Anti-warping glutinous rice glue and preparation method thereof

A technology of glutinous rice glue and glutinous rice, applied in the direction of adhesives, adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of wallpaper warping, glutinous rice glue hardening, etc., achieve enhanced solubility, improved compatibility, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

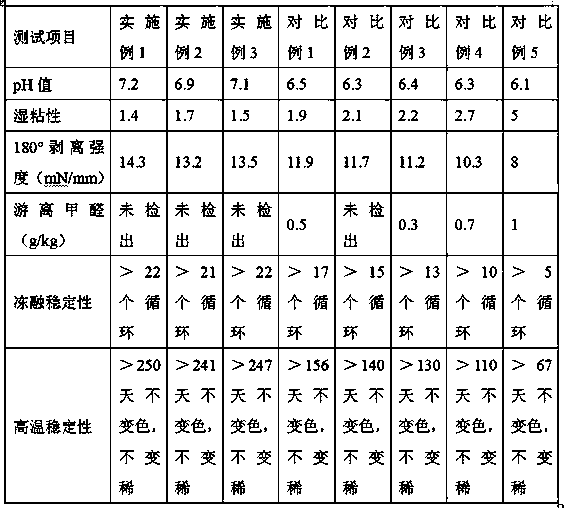

Examples

preparation example Construction

[0032] The preparation method of glutinous rice base glue is:

[0033] (1) Wash the glutinous rice, grind and crush it through a 200-mesh sieve, collect the sieved particles, add water to the sieved particles at a mass ratio of 5~8:10~15, and gelatinize at 50~60°C for 1~3 hours to obtain a paste Add α-amylase with 3-5% gelatinization liquid, stir and mix at 50-60°C for 20-30min, then add 1-3% gelatinized calcium acetate, heat up to 85-95°C 30~50min, inactivate the enzyme, cool to room temperature, and obtain the cooled product;

[0034](2) In terms of parts by mass, take 30~50 parts of cooling material, 0.2~0.5 parts of sodium bromide, 0.03~0.06 parts of 2,2,6,6-tetramethylpiperidine oxide, and 10~15 parts of hydrogen peroxide , Stir and mix at 20~25°C for 20~30min to obtain a mixture, take the mixture according to the mass ratio of 10~15:3~5, add 20% sodium hydroxide solution, stir and mix for 1~3h, adjust the pH to 7~ 7.2. To obtain the stirred mixture, take the stirred mi...

Embodiment 1

[0048] The preparation method of glutinous rice base glue is:

[0049] (1) Wash the glutinous rice, grind and crush it through a 200-mesh sieve, collect the sieved particles, add water to the sieved particles at a mass ratio of 5:10, and gelatinize at 50°C for 1 hour to obtain a gelatinized liquid, add the mass of the gelatinized liquid 3% α-amylase, stirred and mixed at 50°C for 20 minutes, then added calcium acetate of 1% gelatinized liquid mass, raised the temperature to 85°C and kept it for 30 minutes, inactivated the enzyme, cooled to room temperature, and obtained the cooled product;

[0050] (2) In terms of parts by mass, take 30 parts of cooling material, 0.2 parts of sodium bromide, 0.03 parts of 2,2,6,6-tetramethylpiperidine oxide, and 10 parts of hydrogen peroxide, and stir and mix at 20°C for 20 minutes. To obtain a mixture, take the mixture and add a 20% sodium hydroxide solution at a mass ratio of 10:3, stir and mix for 1 hour, and adjust the pH to 7 to obtain a ...

Embodiment 2

[0064] The preparation method of glutinous rice base glue is:

[0065] (1) Wash the glutinous rice, grind and crush it through a 200-mesh sieve, collect the sieved particles, add water to the sieved particles at a mass ratio of 6:13, and gelatinize at 55°C for 2 hours to obtain a gelatinized liquid, add the mass of the gelatinized liquid 4% α-amylase, stirred and mixed at 55°C for 25 minutes, then added calcium acetate with 2% gelatinized liquid mass, raised the temperature to 90°C and kept it for 40 minutes, inactivated the enzyme, cooled to room temperature, and obtained the cooled product;

[0066] (2) In terms of parts by mass, take 40 parts of cooling material, 0.3 part of sodium bromide, 0.05 part of 2,2,6,6-tetramethylpiperidine oxide, and 13 parts of hydrogen peroxide, and stir and mix at 23°C for 25 minutes. To obtain a mixture, take the mixture and add a 20% sodium hydroxide solution at a mass ratio of 13:4, stir and mix for 2 hours, and adjust the pH to 7.1 to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com