Double-sided adhesive sheet for electronic components

An adhesive sheet, double-sided technology, used in adhesive types, ester copolymer adhesives, polyurea/polyurethane adhesives, etc., which can solve problems such as poor device operation, poor component operation, and difficult exhaust. , to achieve the effect of reducing the possibility of warping, low resilience, and reducing the possibility of exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The preparation method of the adhesive layer-forming coating material is not limited, and it may be prepared by mixing only the components for forming the adhesive layer, or by mixing the components with a solvent (sometimes also serving as a dispersion medium). When the components for forming the pressure-sensitive adhesive layer include components that should be dissolved in a solvent, the solvent may be heated to properly dissolve the components.

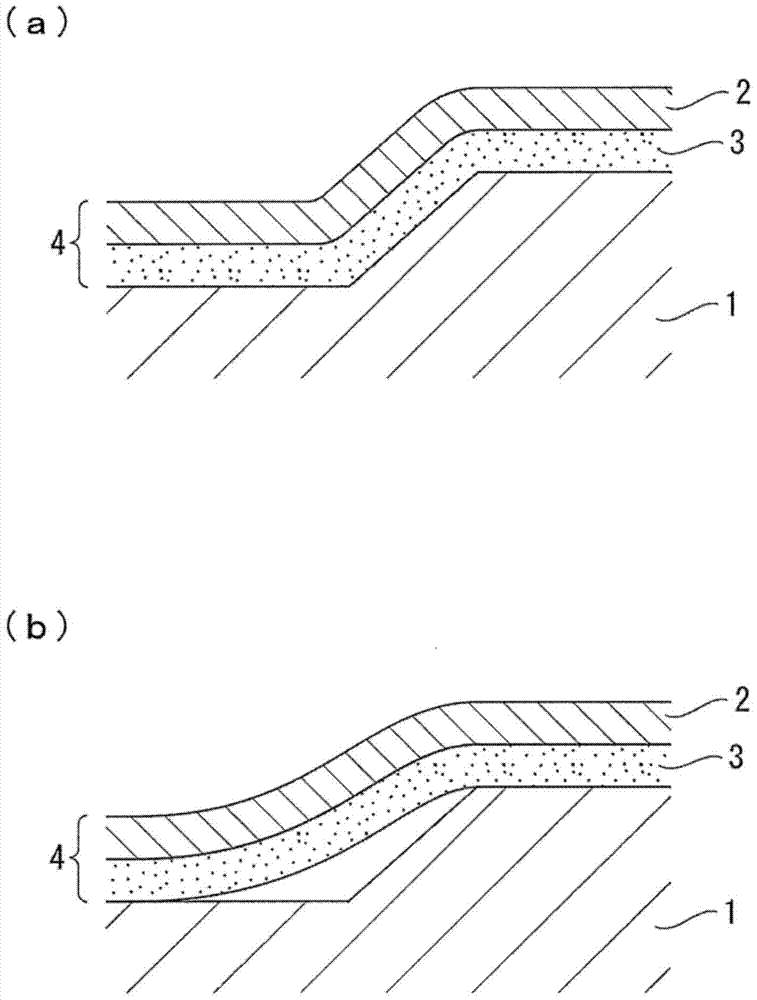

[0082] 3. Manufacturing method of double-sided adhesive sheet

[0083] The manufacturing method of the double-sided adhesive sheet which concerns on this embodiment is not specifically limited. A specific example of a method for producing a double-sided PSA sheet is as follows.

[0084] First, the 1st laminated body and the 2nd laminated body which are both laminated bodies of a release material and an adhesive layer were prepared.

[0085] In order to prepare the first laminate, the above-mentioned coating material for ...

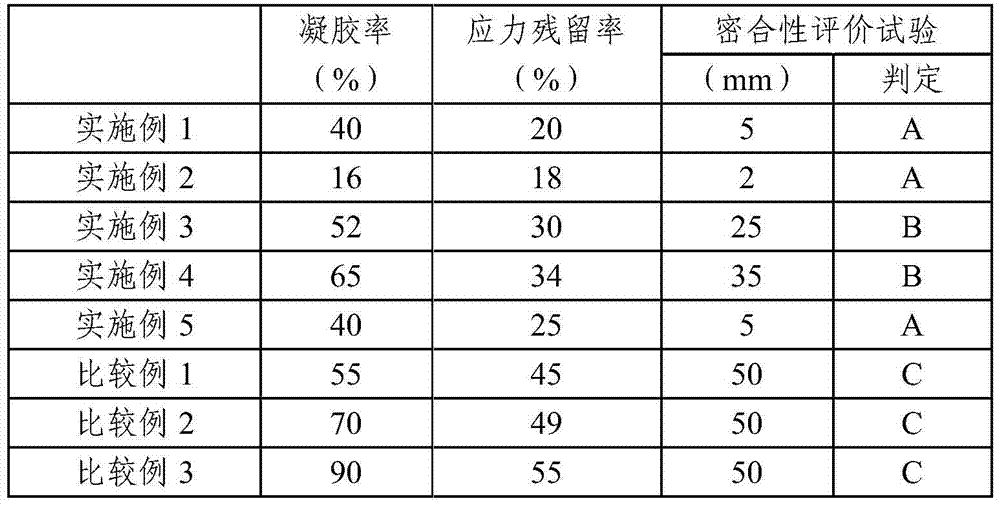

Embodiment 1

[0103] In the cross-linked polymer [BA / MA / ACMO / HEA=83.5 / 2 / 14 / 0.5, weight average molecular weight 600,000, solid content 35% by mass], mixed toluene diisocyanate crosslinking agent [manufactured by Toyo Ink Co., Ltd., trade name "BHS- 8515", solid content 37.5% by mass] 0.45 parts by mass to prepare a coating material for forming an adhesive layer.

[0104] Using a knife coater, apply the adhesive-forming coating material to the release-treated surface of the first release material (easy-release material) [manufactured by Lintec Corporation, trade name "SP-PET381031"], and dry the coated material. The amount of cloth is 25g / m 2 , and heat-dry the obtained coating film at 100° C. for about two minutes to obtain a first laminate in which an adhesive layer is formed on a first release material. Then, a PET film [manufactured by TORAY Industries. Inc., trade name "Lumirror S10"] with a thickness of 12 μm was laminated as a core material on the side of the adhesive layer in the ...

Embodiment 2

[0107] Mix 0.3 parts by mass of toluene diisocyanate-based crosslinking agent [manufactured by Toyo Ink Co., Ltd., trade name "BHS-8515", solid content 37.5 mass%] to prepare a coating material for adhesive formation, in addition , A double-sided adhesive tape was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com