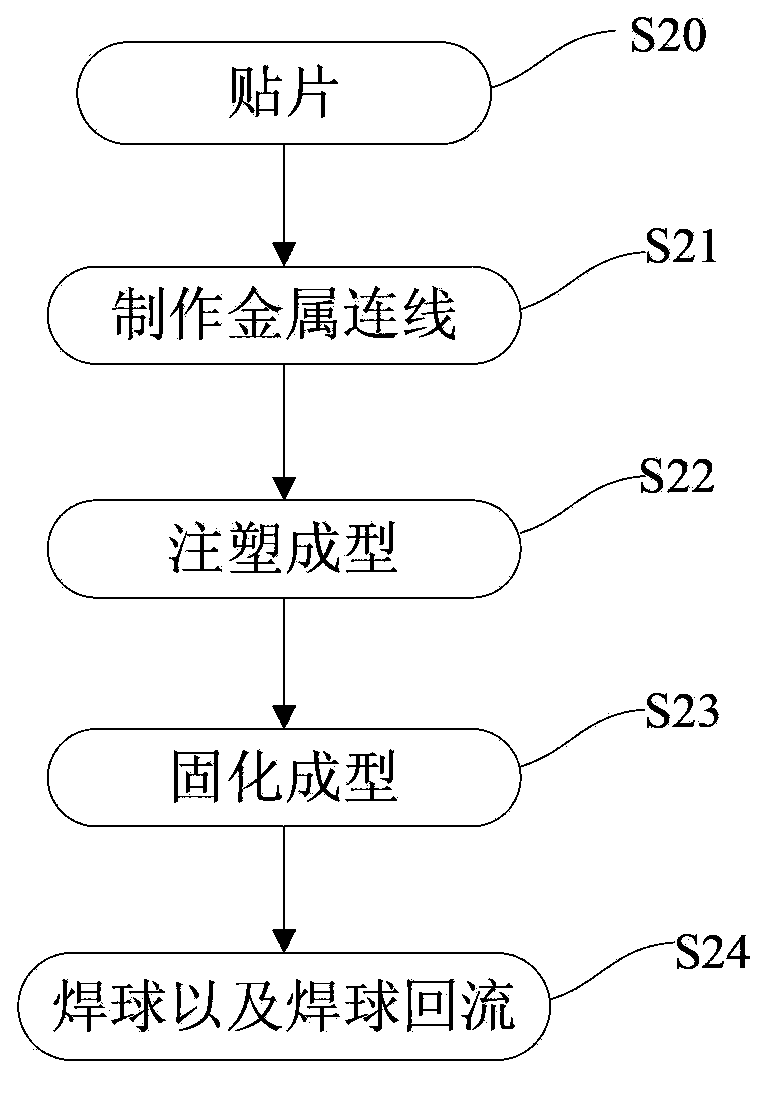

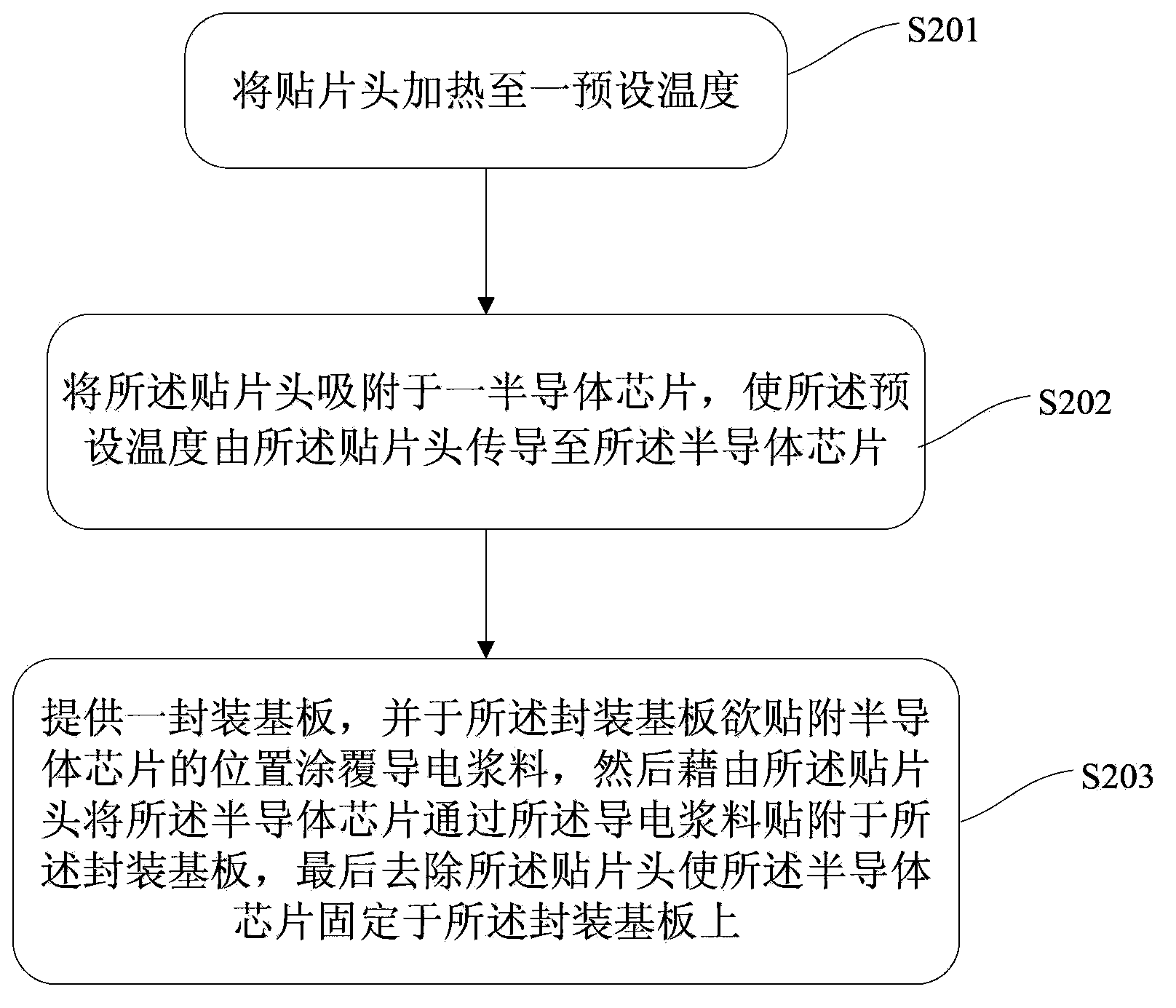

Chip mounting process for semiconductor chip packaging process

InactiveCN103985643AReduce warpageOmit the heating stepSolid-state devicesSemiconductor/solid-state device manufacturingSilver pasteSemiconductor chip

The invention provides a chip mounting process for a semiconductor chip packaging process. The chip mounting process comprises a first step of heating a chip mounting head to a preset temperature; a second step of adsorbing the chip mounting head to a semiconductor chip to conduct the preset temperature to the semiconductor chip from the chip mounting head; a third step of providing a packaging substrate, enabling the position of the packaging substrate where the semiconductor chip is to adhere to be coated with conductive slurry, attaching the semiconductor chip to the packaging substrate through the conductive slurry by means of the chip mounting head, and finally removing the chip mounting head to fix the semiconductor chip on the packaging substrate. The heating of the chip mounting process is transferred to the chip small in thermal expansion coefficient from the substrate high in thermal expansion coefficient, warping of the substrate can be effectively reduced; a substrate heating step is omitted, silver paste is solidified in a follow-up solidification processing process, process time is saved, the production cost is reduced, the warping probability of the substrate is also reduced, and the rate of finished products is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

