Method for manufacturing chip packaging structure

A technology of chip packaging structure and manufacturing method, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. Connection reliability issues, effect of warpage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

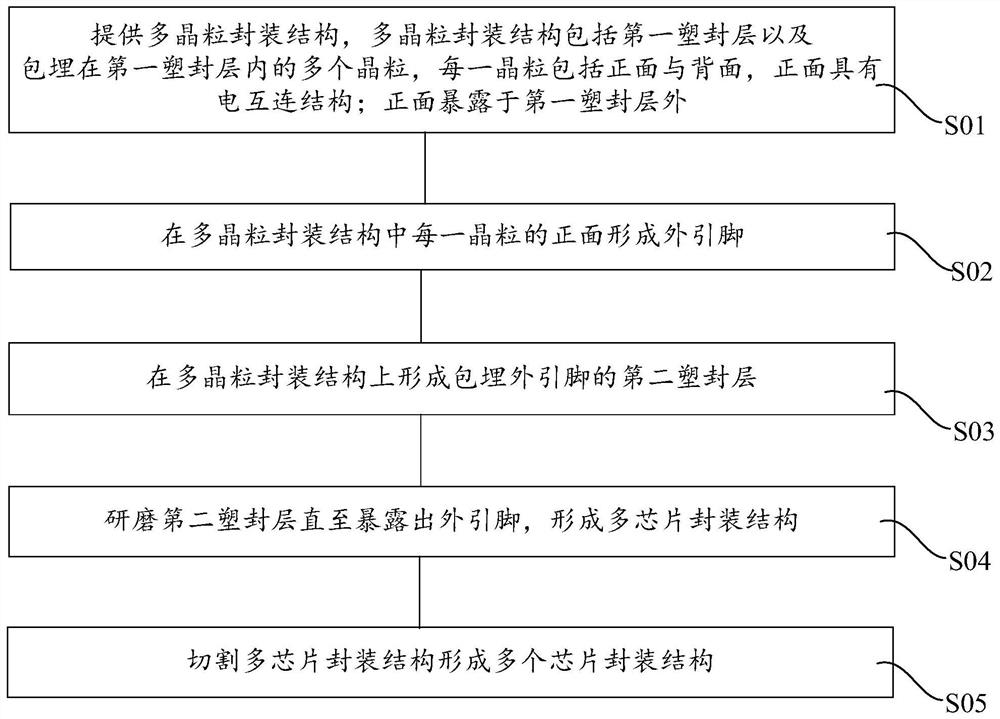

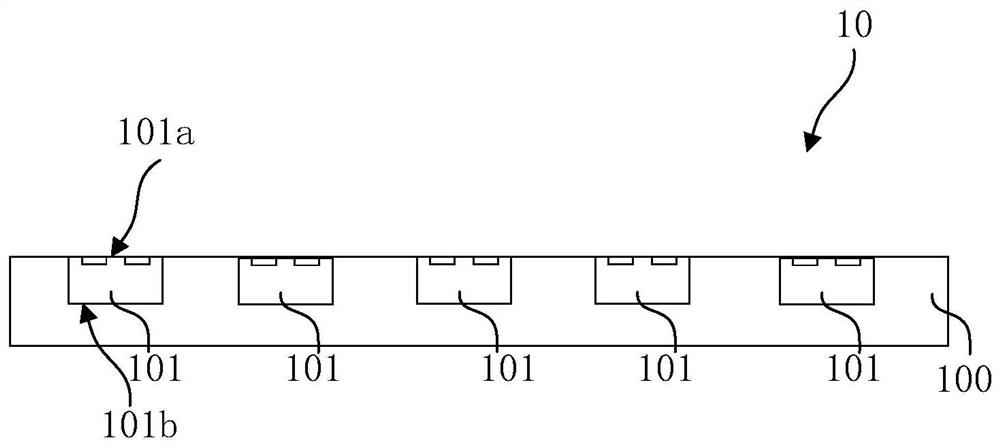

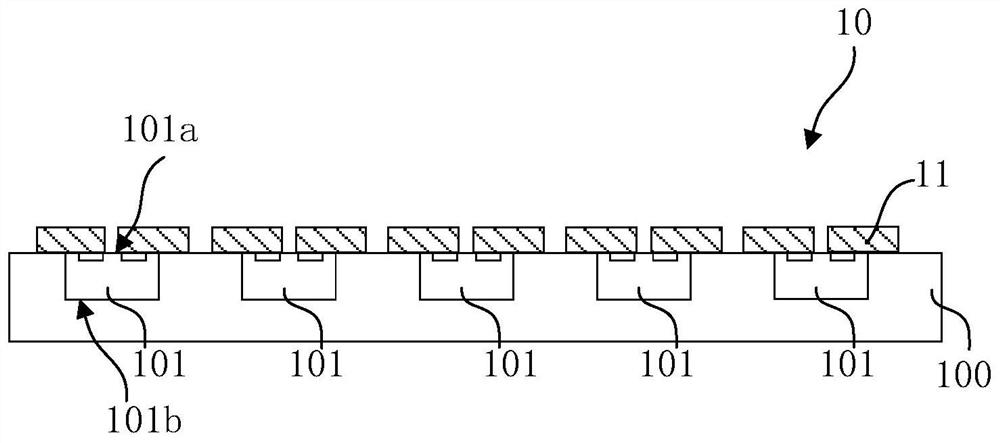

[0068] figure 1 It is a flowchart of a manufacturing method of a chip package structure according to an embodiment of the present invention. Figure 2 to Figure 6 yes figure 1 The schematic diagram of the intermediate structure corresponding to the process in .

[0069] First, refer to figure 1 Step S01 in figure 2 As shown, a multi-chip packaging structure 10 is provided. The multi-chip packaging structure 10 includes a first plastic encapsulation layer 100 and a plurality of dies 101 embedded in the first plastic encapsulation layer 100. Each die 101 includes a front side 101a and a back side 101b, the front side 101a has an electrical interconnection structure (not shown); the front side 101a is exposed to the outside of the first plastic encapsulation layer 100 .

[0070] Next, refer to figure 1 Step S02 in image 3 As shown, the external leads 11 are formed on the front side 101 a of each die 101 in the multi-die package structure 10 .

[0071] After that, refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com