Die cooling structure capable of reducing warpage deformation

A mold cooling and warping technology, applied in the field of injection molds, can solve problems such as warping deformation and different cooling rates, and achieve the effect of reducing the possibility of warping and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

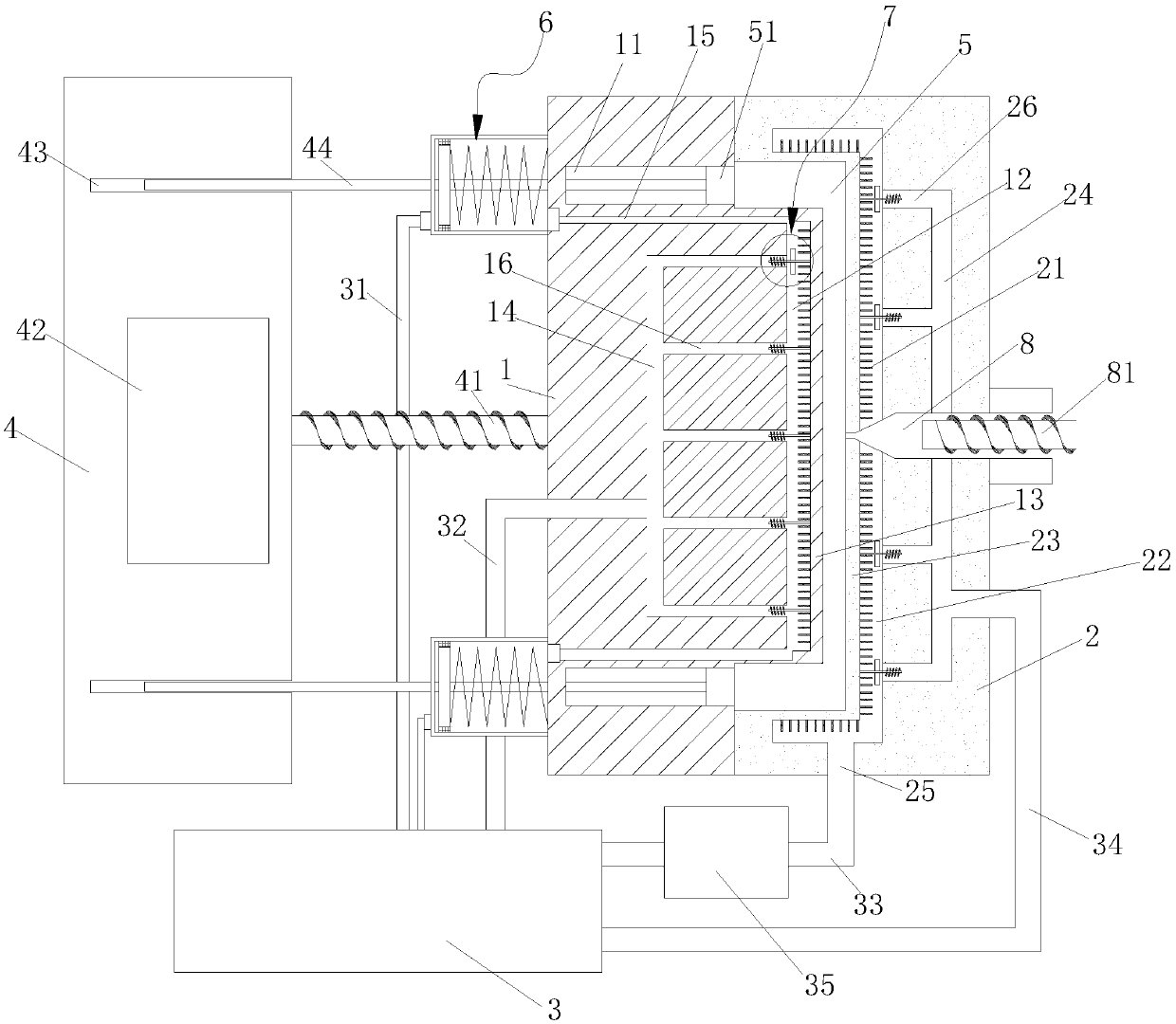

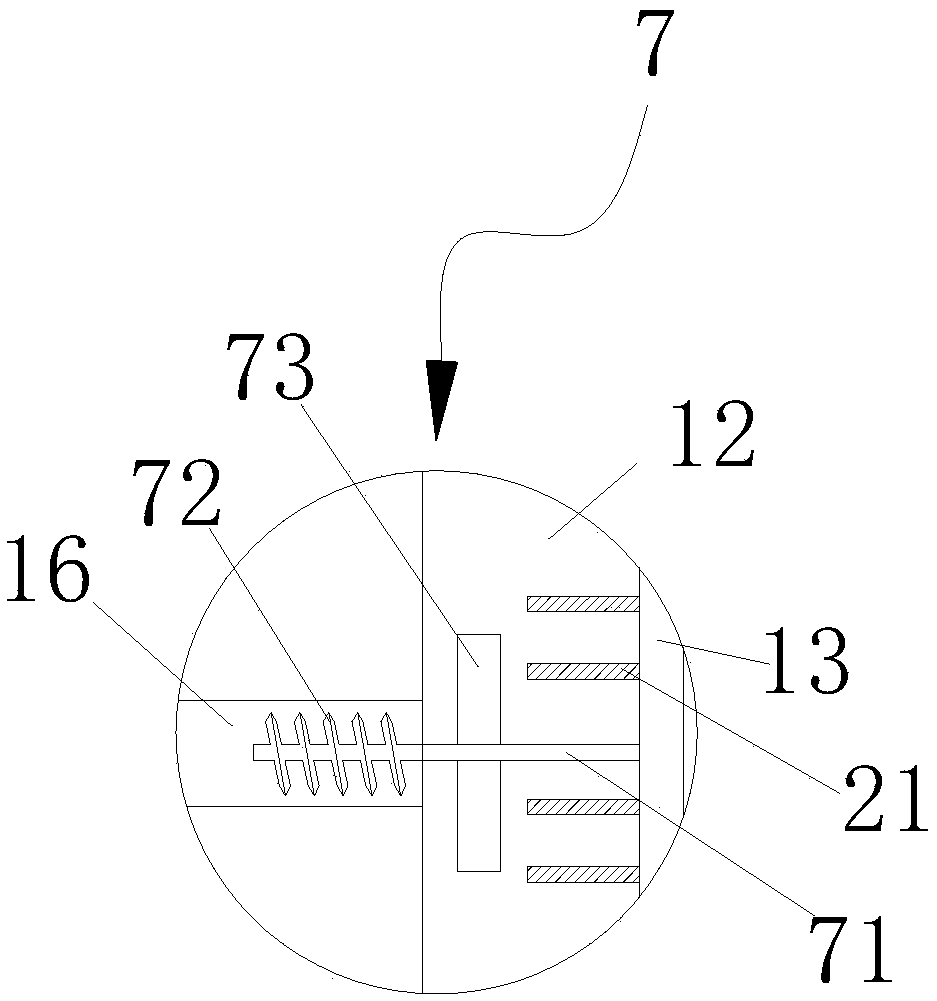

[0026] Such as figure 1 Shown: a mold cooling structure to reduce warping deformation, including a punch 1, a die 2, a water tank 3 and a mounting frame 4, the punch 1 and the die 2 are installed opposite to each other on the left and right, the punch One side of the punch 1 and one side of the die 2 are engaged with each other, and a screw shaft 41 is provided between the other side of the punch 1 and the mounting frame 4, and the punch 1 and the die 2 are engaged with each other to form Mold core cavity 5;