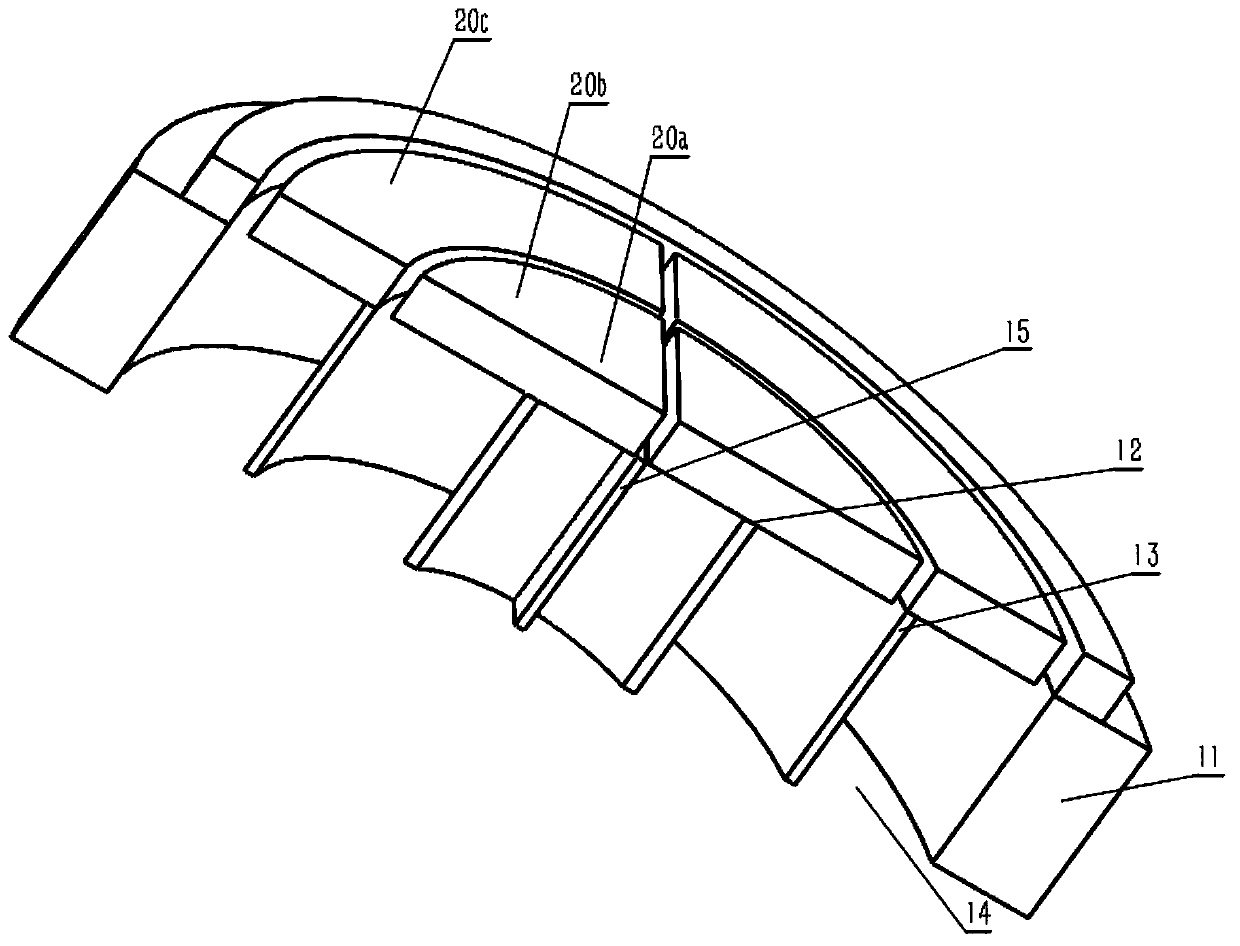

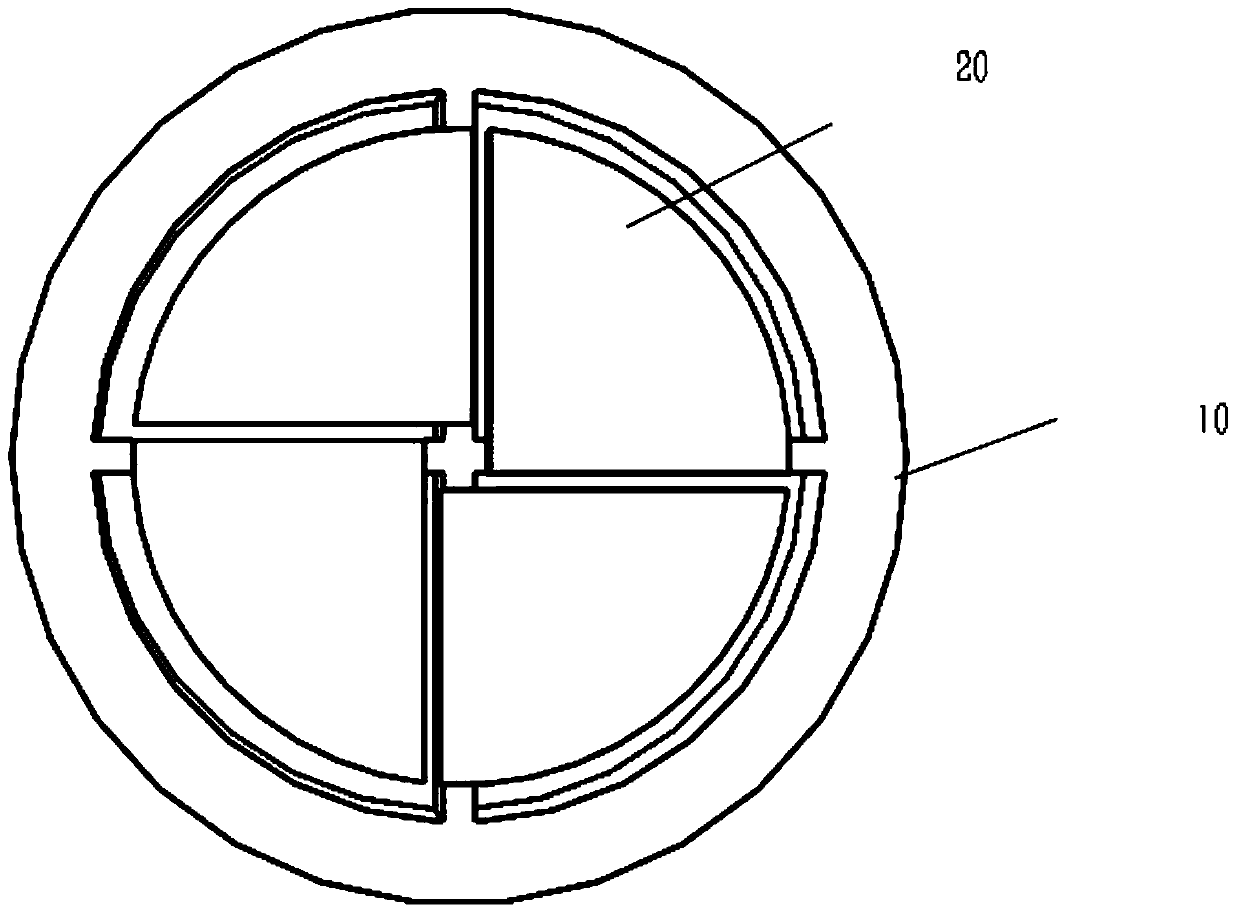

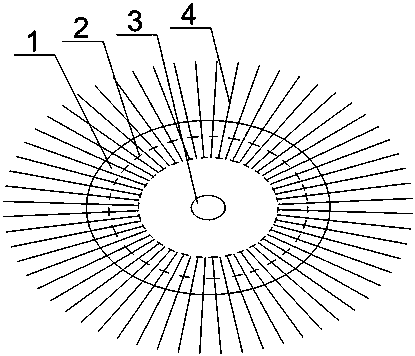

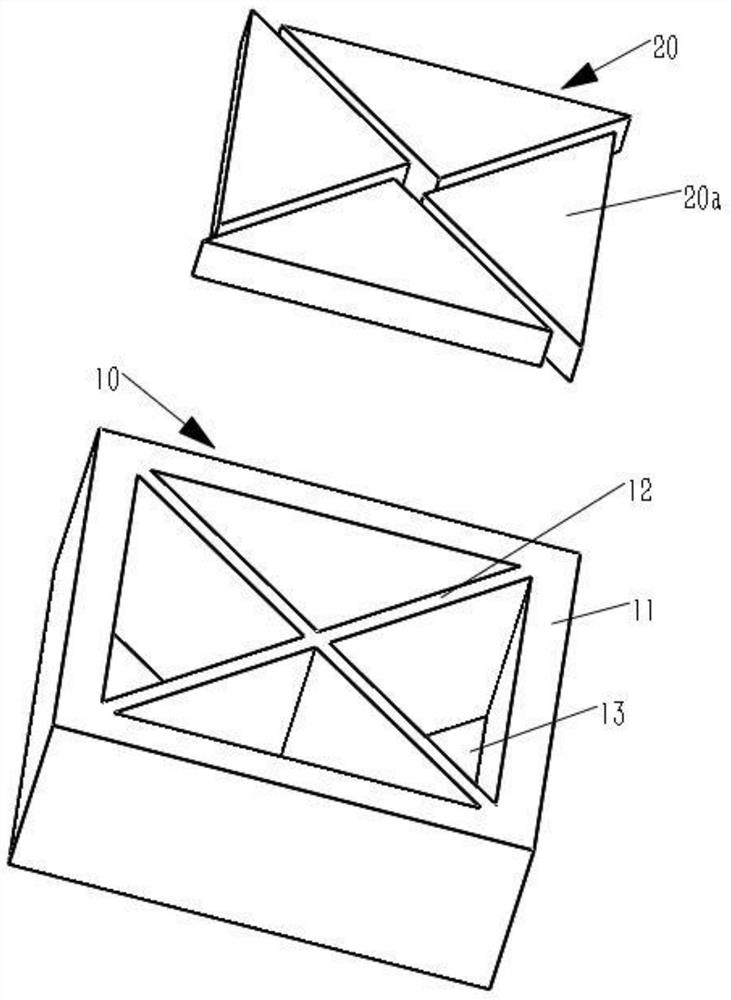

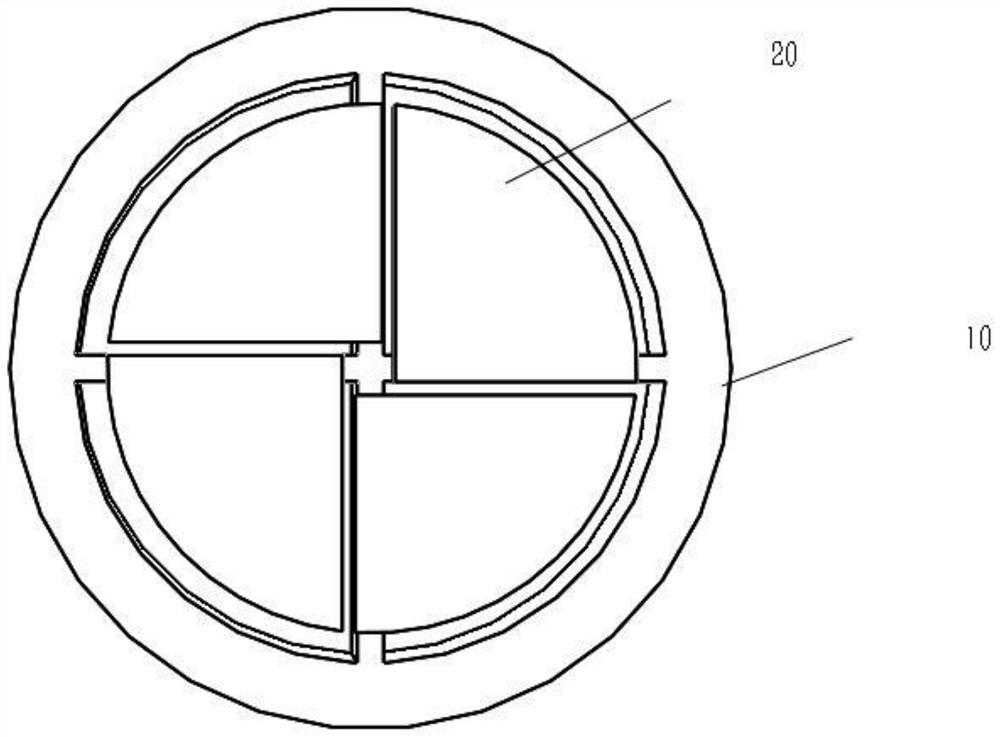

MEMS structure

PendingCN111405445AReduce processing difficultyReduce the chance of warpingMicrophonesLoudspeakersCantilevered beamEngineering

The invention discloses an MEMS structure comprising a substrate which comprises an outer ring body and a first inner ring body which is arranged in the outer ring body and spaced from the outer ringbody, wherein cavities are formed between the outer ring body and the first inner ring body and in the inner side of the first inner ring body; and a piezoelectric composite vibration layer formed above the substrate, and comprising a fixed end connected with the first inner ring body and a free end suspended above the cavity. By arranging one or more inner ring bodies, the length of a cantileverbeam from the fixed end to the free end is shortened, so that the warping probability of the diaphragm of the piezoelectric composite vibration layer is reduced. The sensitivity of a plurality of cantilever beam structures in the piezoelectric composite vibration layer is effectively improved.

Owner:ANHUI ORINFIN ACOUSTIC SCI&TECH CO LTD

MEMS structure

PendingCN111405442AReduce processing difficultyReduce the chance of warpingSemiconductor electrostatic transducersElectrostatic transducer microphonesCantilevered beamEngineering

The invention discloses an MEMS structure, which comprises a substrate comprising an outer ring body and a support plate arranged in the outer ring body and connected with the outer ring body, and characterized in that a cavity is formed between the support plate and the outer ring body; and a piezoelectric composite vibration layer formed above the substrate, and comprising a fixed end connectedwith the support plate and a free end suspended above the cavity. Therefore, compared with the technical scheme that the MEMS structure does not contain the support plates, the length of a cantileverbeam from the fixed end to the free end is shortened by arranging one or more support plates, so that the warping probability of the diaphragm of the piezoelectric composite vibration layer is reduced. Moreover, the process difficulty of the MEMS structure is reduced, and the yield and the stability of the device are improved. In addition, a plurality of cantilever beam structures in the piezoelectric composite vibration layer effectively improve the sensitivity.

