Copper wire pay-off device

A wire payoff, copper wire technology, applied in electrical components, circuits, cable/conductor manufacturing, etc., can solve the problems of copper wire breakage, economic loss, reel wall collision or friction, etc., to avoid contact and reduce wear and tear Volume, easy to get off the roll effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

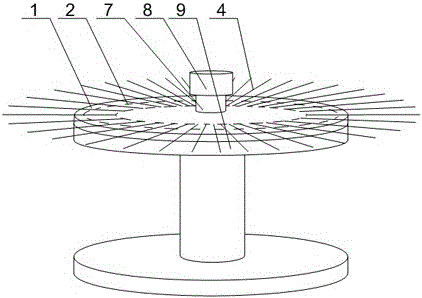

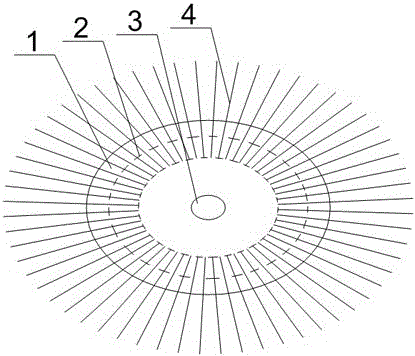

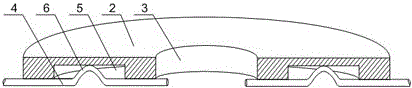

[0028] Such as Figure 1~Figure 5 As shown, this embodiment includes a reel 9, a brush plate 1 and a plurality of thin resin lines 4, and a fixing hole 3 is opened in the middle of the brush plate 1, and a plurality of thin resin lines 4 are arranged along the brush plate 1. The radial direction of the brush plate 1 extends outward, and the upper surface of the brush plate 1 is bonded with a concentric and annular lower pressure plate 2, the lower pressure plate 2 partially covers the resin thin line 4, and The lower surface of the lower pressing plate 2 is provided with an annular groove 5, and a curved section 6 is arranged on the plurality of thin resin wires 4, and the curved section 6 is placed in the annular groove 5, and on the upper end surface of the drum 9 The middle part is provided with a positioning rod 7, and the positioning rod 7 runs through the fixing hole 3, and there are guide grooves 10 with a circular arc-shaped cross section on both sides of the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com