Separator and lithium ion battery

A lithium-ion battery and separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem that the separator cannot meet the technical requirements of ultra-high-power discharge of lithium-ion batteries, and reduce the bonding effect and ensure Safety performance, effect of extending cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

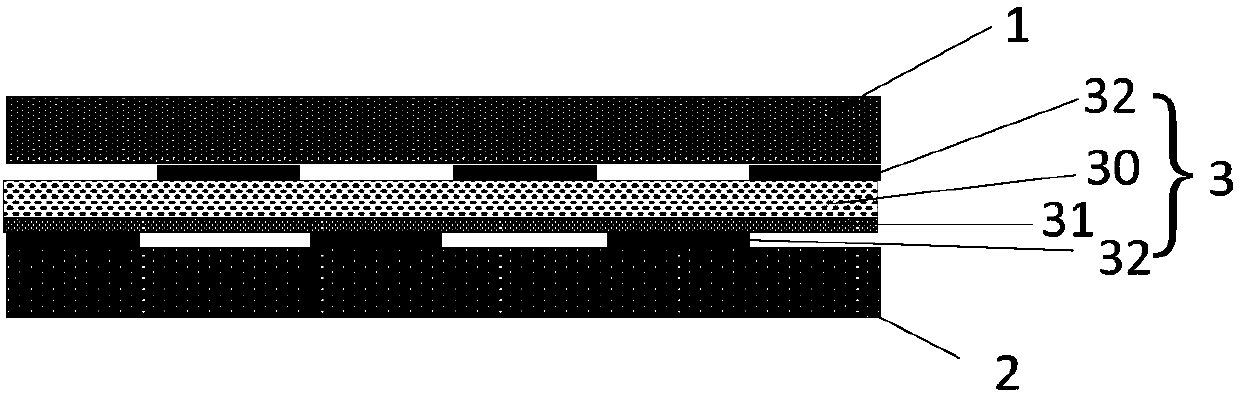

[0039] The preparation method flow process of diaphragm in the embodiment of the present invention is as follows:

[0040] S1: Select a diaphragm substrate with a specified thickness range.

[0041] For example, the base material of the separator is selected as polypropylene, polyethylene, polypropylene / polyethylene / polypropylene three-layer composite film, polyimide film, cellulose non-woven fabric separator, etc. as the separator base material. Its thickness is 7-25um, the porosity of the base film is 40-60%, and the air permeability is 100-300s / 100ml.

[0042] S2: After the specified ceramic powder slurry is stirred and dispersed in a solvent under certain process conditions, a ceramic powder mixed slurry is formed.

[0043] For example, aluminum nitride with a particle size ranging from 0.1um to 1um is dispersed in organic solvents such as ethanol and N-methylpyrrolidone (NMP), and the stirring vacuum is normal pressure; the stirring temperature is 25°C; the stirring spee...

Embodiment 1

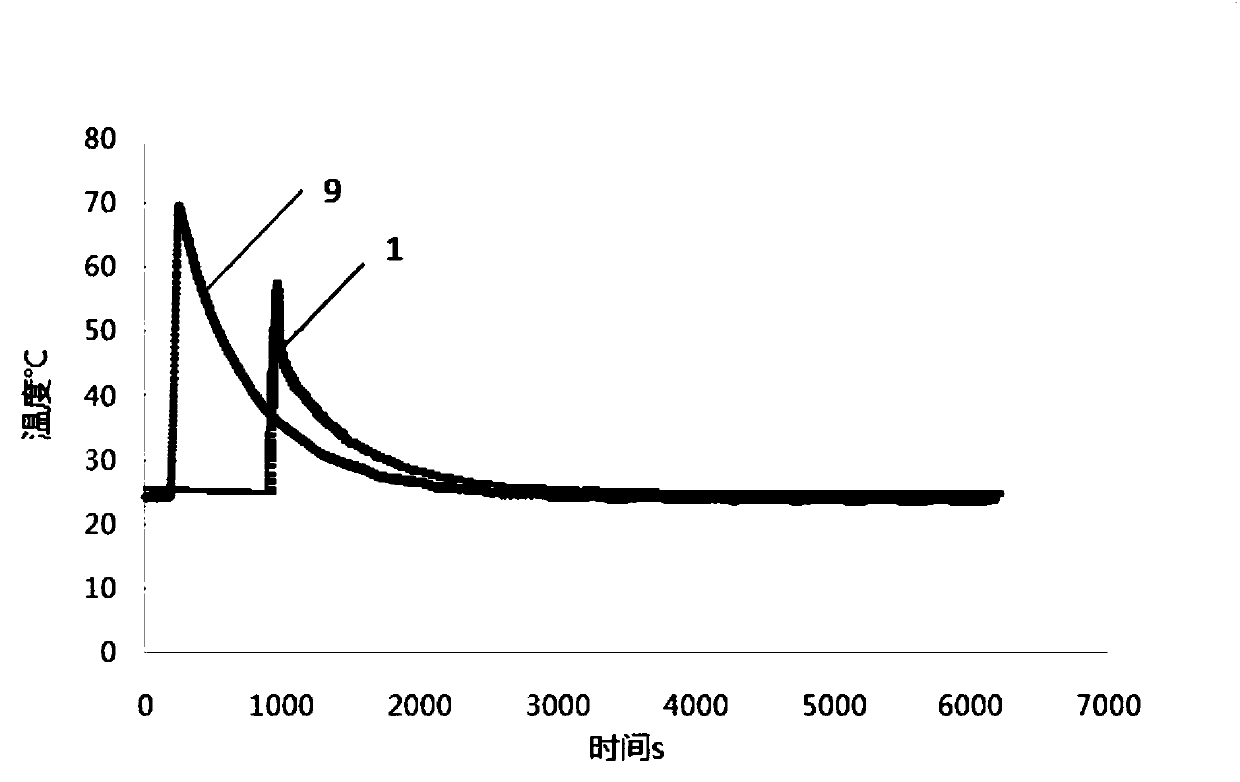

[0060] Select polypropylene with a thickness of 16um as the diaphragm substrate, with a porosity of 50% and an air permeability of 200s / 100ml; AlN ceramic powder with a particle size range of 0.5um and N-methylpyrrolidone (NMP) are used in a mass ratio of 1:2. Pre-stir. Stirring vacuum is normal pressure; stirring temperature is 25°C; stirring speed: 25 revolutions per minute, 1000 revolutions per minute; stirring time is 60 minutes to obtain a premixed slurry. Add a polyvinylidene fluoride (PVDF) solution with a mass ratio of 20% to the above premixed slurry, and continue to stir in vacuum for 3 hours, stirring speed: 25 revolutions per minute, 2500 revolutions per minute, to obtain a ceramic coating Slurry, when the measured viscosity of the ceramic coating slurry is less than 500mPas., it can be discharged. Add the organic polymer polymethyl methacrylate to the ester solvent in a mass ratio of 10:90 into the stirring tank, stir at 25°C±5°C for 4h, stirring speed: revolutio...

Embodiment 2

[0066] The difference from Example 1 is that the coating surface of the organic coating on the diaphragm is different. In Example 2, the adhesive is applied to the film surface of the diaphragm substrate through a micro-gravure plate to form a multi-gap strip-like dispersed morphology, that is, one side of the diaphragm. A ceramic coating is applied and an organic coating is applied on the other side. The rest are the same as in Embodiment 1, and the lithium-ion battery 2 is assembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com