Owner:ANHUI ORINFIN ACOUSTIC SCI&TECH CO LTD

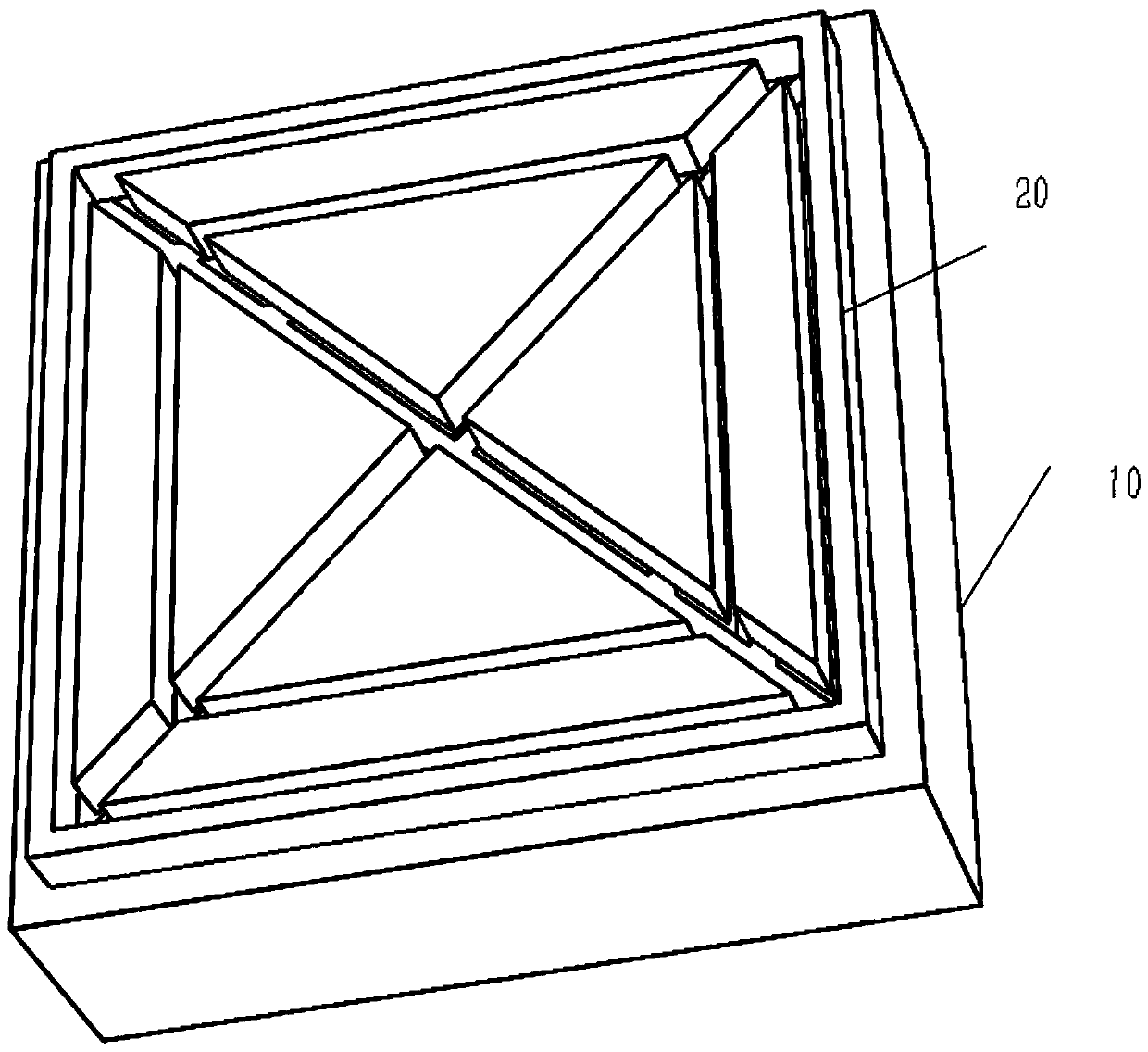

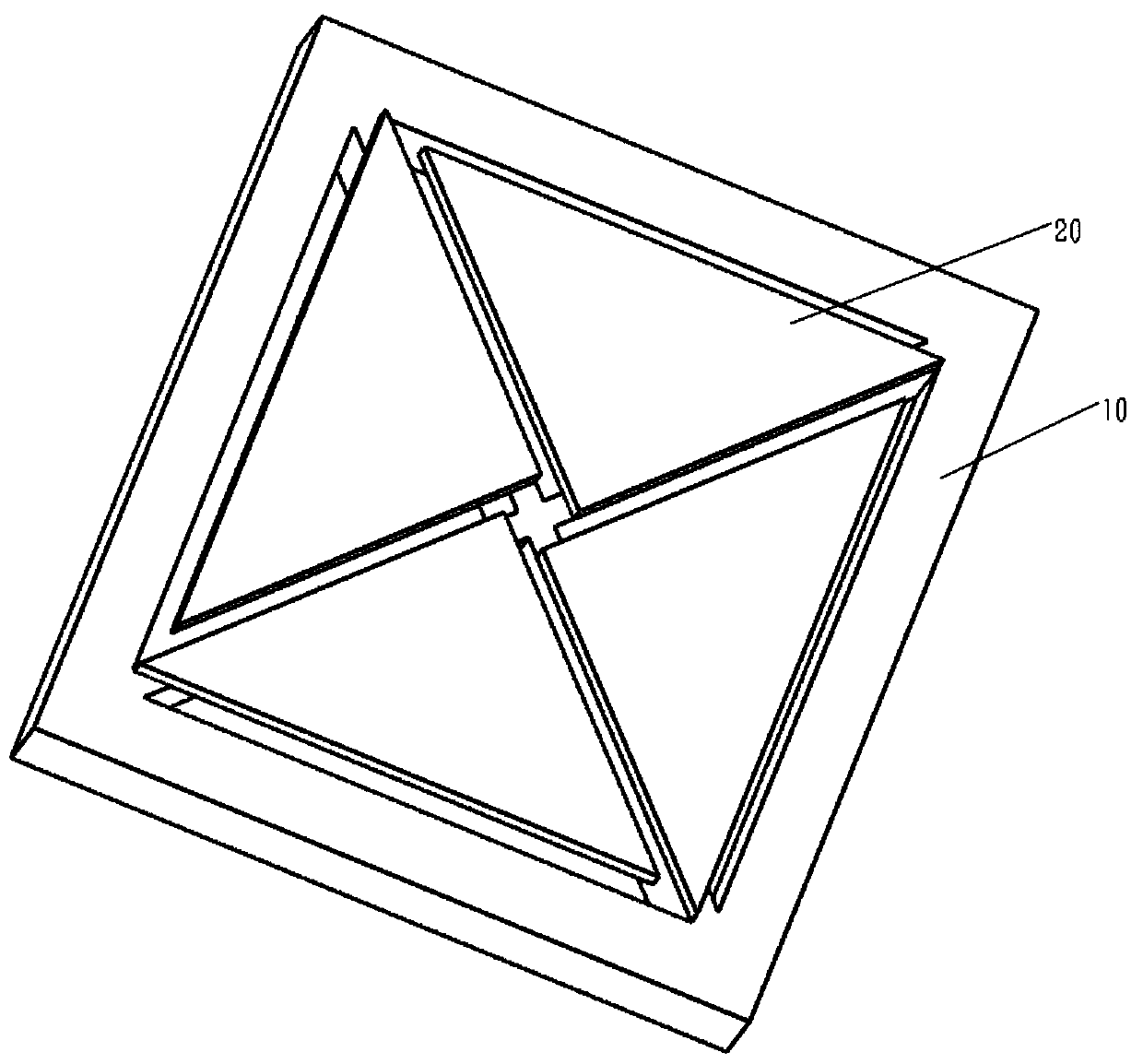

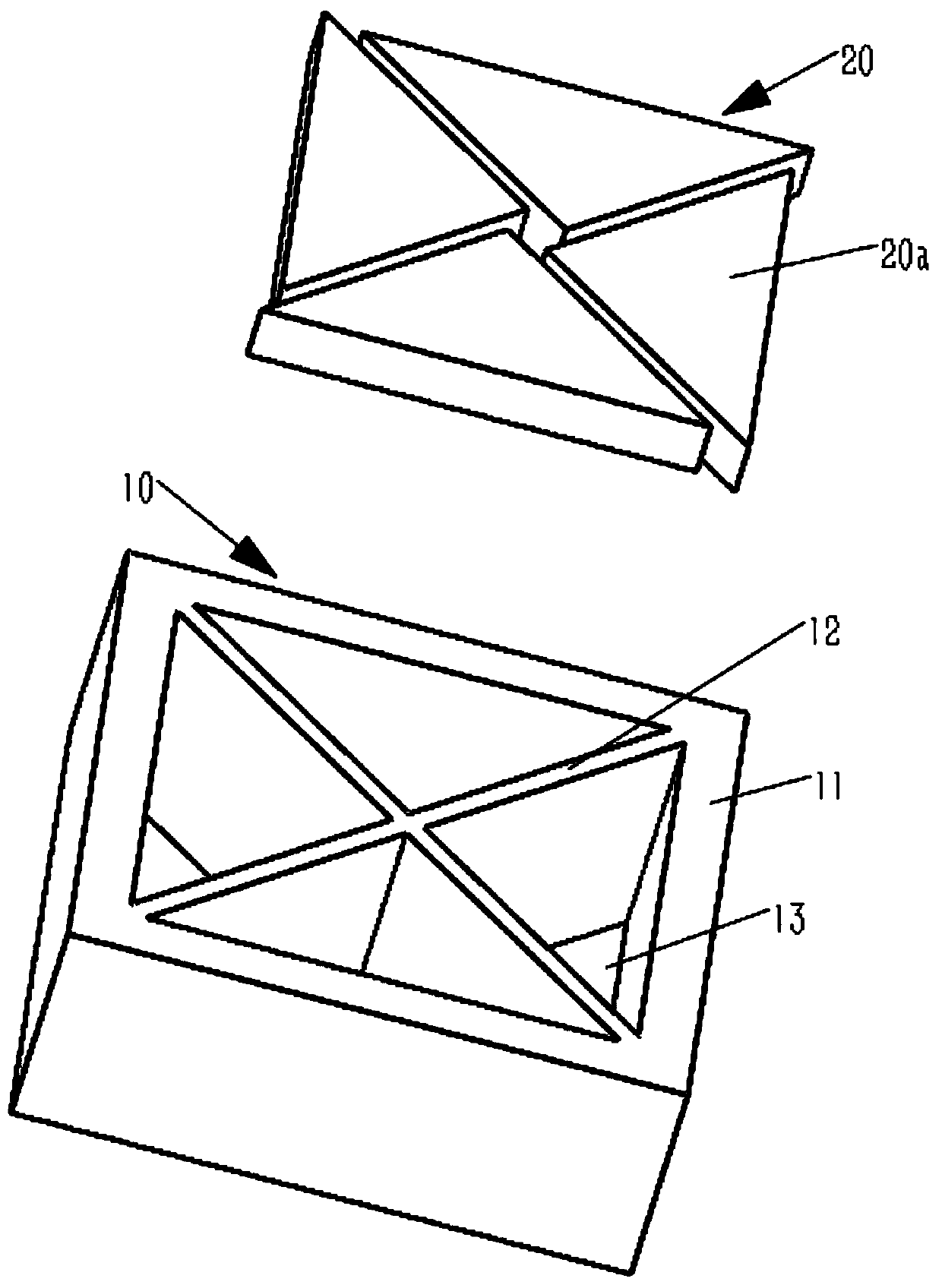

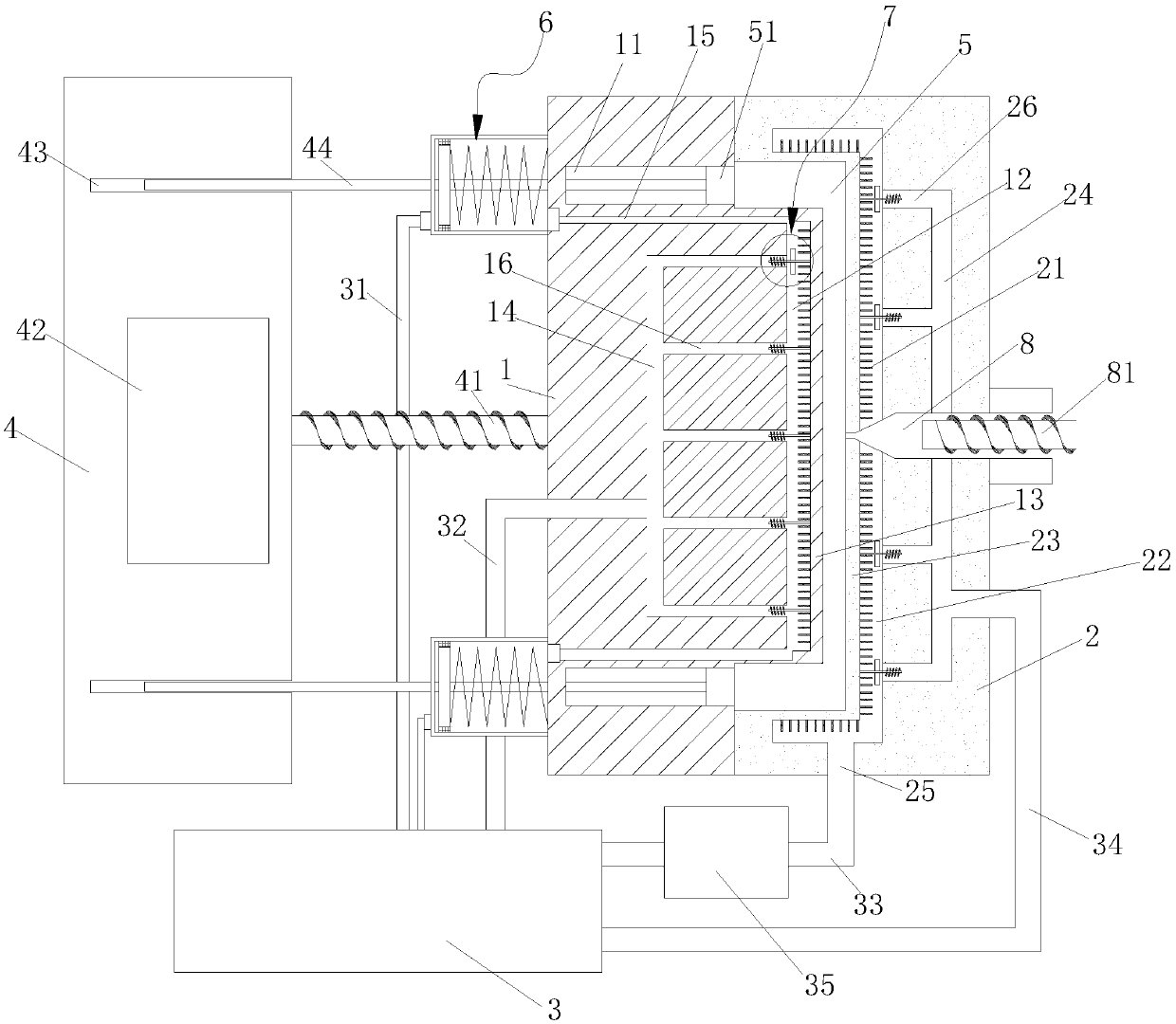

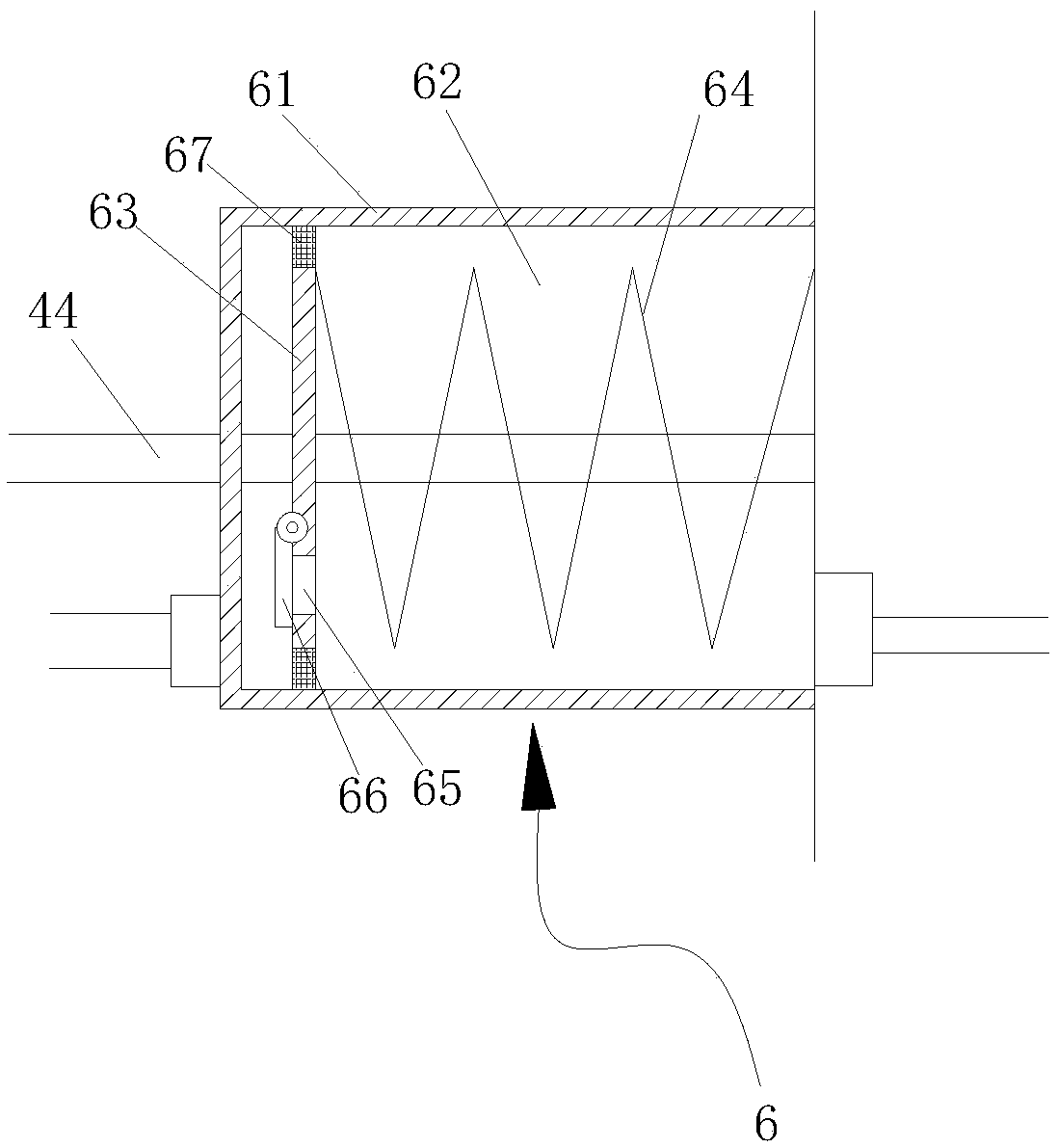

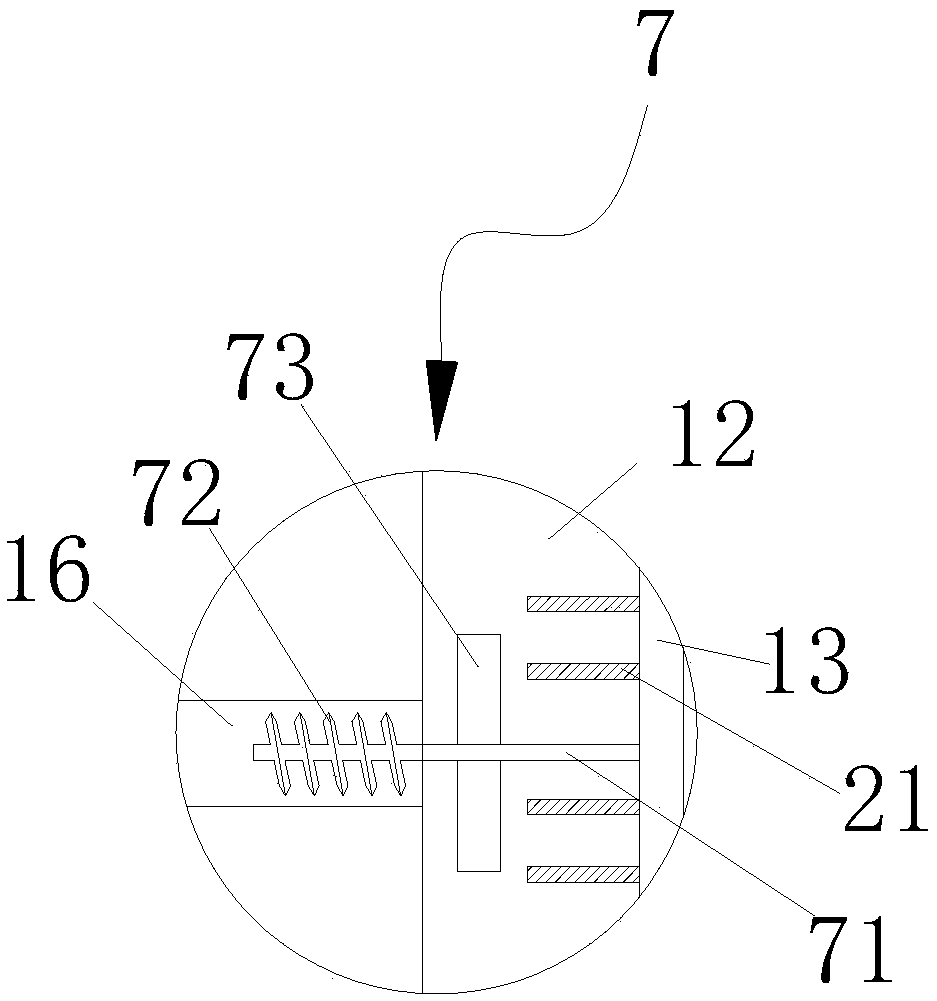

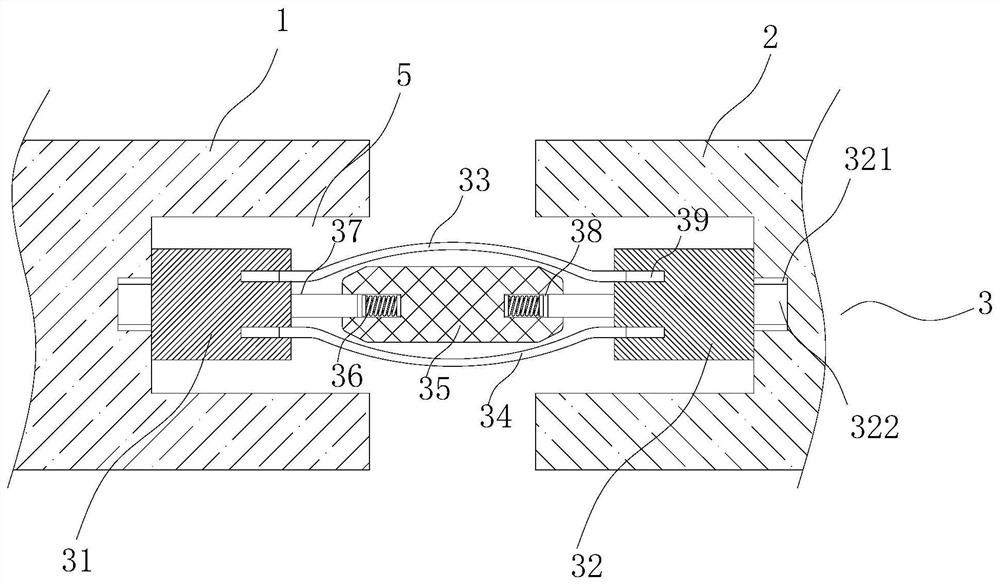

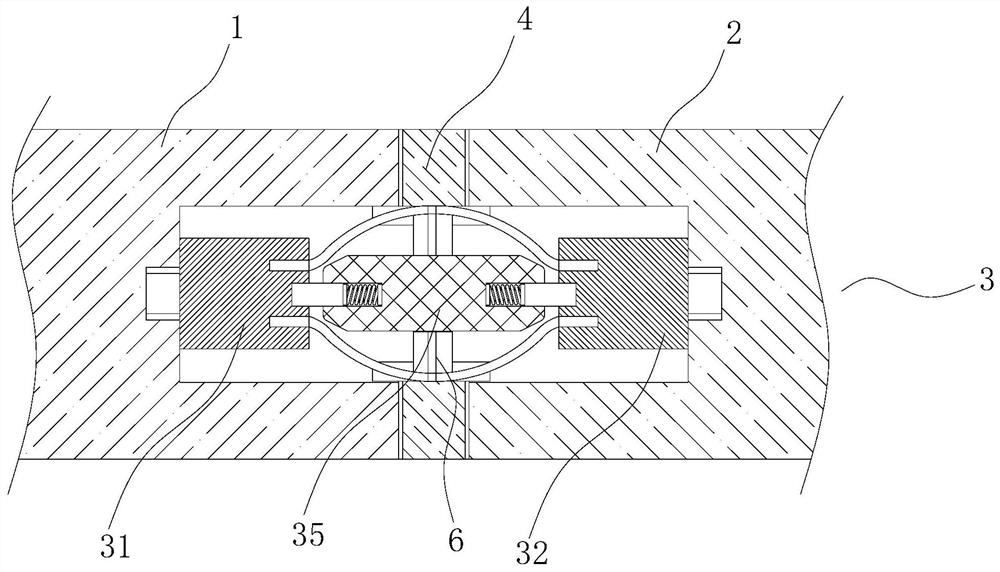

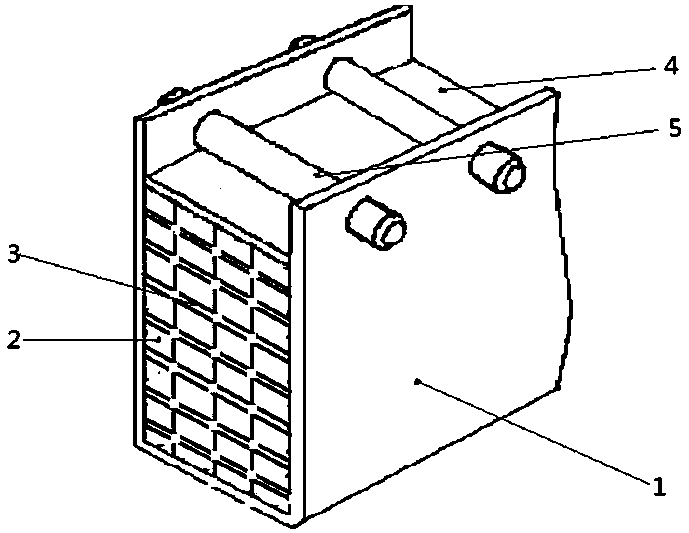

Die cooling structure capable of reducing warpage deformation

PendingCN109676884AReduce the chance of warpingEven heat dissipationMechanical engineeringWater pipe

The invention discloses a die cooling structure capable of reducing warpage deformation. The die cooling structure comprises a male die, a female die, a water tank and a mounting frame, the male die and the female die are clamped with each other to form a die core cavity; and the left side and the right side of the die core cavity are respectively provided with a heat dissipation cavity I and a heat dissipation cavity II, and a main pipeline I, four water return pipelines I and a plurality of branch pipelines I are arranged in the male die, wherein one end of each branch pipeline I is connected with the heat dissipation cavity I. Different from the cooling method in which multiple water pipes are distributed in the die in the conventional technical means, the heat dissipation cavity I is used to cool and dissipate heat. The water injection mode in the male die is to inject water into the heat dissipation cavity I through the plurality of branch pipelines I, so that the speed of the cold water entering the heat dissipation cavity I is synchronous. Different from the cooling mode of the heat absorption of the pipeline in the die of the conventional technical means, the warpage deformation possibility of the die core can be reduced through a uniform water injection mode.

