Pay-off spool for copper wire stranding process

A pay-off reel and process technology, applied in conductor/cable supply devices, electrical components, circuits, etc., can solve problems such as economic loss, copper wire breakage, reel wall collision or friction, etc., to reduce wear and avoid problems. Contact, easy to get off the roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

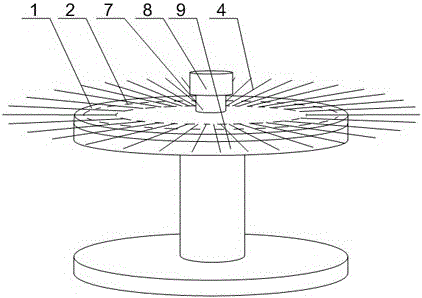

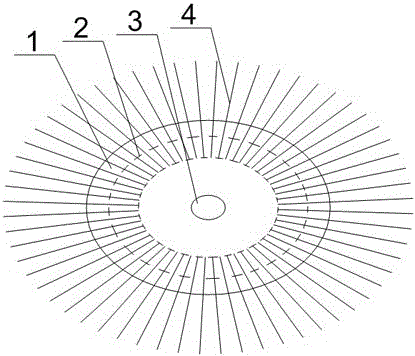

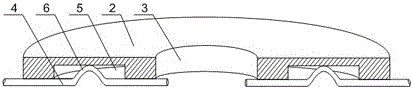

[0025] Such as Figure 1~Figure 3 As shown, the present embodiment includes a reel 9, a brush plate 1 and a plurality of resin threads 4, a fixing hole 3 is opened in the middle of the brush plate 1, and a plurality of resin threads 4 run along the brush plate 1. The radial direction of the brush plate 1 extends outward, and the upper surface of the brush plate 1 is bonded with a concentric and annular lower pressing plate 2 which covers a part of the resin thread 4, and The lower surface of the lower pressing plate 2 is provided with an annular groove 5, and a curved section 6 is provided on the plurality of thin resin wires 4, and the curved section 6 is placed in the annular groove 5 on the upper end surface of the reel 9. A screw 7 is provided in the middle of the screw 7 which penetrates the fixing hole 3, and a nut 8 is installed at the upper end of the screw 7.

[0026] Prior art-In the copper wire stranding process, the reel is placed vertically, that is, the turns of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com