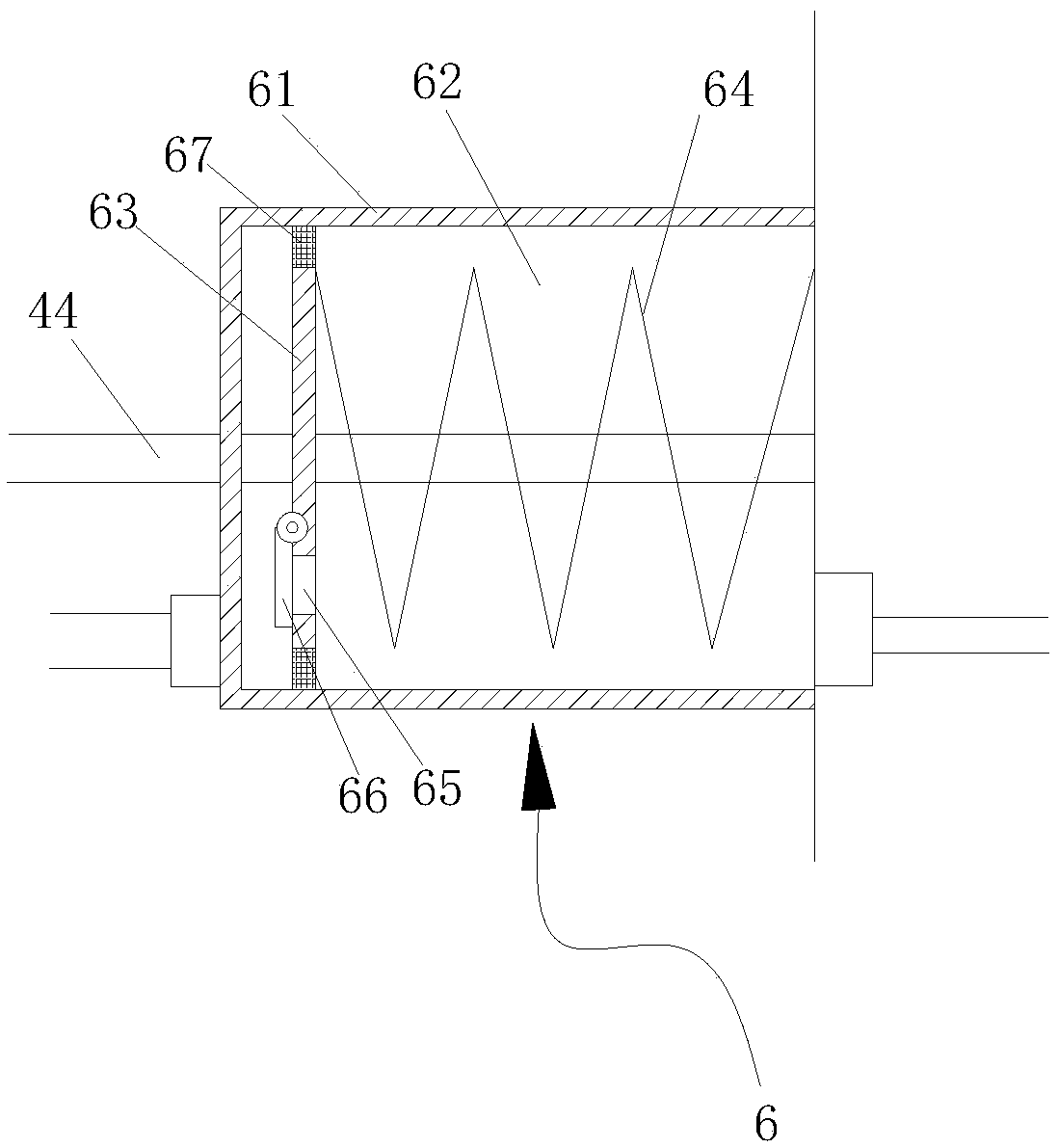

[0027] A motor 42 is installed in the mounting frame 4, the driving end of the motor 42 is in transmission cooperation with one end of the screw shaft 41, and the other end of the screw shaft 41 is rotationally connected with the left center of the punch 1, and the mounting frame 4. Four tube grooves 43 are also provided, and the four tube grooves 43 are evenly arranged around the screw shaft 41 with the screw shaft 41 as the axis center. The chute 11, the piston 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com