Owner:TONGLING CHANGMAN PLASTIC CO LTD

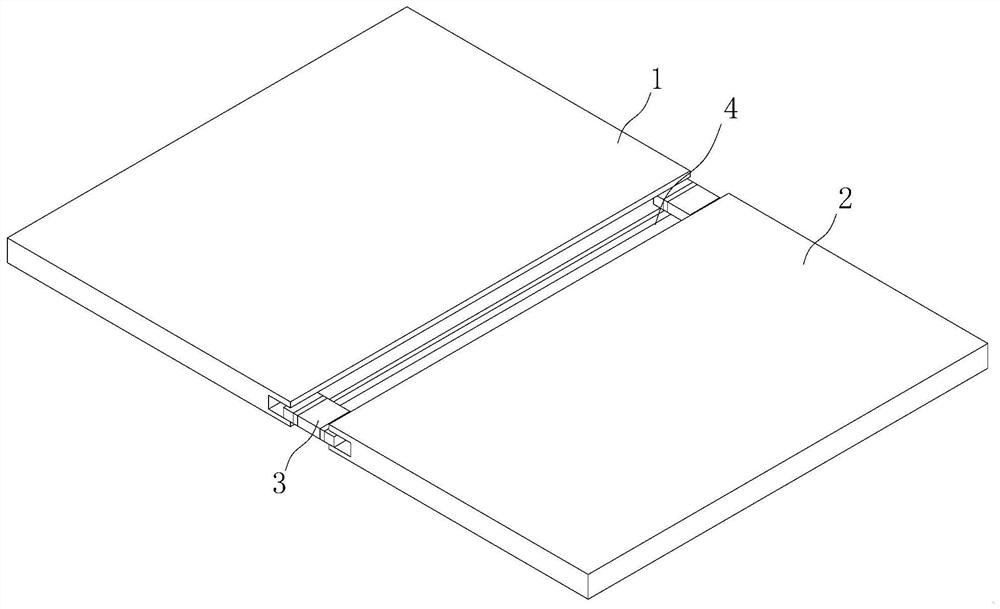

Household solid wood floor

ActiveCN113389349AGuaranteed flatnessReduce the chance of warpingCovering/liningsFlooring insulationsSolid woodStructural engineering

The invention discloses a household solid wood floor. The household solid wood floor comprises a first floor body and a second floor body, strip-shaped grooves are formed in the adjacent faces of the first floor body and the second floor body correspondingly, the two grooves are the same in size, an insertion strip is fixedly connected to the middle position in the groove formed in one side of the second floor body, and insertion connection mechanisms are installed at the front end and the rear end of the groove correspondingly, and 5-10cm gaps for mounting the insertion mechanism are reserved at the front and rear ends of the insertion strip and the two ends of the groove. The insertion connection mechanism is additionally arranged on the household solid wood floor, a specified gap is automatically reserved for spliced solid wood floors through the insertion connection mechanism during working, and when adjacent solid wood floors are spliced, the adjacent solid wood floors extrude the insertion connection mechanism, and an upper elastic piece and a lower elastic piece are forced to deform and extrude elastically through guidance displacement, so that flatness is ensured; and in the later physical change process of expansion caused by heat and contraction caused by cold of the solid wood floor, the splicing position is further fixed, and the probability of warping deformation of the solid wood floor is reduced.

Owner:湖北三森木业股份有限公司

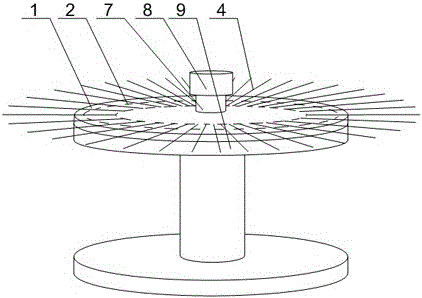

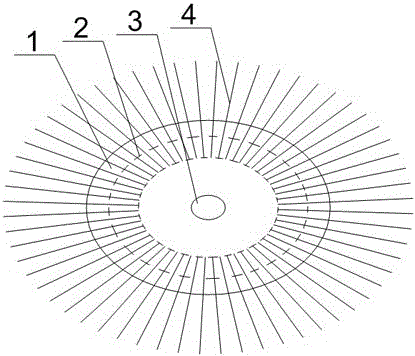

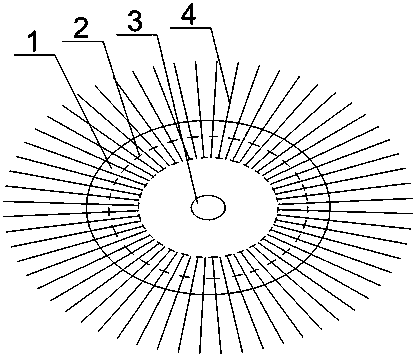

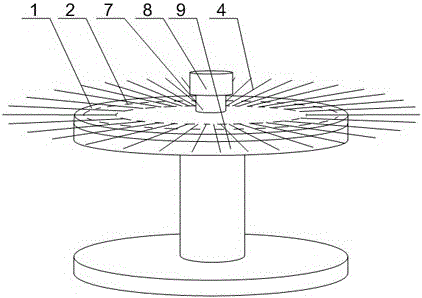

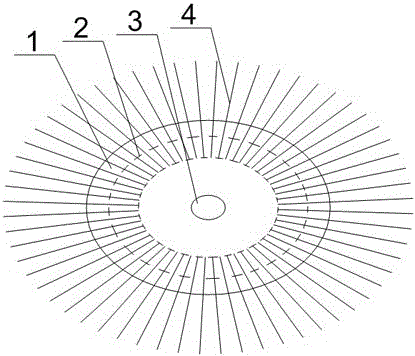

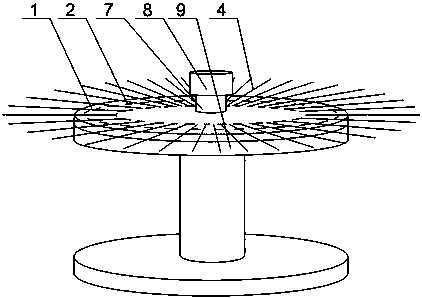

Copper wire pay-off device

InactiveCN105788765AEasy to disengageEasy to disengage copper wire quicklyCable/conductor manufactureCopper wireEngineering

A copper wire pay-off device disclosed by the present invention comprises a brush plate and a plurality of resin fine wires, a fixing hole is arranged in the middle part of the brush plate, and the plurality of resin fine wires extend outwards along the radial direction of the brush plate. A concentric and annular lower platen is adhered on the upper surface of the brush plate, the resin fine wires are covered by the lower platen locally, and the lower surface of the lower platen is equipped with an annular groove in which a bending segment is placed. According to the present invention, by utilizing the flexibility of the plurality of resin fine wires on the brush plate and extending outwards, a copper wire is contacted with the resin fine wires directly before breaking away from a drum, so that the operation amplitude of the copper wire is increased when the copper wire breaks away from the drum, the resin fine wires recover to the initial positions because of the own elastic deformation recovery effects after generating a certain swing upwards along with the copper wire, at the same time, the wear extent caused by the contact of the copper wire and the resin fine wires can be neglected, namely, the wear of the copper wire is reduced while the copper wire can break away from the drum conveniently and rapidly.

