Backlight module

A backlight module and backplane technology, applied in the direction of optics, electric light source, light source fixation, etc., can solve the problems of backlight module temperature rise, warpage, affecting light guide function, etc., to avoid taste and brightness, reduce warpage probability, and the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

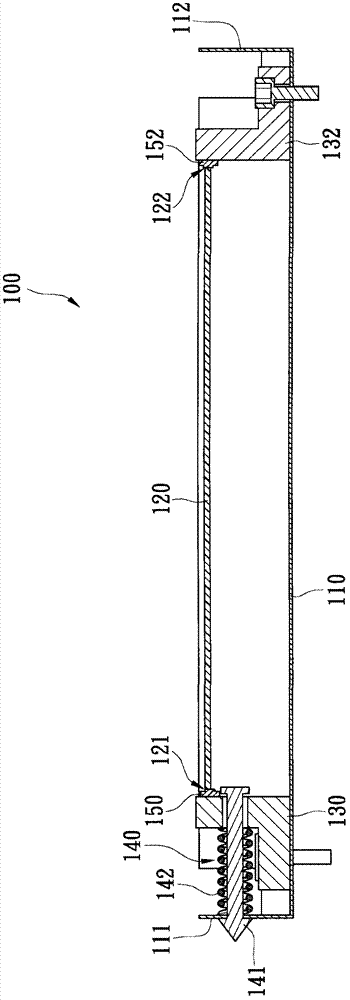

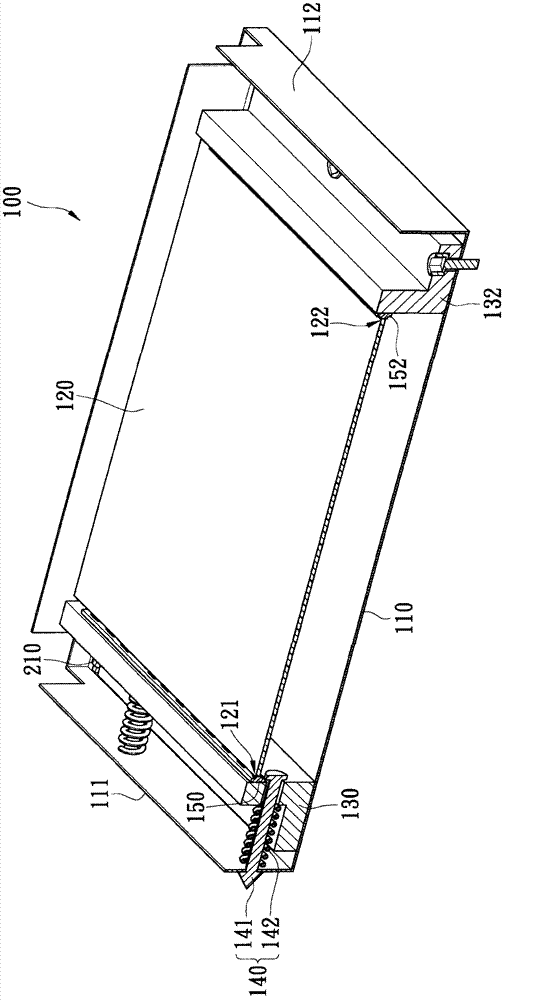

[0030] figure 1 A schematic cross-sectional structure diagram of the backlight module according to the first embodiment of the present invention is shown. The backlight module 100 includes a backplane 110 , a light guide plate 120 , cooling elements 130 , 132 , elastic elements 140 and light bars 150 , 152 . The backboard 110 has two parallel sidewalls 111 , 112 , which are formed by two mutually parallel edges of the backboard 110 protruding upward in a direction perpendicular to the surface of the backboard 110 . The accommodating space formed by the back plate 110 is suitable for assembling components such as the light guide plate 120 , the heat dissipation elements 130 , 132 , the elastic element 140 , and the light bars 150 , 152 .

[0031] The light guide plate 120 is disposed on the back plate 110 and has two light incident sides 121 , 122 parallel to each other. According to its position, the two light incident sides 121 , 122 correspond to the side walls 111 , 112 re...

no. 2 example

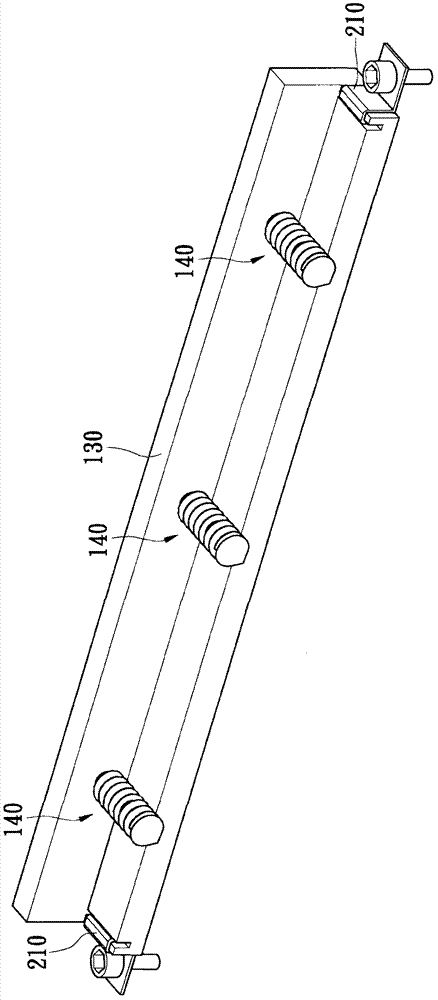

[0040] The light source structures on both sides of the light guide plate 120 can be movable structures, such as Figure 5 and Image 6 as shown, Figure 5 A schematic cross-sectional structure diagram showing the backlight module of the second embodiment of the present invention, Image 6 A schematic diagram showing the three-dimensional structure of the backlight module according to the second embodiment of the present invention. The heat dissipation elements 130, 133 located on both sides of the light guide plate 120 are movably arranged on the back plate 110, and are respectively provided with at least one elastic element 140 and 145, so that the light strips 150, 152 on the heat dissipation elements 130, 133 can be closely abutted against On the two light incident sides 121 , 122 of the light guide plate 120 . Both sides of the cooling element 133 are provided with limiting elements 212 similar in structure to the limiting element 210 , which can be used to limit the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com