A kind of processing method of whole bamboo dense floor

A processing method and compact technology, applied in the direction of wood processing equipment, sugarcane machining, manufacturing tools, etc., can solve the problems affecting the use range and field of the whole bamboo floor, the large stress of the bamboo material, the easy warping and deformation of the product, etc. Stability, eliminate internal stress, reduce the effect of warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

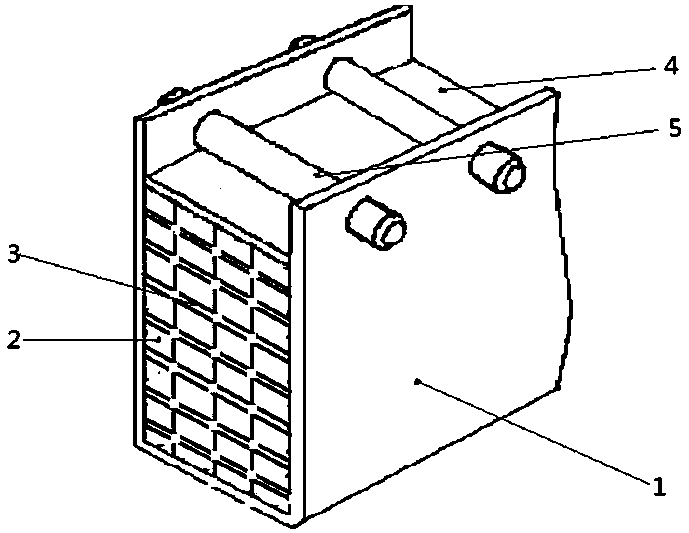

Image

Examples

Embodiment 1

[0030] A kind of processing method of whole bamboo compact floor comprises the steps:

[0031] Step 1: Take the bamboo section with a wall thickness of 19-22mm, cut into slices, remove internal nodes, soften and flatten to make flat bamboo slices, and then planed by double-sided planing to make thickness control 17mm whole bamboo floor blank, spare;

[0032] Step 2: Neatly stack the whole bamboo floor blanks obtained in step 1 in a metal tank, press a weight on the top layer of the stack of whole bamboo floor blanks, dilute the water-soluble phenolic resin and water at a volume ratio of 1:1.5, After mixing thoroughly, pour in metal tank, the liquid level of glue is higher than whole bamboo floor blank stacking top layer 10cm, closes the opening of metal tank; The formula of described water-soluble phenolic resin: the mass ratio of phenol, formaldehyde and NaOH is 1: 2.9:0.33, cured product content 48wt%, free formaldehyde content<0.16wt%, resin pH value 8.9;

[0033] Step 3:...

Embodiment 2

[0042] Step 1: Take the bamboo section with a wall thickness of 19-22mm, cut into slices, remove internal nodes, soften and flatten to make flat bamboo slices, and then planed by double-sided planing to make thickness control 17mm whole bamboo floor blank, spare;

[0043] Step 2: Neatly stack the whole bamboo floor blanks obtained in step 1 in a metal tank, press with a weight on the top layer of the stack of whole bamboo floor blanks, dilute the water-soluble phenolic resin and water at a volume ratio of 1:2, After mixing thoroughly, pour in metal tank, the liquid level of glue is higher than whole bamboo floor blank stacking top layer 10cm, closes the opening of metal tank; The formula of described water-soluble phenolic resin: the mass ratio of phenol, formaldehyde and NaOH is 1: 2.9:0.33, cured product content 48wt%, free formaldehyde content<0.16wt%, resin pH value 8.9;

[0044] Step 3: Open the ball valve switch on the top of the closed metal tank connected to the air c...

Embodiment 3

[0053] Step 1: Take the bamboo section with a wall thickness of 19-22mm, cut into slices, remove internal nodes, soften and flatten to make flat bamboo slices, and then planed by double-sided planing to make thickness control 17mm whole bamboo floor blank, spare;

[0054] Step 2: Place the whole bamboo floor blanks obtained in step 1 neatly in the metal tank, press the weight on the top layer of the stack of whole bamboo floor blanks, dilute the water-soluble phenolic resin and water at a volume ratio of 1:1.8, After mixing thoroughly, pour in metal tank, the liquid level of glue is higher than whole bamboo floor blank stacking top layer 10cm, closes the opening of metal tank; The formula of described water-soluble phenolic resin: the mass ratio of phenol, formaldehyde and NaOH is 1: 2.9:0.33, cured product content 48wt%, free formaldehyde content<0.16wt%, resin pH value 8.9;

[0055] Step 3: Open the ball valve switch on the top of the closed metal tank and the air compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com