Owner:CHENGDU XINGDA OF COPPER CO LTD

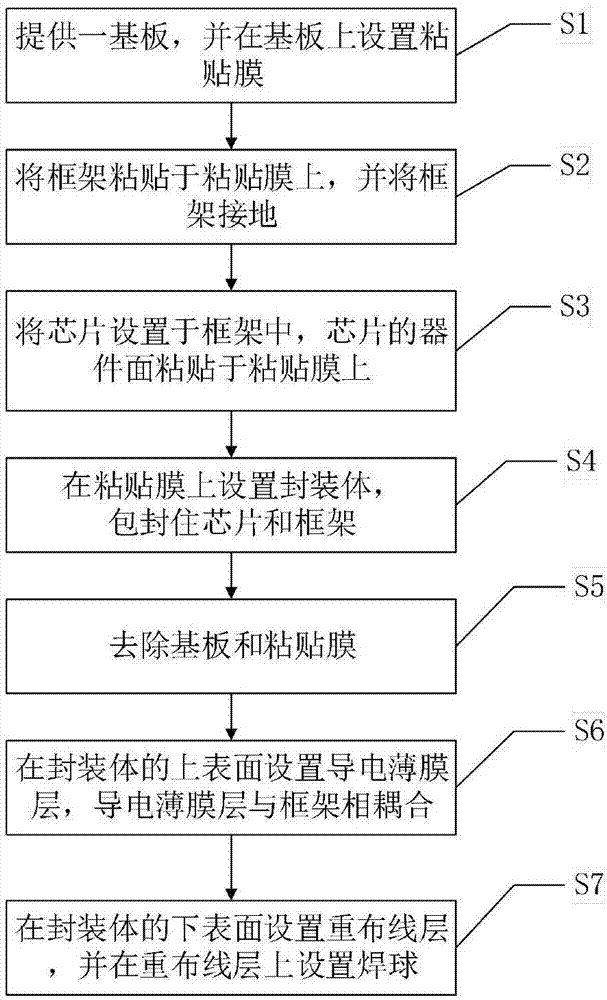

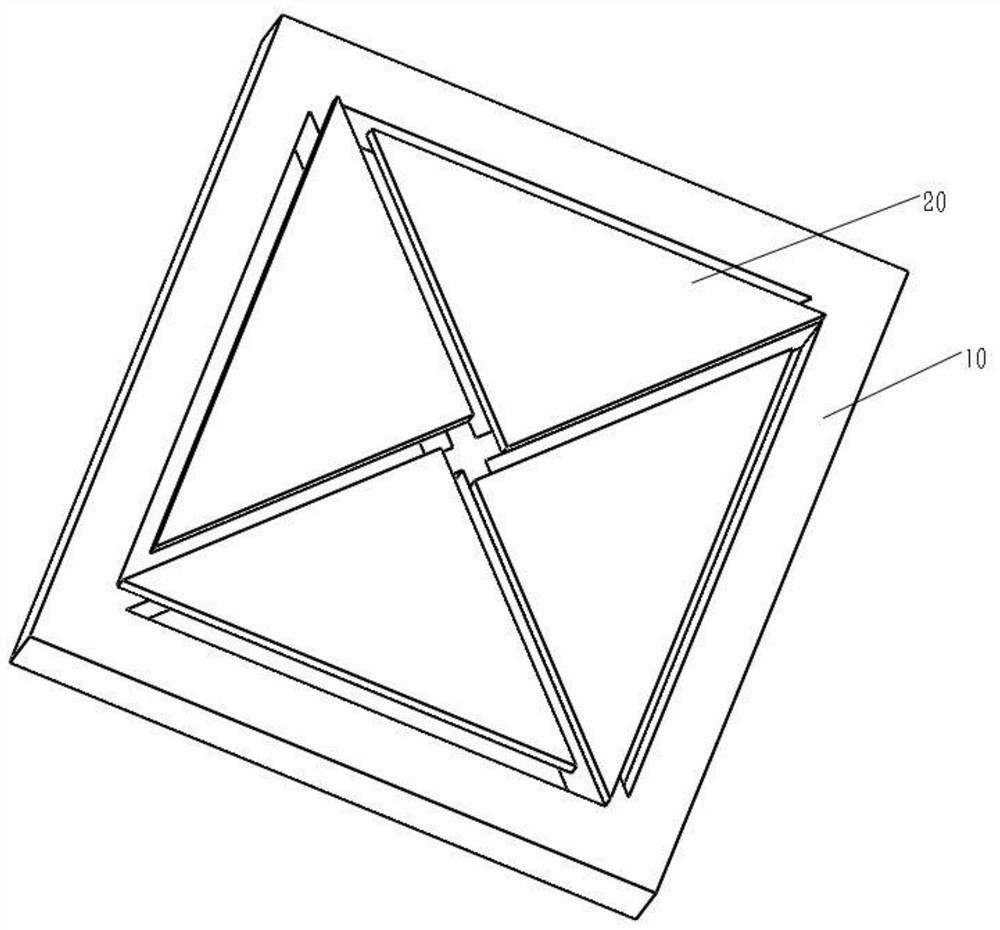

Method for manufacturing chip packaging structure

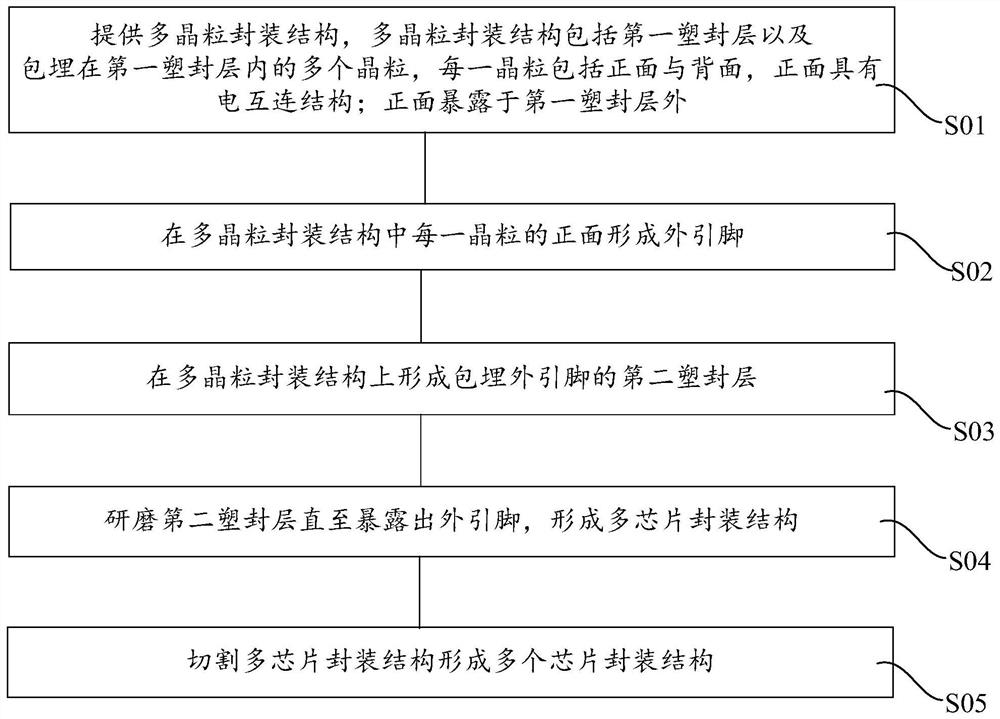

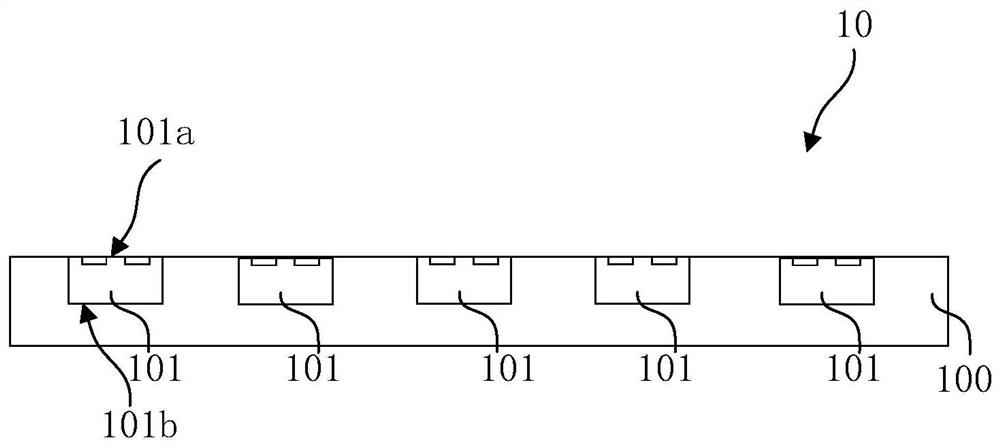

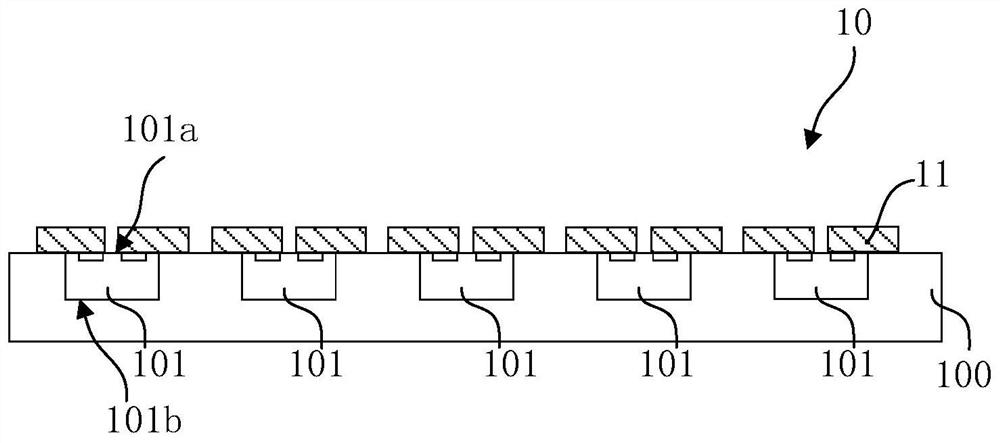

ActiveCN112117202AReduce warpageImprove electrical connection reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingPlastic packagingElectrical connection

The invention provides a method for manufacturing a chip packaging structure, and the method comprises the steps: dividing a multi-crystal-grain packaging structure into a plurality of regions, and enabling each region to comprise a plurality of crystal grains; and when a second plastic packaging layer for embedding the outer pins is formed on the crystal grain packaging structure, curing the second plastic packaging layer by using a multi-cavity mold with a partition plate. The multi-cavity mold can reduce the curing shrinkage range of the second plastic package layer from one whole block toa plurality of small blocks, so that the shrinkage stress is reduced exponentially due to the reduction of the shrinkage range when the liquid plastic package material is cured, the warping degree ofthe multi-grain package structure is reduced, and the problem of the electrical connection reliability of the outer pins can be improved.

Owner:SIPLP MICROELECTRONICS CHONGQING CO LTD

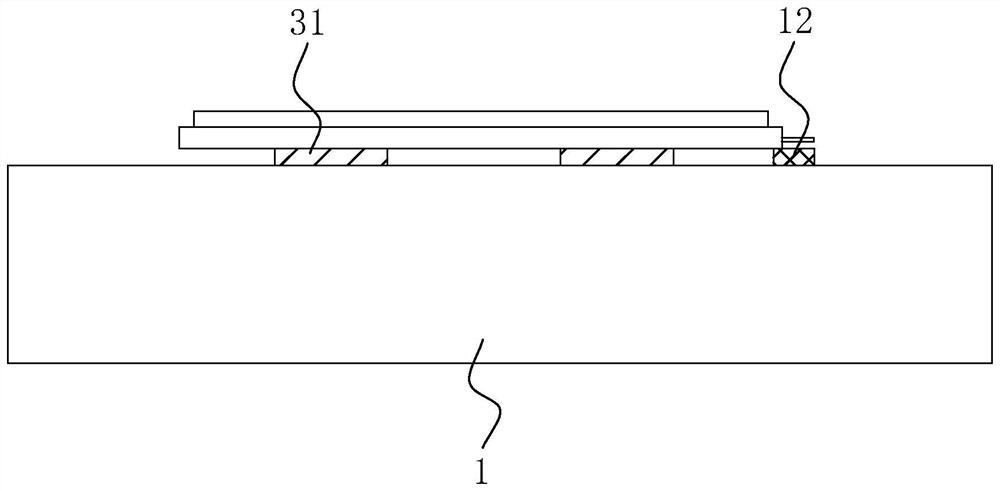

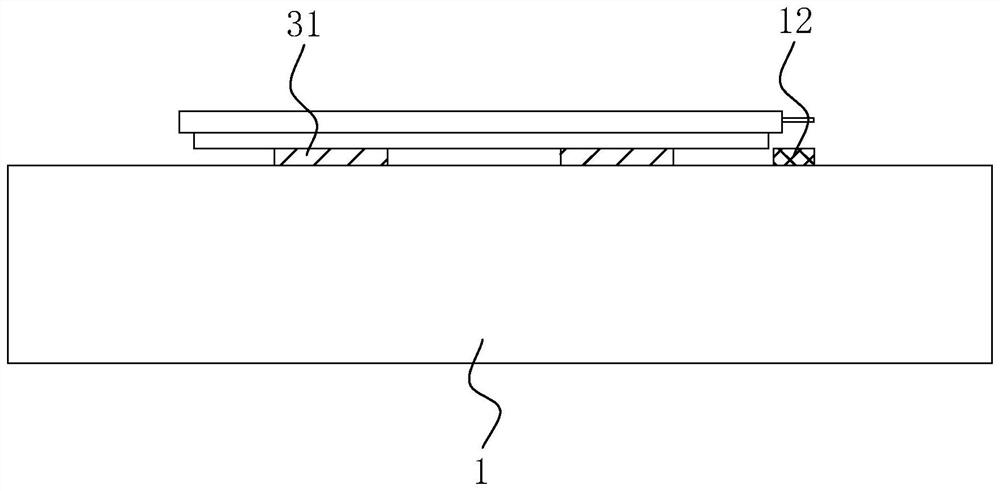

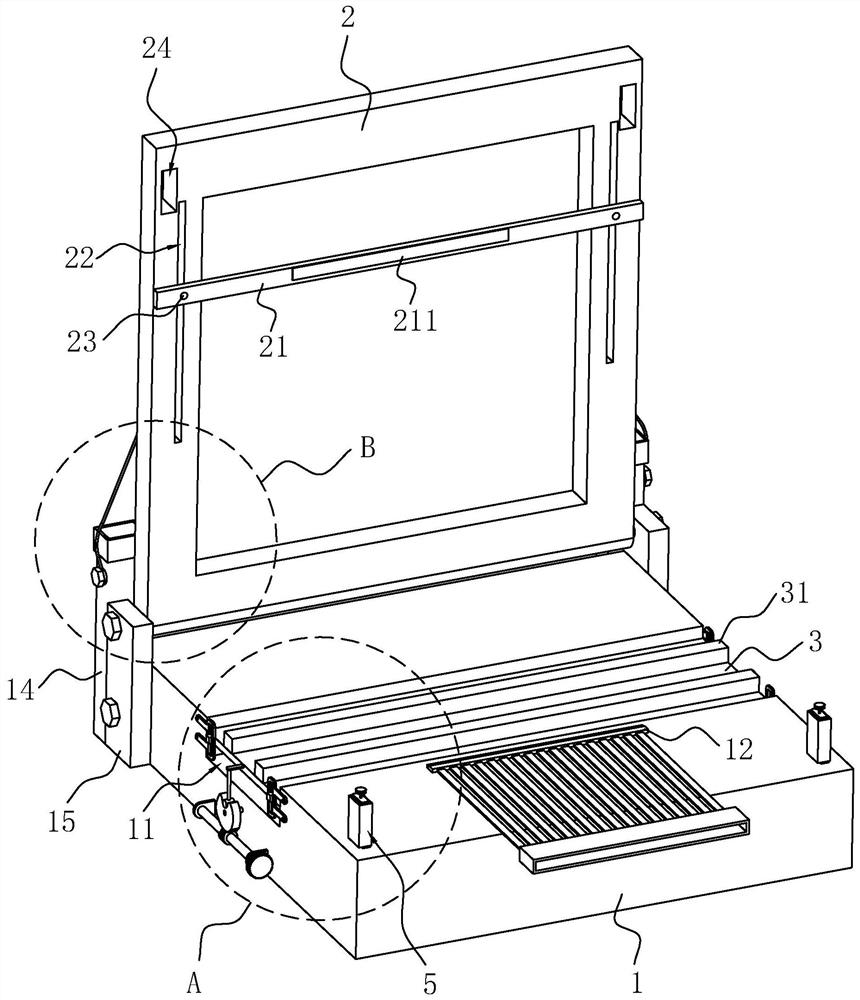

LCD (Liquid Crystal Display) electric detection test device

ActiveCN114200699AReduce warpageImprove compatibilityStatic indicating devicesNon-linear opticsLiquid-crystal displayElectrically conductive adhesive

