Single-chip packaging piece with adhesive film replacing bottom fillers and manufacture process thereof

A manufacturing process and single-chip technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as easy warpage and unguaranteed packaging reliability, achieve good protection of solder balls, reduce Possibility of wafer warpage, effect of reducing packaging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

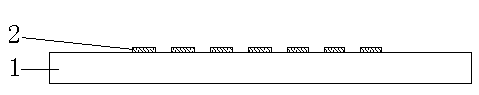

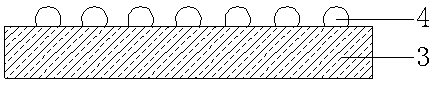

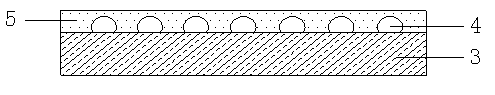

[0022] As shown in the figure, a single-chip package with an adhesive film instead of an underfill is mainly composed of a substrate 1, a nickel-gold pad 2, a chip 3, a tin-silver bump 4, an adhesive film 5, and a solder ball 8; The nickel-gold pad 2 is fixedly connected to the substrate 1, and the tin-silver bump 4 is fixedly connected to the chip 3; the tin-silver bump 4 coincides with the center line of the nickel-gold pad 2 and is connected by welding; the adhesive film 5 The gap between the substrate 1 and the chip 3 is filled, and the nickel-gold pad 2 and the tin-silver bump 4 are surrounded.

[0023] The chip 3 constitutes a circuit power supply and signal channel through tin-silver bumps 4 , nickel-gold pad 2 , substrate 1 and tin balls 8 .

[0024] As shown in the figure, a manufacturing process of a single-chip package with an adhesive film instead of an underfill is carried out in the following steps:

[0025] The first step, adhesive film 5: First, uniformly spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com