The application relates to an LCD electric detection test device, which comprises a base and a gland, the upper surface of the base is provided with an insulating cushion layer for placing an LCD product and a first conductive adhesive tape for abutting against a connecting terminal of the LCD product, the lower surface of the insulating cushion layer is provided with a supporting plate, and the supporting plate is slidably connected to the base. The sliding direction of the supporting plate and the height direction of the base are arranged in the same direction; and a positioning mechanism for positioning the supporting plate is arranged between the supporting plate and the base. The gland is connected to the upper portion of the base in a flip mode, a pressing strip is installed on the side, facing the base, of the gland, a second conductive adhesive tape is bonded to the side, facing the base, of the pressing strip, and when the gland is pressed on the base, the first conductive adhesive tape and the second conductive adhesive tape are attached to each other. The LCD electric detection test device can be suitable for front-mounted and back-mounted LCD products at the same time, the possibility of tilting of the LCD products during electric detection test is reduced, and then the compatibility of the LCD products and the accuracy of electric detection test results are improved.

Owner:深圳恩泽瑞显示科技有限公司

Wire drawing and paying-off structure

InactiveCN107768016AEasy to disengageEasy to disengage copper wire quicklyCable/conductor manufactureCopper wireThin wire

The invention discloses a wire-drawing and unwinding structure, including a brush plate and a plurality of thin resin wires, a fixing hole is opened in the middle of the brush plate, and a plurality of thin resin wires extend outwards of the brush plate along the radial direction of the brush plate. The upper surface of the brush disc is bonded with a concentric and ring-shaped lower pressing plate, the lower pressing plate partially covers the thin resin lines, the lower surface of the lower pressing plate is provided with an annular groove, and the curved section is placed in the annular groove. The present invention utilizes the flexibility of a plurality of resin thin wires extending outward on the brush disc to make the copper wires directly contact with the resin thin wires before detaching from the reel, so that the running range of the copper wires when detached from the reel increases, The thin resin wire will return to its original position due to its own elastic deformation recovery after a certain swing upward with the copper wire. At the same time, the amount of wear caused by the contact between the copper wire and the thin resin wire is negligible, which is convenient for the copper wire. While quickly detaching from the drum, the wear of the copper wire is reduced.

Owner:胡峻源

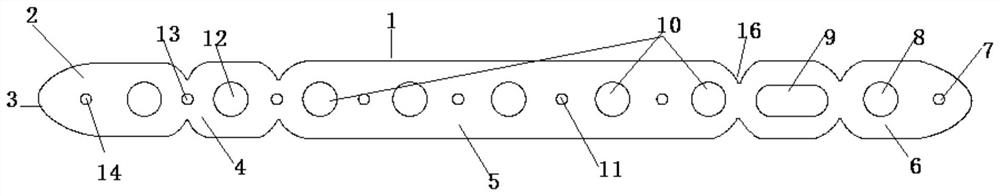

Bone fracture plate for ulna and radius shaft

The invention discloses a bone fracture plate for an ulna and radius shaft. Thebone fracture plate comprises a bone fracture plate body, the bone fracture plate body is in a long strip shape, the section of the bone fracture plate body is an arc-shaped face, the two ends of the bone fracture plate body are of fusiform structures, the end faces of the fusiform structures are in a smooth arc shape, and the bone fracture plate body is divided into a near joint section, a middle section and a far joint section. A far-end kirschner wire hole, a far-end locking hole and a sliding hole are sequentially formed in the far joint section, the far-end kirschner wire hole is located in the end of the far joint section, a plurality of middle locking holes are formed in the middle section, middle kirschner wire holes are formed between the adjacent middle locking holes, a plurality of near-end locking holes and near-end upper kirschner wire holes are formed in the near joint section, the near-end locking holes and the near-end upper kirschner wire holes are sequentially and alternately arranged along the near-joint section, and near-end lower kirschner wire holes are formed in the end of the near-joint section. The bone fracture plate is more suitable for the width-to-thickness ratio of the ulna and the radius, double-layer cortex fixation of the screw is facilitated, and the probability of complications is reduced.

Owner:SHANGHAI EAST HOSPITAL EAST HOSPITAL TONGJI UNIV SCHOOL OF MEDICINE

Pay-off spool for copper wire stranding process

InactiveCN105931751AEasy to disengageEasy to disengage copper wire quicklyApparatus for feeding conductors/cablesCopper wireReturn function

The invention discloses a pay-off spool for copper wire stranding process. The pay-off spool comprises a brush disk and a plurality of resin thin lines. The brush disk is provided with a fixation hole in the center; the plurality of resin thin lines extend out of the brush disk along the radial direction of the brush disk; the upper surface of the brush disk is bonded with a circular press plate concentric with the brush disk; the press plate covers a part of the resin thin lines; the lower surface of the press plate is provided with a circular groove; and bend sections are arranged in the circular groove. The flexibility of the plurality of resin thin lines extending outwards on the brush disk is utilized to enable copper wires to make direct contact with the resin thin lines before separating from a reel, so that operation amplitude of the copper wires is allowed to be enlarged when separating from the reel, the resin thin lines are allowed to return to initial positions due to elastic deformation return function of the resin thin lines after having a certain amplitude upwards with the copper wires, and meanwhile, abrasion loss caused when the copper wires make contact with the resin thin lines can be ignored, that is, the copper wires can be separated from the reel conveniently and quickly, and meanwhile, loss of the copper wires is reduced.

Owner:CHENGDU XINGDA OF COPPER CO LTD

Tab flattening device with simple and convenient operation for lithium ion battery production

ActiveCN112670675AEven by forceNot easy to damageFinal product manufactureCell component detailsStructural engineeringLithium-ion battery

The invention discloses a tab flattening device with simple and convenient operation for lithium ion battery production, which comprises a box body, wherein a buffer frame is arranged on the upper portion of an inner cavity of the box body, a pressing frame is embedded in the buffer frame, first transmission rollers are movably installed at the left end and the right end of the inner cavity of the pressing frame correspondingly, the surfaces of the two first transmission rollers are jointly sleeved with a lower pressing belt, lower pressing rollers are embedded in the lower pressing belt at equal intervals, a conveying belt is arranged below the lower pressing belt, supporting rollers are embedded in the middle of the conveying belt at equal intervals, and a sleeve is embedded in the top of the box body through a bearing. According to the invention, the lower pressing belt is used for extruding and flattening the whole tab so as to enable the whole tab to be stressed uniformly and not easy to damage, the probability that the edges of the tab tilt is reduced, the whole flattening effect on the tab is good, and the distance between the lower pressing belt and the conveying belt can be adjusted by rotating the handle, so that the pressure on the whole tab is adjusted, and the tab flattening effect is effectively improved.

Owner:湖南久森新能源有限公司

Adjusting device capable of realizing wire drawing and paying-off of copper wire

InactiveCN107768033AEasy to disengageEasy to disengage copper wire quicklyCable/conductor manufactureAdhesive discCopper wire

The invention discloses an adjusting device capable of realizing wire drawing and paying-off of a copper wire. The adjusting device comprises a hairbrush disc and a plurality of resin thin wires. Themiddle part of the hairbrush disc is provided with a fixing hole. The plurality of resin thin wires extend to outside of the hairbrush disc along the radial direction of the hairbrush disc. A downwardpressing plate which is concentric with the hairbrush disc and is annular is adhered on the upper surface of the hairbrush disc. The downward pressing plate covers partial parts of the resin thin wires. The lower surface of the downward pressing plate is provided with an annular trough in which a bent segment is arranged. According to the adjusting device, flexibility of the plurality of resin thin wires which outwards extend on the hairbrush disc is utilized so that the copper wire directly contacts with the resin thin wires before disengaging from a reel, and operation amplitude is increased in disengaging from the reel by the copper wire. After certain swinging amplitude of the resin thin wires in the vertical direction along the copper wire is generated, the resin thin wires restore to an initial position because of a self elastic deformation restoring function. Furthermore a wearing amount caused by contact between the copper wire and the resin thin wires can be ignored. Quick disengagement of the copper wire from the reel is realized, and furthermore wearing of the copper wire is reduced.

Owner:胡峻源

A kind of processing method of whole bamboo dense floor

ActiveCN105946067BEliminate internal stressGood dimensional stabilityCane mechanical workingReed/straw treatmentRoom temperatureEngineering

The invention discloses a machining method for whole bamboo dense floors. Firstly, fresh bamboo sections are manufactured into flat plate bamboo chips after the procedures of chip cutting, inner segment removing, softening and flattening, the flat plate bamboo chips are planed through a pressuring planer, and then whole bamboo floor blanks are manufactured; then, after the whole bamboo floor blanks are subjected to pressure impregnation and glue drainage, the whole bamboo floor blanks are stacked in a steel solidification tank in order, and the steel solidification tank is fed into a prepress for pressurizing and densifying; and finally, the steel solidification tank in which the whole bamboo floor blanks are stacked is fed into a wood drying kiln for drying and solidifying, after the steel solidification tank is placed for 10-20 days at room temperature, the whole bamboo floor blanks are fed into a matcher and a double-end profiler for machining, and the finished whole bamboo dense floors are manufactured after the procedures of sanding and varnishing are conducted. Internal stress generated due to high-temperature softening in flattened whole bamboo floors can be eliminated, the dimensional stability of the whole bamboo floor products can be improved, the probability of occurrence of buckling deformation of the whole bamboo floor products can be reduced, and therefore wide market development prospects are achieved.

Owner:莘县鲁开综合服务有限公司

A kind of manufacturing method of mems structure

ActiveCN111417060BReduce processing difficultyImprove performanceSemiconductor electrostatic transducersElectrostatic transducer microphonesPiezoelectric compositeMechanical engineering

The present application discloses a method for manufacturing a MEMS structure, comprising: forming a piezoelectric composite vibration layer on the front surface of a substrate; etching the back surface of the substrate until reaching the piezoelectric composite vibration layer, so that the substrate includes an outer ring body and a support plate arranged in the outer ring body and connected to the outer ring body, wherein a cavity is formed between the support plate and the outer ring body; the piezoelectric composite vibration layer is divided by etching , the piezoelectric composite vibration layer includes a fixed end connected to the support plate and a free end suspended above the cavity. The manufacturing method of the MEMS structure provided by the application reduces the process difficulty and improves the performance of the MEMS structure.

Owner:ANHUI ORINFIN ACOUSTIC SCI&TECH CO LTD

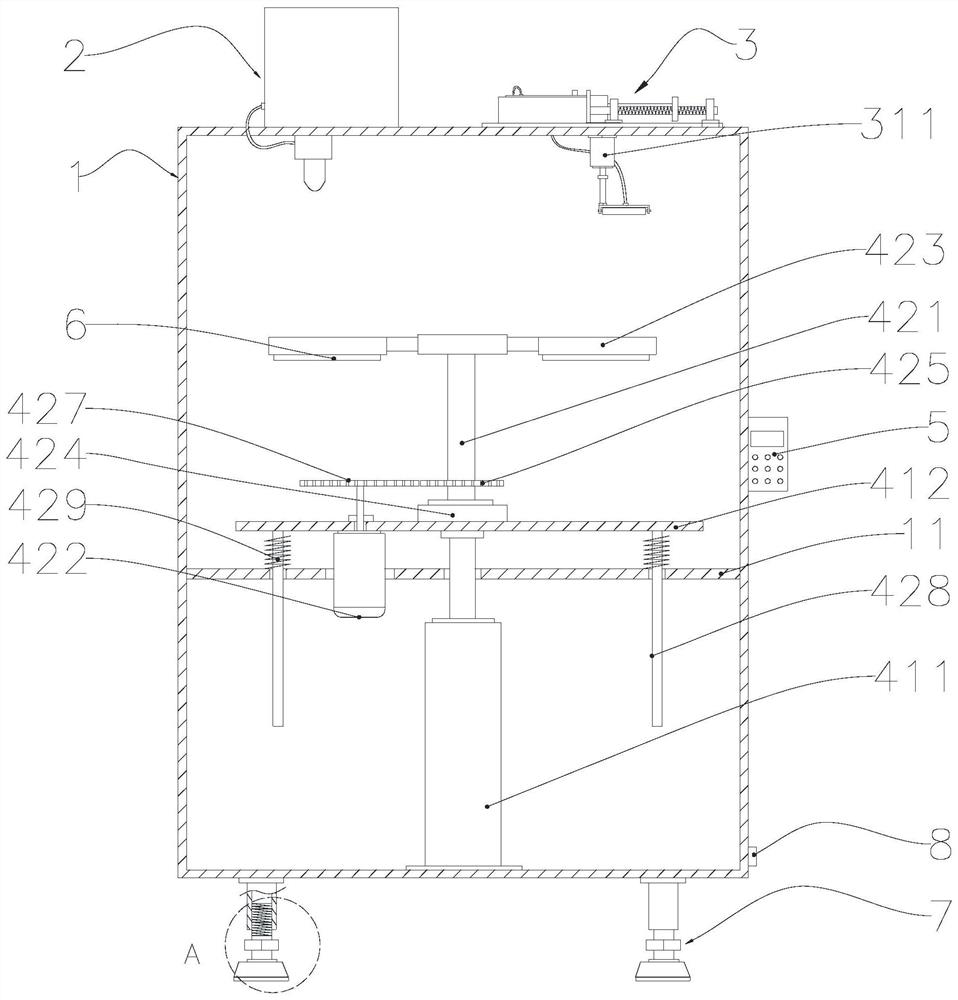

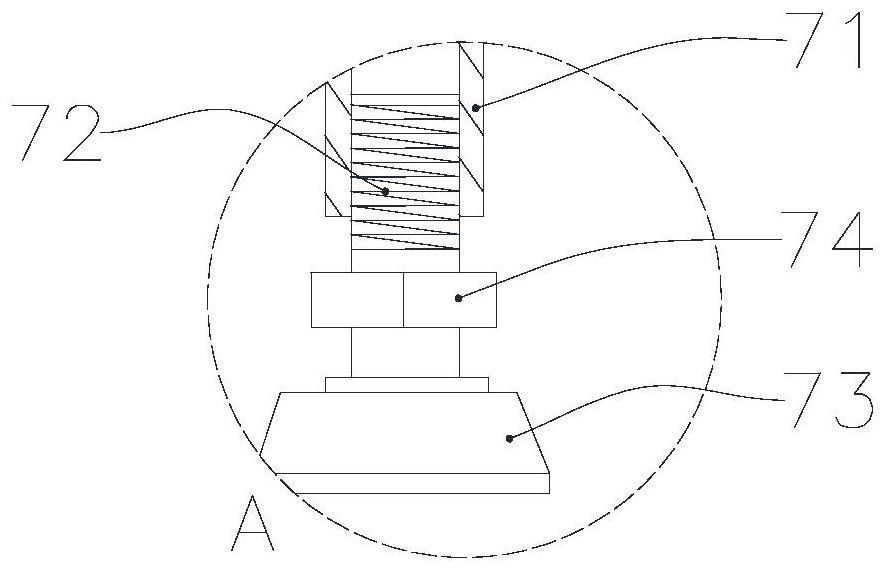

3D printer with edge warping prevention function

PendingCN113290862AImprove work efficiencyHigh precisionManufacturing platforms/substrates3D object support structuresRotational axisComputer printing

The invention relates to the technical field of 3D printing equipment, in particular to a 3D printer with an edge warping prevention function. A switching assembly comprises a lifting part fixedly arranged on the inner bottom wall of a box body and a rotating assembly arranged on the lifting part; the lifting part is used for driving the rotating assembly to ascend and descend in the box body; the rotating assembly includes a rotating shaft, a driving part and two trays, wherein the lower end of the rotating shaft is rotationally connected to the lifting part, the driving part is fixedly arranged on the lifting part and used for driving the rotating shaft to rotate, and the two trays are fixedly arranged at the upper end of the rotating shaft; and a processor is electrically connected to a printing device, a glue brushing device, the lifting part and the driving part, so that the rotating shaft is driven to rotate through a control instruction of the processor so as to drive the two trays to be paused under the glue brushing device and the printing device respectively, and the tray brushed with glue through the glue brushing device rotates to the position under the printing device. The problems that an existing 3D printer is low in printing efficiency, a printing material falls on a tray and shrinks when cooled, and a printed sample is prone to edge warping are solved.

Owner:WUHAN ALLCCT TECH CO LTD

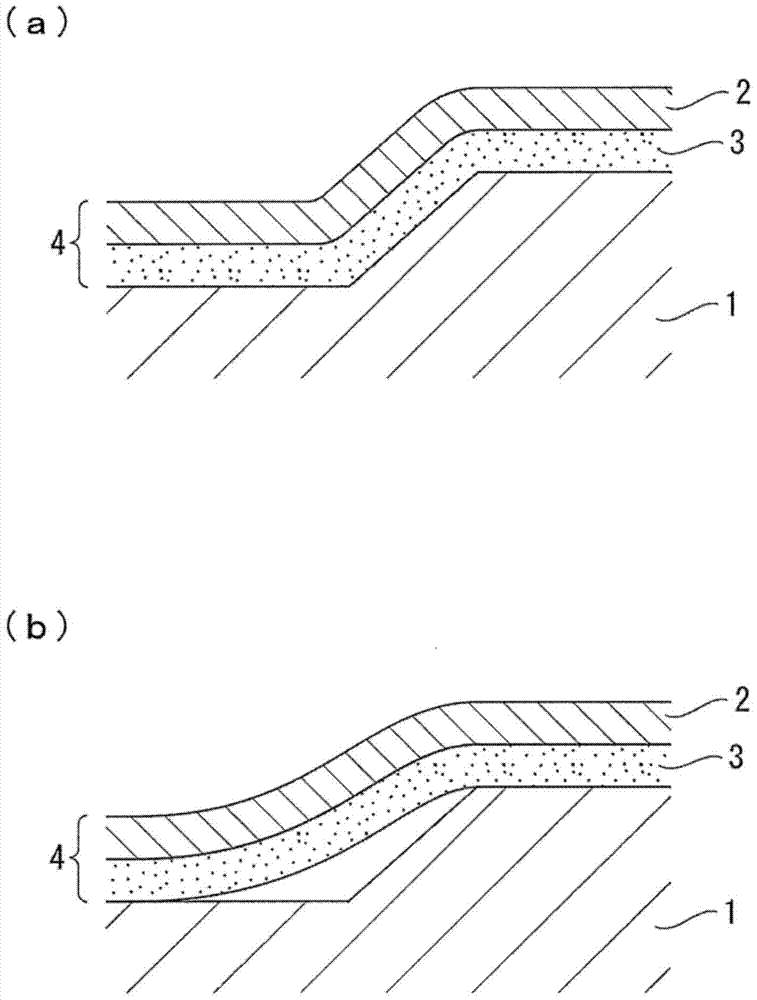

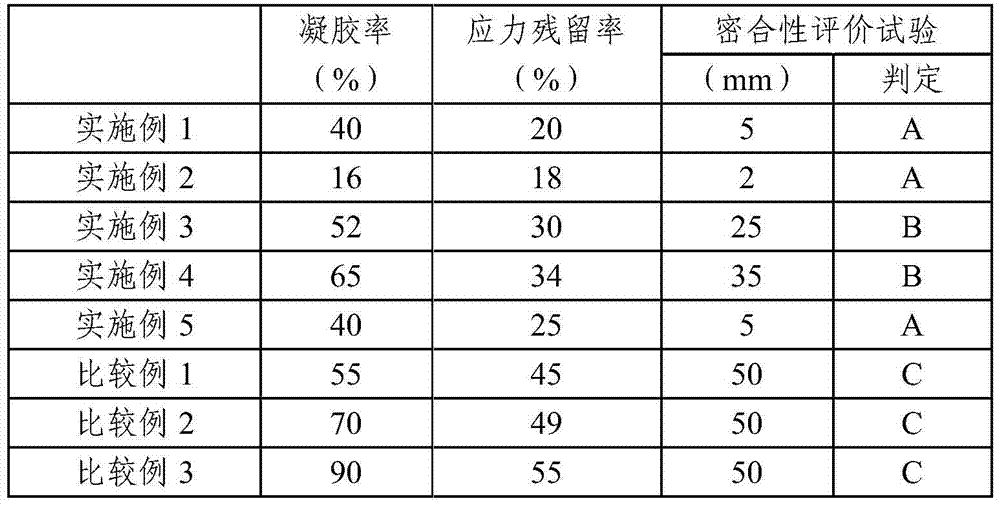

Double-sided adhesive sheet for electronic components

ActiveCN104640948BReduce the chance of warpingIncrease contentPolyureas/polyurethane adhesivesEster polymer adhesivesElectronic componentPolymer

The present invention provides a double-sided pressure-sensitive adhesive sheet. The double-sided pressure-sensitive adhesive sheet of the present invention has a pressure-sensitive adhesive layer including a cross-linked structure formed by the reaction of a cross-linking agent and a cross-linkable polymer. The core material has an adhesive layer laminated on each main surface, wherein the adhesive layer has a residual stress ratio of less than 40%, and the crosslinking agent contains toluene diisocyanate. It is preferable to form the pressure-sensitive adhesive layer at a gel rate of 10% or more and 70% or less. With such a double-sided PSA sheet, even when the adherend has a highly curved surface, peeling is less likely to occur and the possibility of outgassing can be reduced.

Owner:LINTEC CORP

A preheating cylinder for high-temperature laser selective sintering and its forming method

ActiveCN109501248BReduce consumptionReduce consumption Independent temperature controlManufacturing heating elementsAdditive manufacturing with solidsFiberTemperature control

The invention belongs to the related field of advanced manufacturing technology, and discloses a pre-heating cylinder body used for high-temperature laser area selective sintering. In the thickness direction of a cylinder body, the cylinder body comprises an anisotropy heat conduction layer, a ceramic unit temperature control element, a carbon fiber supporting pad, a ceramic heat insulation heat preservation plate and a heating power protection layer from inside to outside, and specific structures and arrangement manners of components are further subjected to optimized design. The invention further discloses a corresponding forming method. Through the method, the longitudinal heating area is selectively controlled, powder, with a certain thickness, to be fed only needs to be preheated to be within the sintered window range, lower mostly-stored powder is subjected to gradient preheating, the temperature is reduced layer by layer, distribution type uniform control over the temperature ofthe pre-heating cylinder body is achieved, and dissipation of redundant heat is reduced while the preheating efficiency is improved. In addition, 400 DEG C high-temperature preheating of the laser sintering temperature field can be effectively achieved, and the pre-heating cylinder body is particularly suitable for SLS machining forming application occasions of high-melting-point polymer like PEEK parts.

Owner:HUAZHONG UNIV OF SCI & TECH

A fan-out wafer level chip packaging structure and packaging method

ActiveCN107946249BFast heat conductionImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectromagnetic wave interferencePhysics

The present invention provides a fan-out wafer-level chip packaging structure and a packaging method, wherein the fan-out wafer-level chip packaging structure includes: a conductive layer, on which grooves for setting chips are formed; On the substrate; the insulating layer is arranged between the conductive layer and the substrate, and is used to fill the gap between the conductive layer and the substrate; the package is arranged on the upper surface of the conductive layer; the chip is packaged in the package, and the pad of the chip exposed outside the package; the conductive post is arranged in the package, one end is coupled with the conductive layer, and the other end is exposed outside the package; the conductive post is connected to the ground wire. By placing the chip in the groove on the conductive layer, and the conductive layer is connected to the ground wire through the conductive column, an electromagnetic shielding structure inside the fan-out wafer-level chip packaging structure can be formed, which can reduce the impact of the chip on the packaging structure. The possibility of electromagnetic wave interference of internal devices and external devices is less difficult to prepare and the production cost is lower.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com